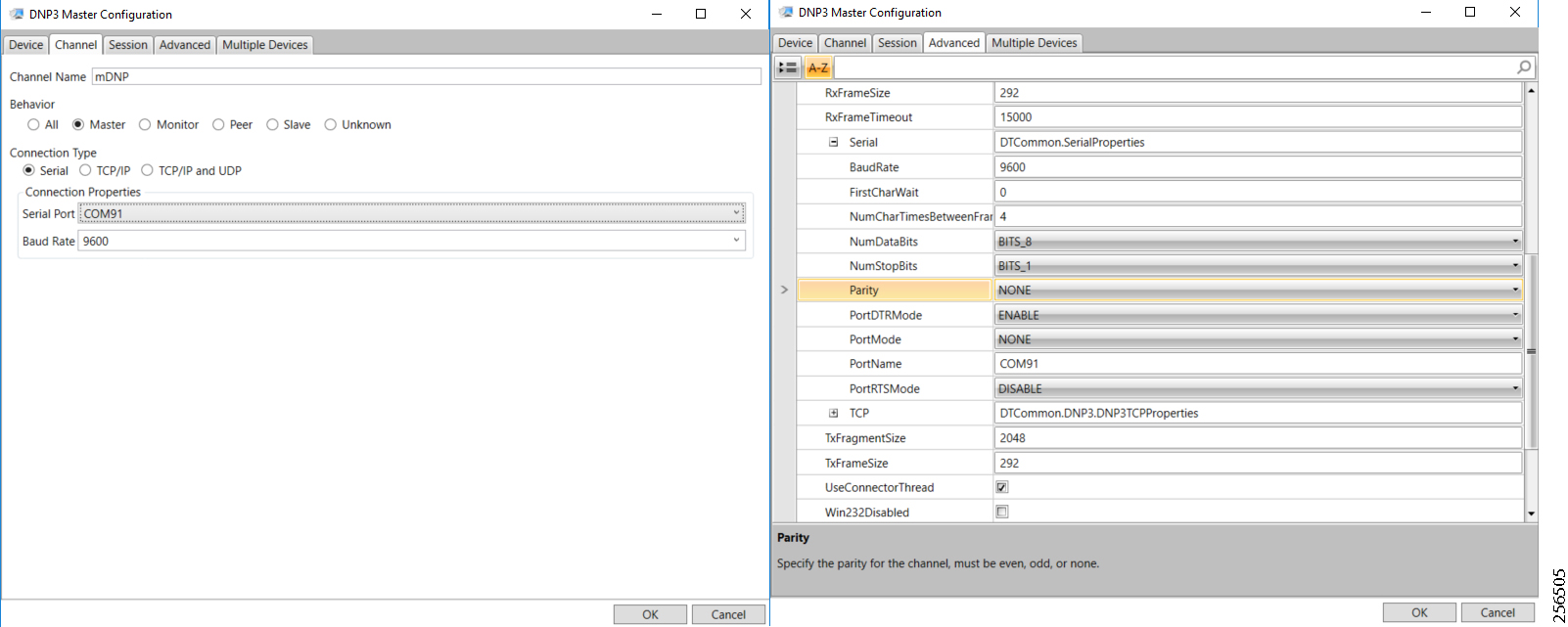

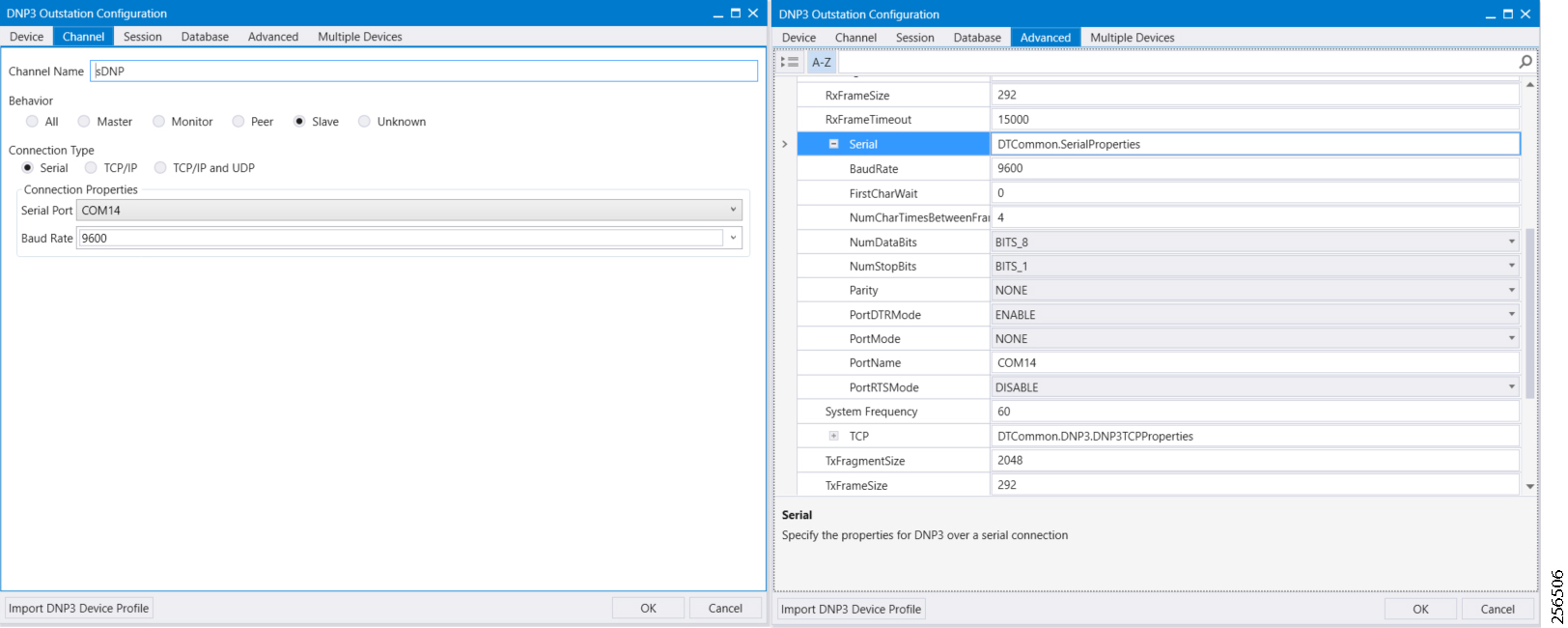

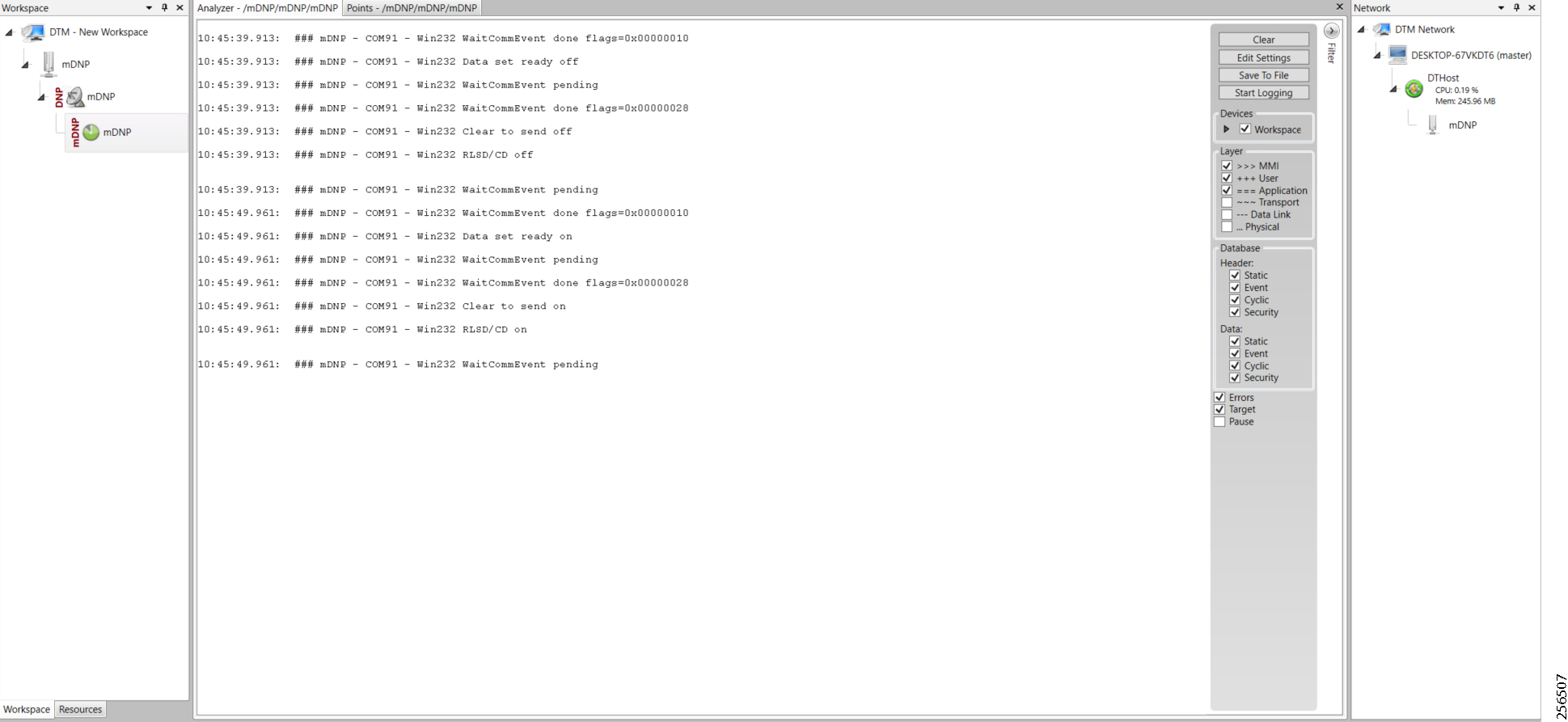

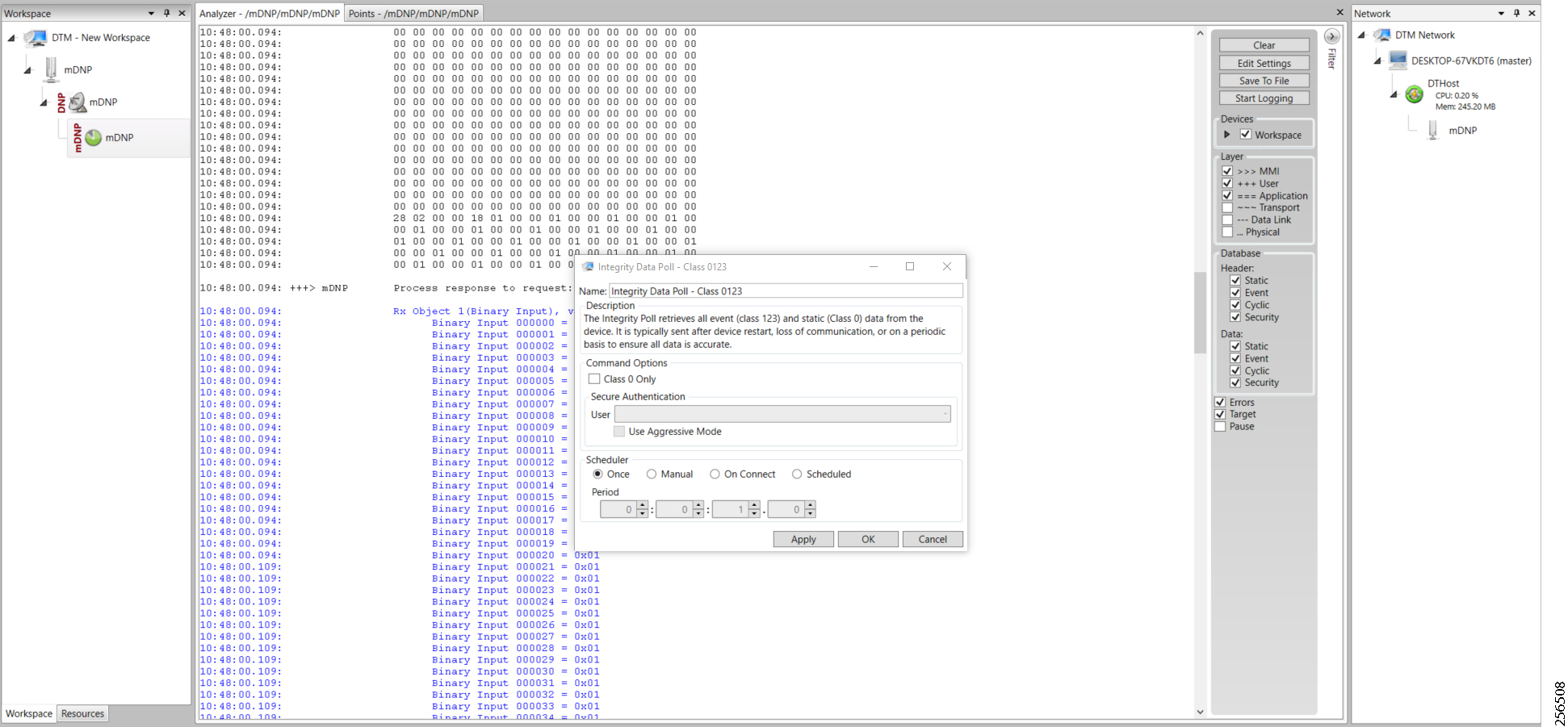

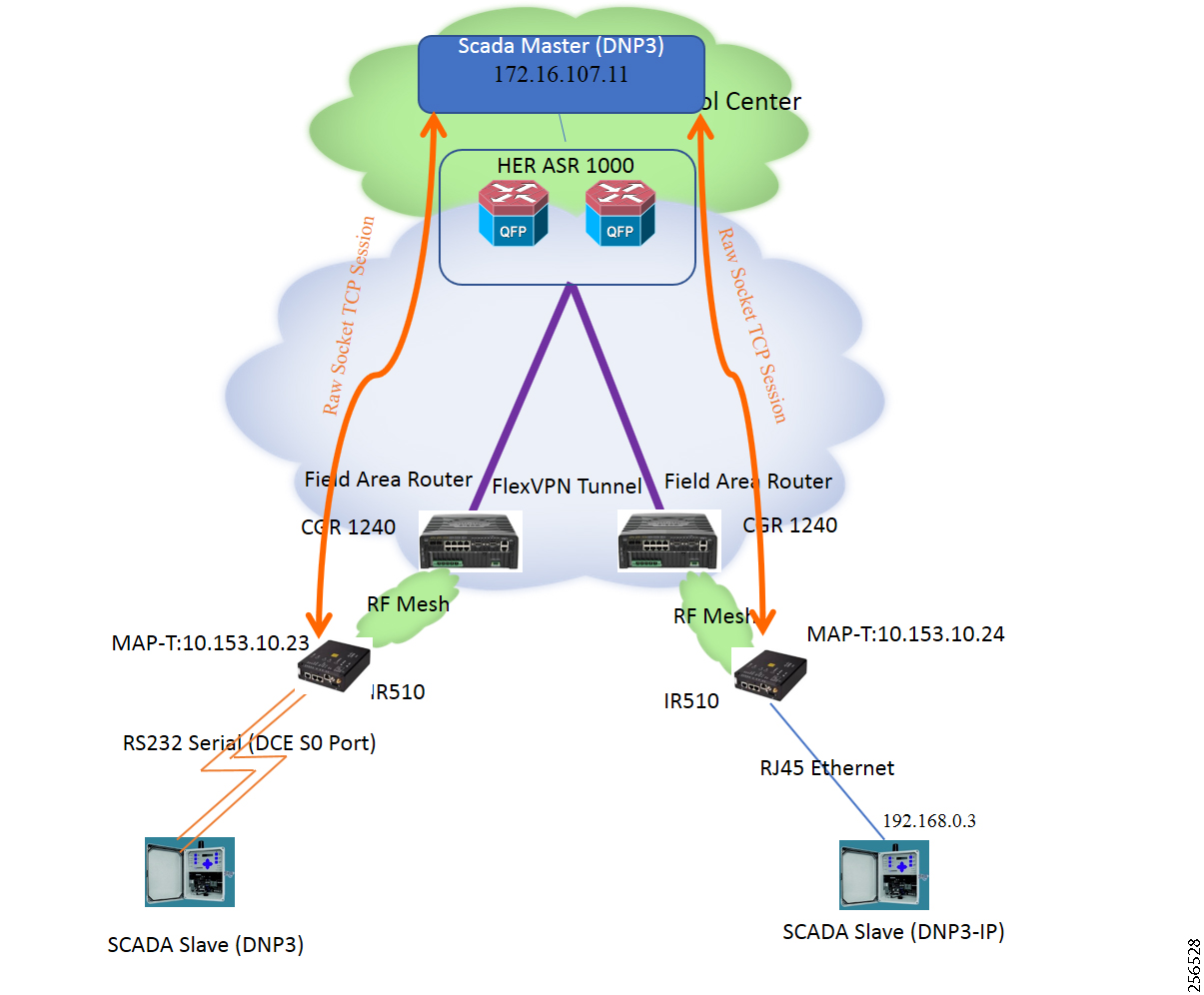

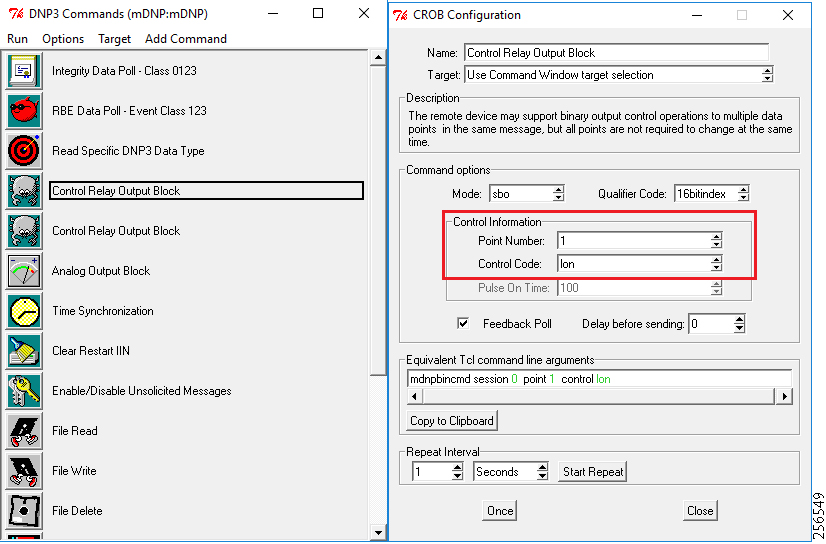

- SCADA Control Center Point-to-Point Implementation Scenarios Over Cellular Gateways

