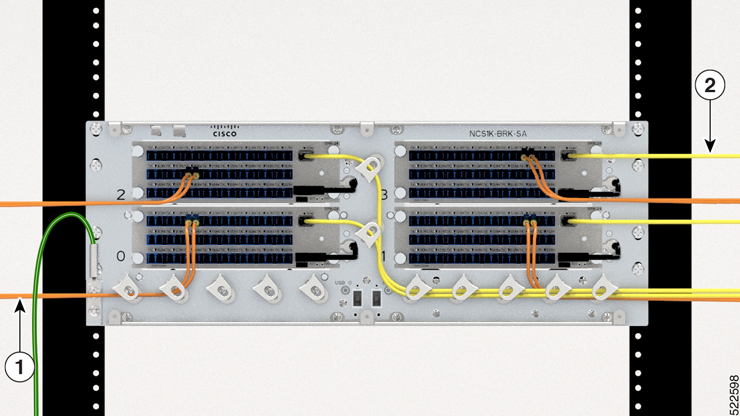

Rack Compatibility

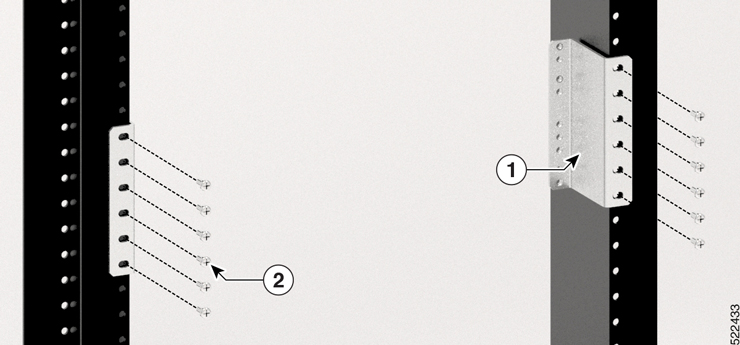

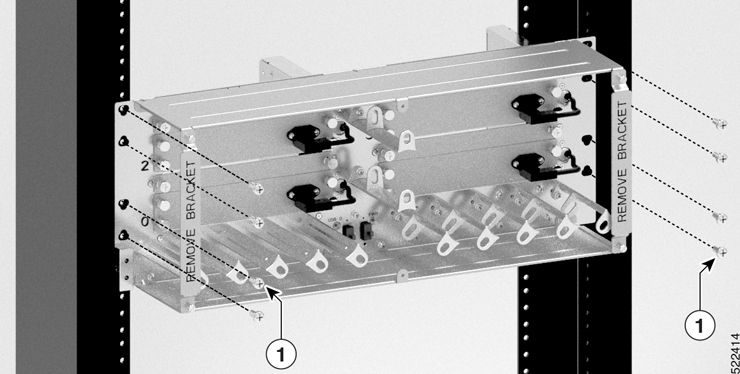

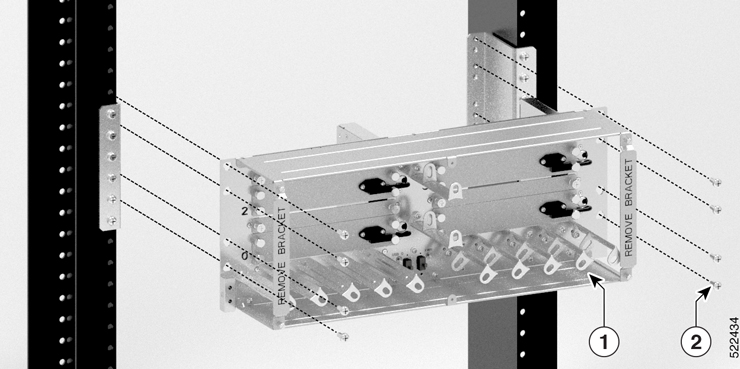

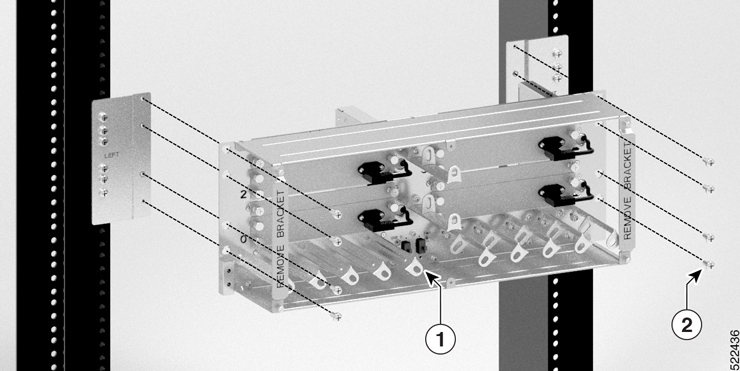

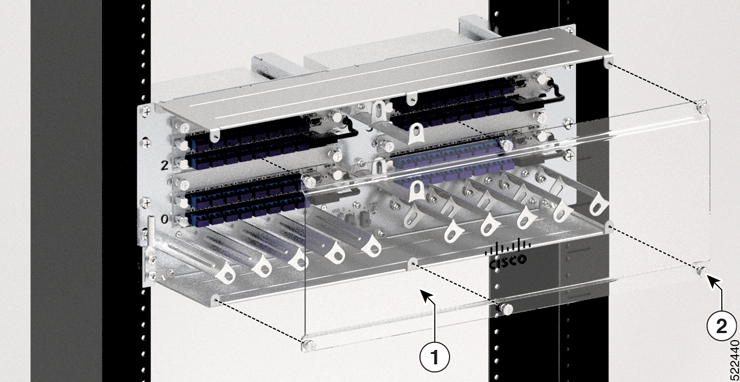

The Cisco NCS 1000 Breakout Patch Panel can be installed in a standard ANSI/EIA (19"), ANSI (23"), or ETSI (21") rack.

-

The rack can be two-post type or four-post type rack.

-

The 19" and 23" racks must be compliant with "EIA Universal" holes.

-

The ETSI Rack must be compliant with "ETSI Universal" holes.

|

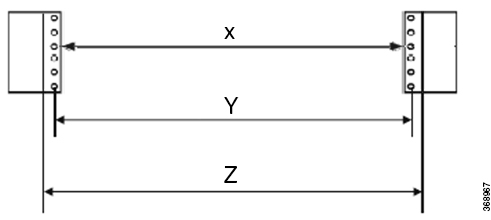

Rack Type |

Rack Front Opening X |

Rack Mounting Hole Center-Center Y |

Mounting Flange Dimension Z |

|---|---|---|---|

|

ANSI 19" racks |

450.8mm (17.75") |

465mm (18.312") |

482.6mm (19") |

|

ANSI 23" racks |

552.45mm (21.75") |

566.7mm (22.312") |

584.2mm (23") |

|

ETSI 21" racks |

500.0mm(19.68") |

515.0mm(20.276") |

533.4mm(21") |

Feedback

Feedback