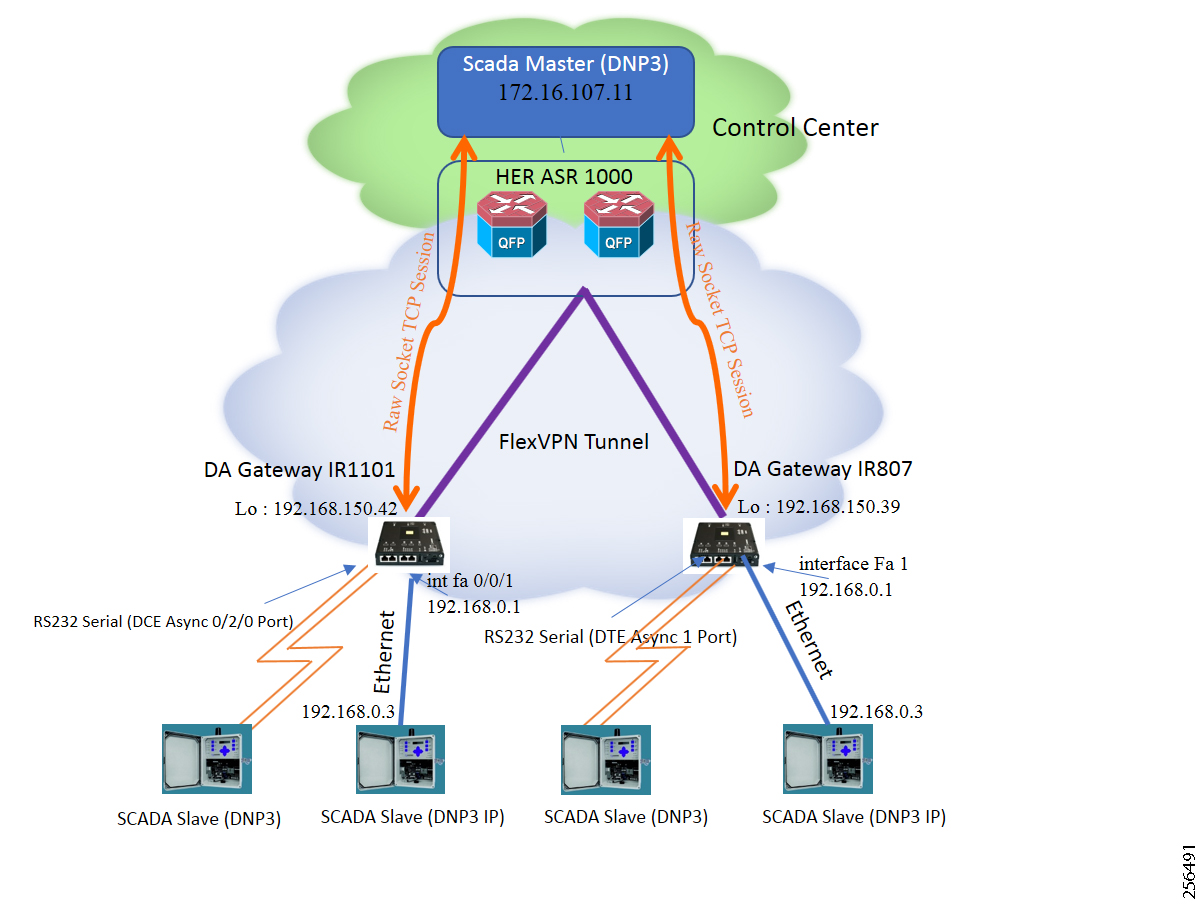

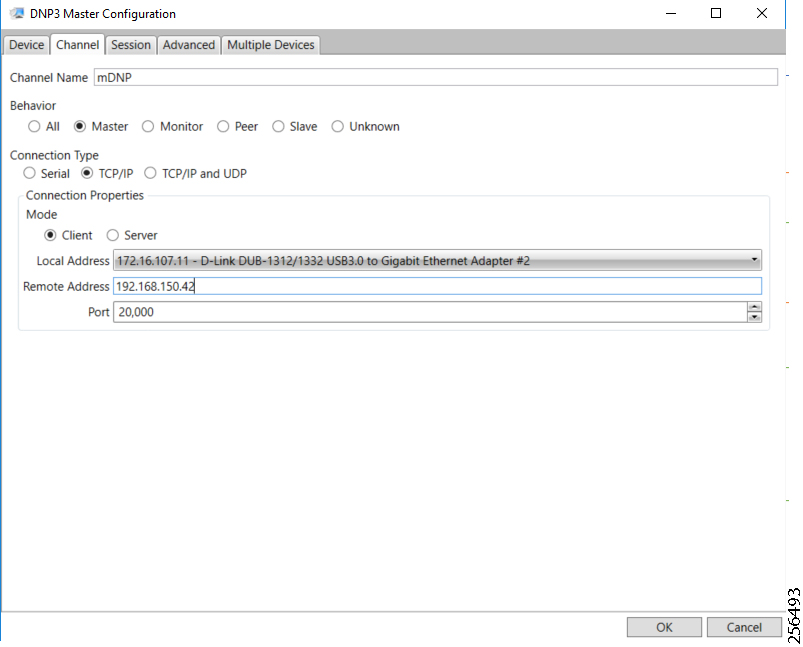

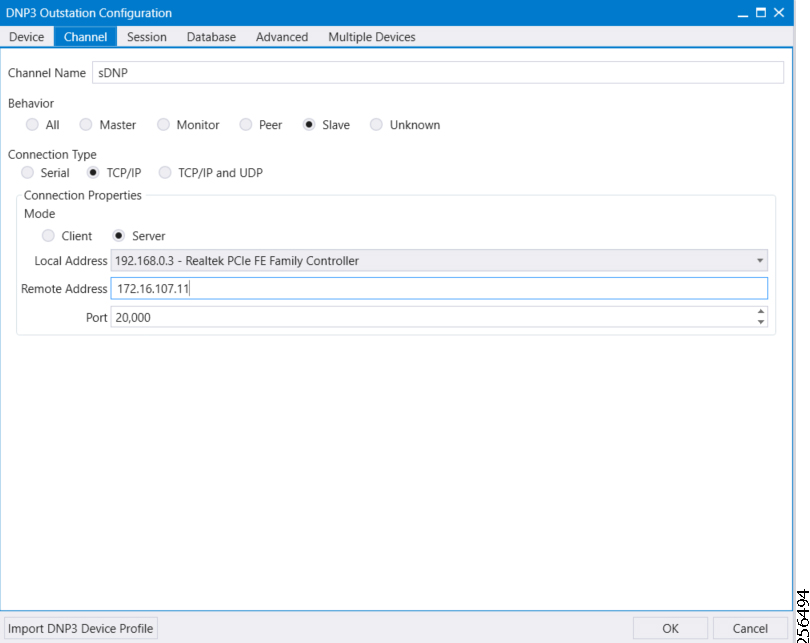

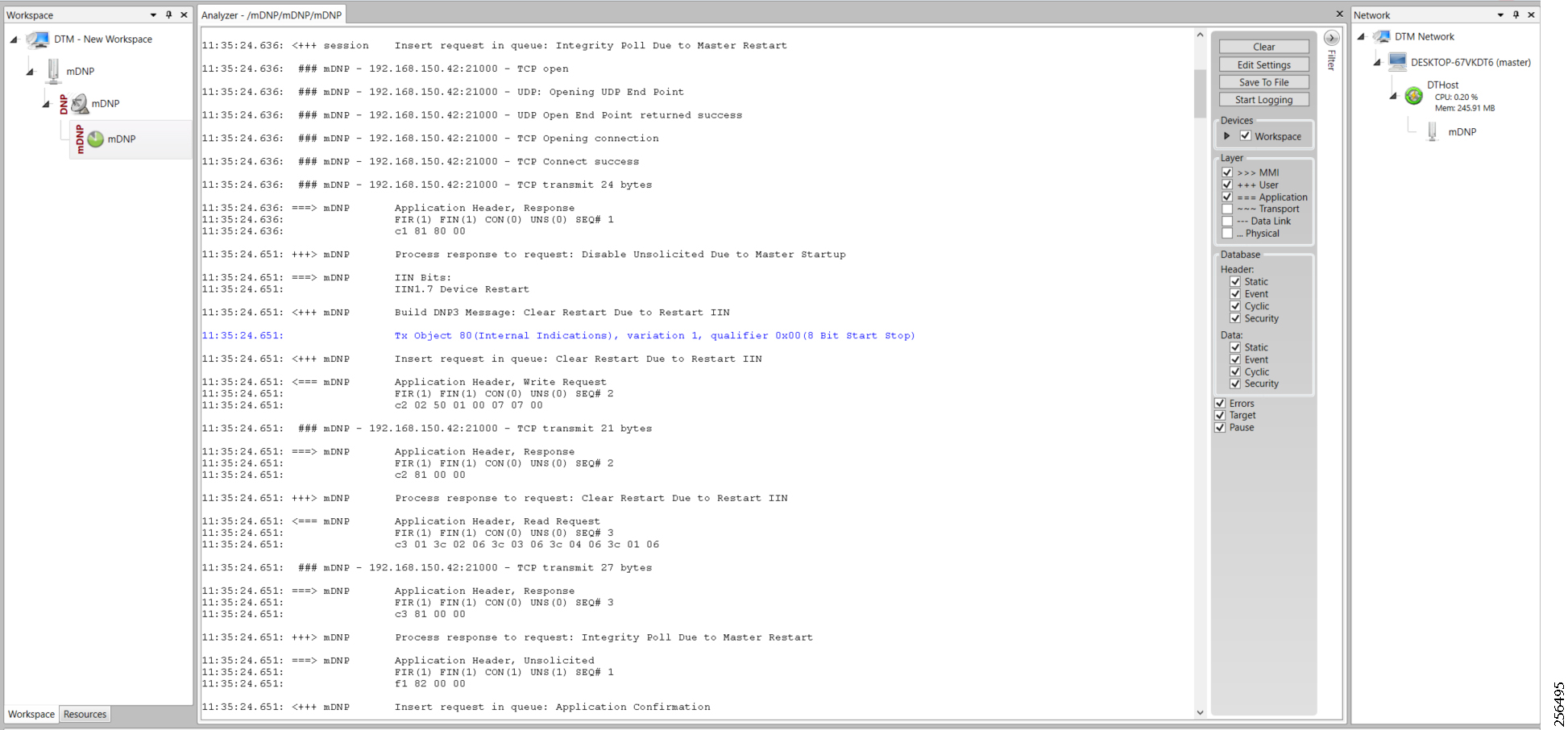

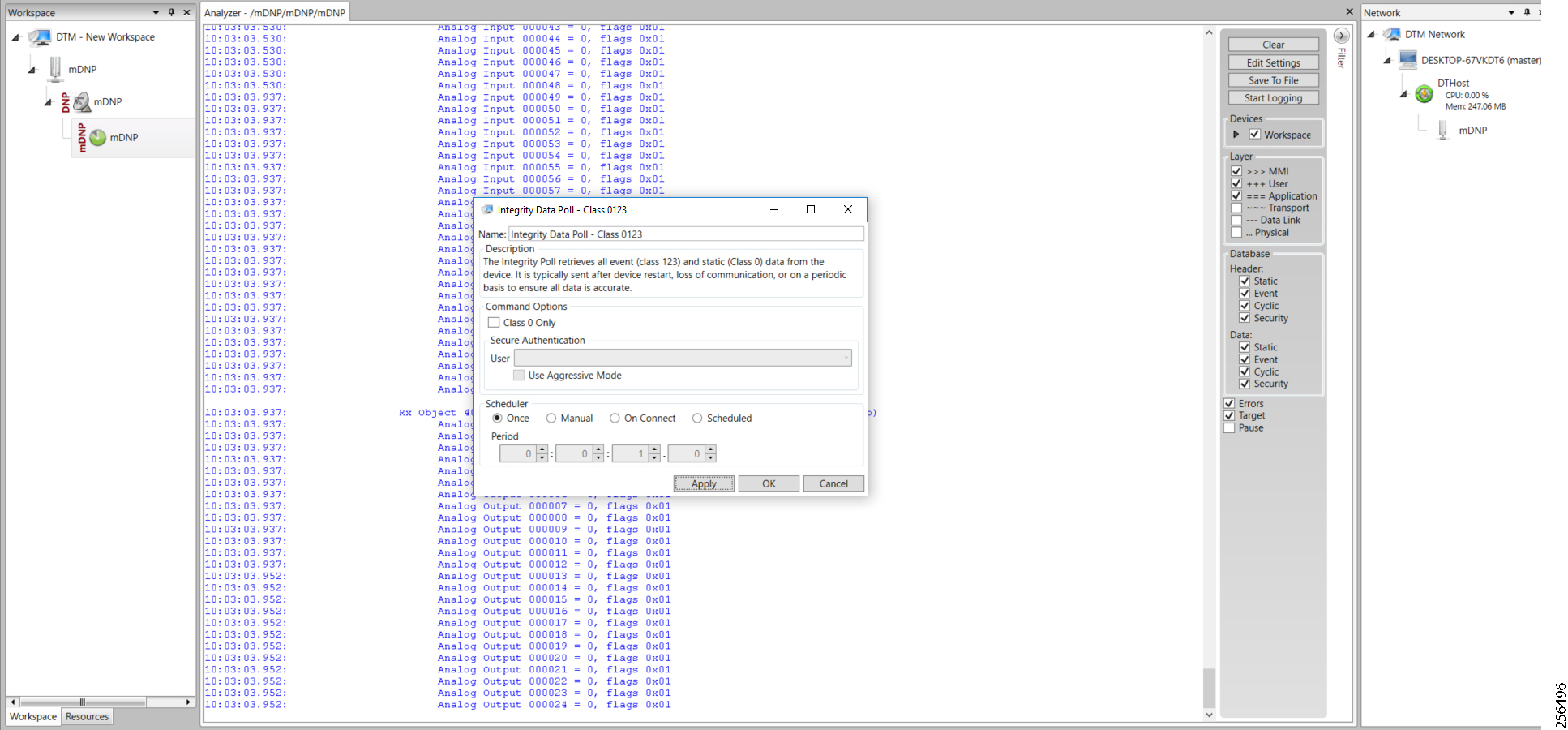

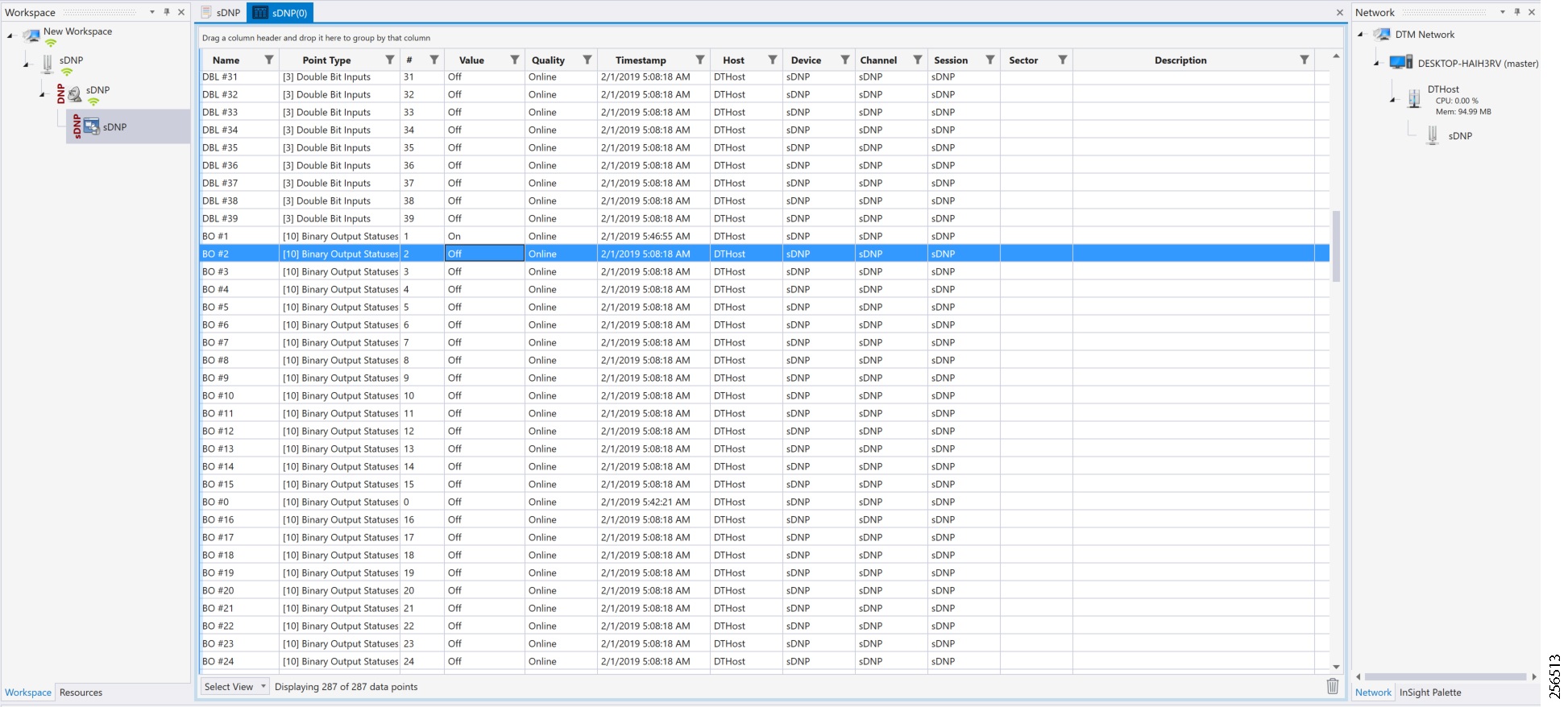

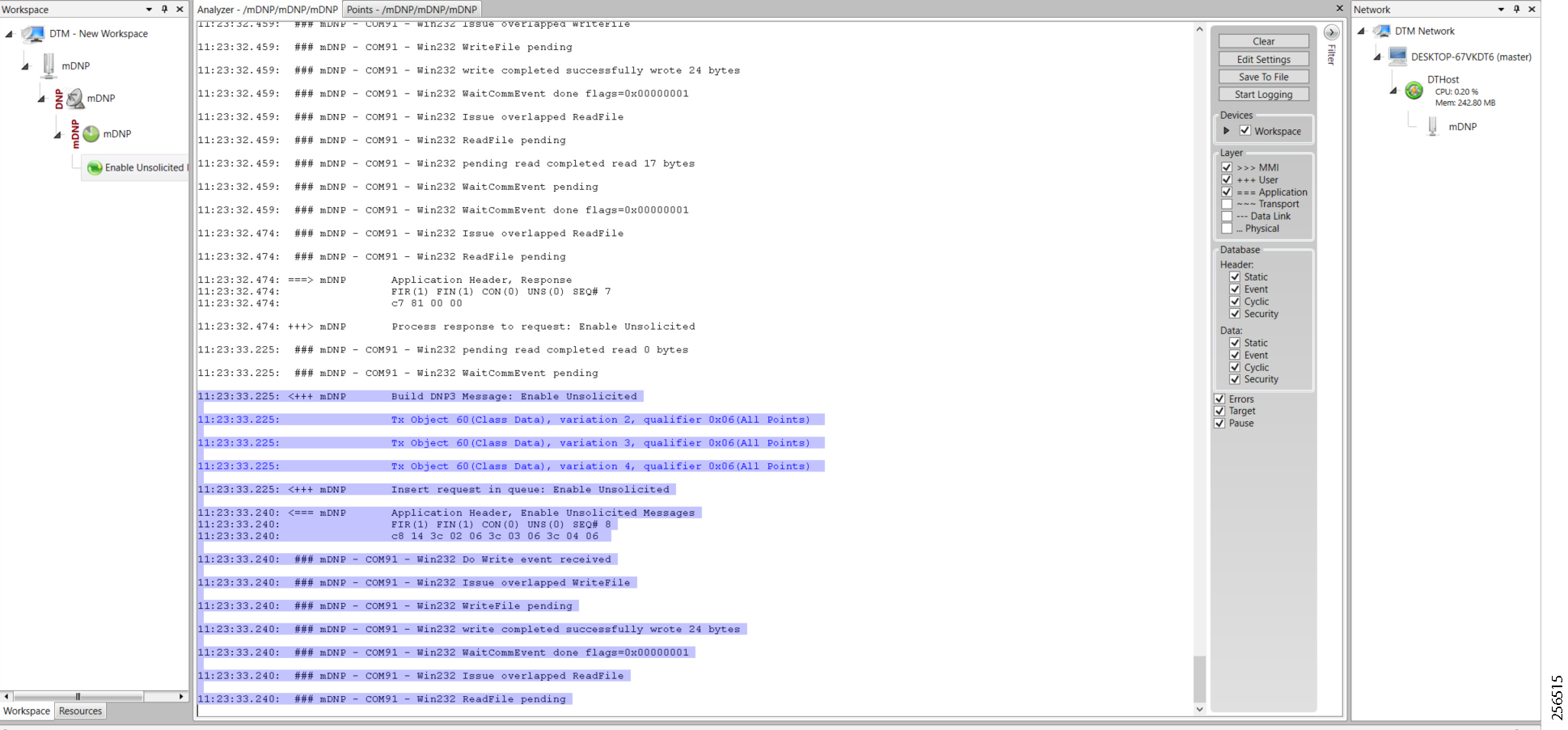

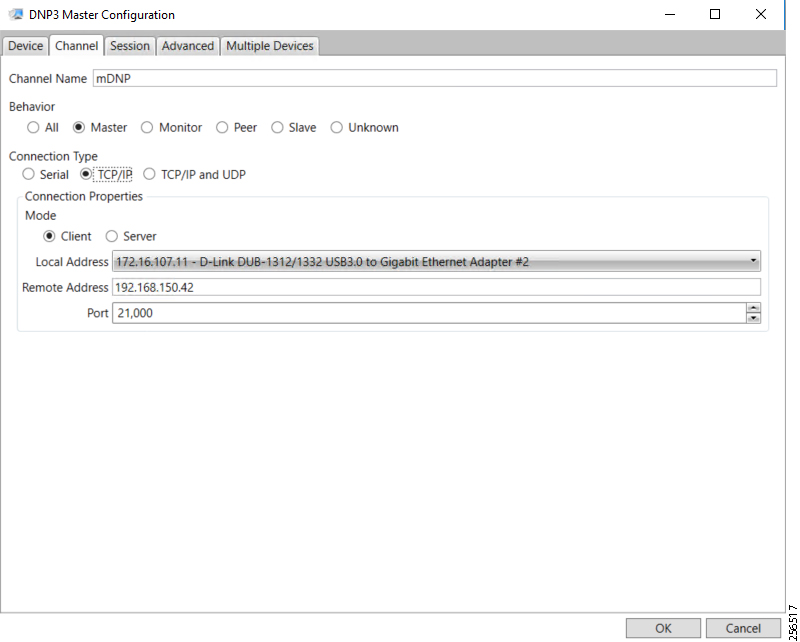

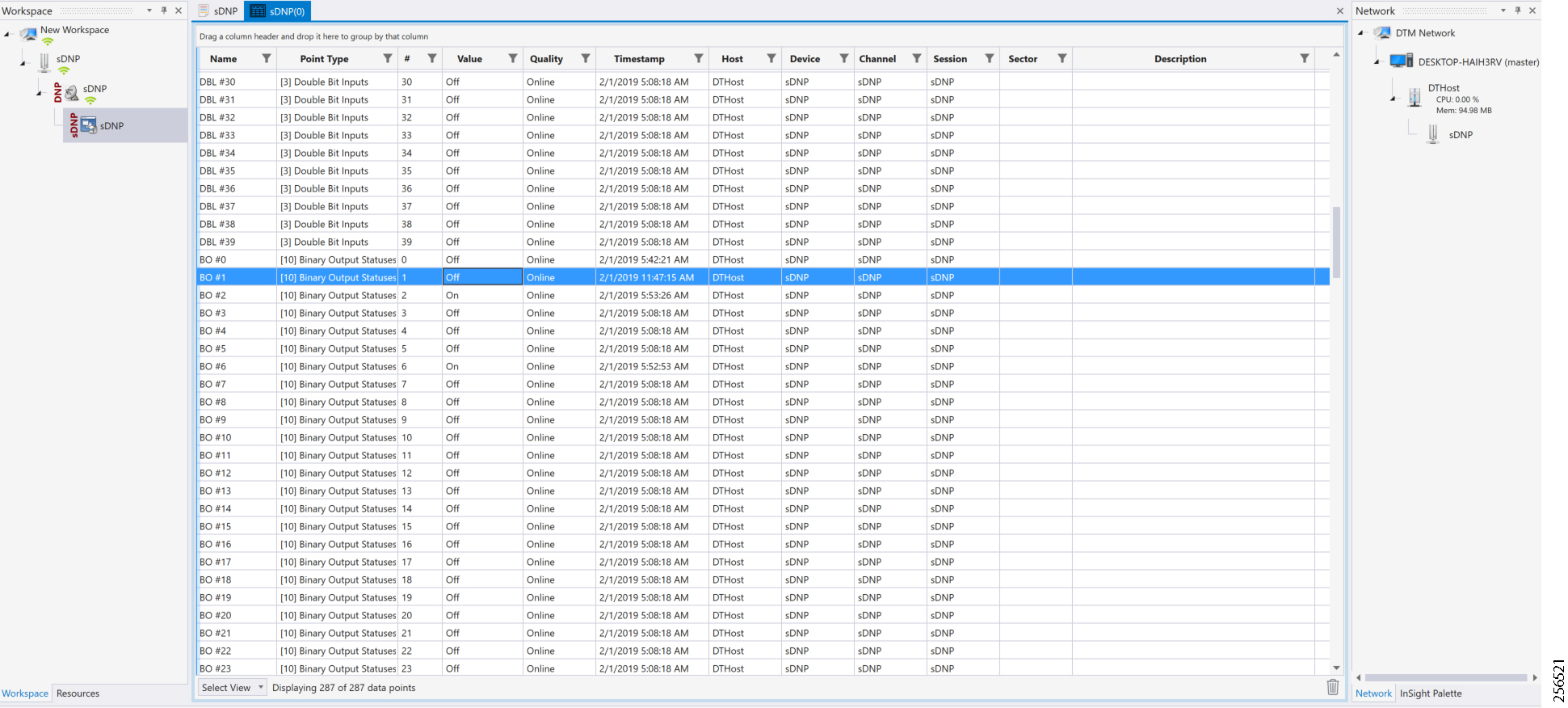

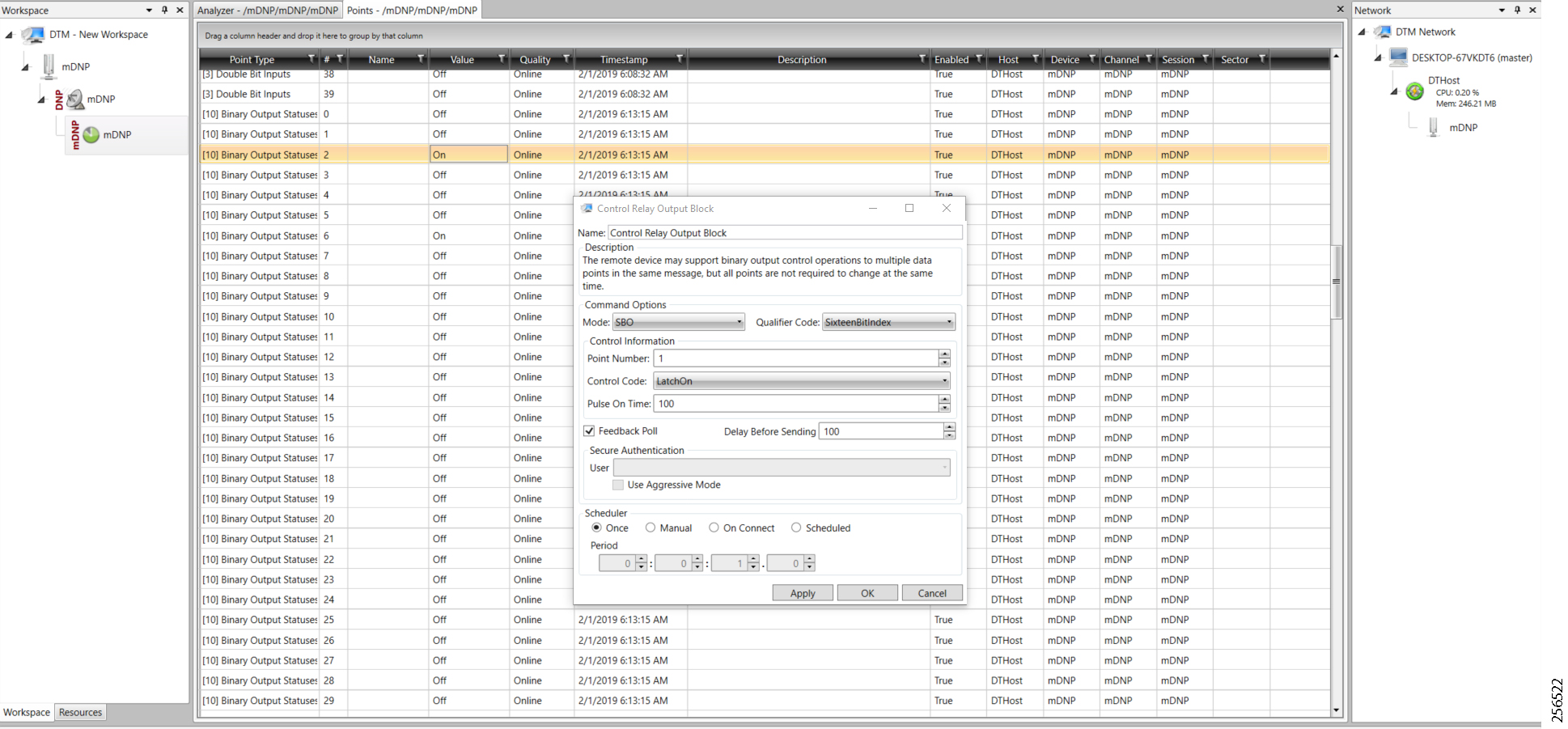

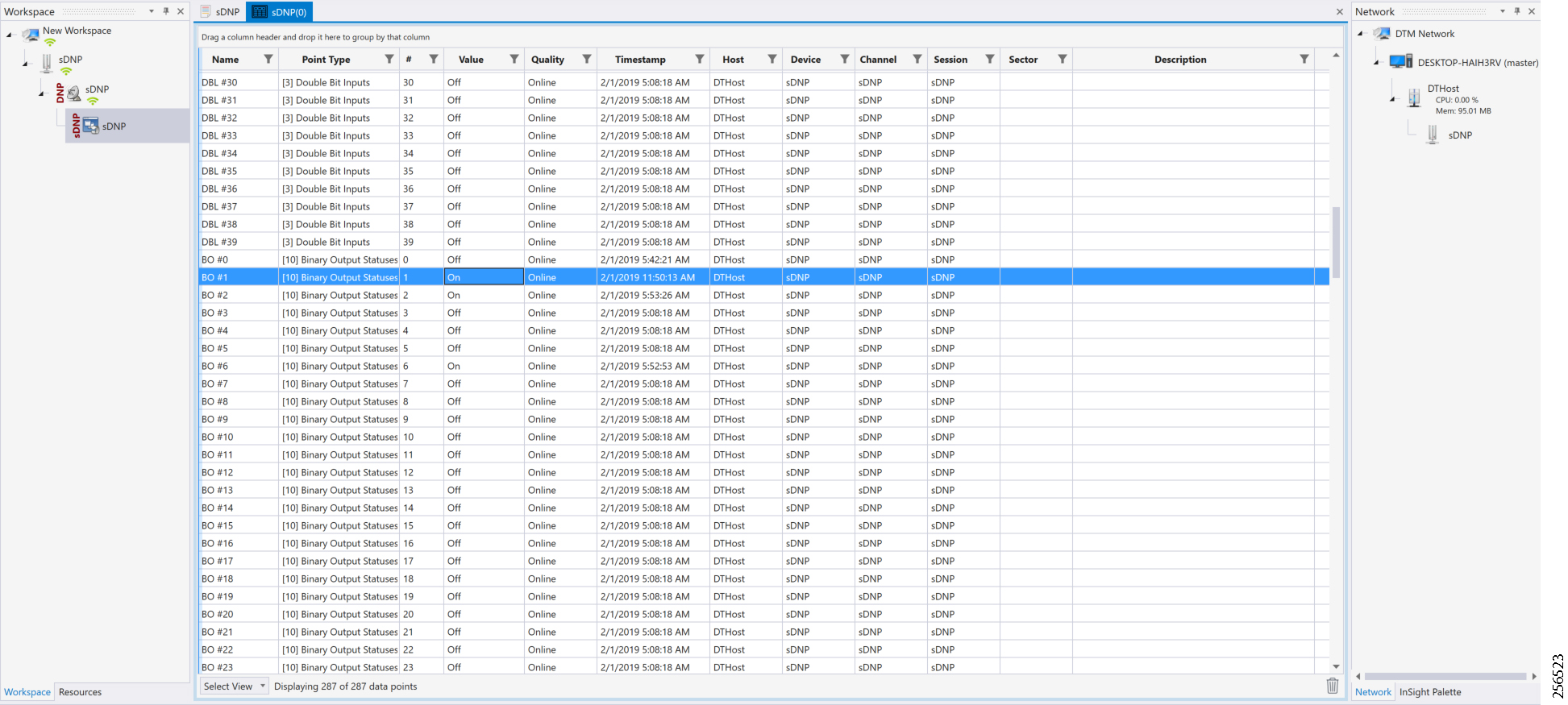

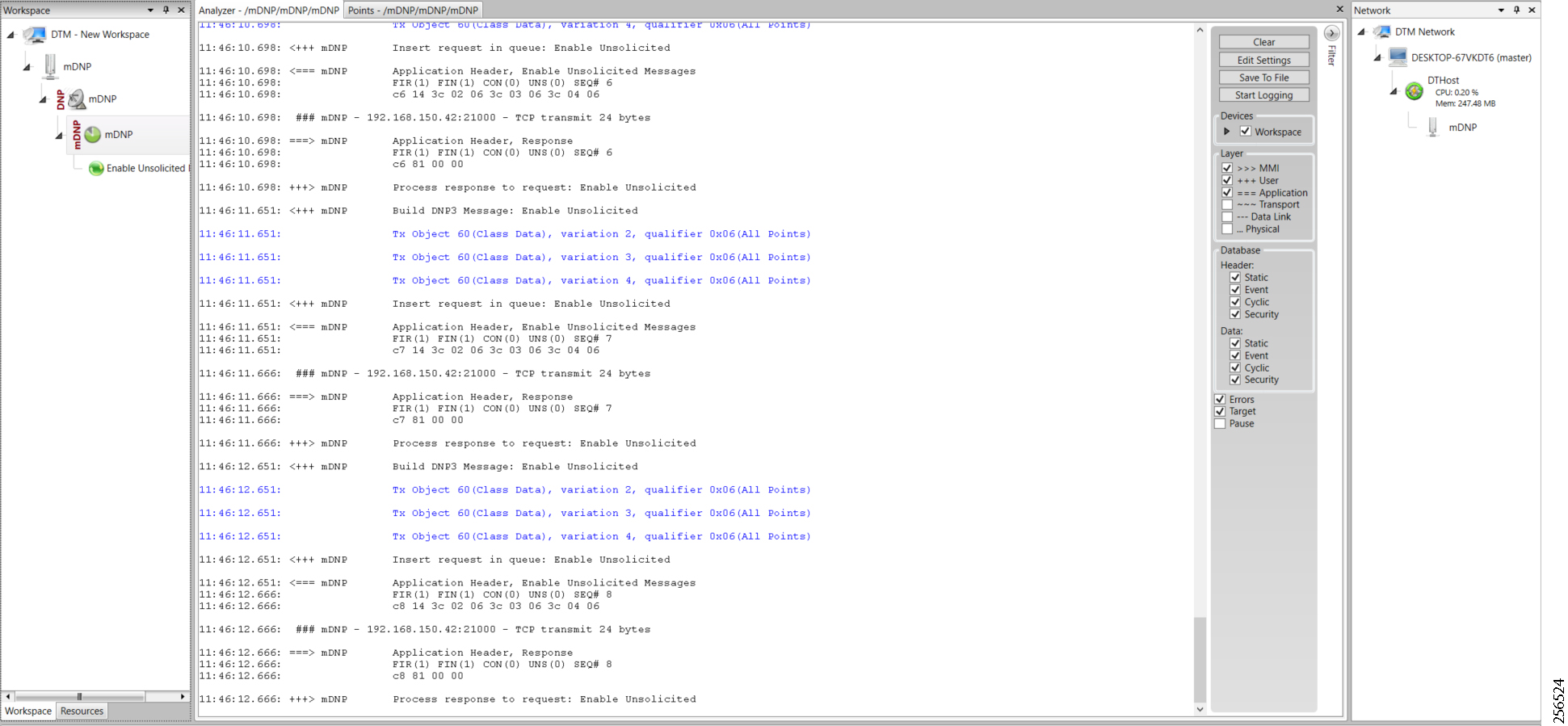

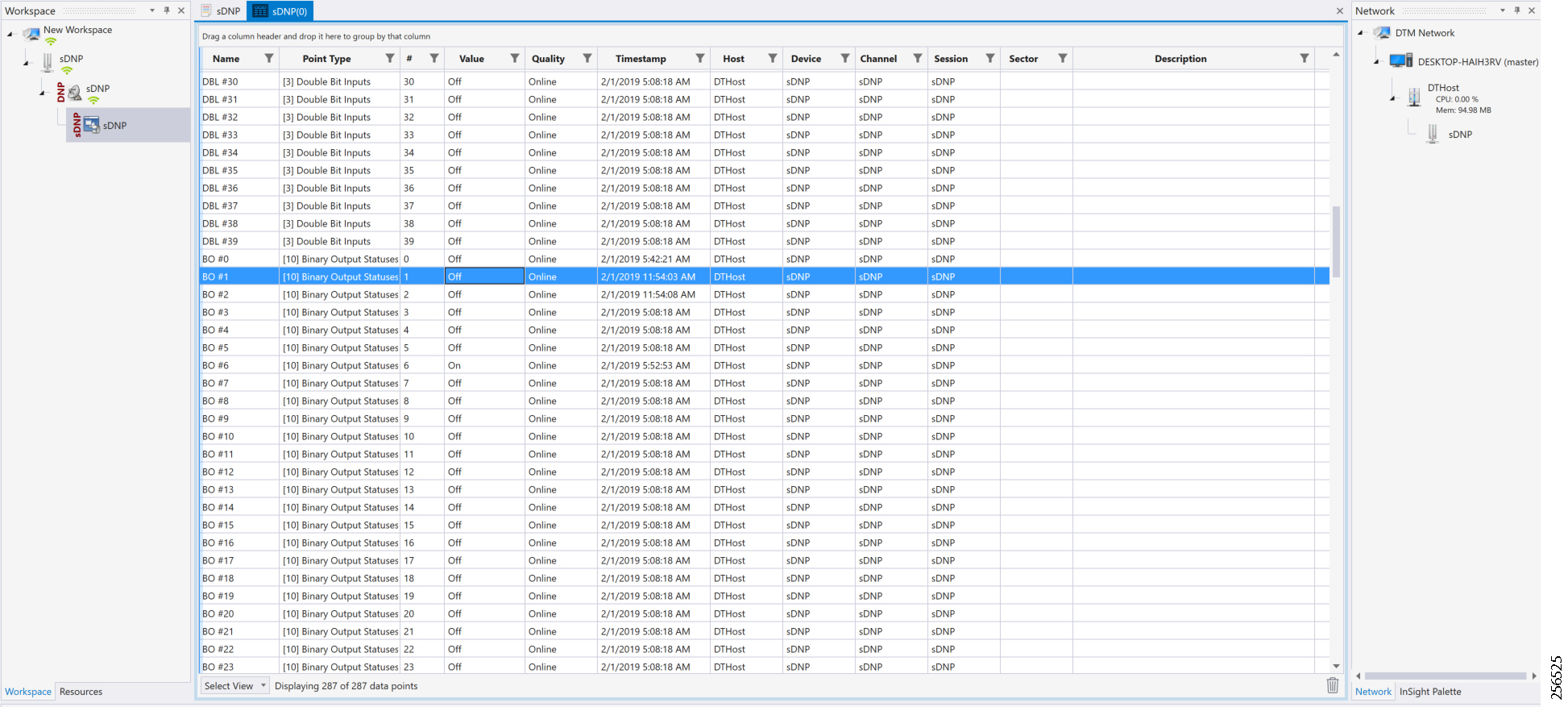

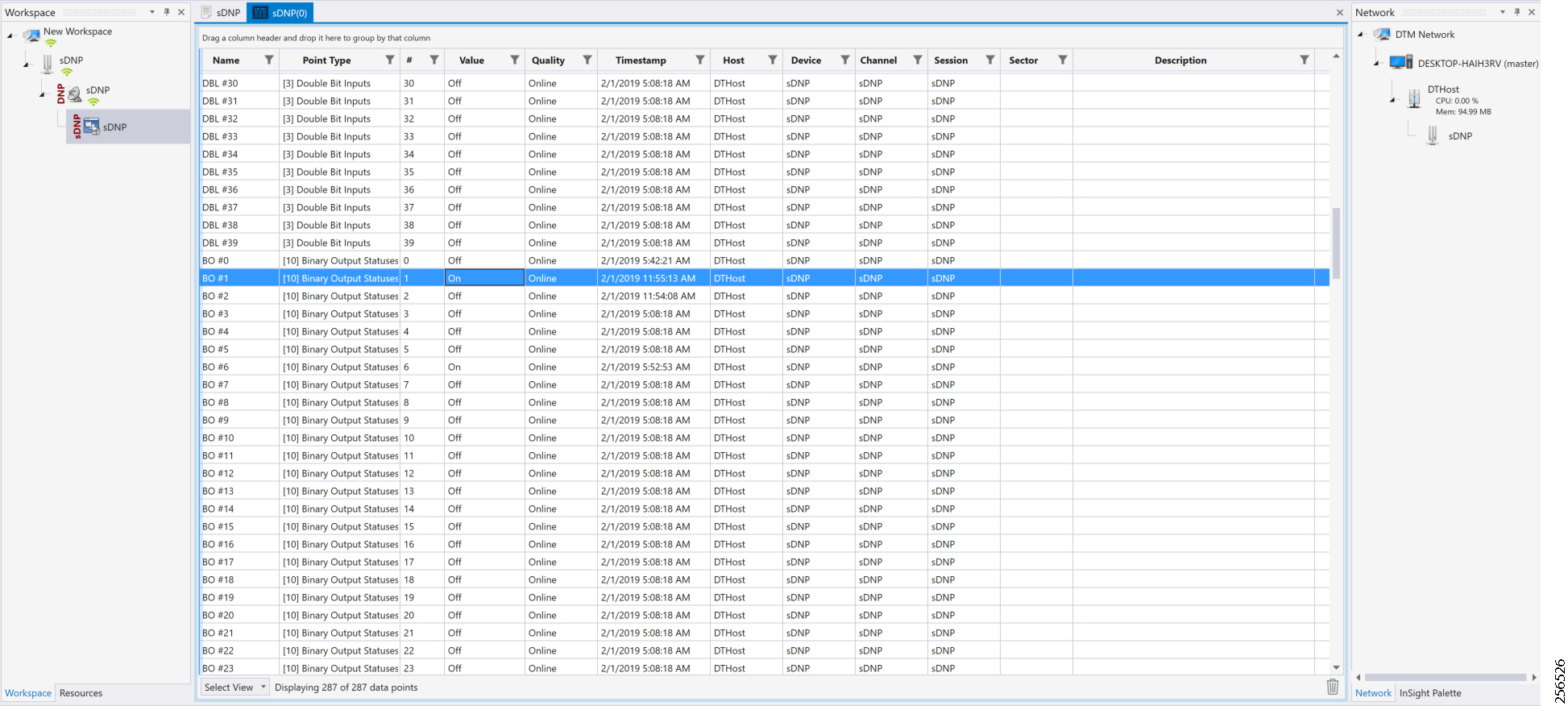

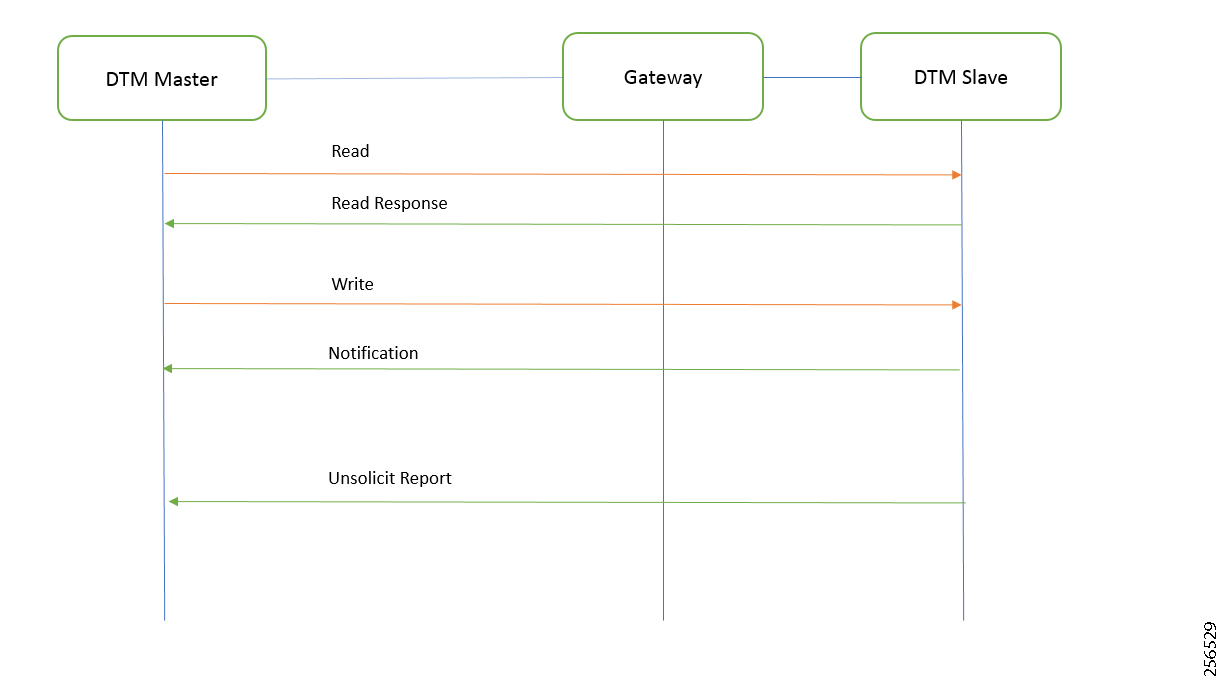

- SCADA Communication with IP Intelligent Devices

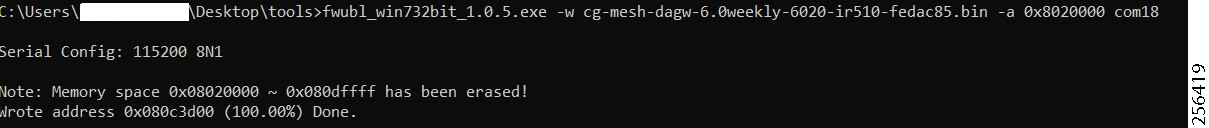

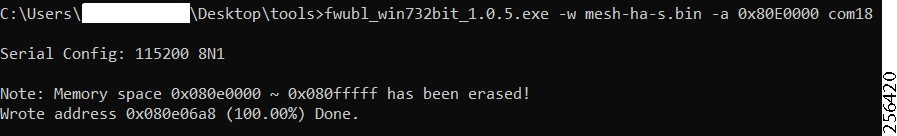

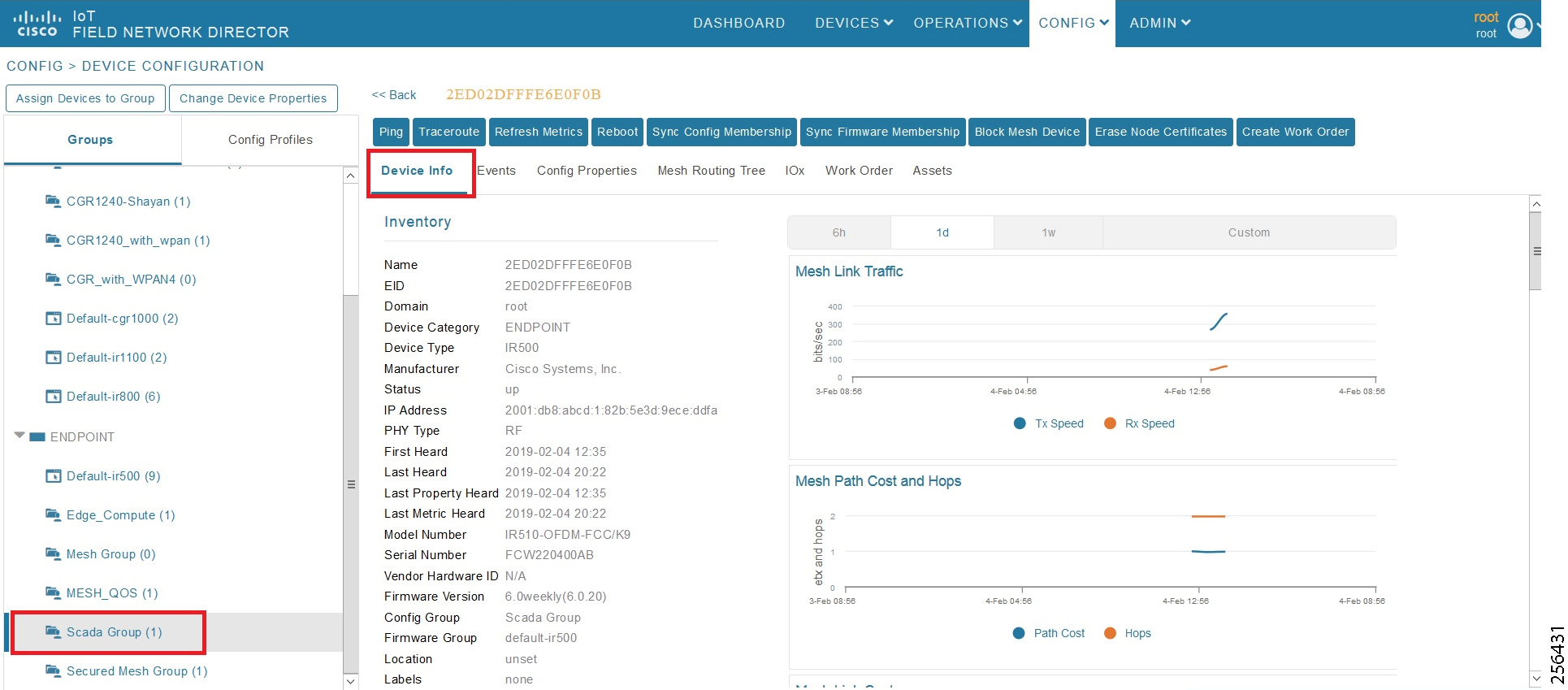

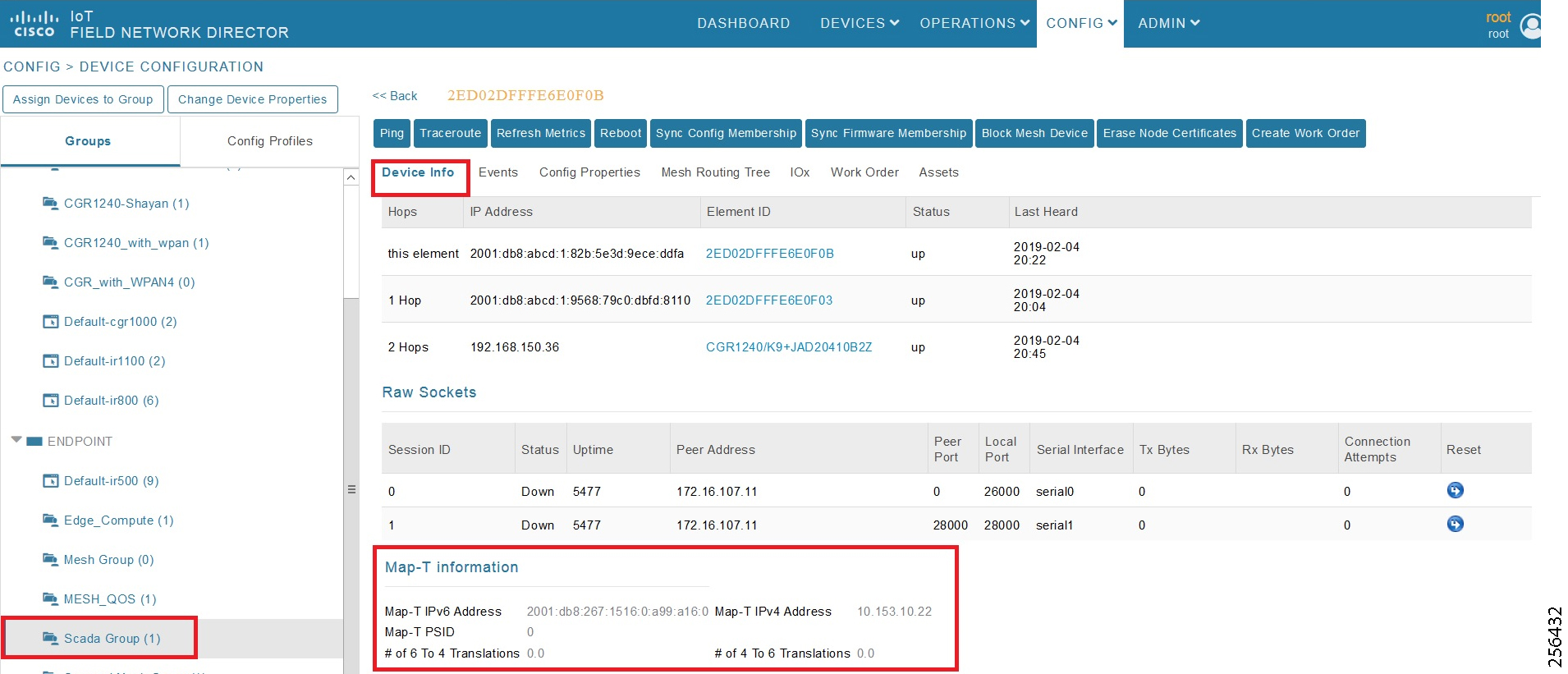

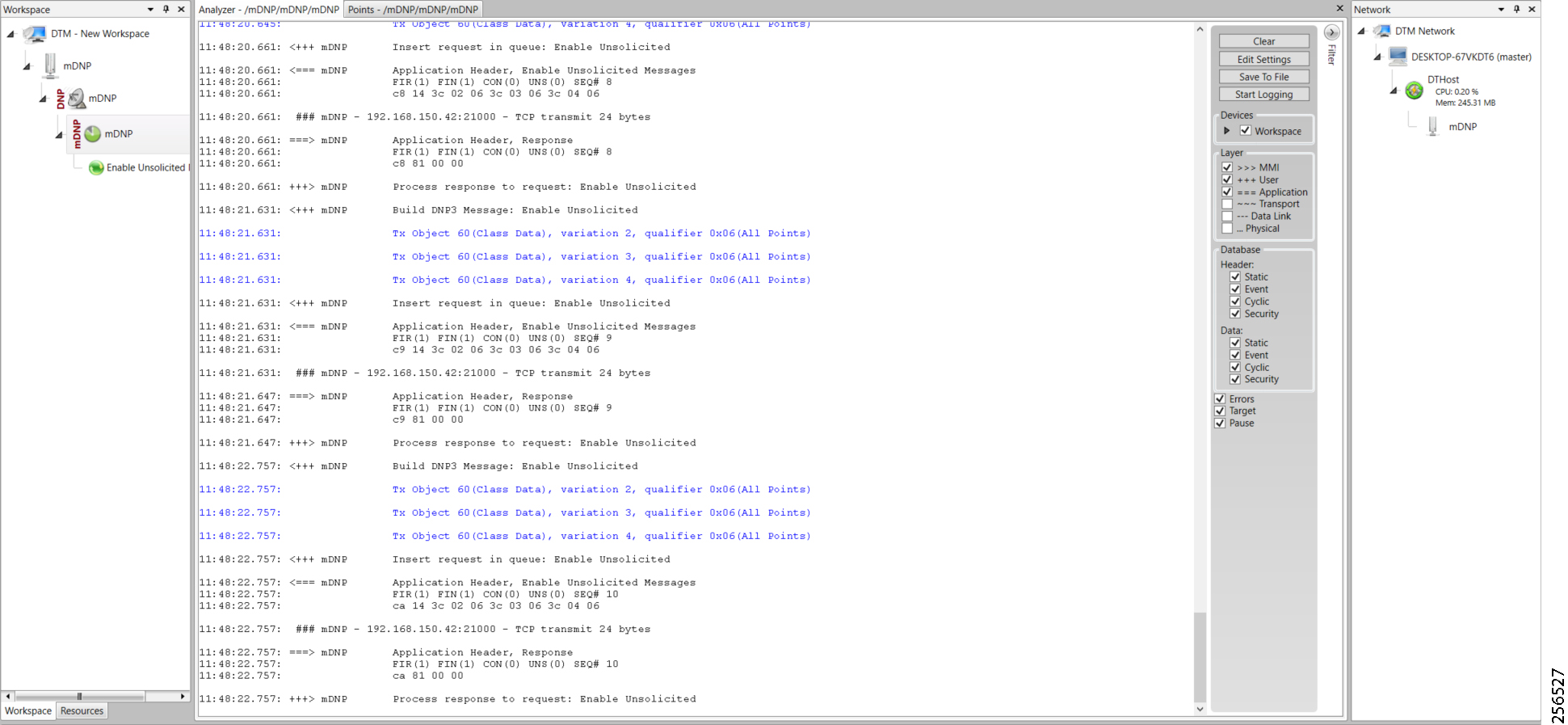

- SCADA Communication Scenarios over CR Mesh Network (IEEE 802.15.4)

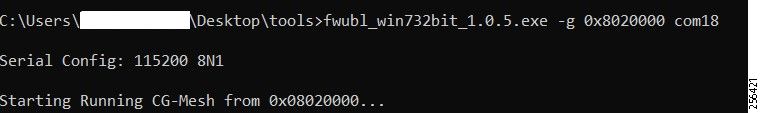

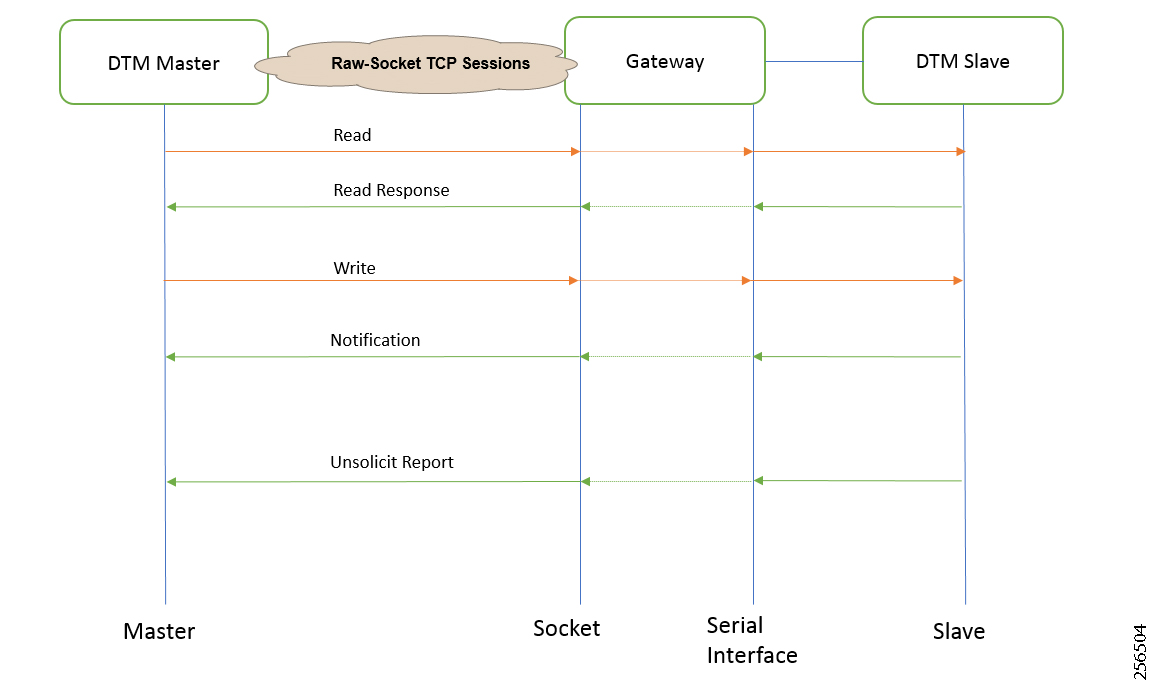

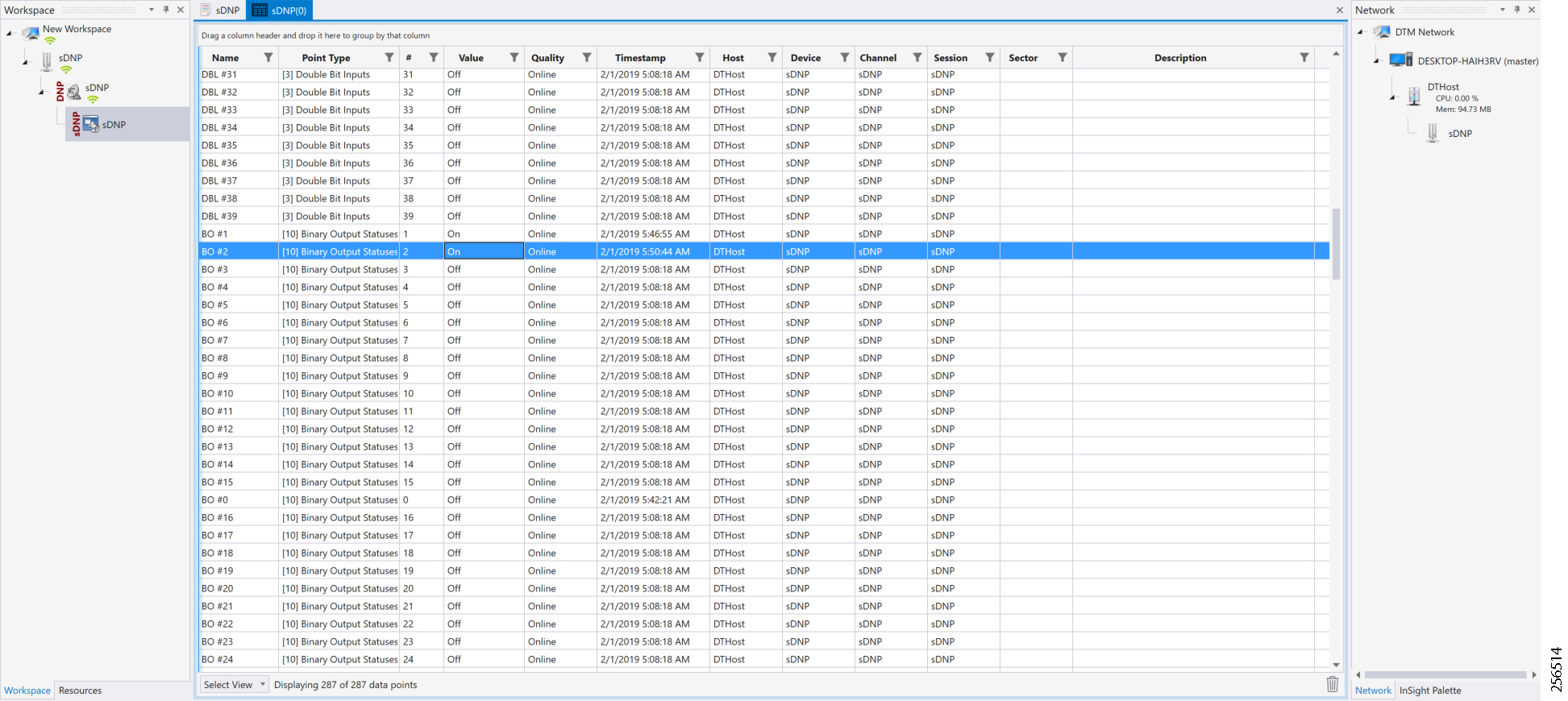

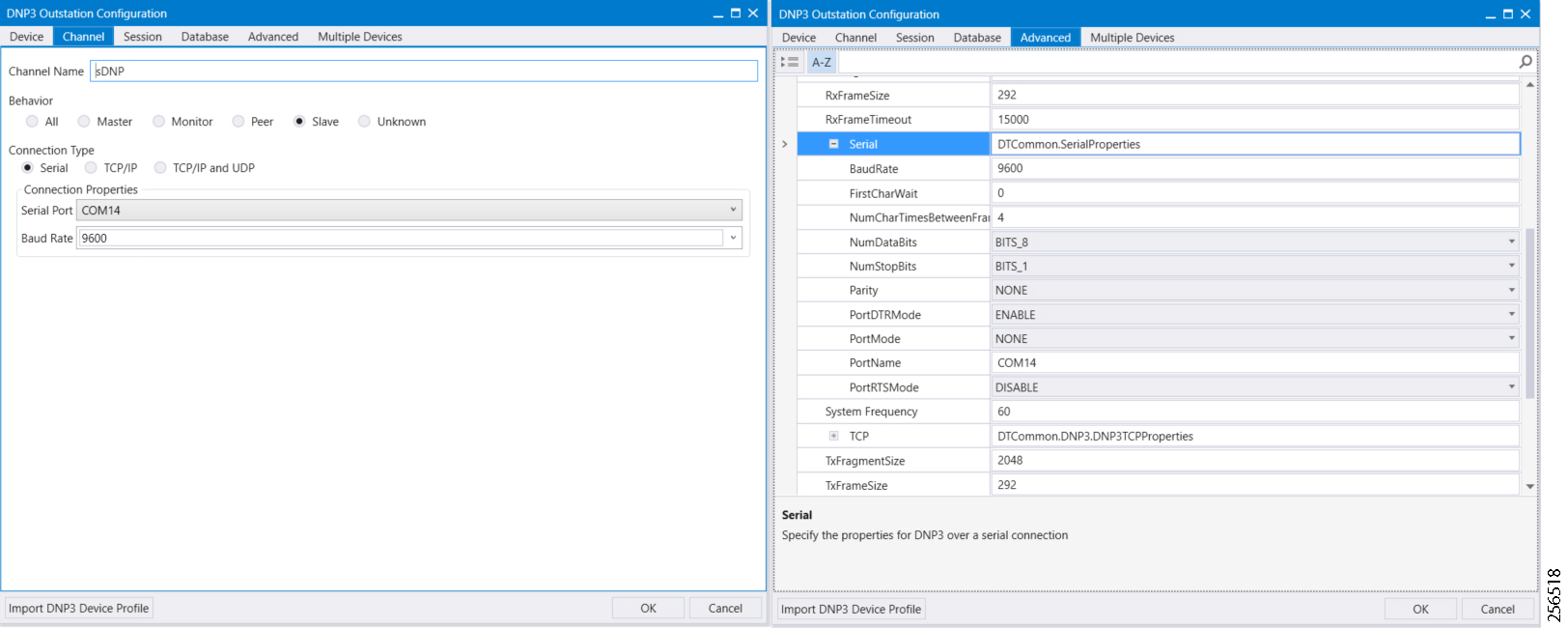

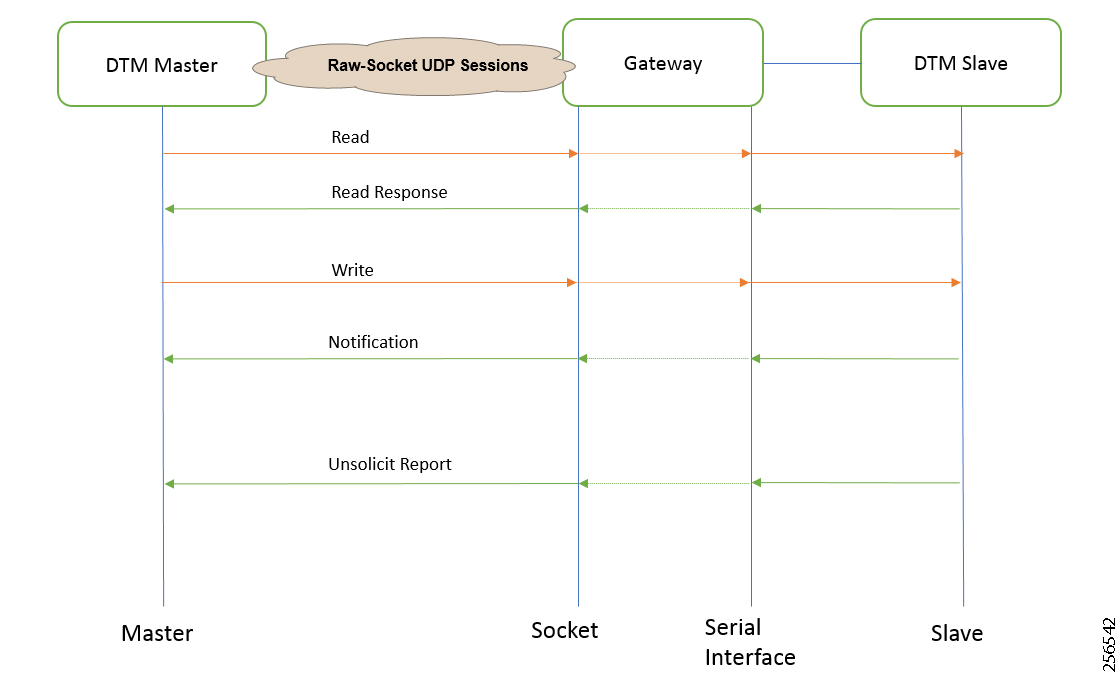

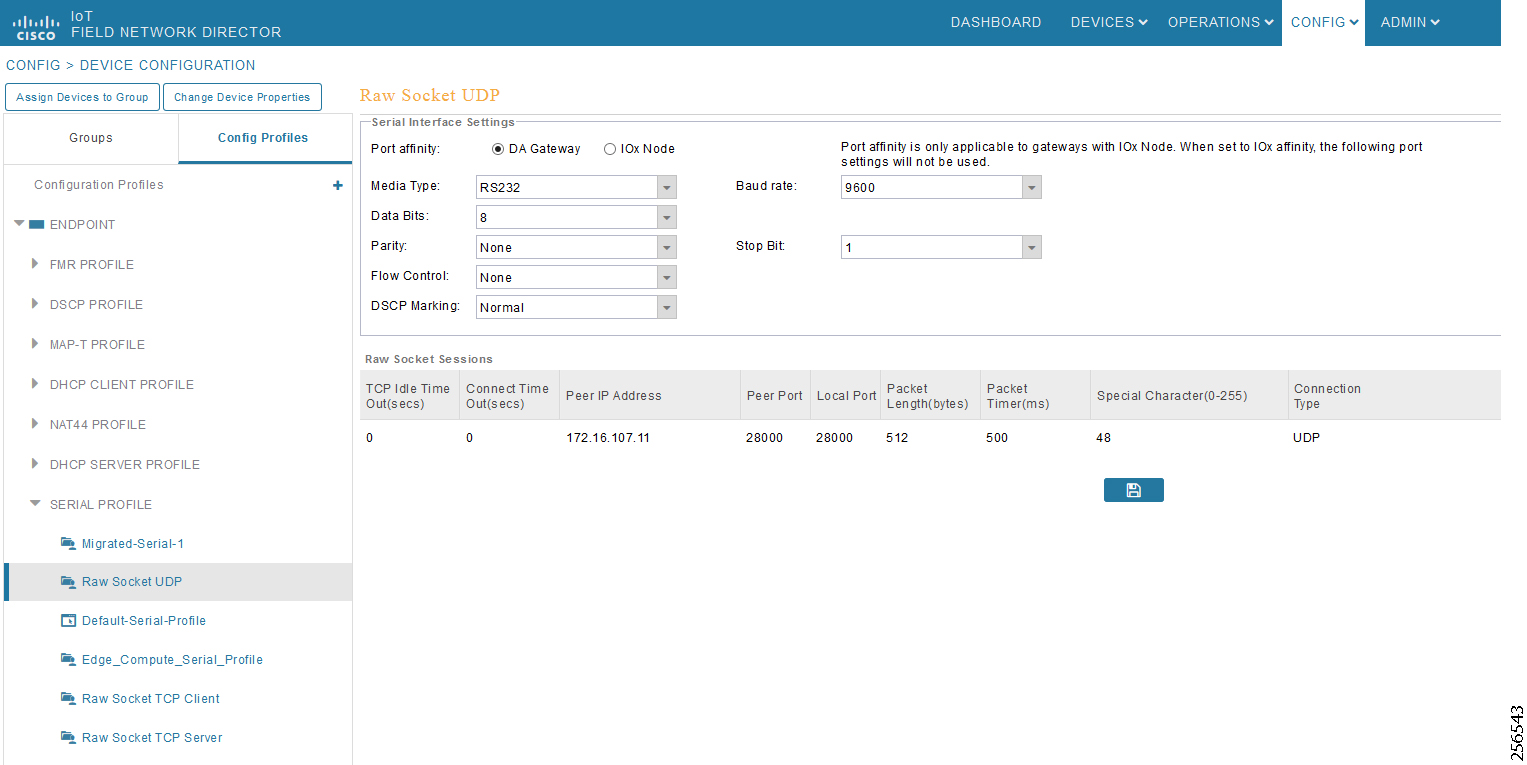

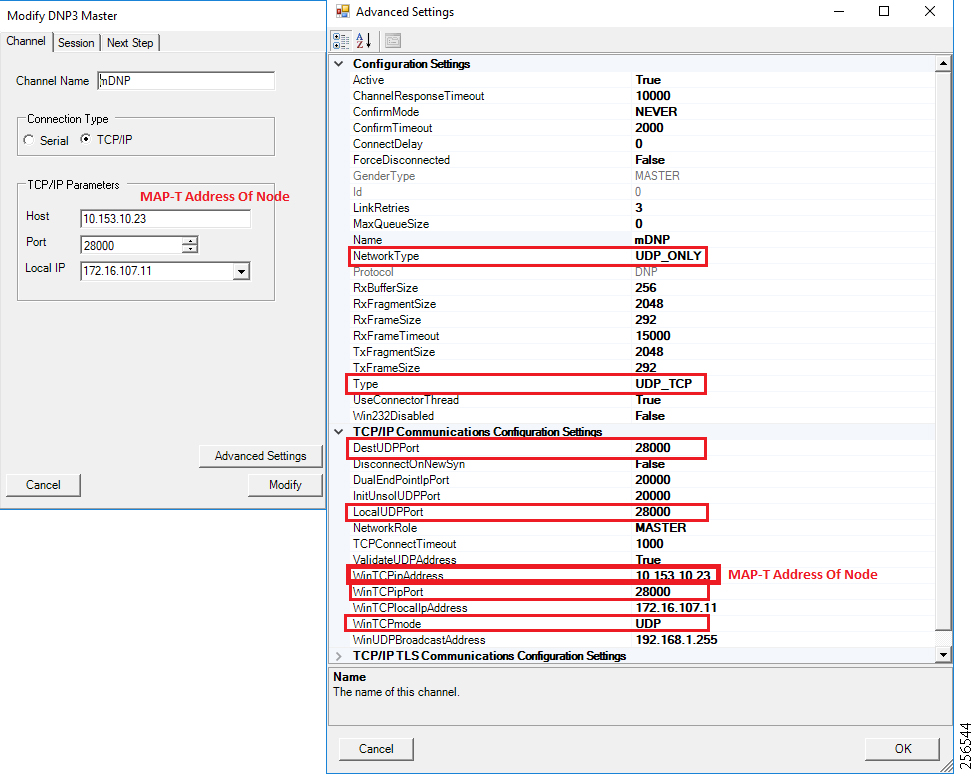

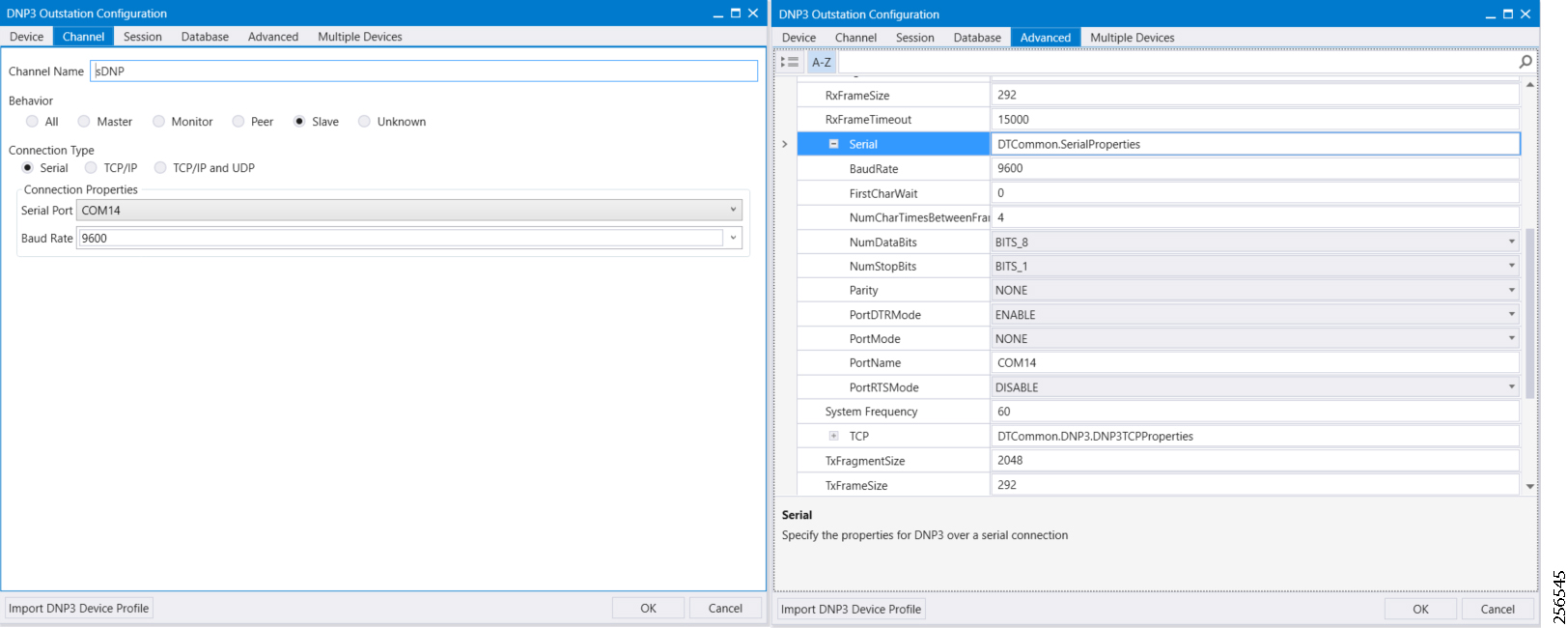

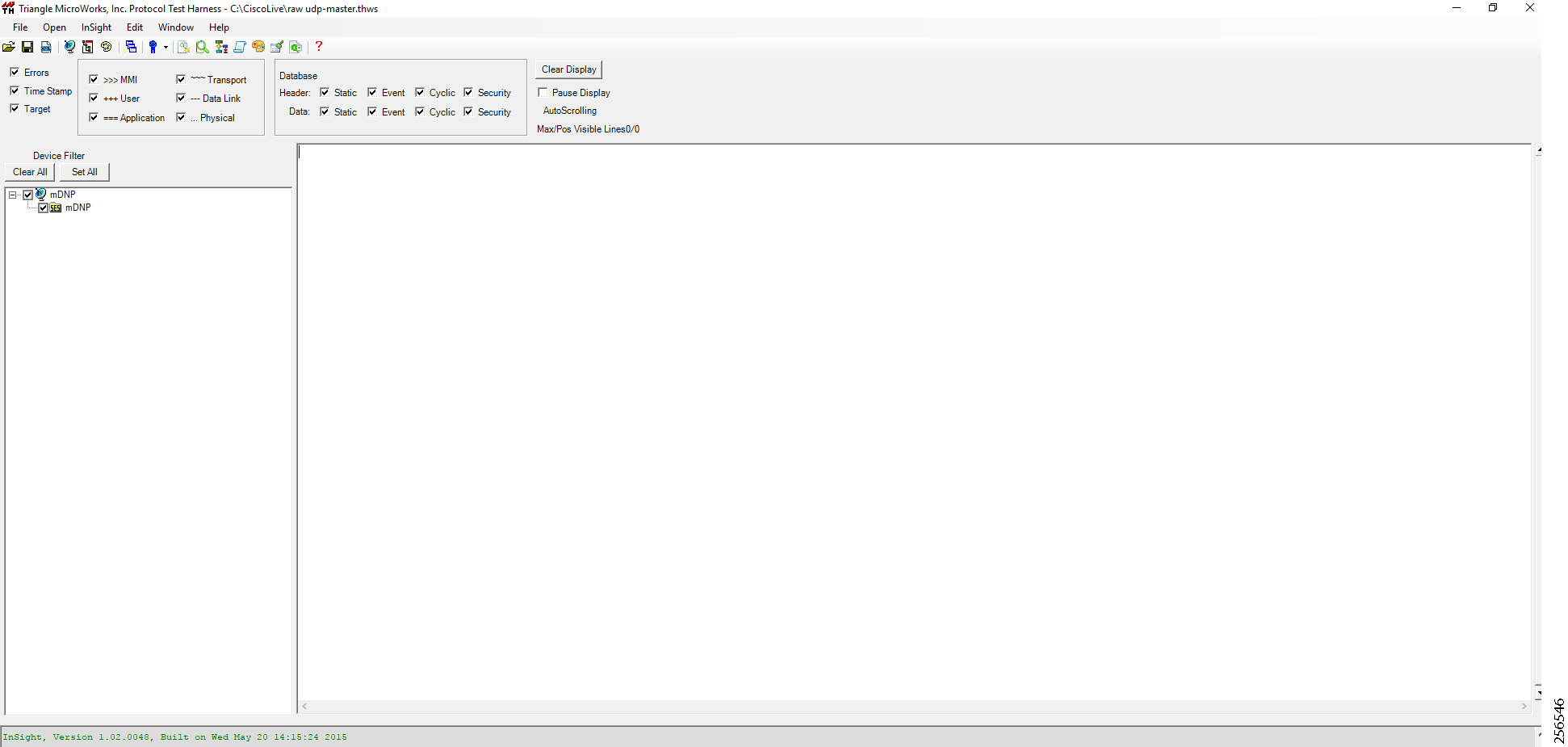

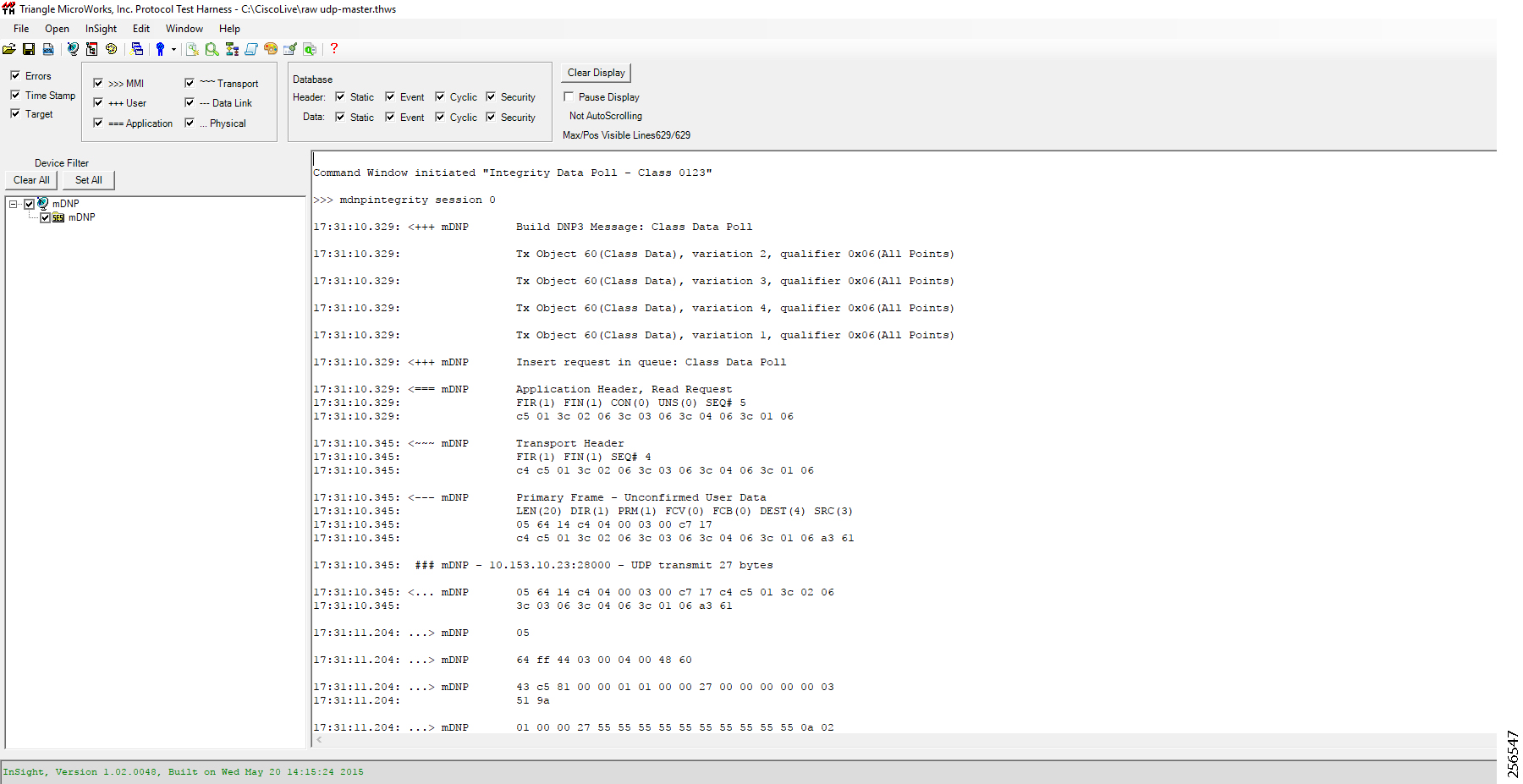

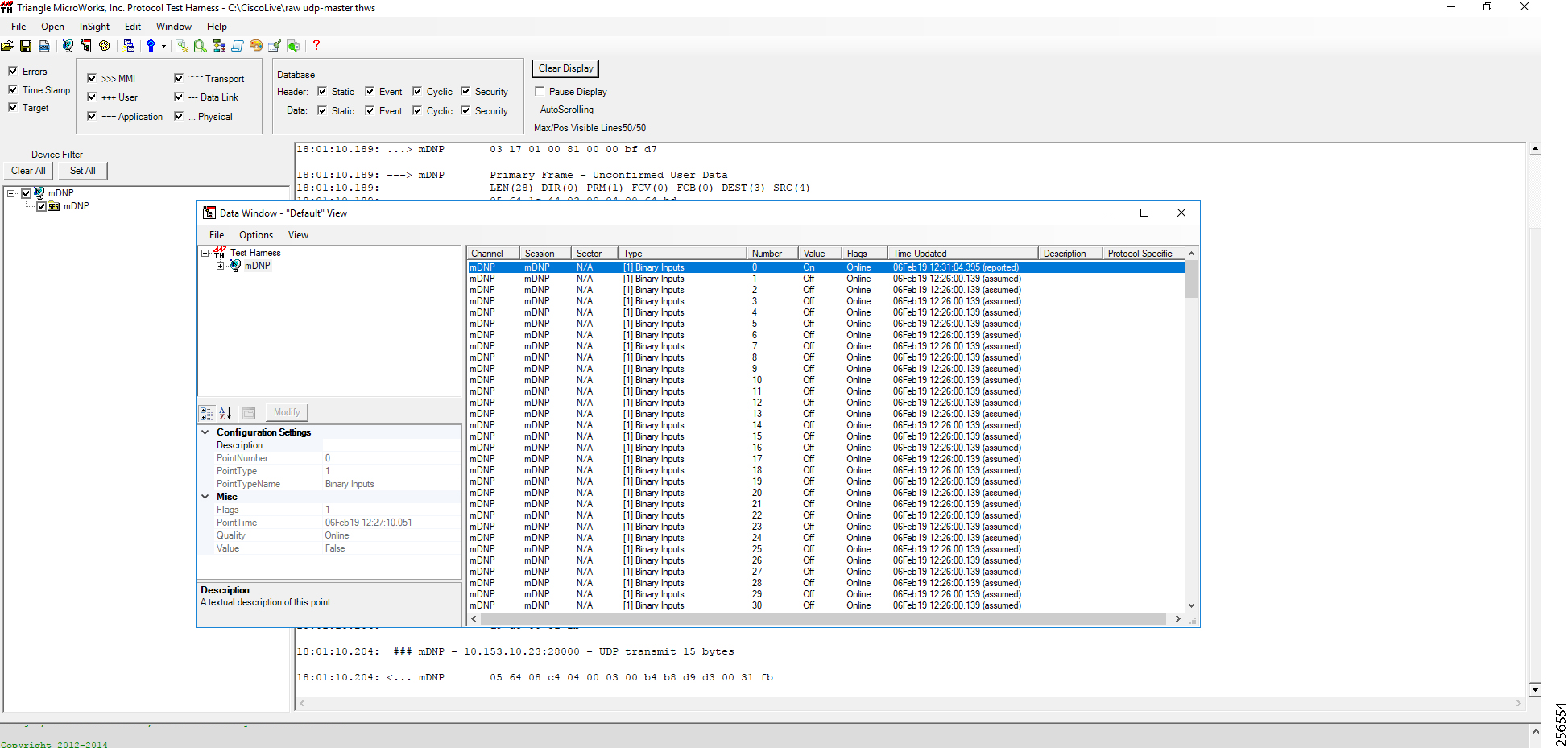

- SCADA Communication with Serial-based SCADA using Raw Socket UDP

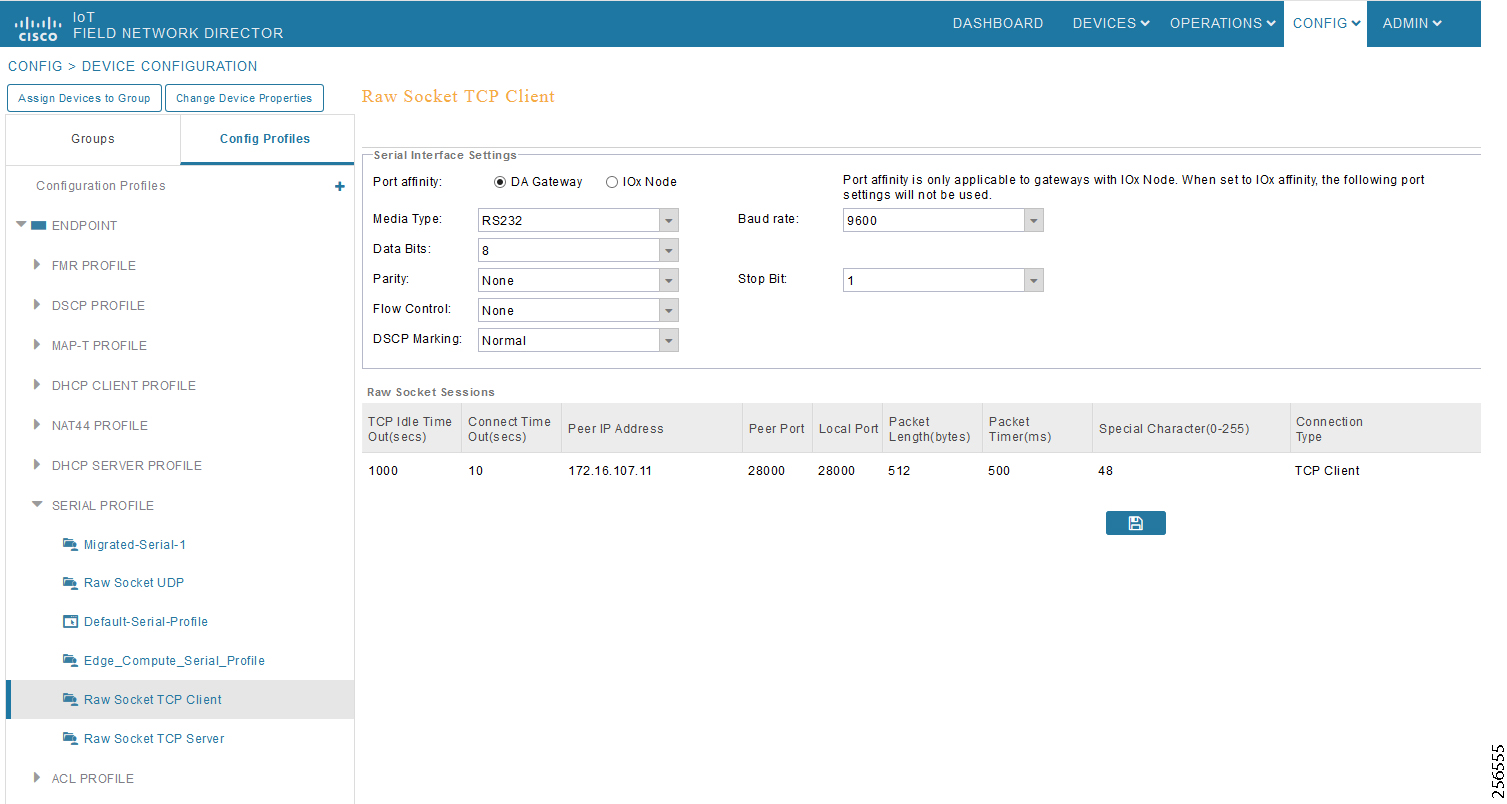

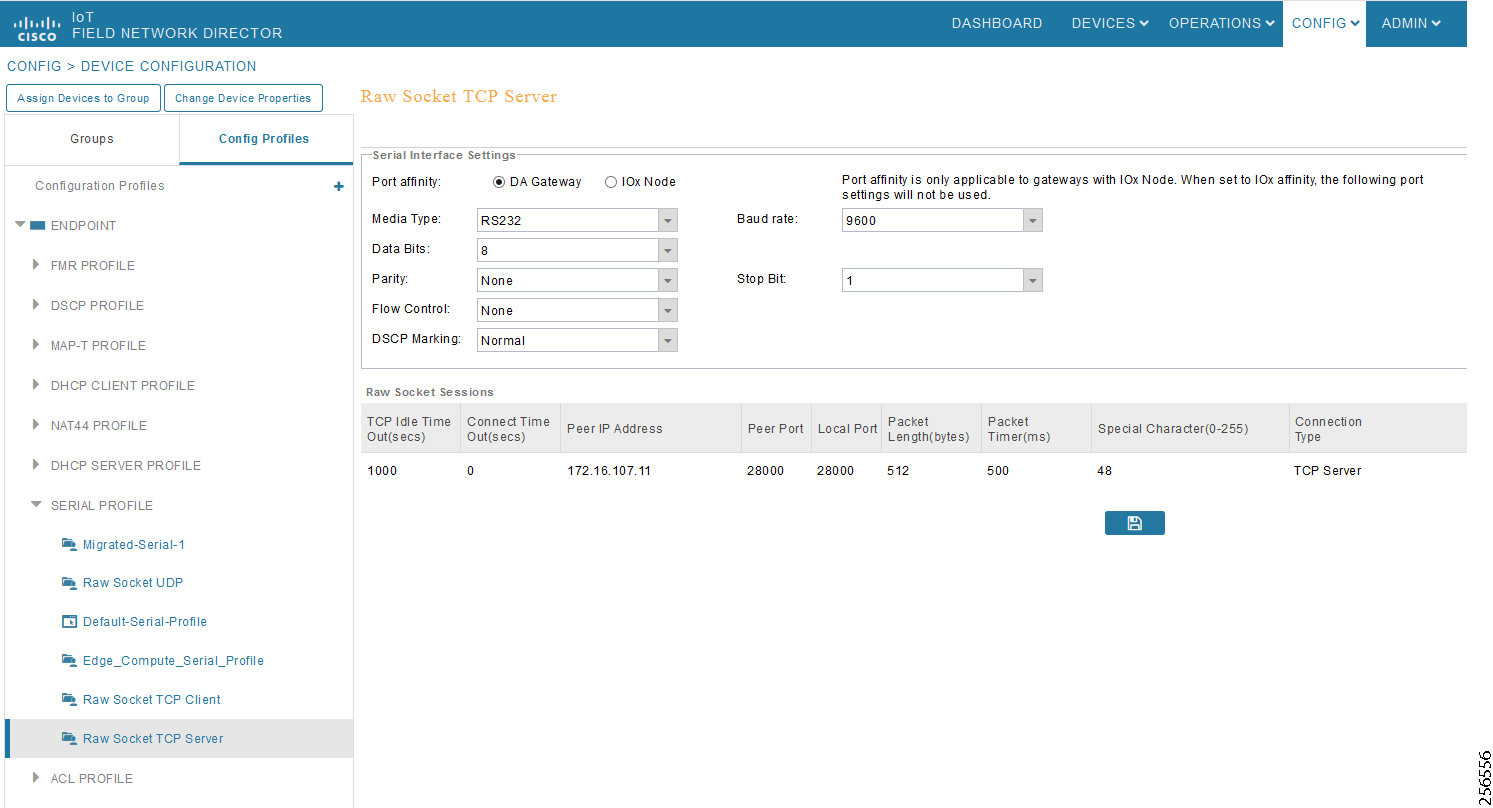

- SCADA Communication with Serial-based SCADA using Raw Socket TCP

- Legacy SCADA (Raw Socket TCP Server)

Distribution Automation - Feeder Automation Implementation Guide

This Cisco Distribution Automation- Feeder Automation Implementation Guide provides a comprehensive explanation of the Cisco Smart Grid Field Area Network solution implementation for Distribution Automation use cases such as Fault Location, Isolation, and Service Restoration (FLISR) and Volt/VAR. This implementation document includes information about the solution architecture, possible deployment models, and guidelines for deployment. It also recommends best practices and potential issues when deploying the reference architecture.

Navigator

The document covers the following:

Audience

The audience for this guide comprises, but is not limited to, system architects, network/compute/systems engineers, field consultants, Cisco Advanced Services specialists, and customers. Readers should be familiar with networking protocols, Network Address Translation (NAT), Supervisory Control and Data Acquisition (SCADA) protocols, and be exposed to Field Area Networks.

New Capabilities in DA2.0 Feeder Automation

■![]() Implementation details of the FLISR (Fault Location Isolation and Service Restoration) use cases.

Implementation details of the FLISR (Fault Location Isolation and Service Restoration) use cases.

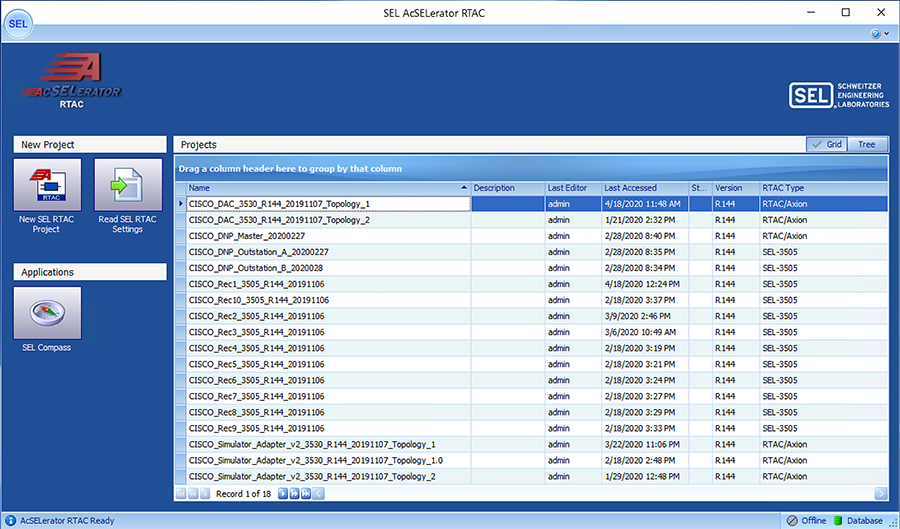

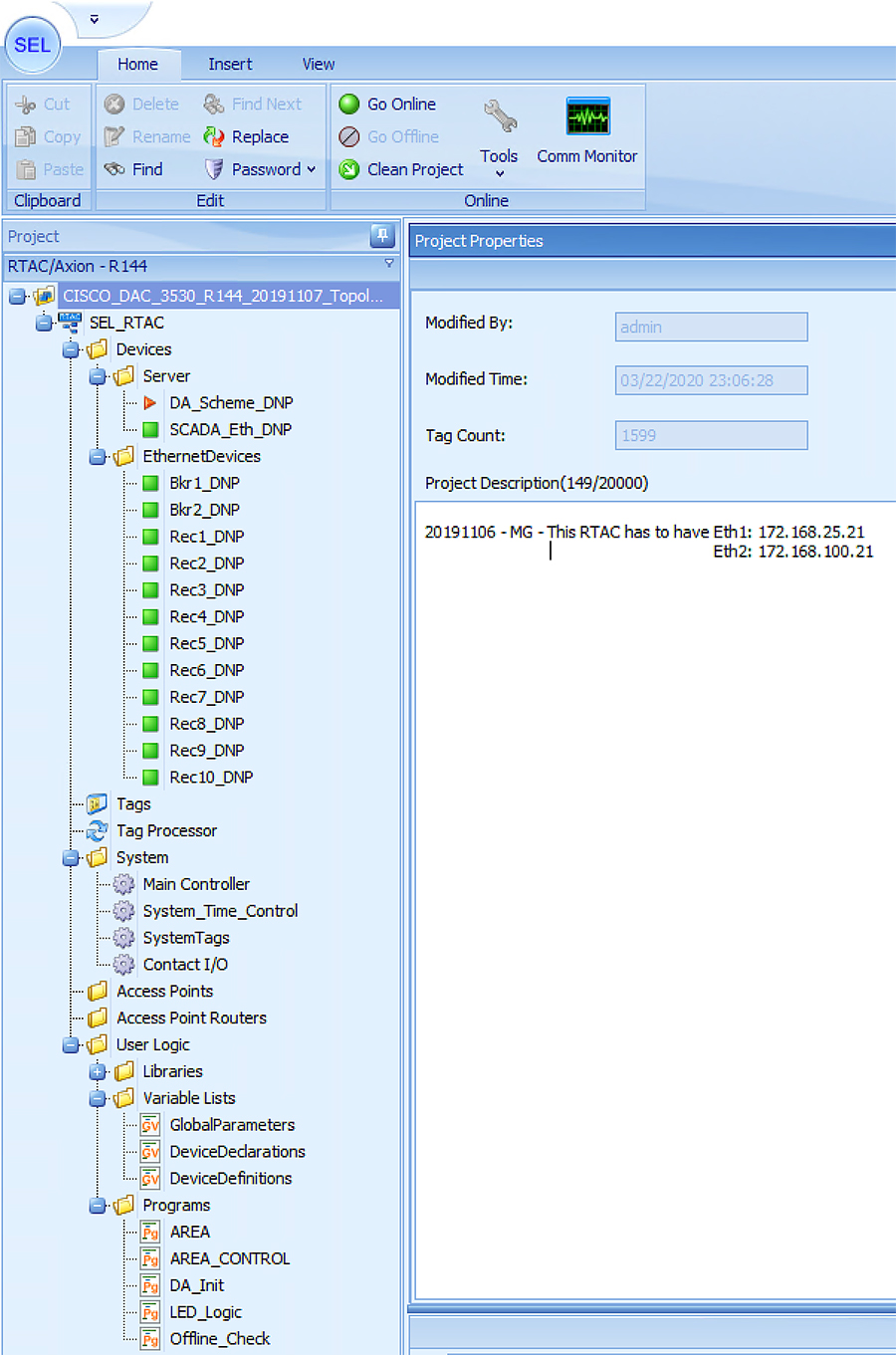

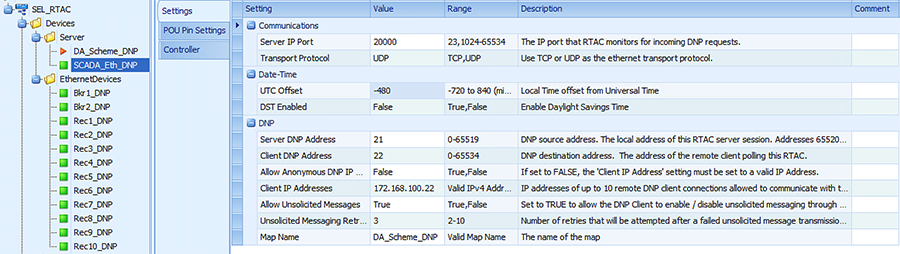

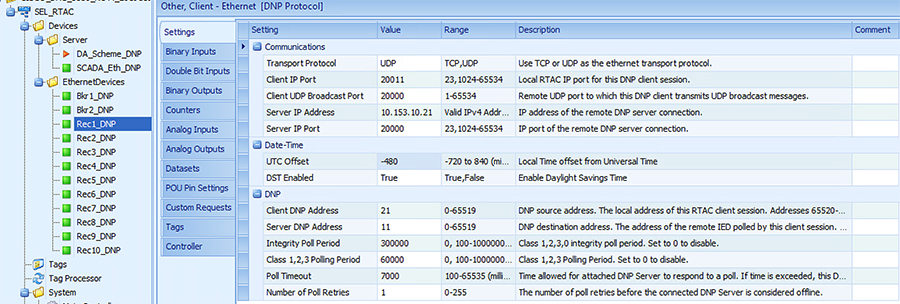

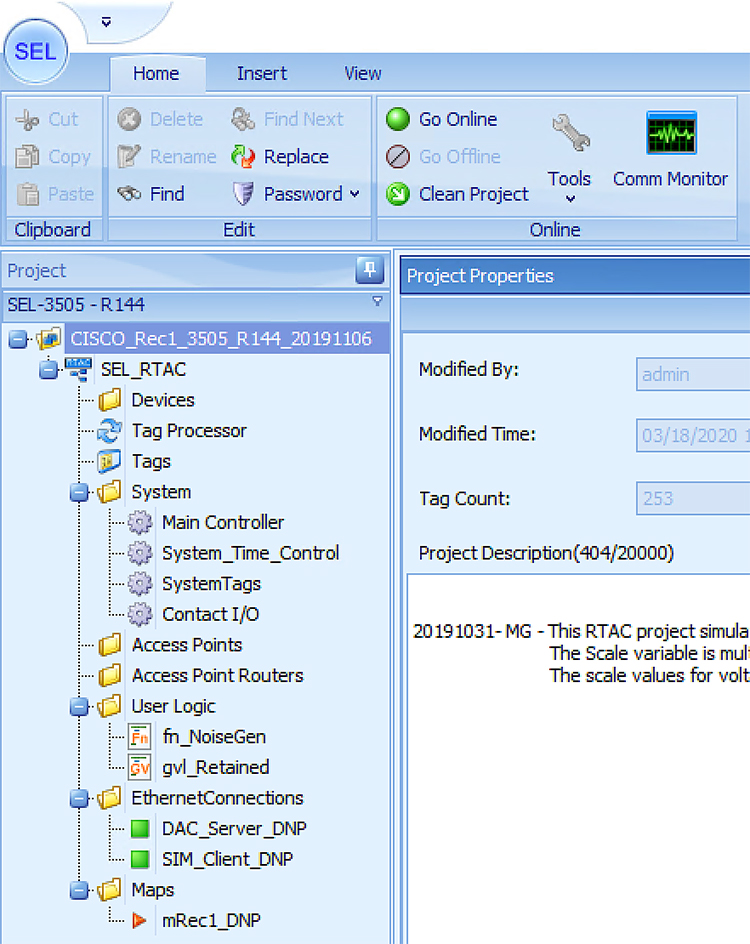

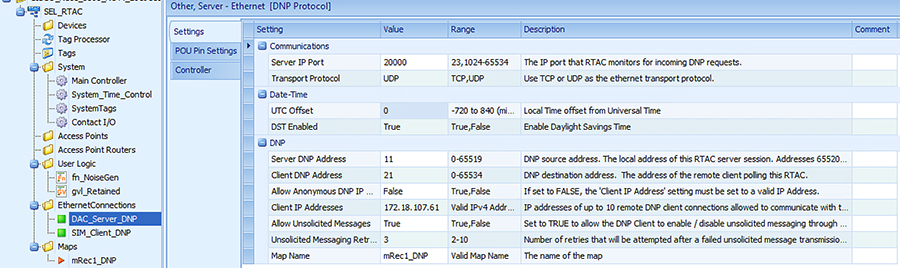

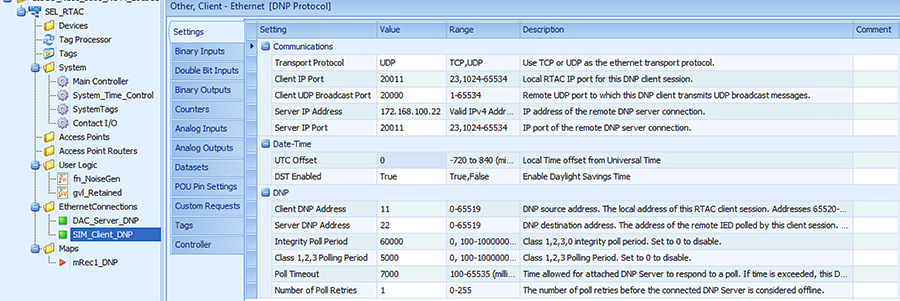

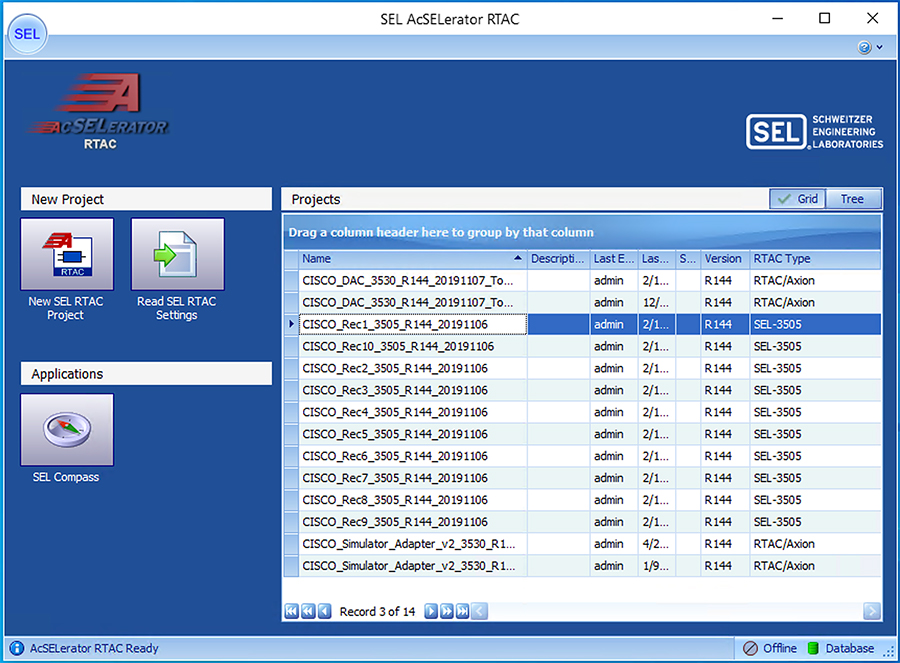

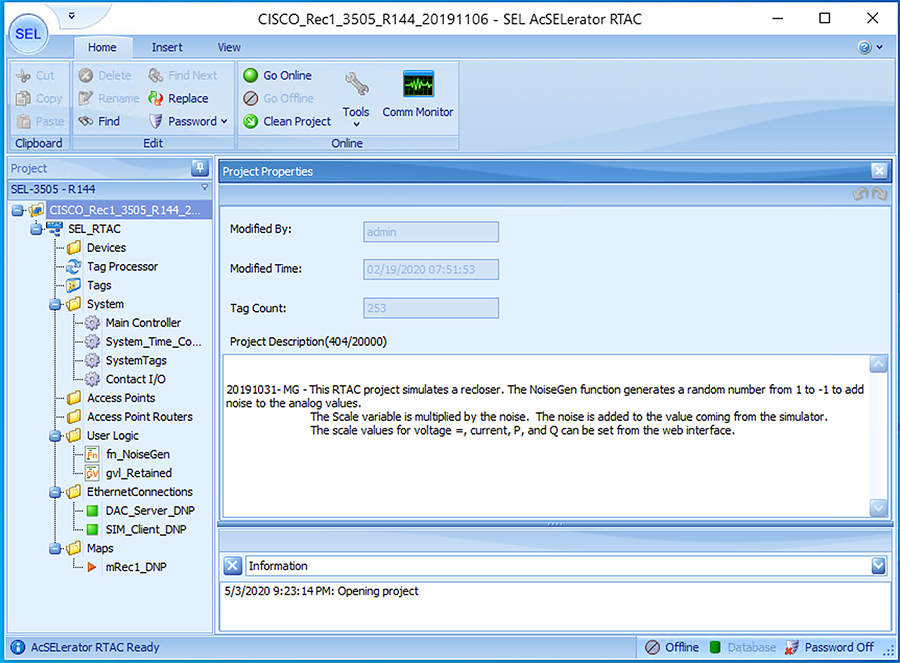

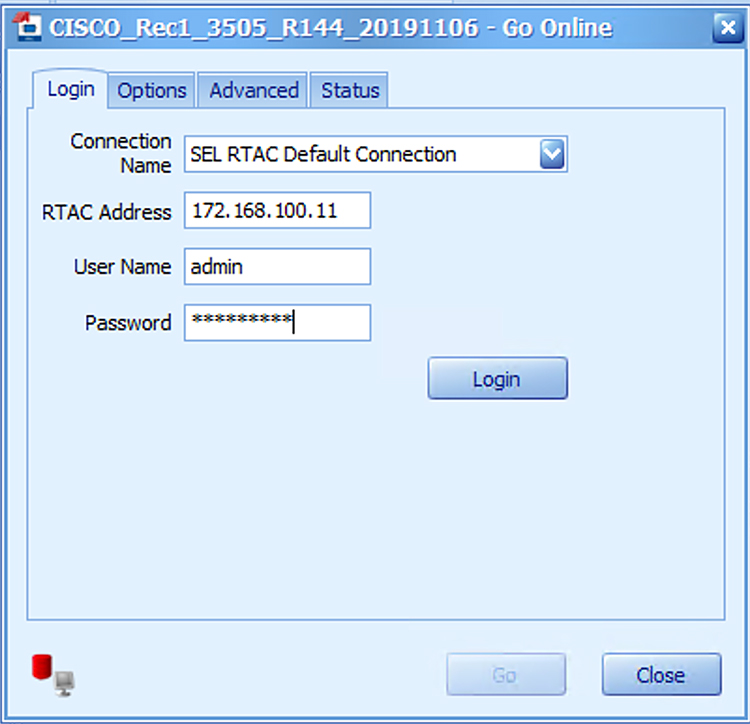

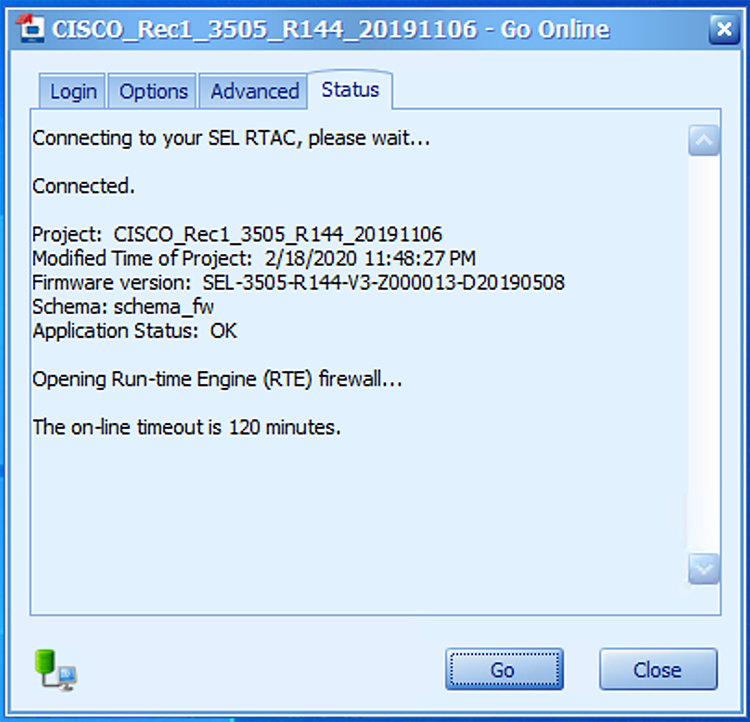

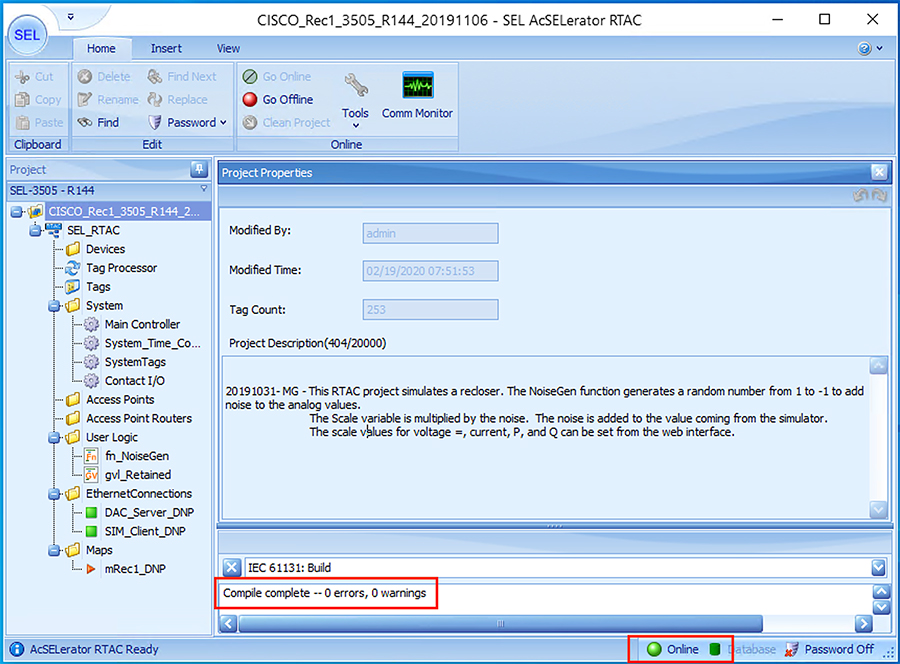

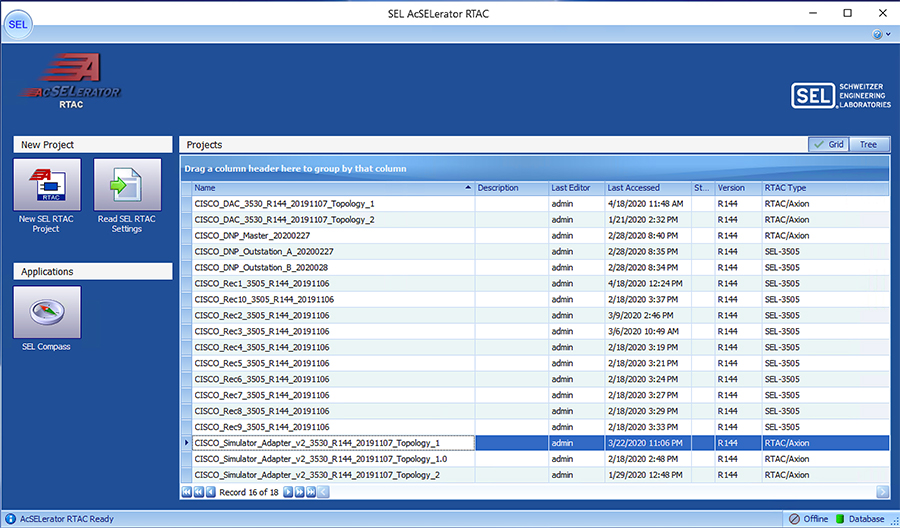

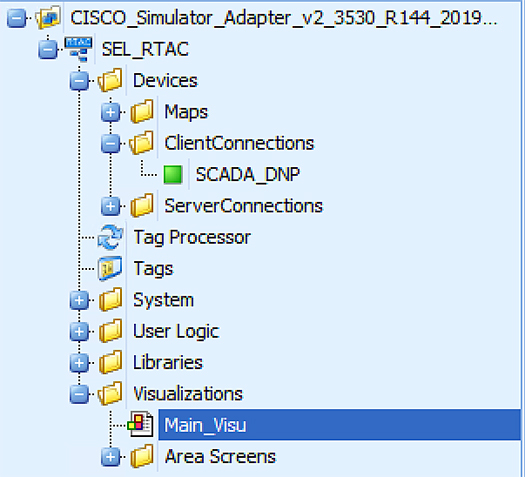

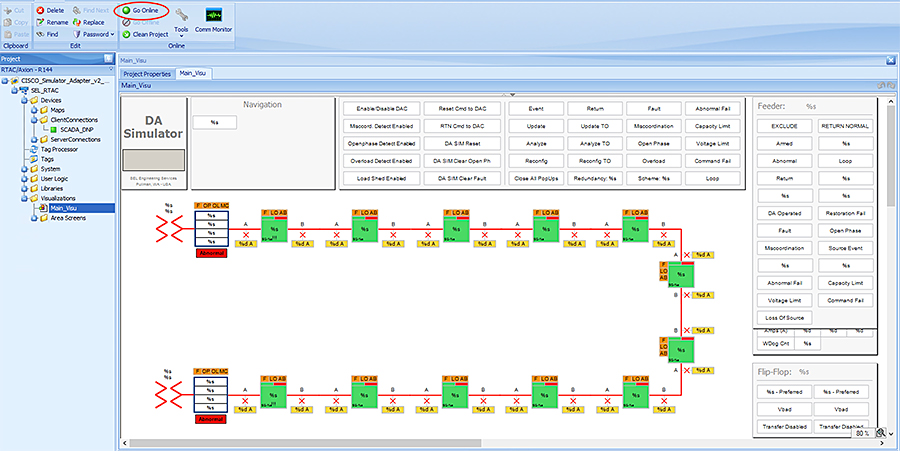

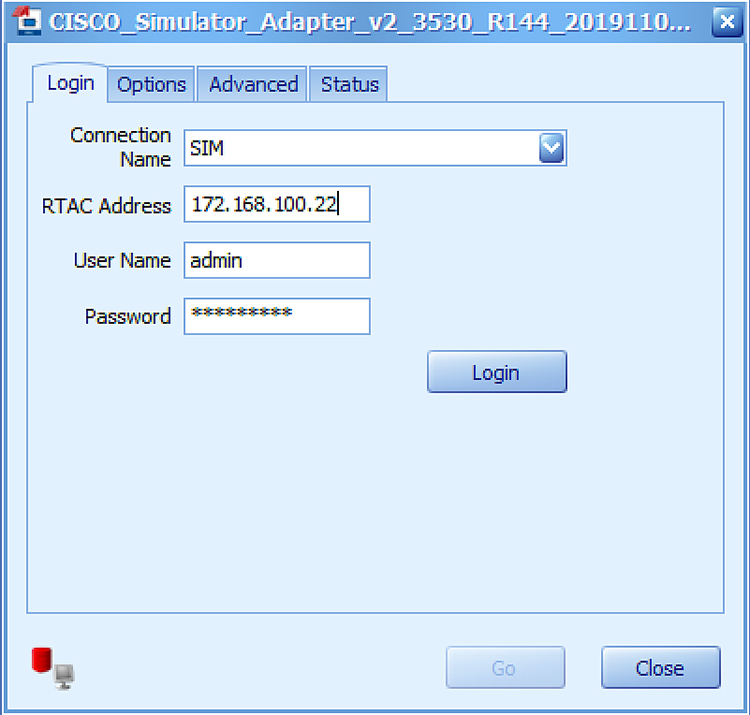

■![]() Simulation details of the FLISR (Fault Location Isolation and Service Restoration) use cases, using SEL application AcSELerator.

Simulation details of the FLISR (Fault Location Isolation and Service Restoration) use cases, using SEL application AcSELerator.

Introduction

The Cisco Field Area Network solution is a multi-service, secured, and scalable architecture, which addresses multiple utility use cases like Distribution Automation (DA), Advance Metering Infrastructure (AMI), Distributed Energy Resource (DER), and Demand Response (DR). This document details the implementation of FAN Distribution Automation, FLISR, and Volt/VAR use cases targeting deployment in the America region.

The implementation in this guide focuses on Distributed Network Protocol 3 (DNP3) and DNP3/IP SCADA protocols. For implementing Distribution Automation use cases using T101 or T104 SCADA protocols, please refer to the Distribution Automation - Feeder Automation Implementation Guide at the following URL:

■![]() https://salesconnect.cisco.com/open.html?c=06d2f8be-8c59-4d3d-9659-0d780c3da744

https://salesconnect.cisco.com/open.html?c=06d2f8be-8c59-4d3d-9659-0d780c3da744

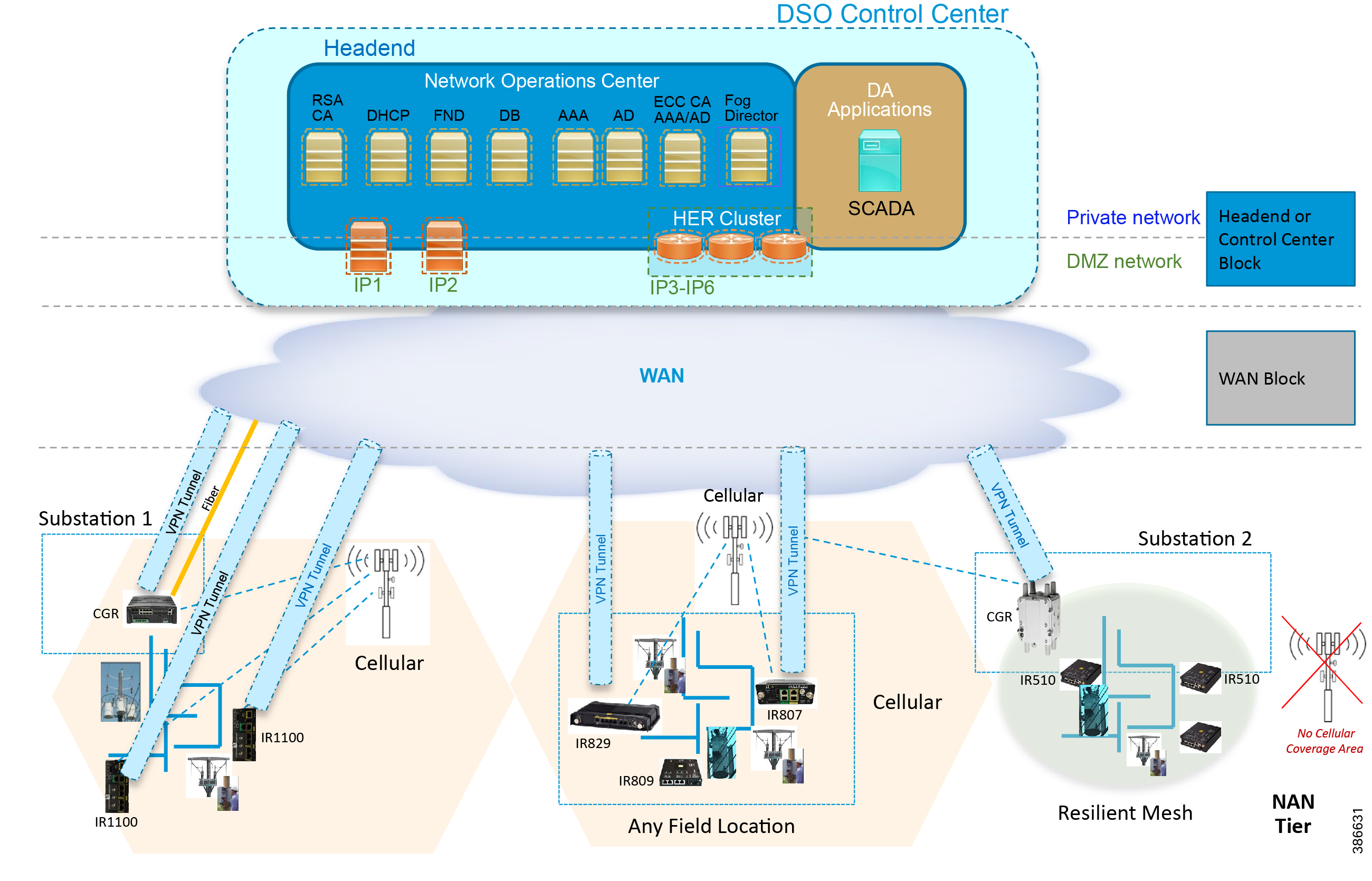

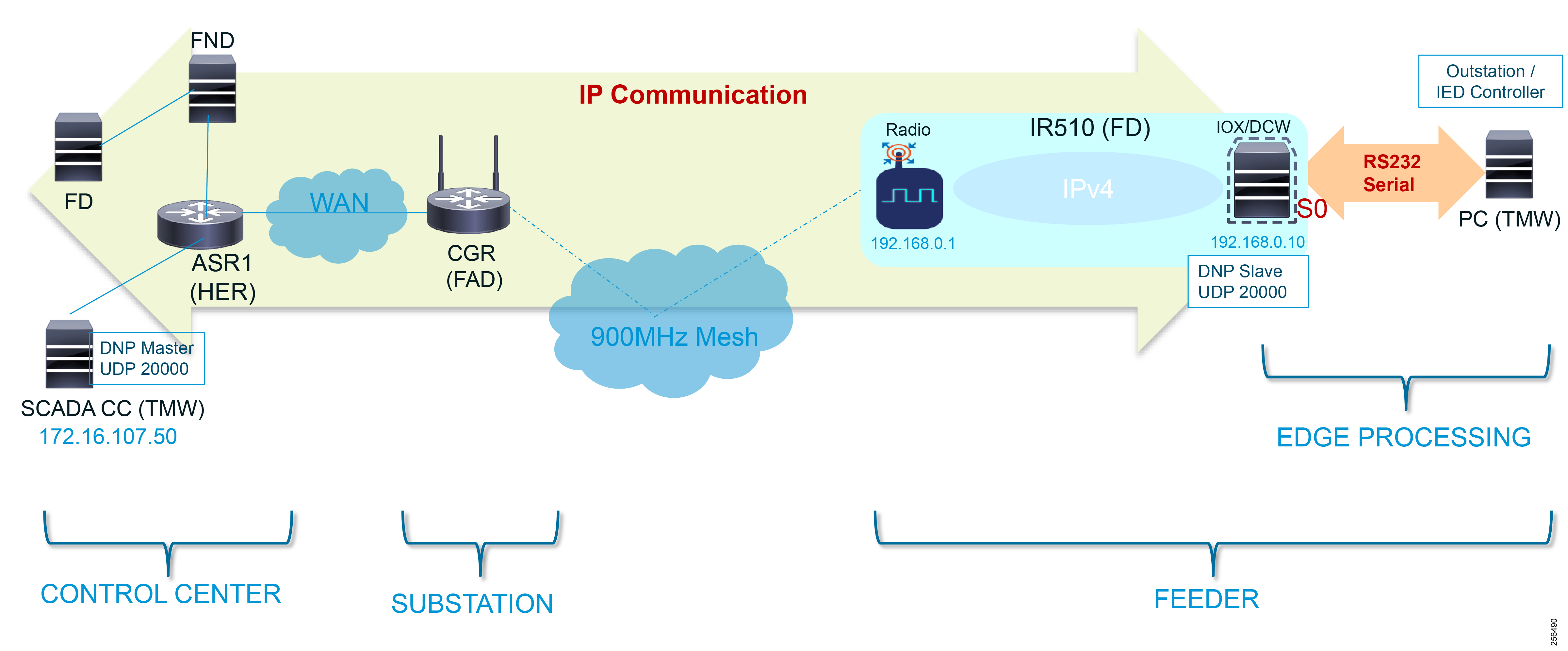

The Cisco FAN solution is a centralized two-tier architecture, as shown in Figure 1. Distribution Automation applications like Distribution Management System and Outage Management System reside in the Distribution System Operator (DSO) control center.

Cisco’s Distribution Automation Gateways interface with Distribution Automation control devices like Capacitor Bank Controllers (CBCs) and recloser controllers that reside on the distribution feeder (in some cases, inside distribution substations like the Load Tap Controller). This interfacing could be either the Ethernet or Serial type.

Cisco’s Distribution Automation Gateways could transport their traffic over a Cellular backhaul or Ethernet backhaul, or via the Neighbor Area Network (NAN) formed by Cisco Resilient Mesh Gateways. Cisco Gateways, which have one leg in the NAN tier and the other in the WAN tier, aggregate the distribution traffic from the NAN tier and route traffic to various DA applications via the WAN tier (which could be a Cellular or Fiber backhaul connection). To choose the correct DA Gateway, please refer to the Distribution Automation - Feeder Automation Design Guide at the following URL:

■![]() https://www.cisco.com/c/dam/en/us/td/docs/solutions/Verticals/Distributed-Automation/Feeder-Automation/DG/DA-FA-DG.pdf

https://www.cisco.com/c/dam/en/us/td/docs/solutions/Verticals/Distributed-Automation/Feeder-Automation/DG/DA-FA-DG.pdf

This implementation guide covers both Cisco Cellular Gateway and Cisco Resilient Mesh Gateway deployments.

Cisco Resilient (CR) Mesh implementation will be the correct choice for areas where Cellular coverage is not available or less prevalent. Cisco CR mesh has three types of devices:

■![]() CR Mesh Co-ordination or Field Area Aggregation Router (FAR)

CR Mesh Co-ordination or Field Area Aggregation Router (FAR)

■![]() CR Mesh Gateways or Field Devices (FD)

CR Mesh Gateways or Field Devices (FD)

Cisco CGR 1240 with WPAN RF Module router plays the role of CR Mesh aggregator. CGR 1240 aggregates DA traffic and routes traffic to applications in the DSO control center. Distribution Automation controllers are connected to CR Mesh Gateways like IR510 via Ethernet or Serial (RS232) interfaces. When RF mesh coverage needs to be extended, Cisco IR530 could be deployed as range extenders. The CR Mesh is formed using FAR, FD, and range extenders and can be implemented in multiple PHY modes. This implementation guide is focused on DA use cases and requires relatively larger bandwidth when compared to the AMI use case; therefore, OFDM modulation with 800 Kbps profile has been chosen. This implementation covers Fixed OFDM 800 Kbps modulation. Adaptive Rate modulation, although supported, is not covered in this guide.

Cisco Cellular DA Gateways like IR1101, IR807, IR809, and CGR 1120 can be chosen for deployments where:

■![]() DA Application demands more bandwidth and has time sensitive requirements.

DA Application demands more bandwidth and has time sensitive requirements.

■![]() Distribution Feeder has better Cellular signal coverage (for example, urban areas).

Distribution Feeder has better Cellular signal coverage (for example, urban areas).

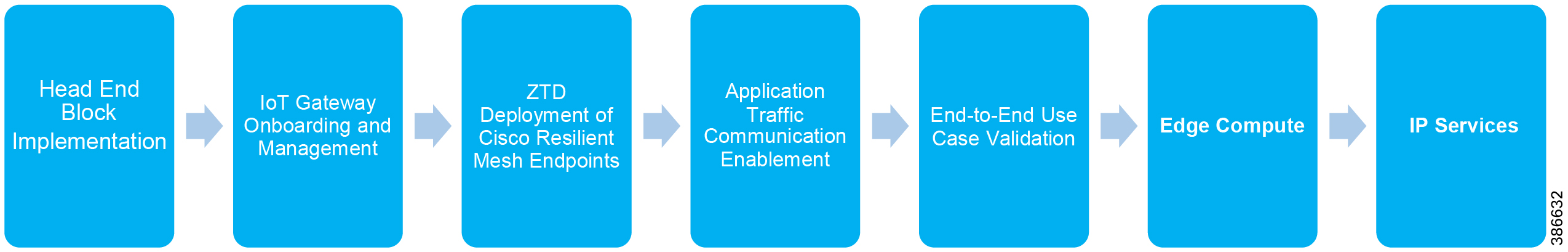

The flow of this implementation guide is depicted in Figure 2.

Note: For Headend Block Implementation, please refer to the Cisco FAN - Headend Deep Dive Implementation and FAN Use Cases at the following URL:

■![]() https://salesconnect.cisco.com/open.html?c=da249429-ec79-49fc-9471-0ec859e83872

https://salesconnect.cisco.com/open.html?c=da249429-ec79-49fc-9471-0ec859e83872

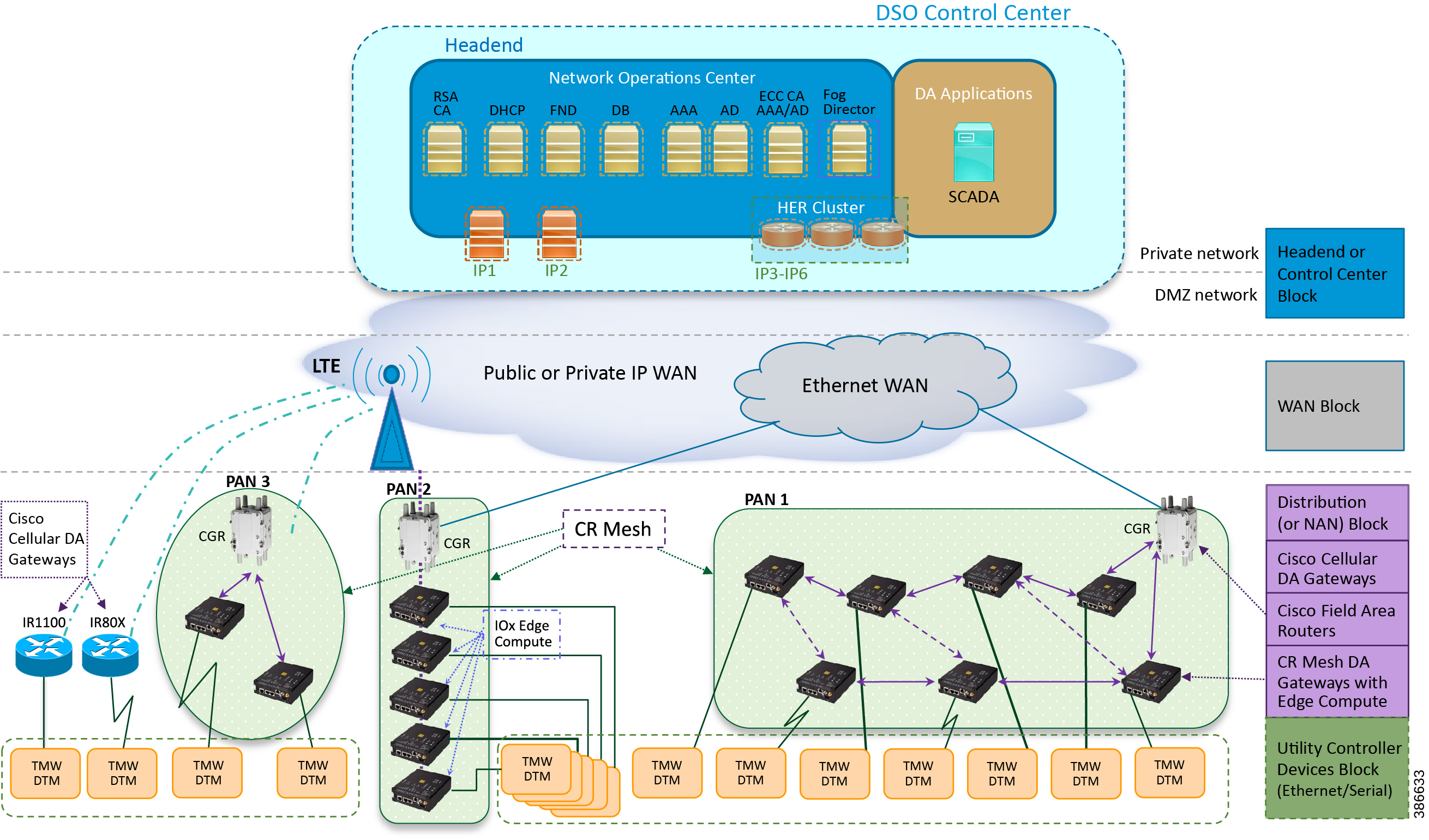

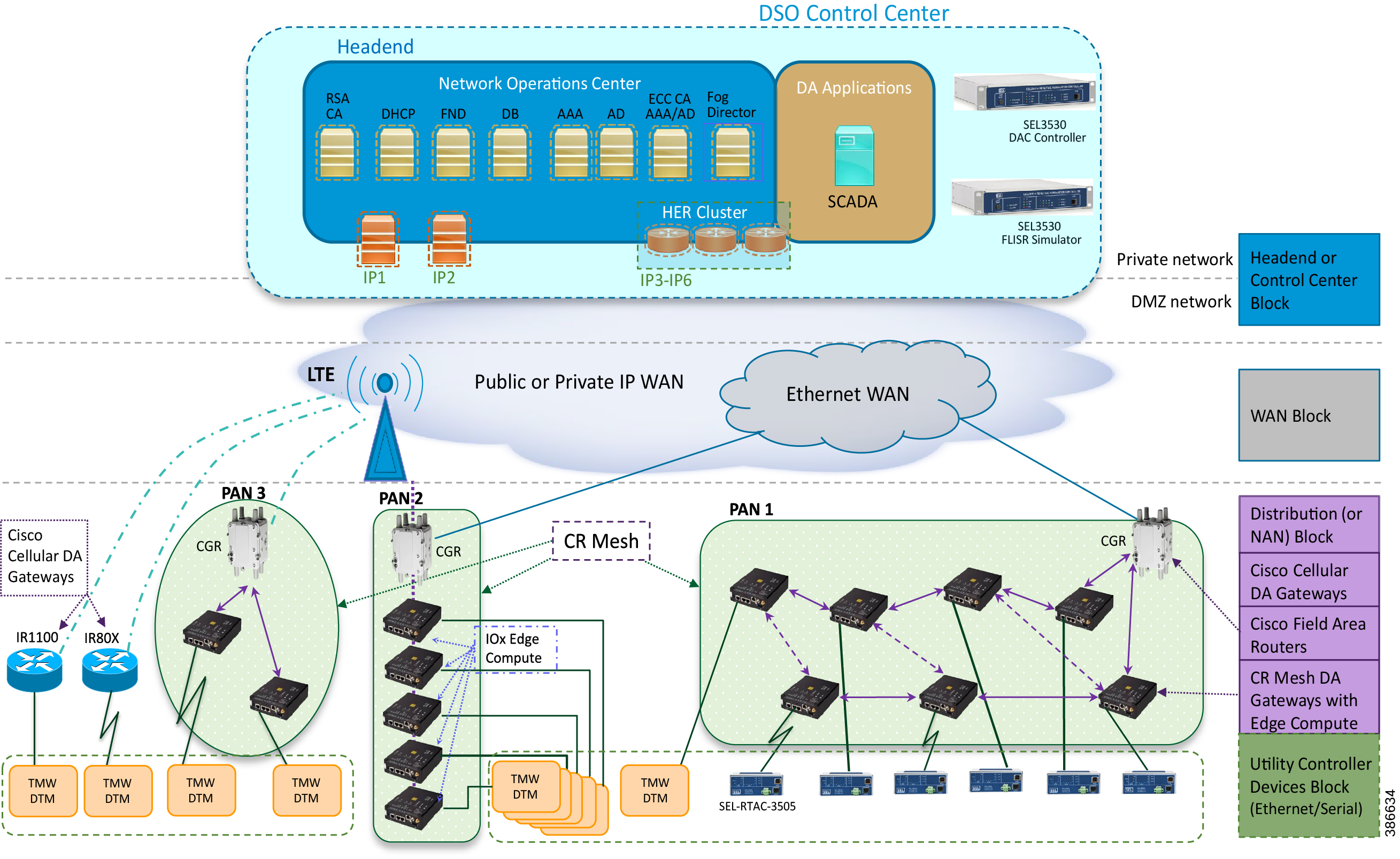

Solution Network Topology and Addressing

This chapter, which focuses on the network topology used for solution validation and implementation of the Cisco DA Feeder Automation solution and the addressing (both IPv4 and IPv6) used in this implementation, includes the following major topics:

Topology Diagram

This section describes the high-level solution validation topology that has been used in this Feeder Automation Implementation Guide. Figure 3 depicts the high-level solution validation topology.

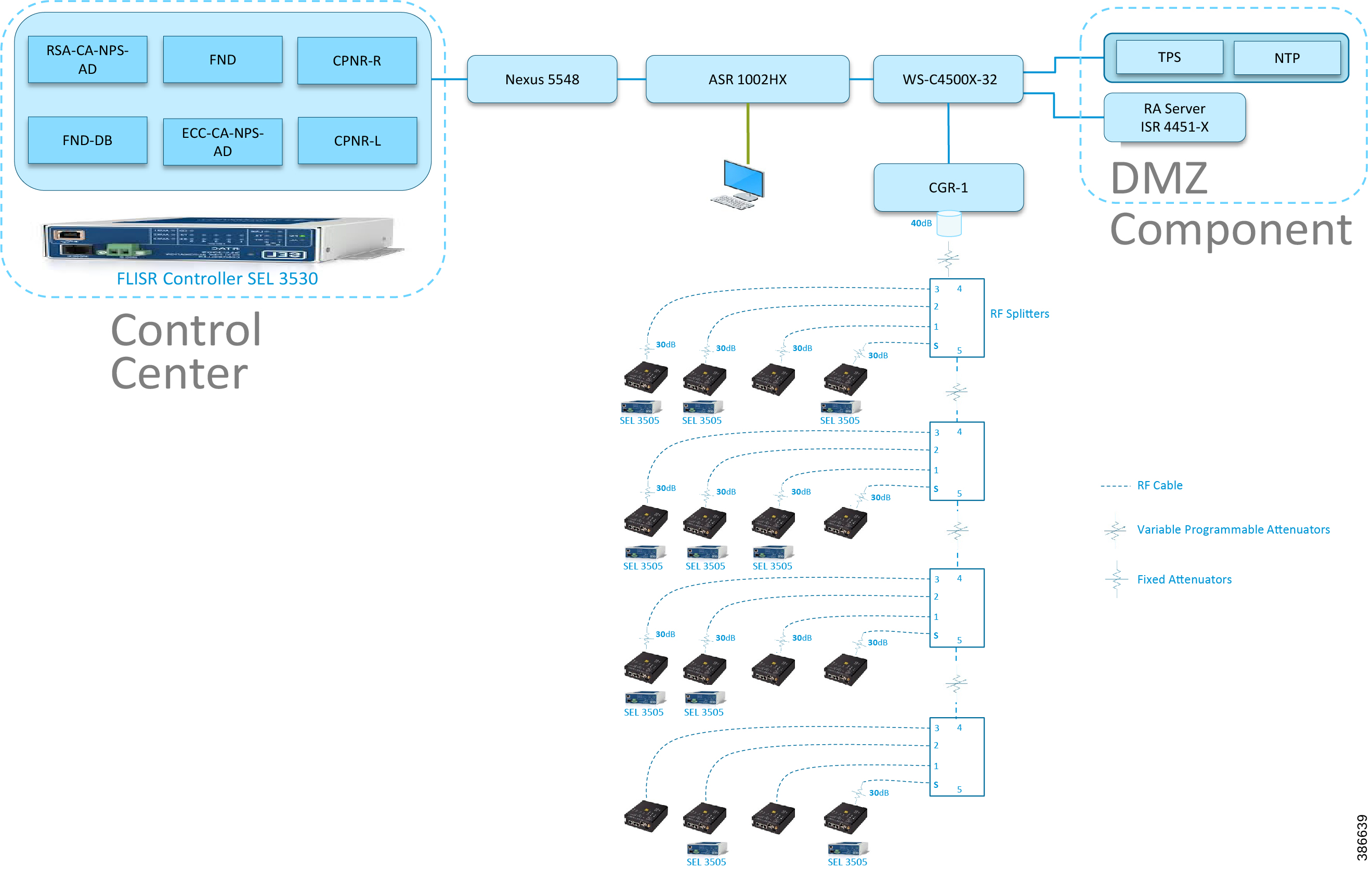

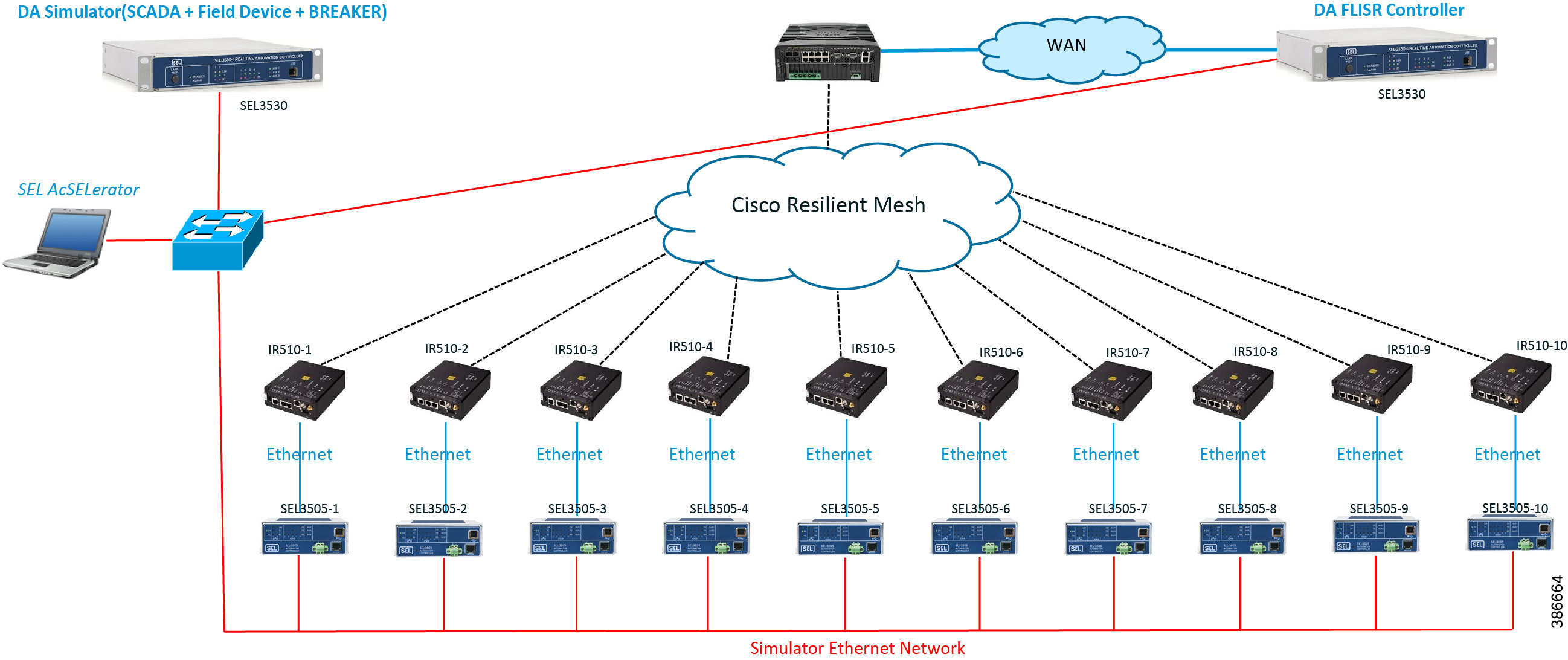

Figure 3 Cisco DA Feeder Automation Solution Validation Topology

The multiple layers of topology include:

■![]() The Headend or Control Center Block, which hosts the DSO Control Center, includes:

The Headend or Control Center Block, which hosts the DSO Control Center, includes:

–![]() DA application servers (for example, SCADA application server):

DA application servers (for example, SCADA application server):

–![]() Network Operations Center (NOC), which hosts the following headend components:

Network Operations Center (NOC), which hosts the following headend components:

- Certificate Authority (RSA encryption), Dynamic Host Configuration Protocol (DHCP), Field Network Director (FND), FND Database, Authentication Authorization and Accounting (AAA), Active Directory (AD), Certificate Authority (ECC encryption), Fog Director (FD), Registration Authority (RA), Tunnel Provisioning Server (TPS), and Cluster of Headend Routers.

- These components are essential for the ZTD of the Cisco IOS Routers, which could be DA Gateways (IR1101, IR807, IR800) that are positioned along the Distribution Feeder or CGR1000 series of routers positioned as FARs.

–![]() Headend block, which includes:

Headend block, which includes:

- Private network, where the protected part of the headend is located, along with SCADA and other application servers.

- DMZ network, where the exposed part of the headend is located; it includes TPS, RA, and HER Cluster.

■![]() The WAN Block commonly refers to the public Internet over Ethernet/cellular backhaul. It could also be a private IP network.

The WAN Block commonly refers to the public Internet over Ethernet/cellular backhaul. It could also be a private IP network.

■![]() The Distribution Block, which comprises the following three major sub-blocks:

The Distribution Block, which comprises the following three major sub-blocks:

–![]() Cisco Cellular DA Gateways, which refer to Cisco IOS Routers like IR1100, IR807, and IR809.

Cisco Cellular DA Gateways, which refer to Cisco IOS Routers like IR1100, IR807, and IR809.

–![]() Cisco Field Area Routers, which refer to Cisco IOS Routers like CGR1240 and CGR1120. These routers are used for aggregating the Cisco Resilient Mesh Endpoints (also referred as CR Mesh DA Gateways). The NAN Block is a subset of the Distribution Block, comprising CR Mesh devices, including Cisco FAR and CR Mesh endpoints.

Cisco Field Area Routers, which refer to Cisco IOS Routers like CGR1240 and CGR1120. These routers are used for aggregating the Cisco Resilient Mesh Endpoints (also referred as CR Mesh DA Gateways). The NAN Block is a subset of the Distribution Block, comprising CR Mesh devices, including Cisco FAR and CR Mesh endpoints.

–![]() Cisco Resilient (CR) Mesh DA Gateways with Edge Compute, which refer to the Cisco IR510 WPAN Industrial Router.

Cisco Resilient (CR) Mesh DA Gateways with Edge Compute, which refer to the Cisco IR510 WPAN Industrial Router.

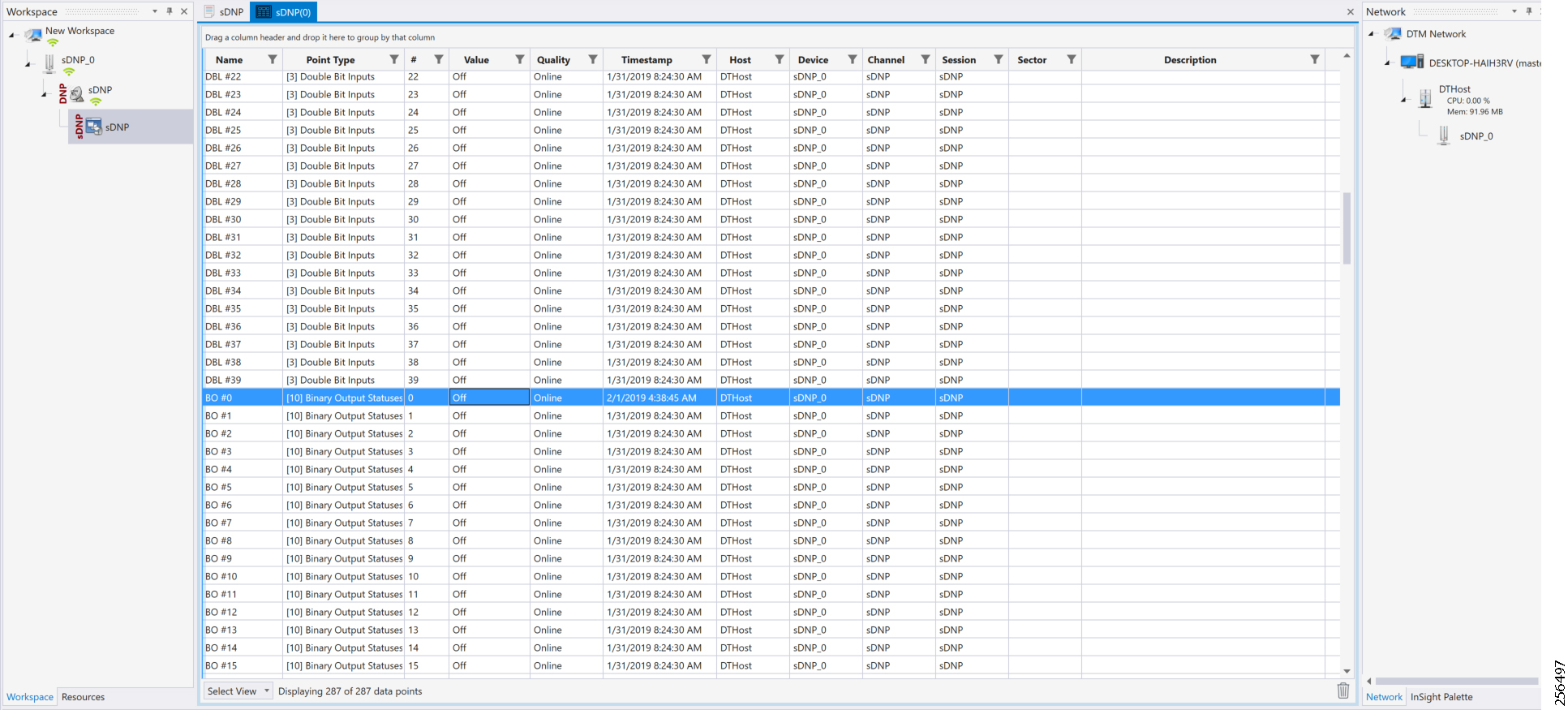

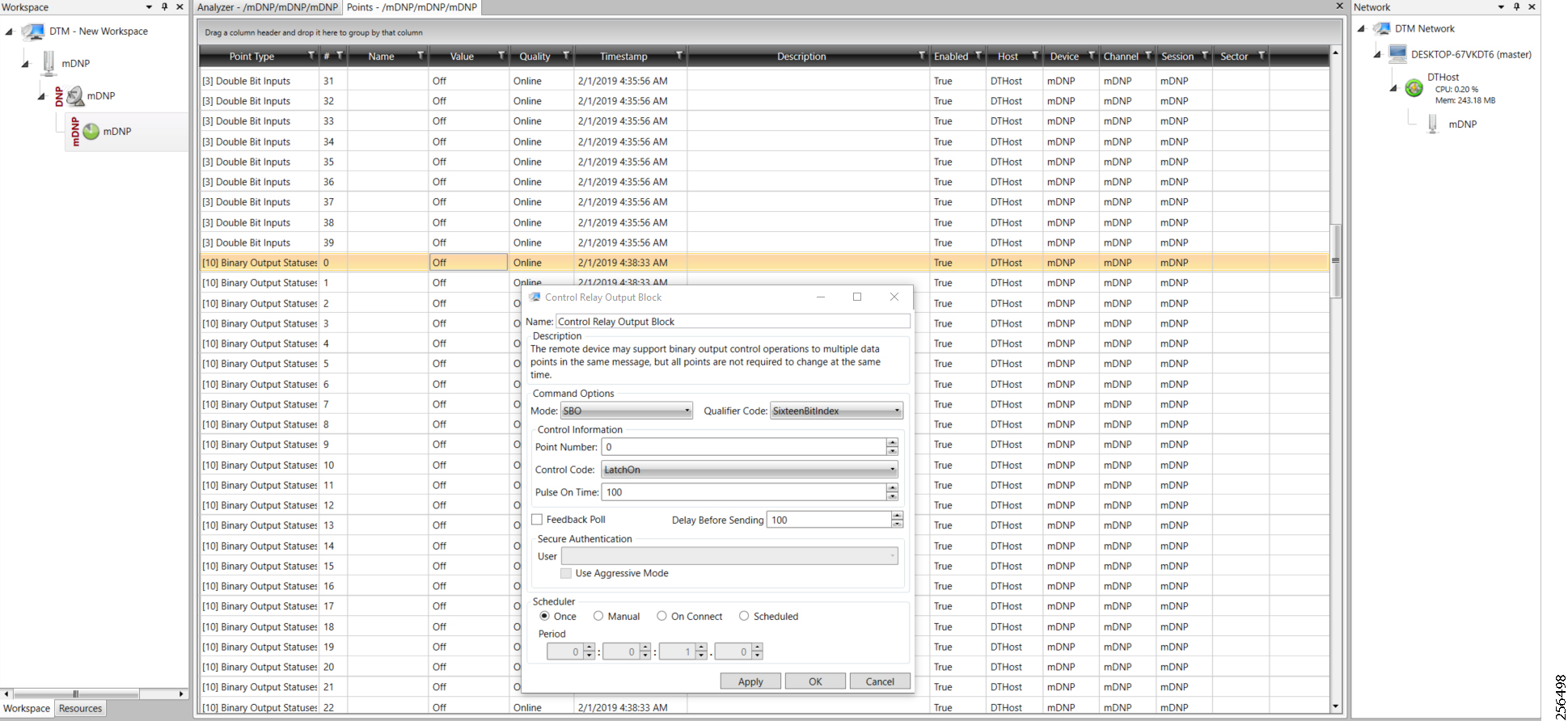

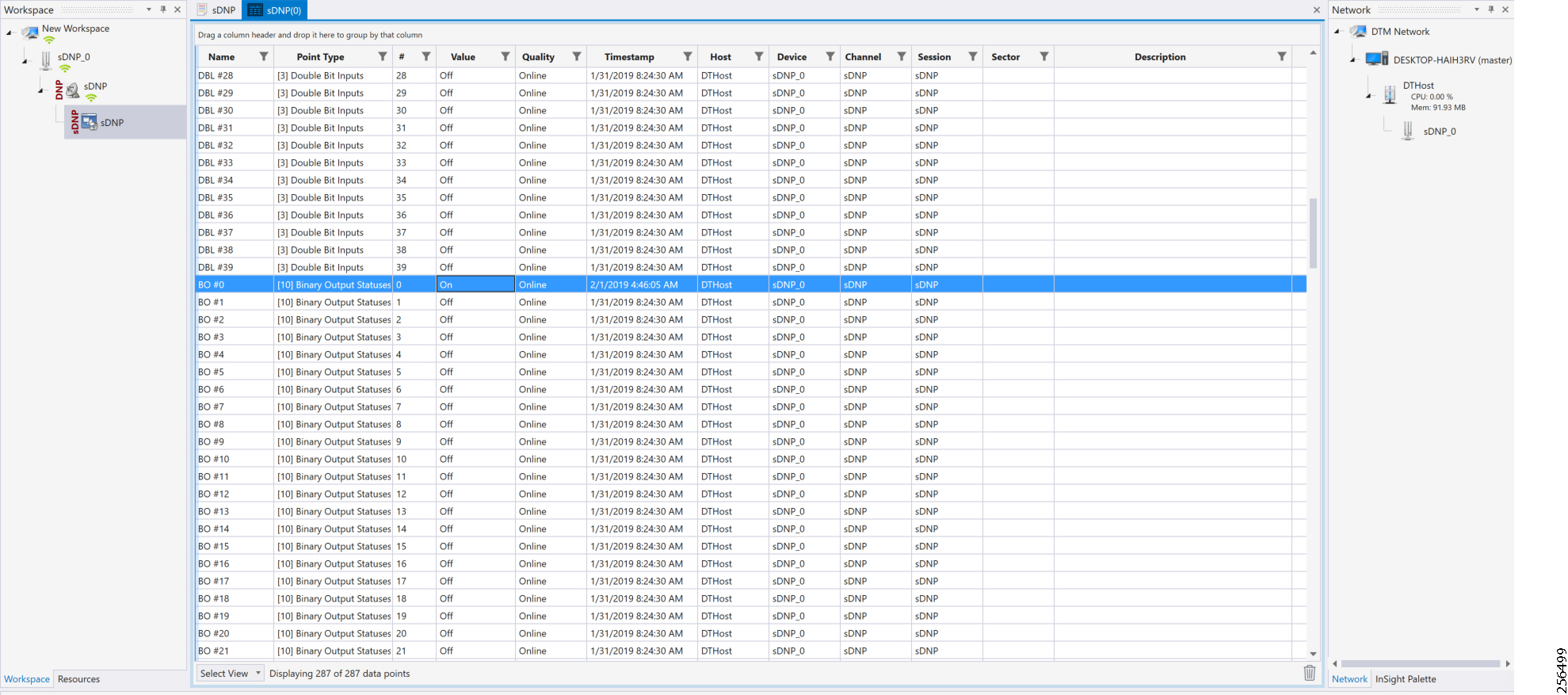

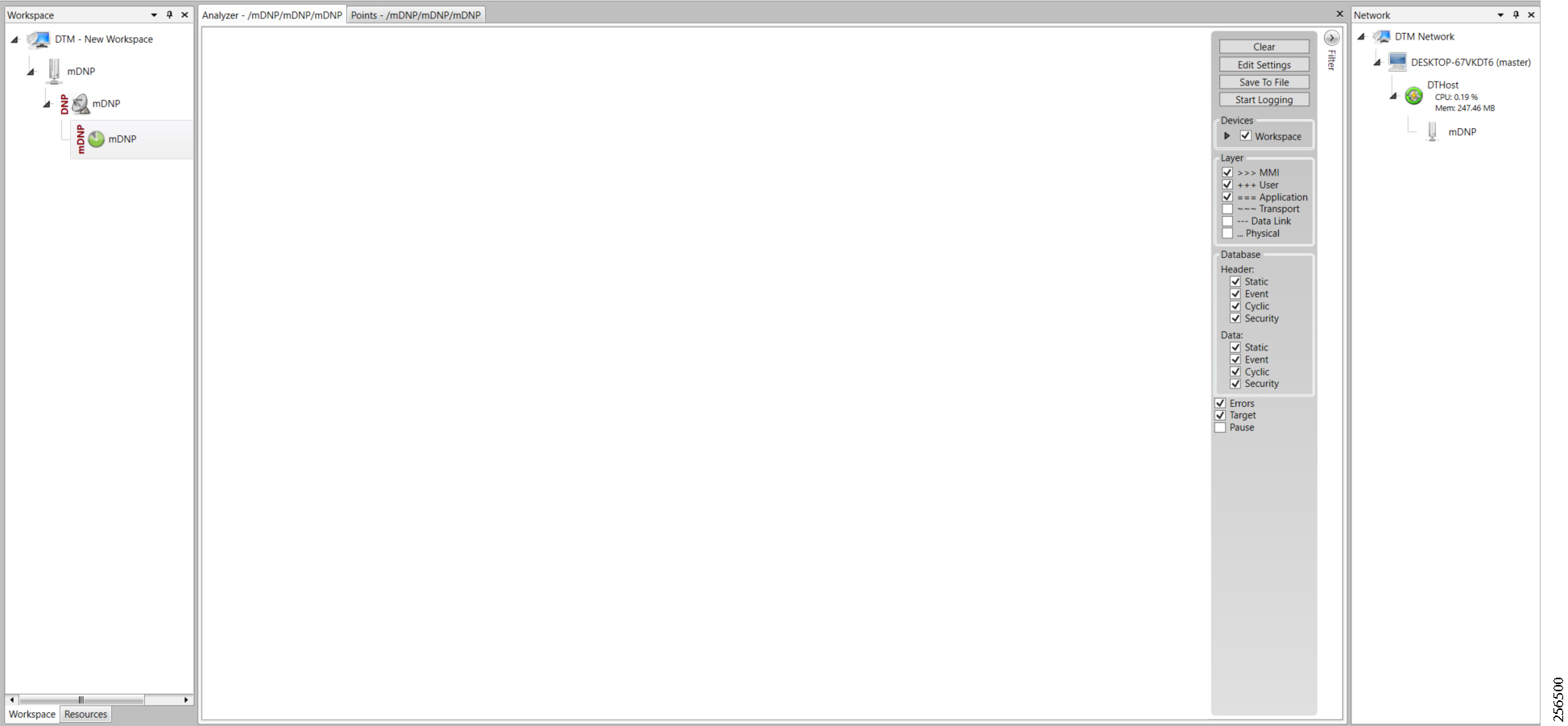

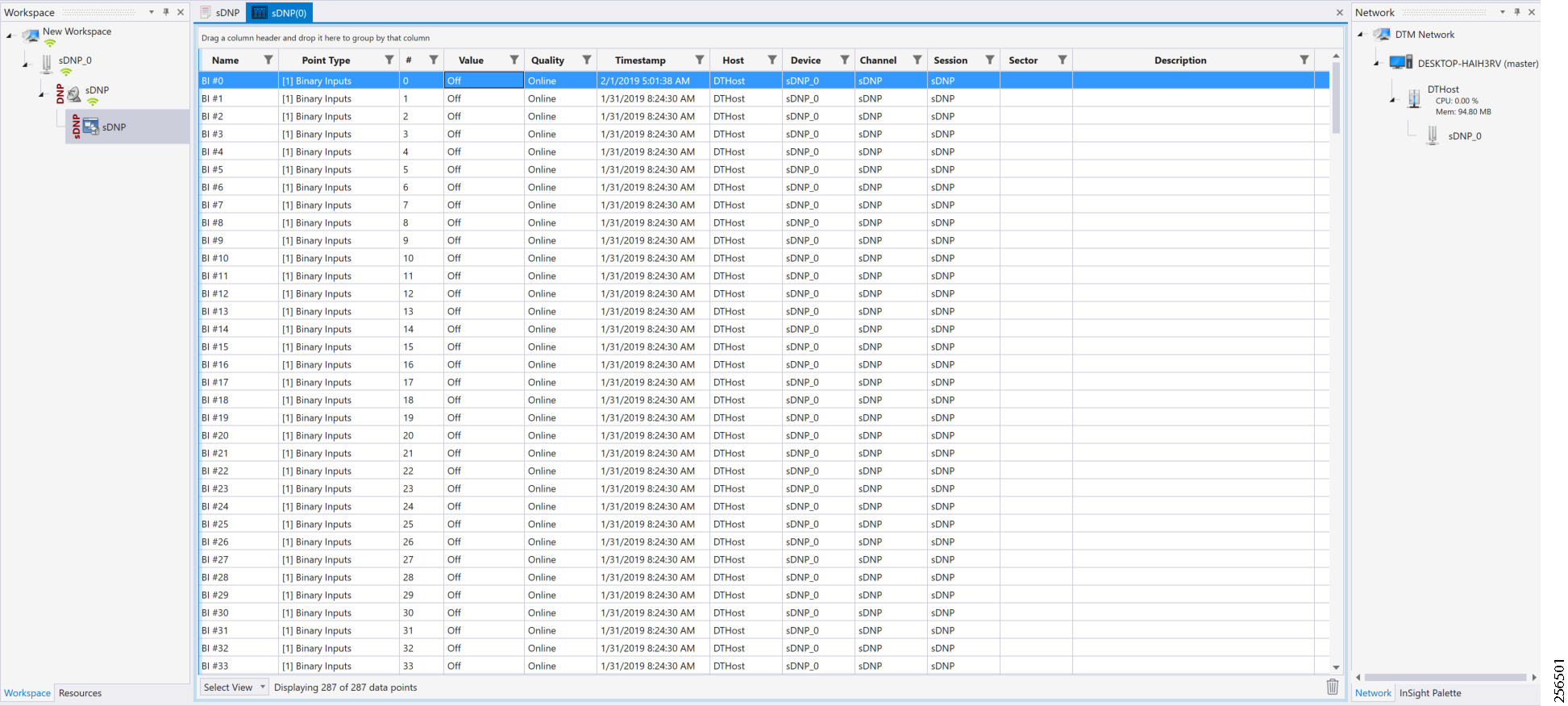

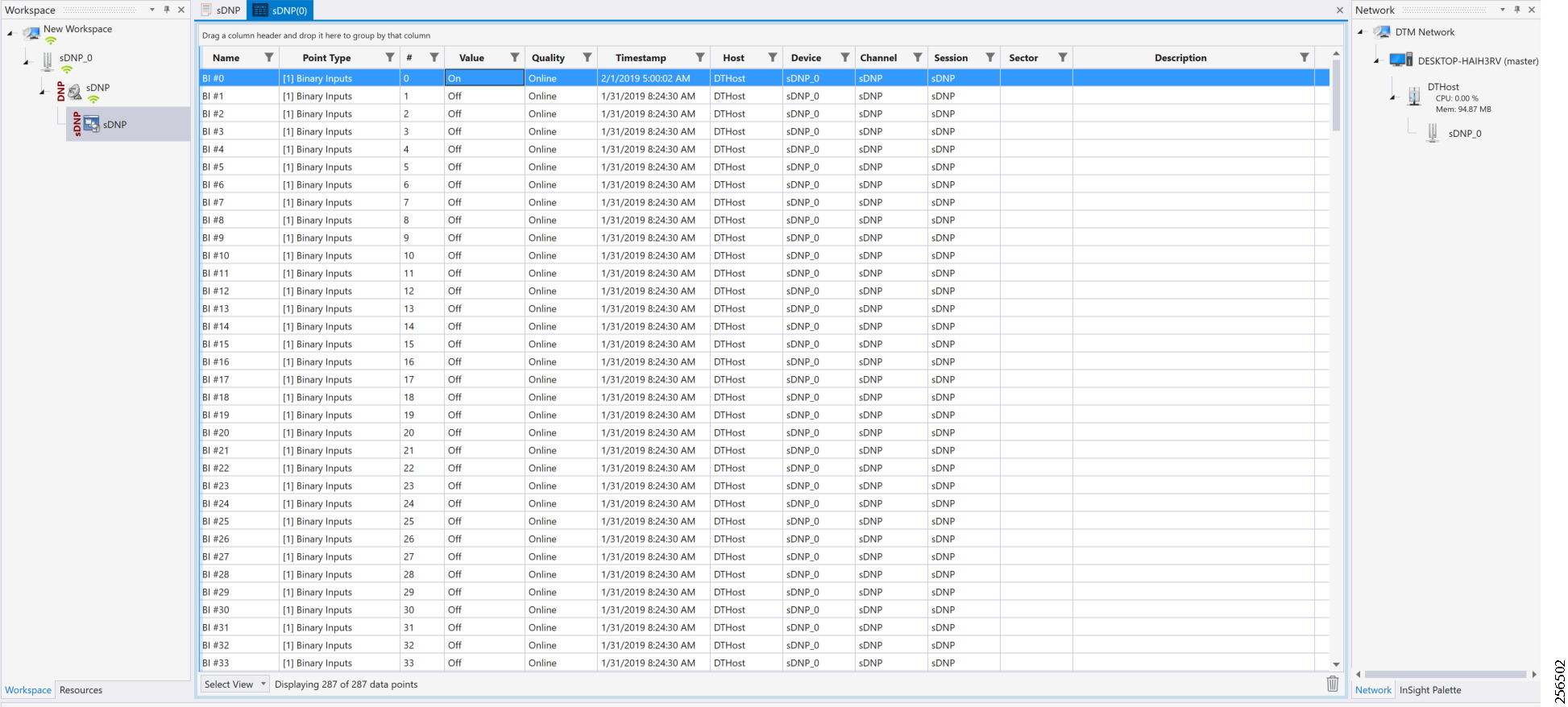

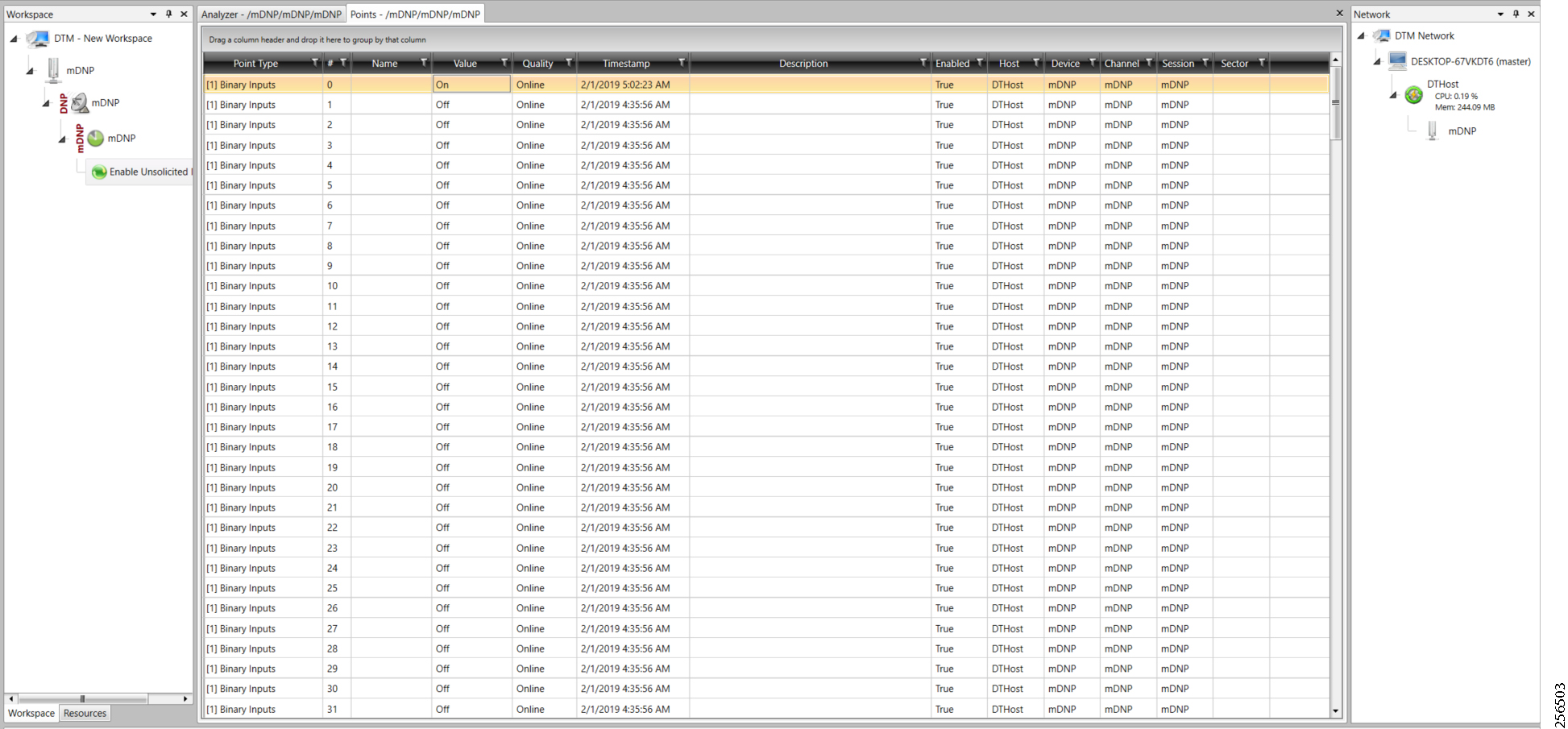

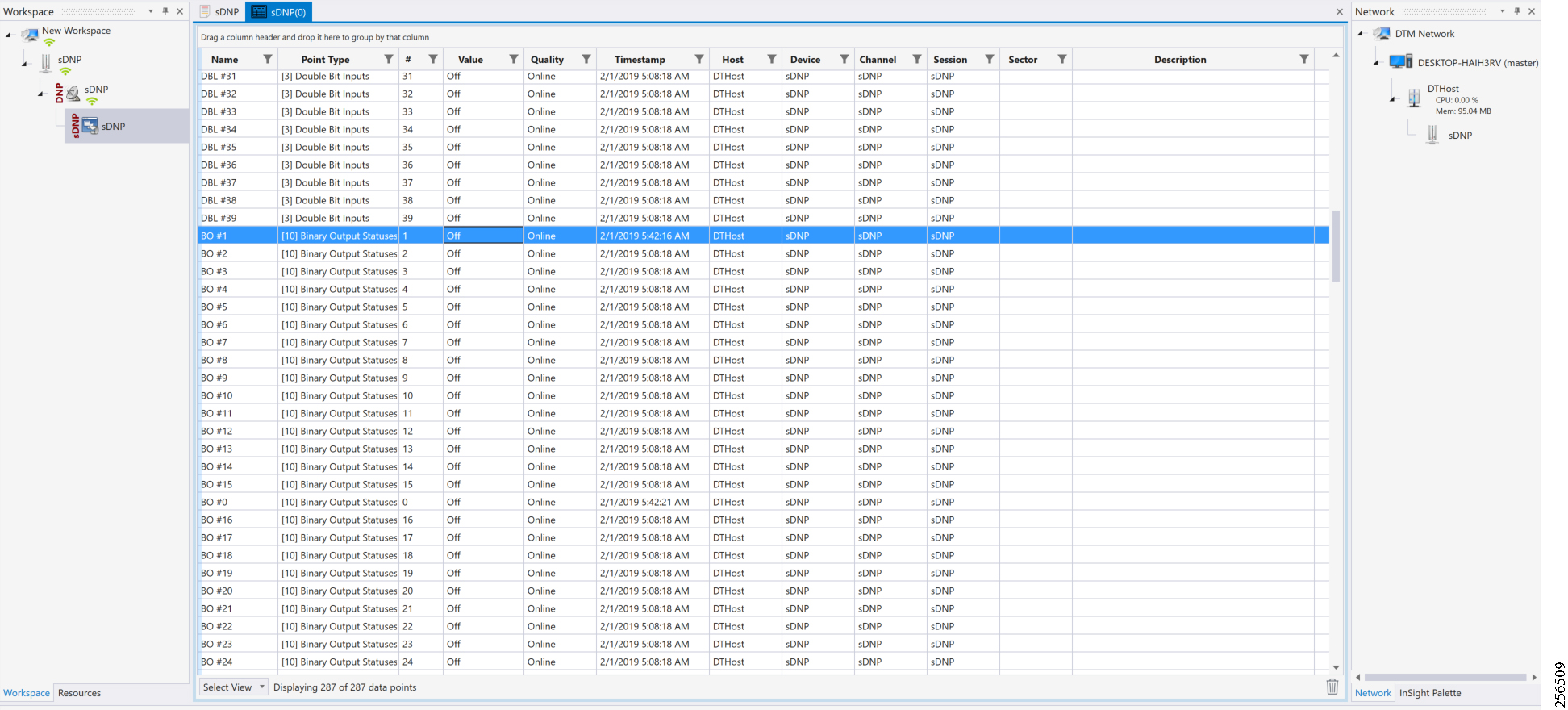

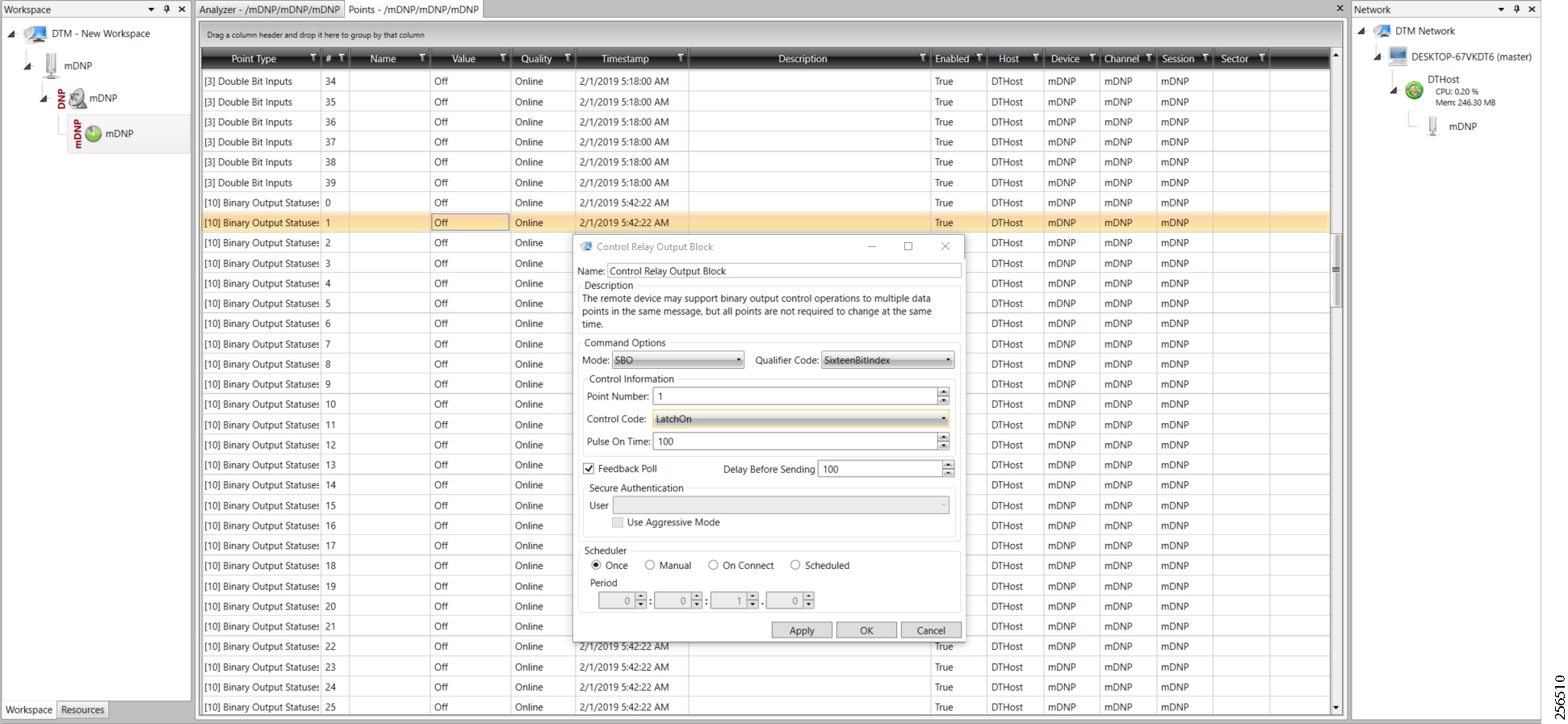

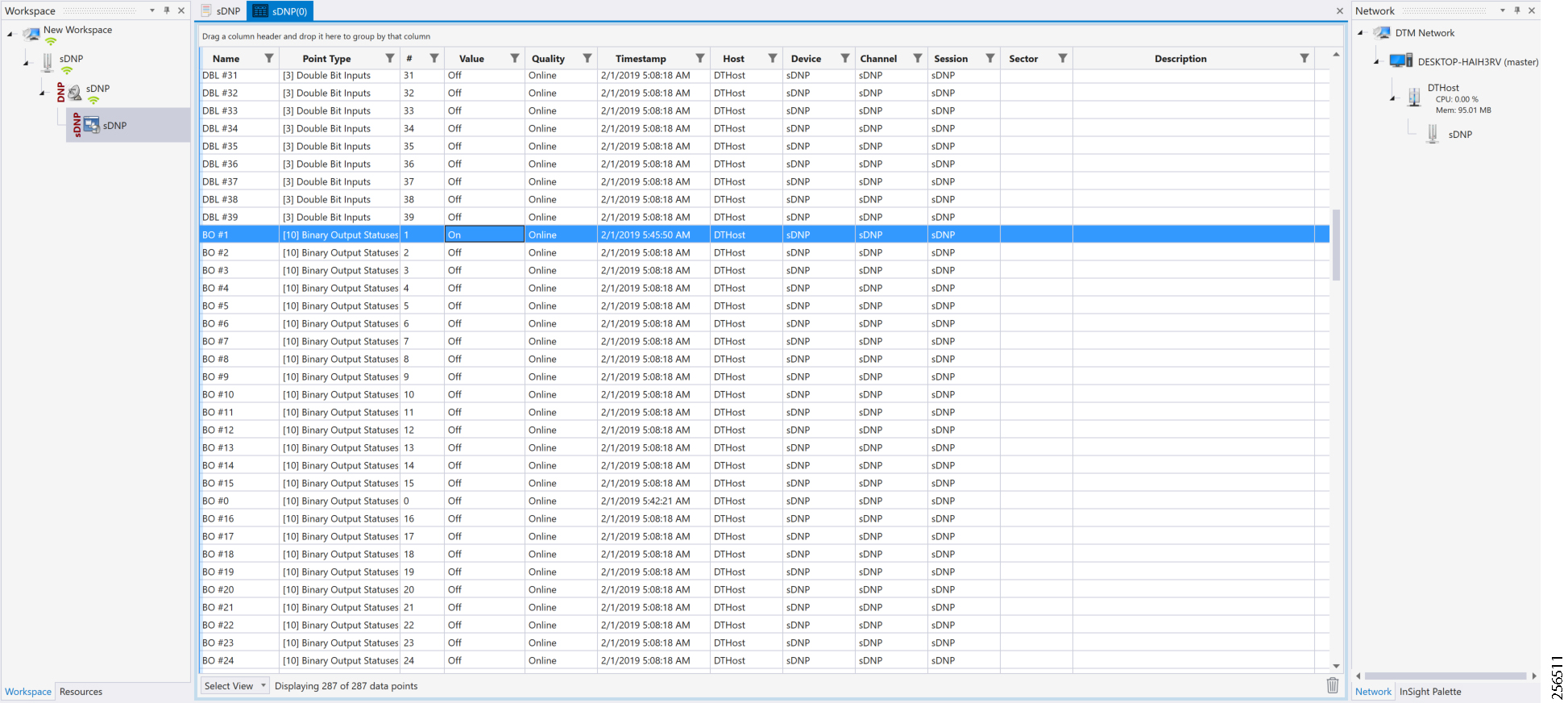

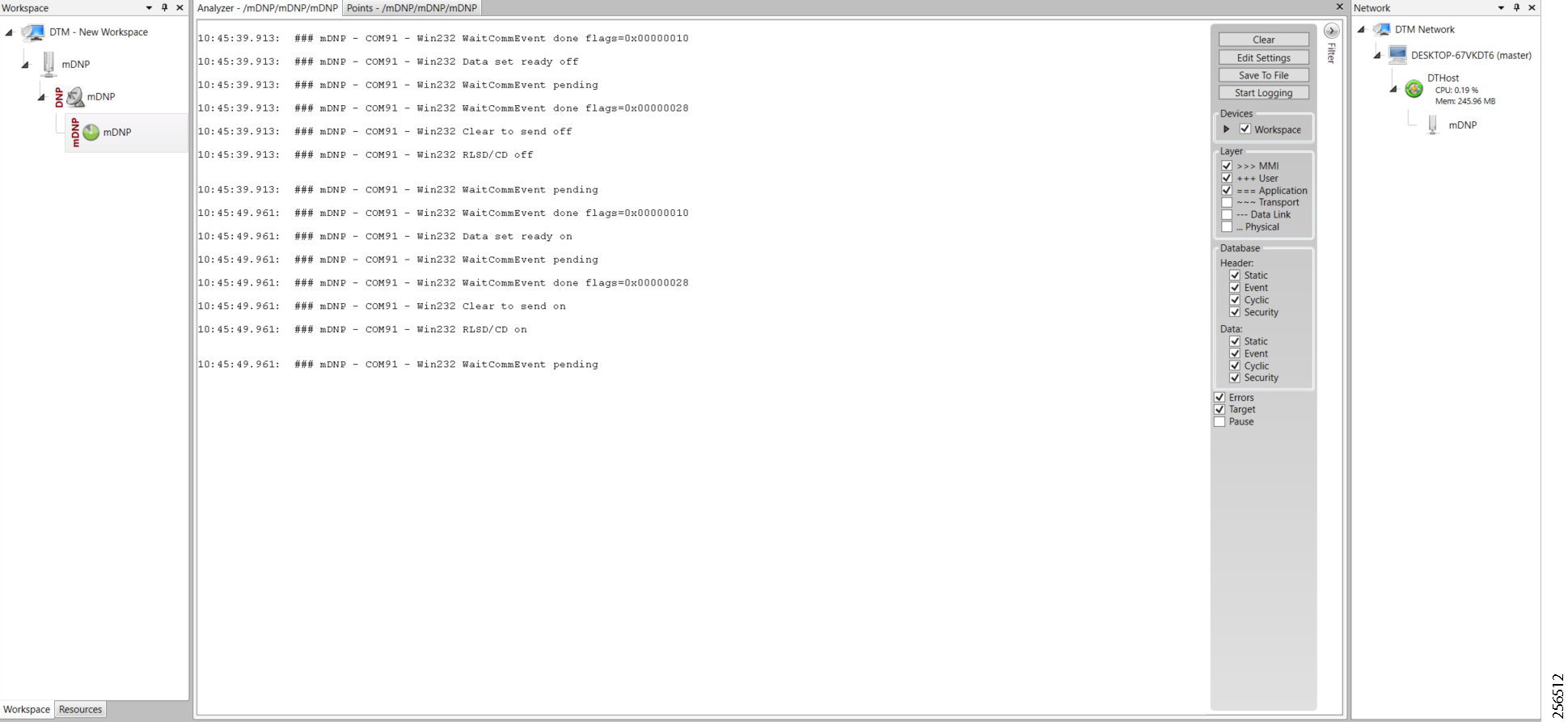

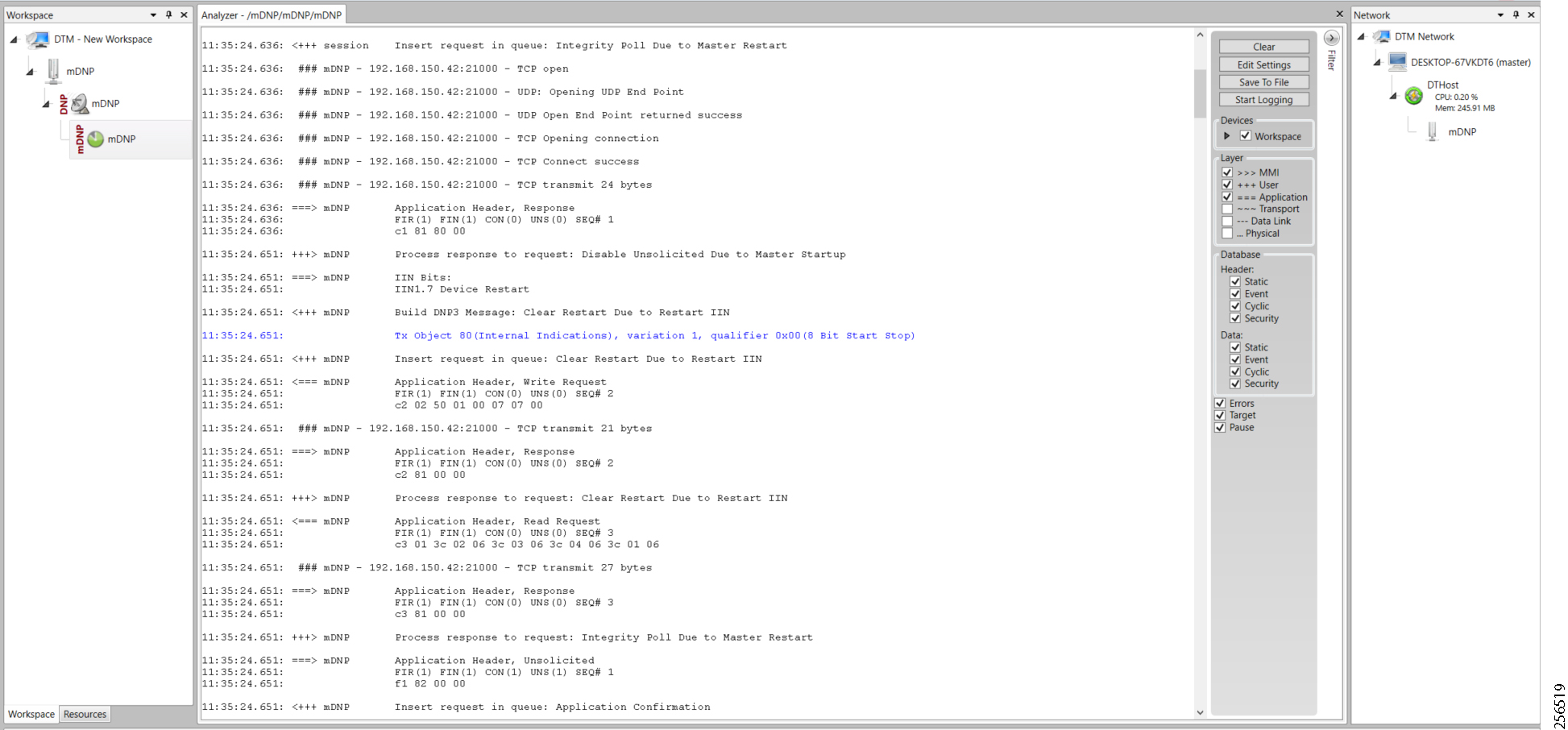

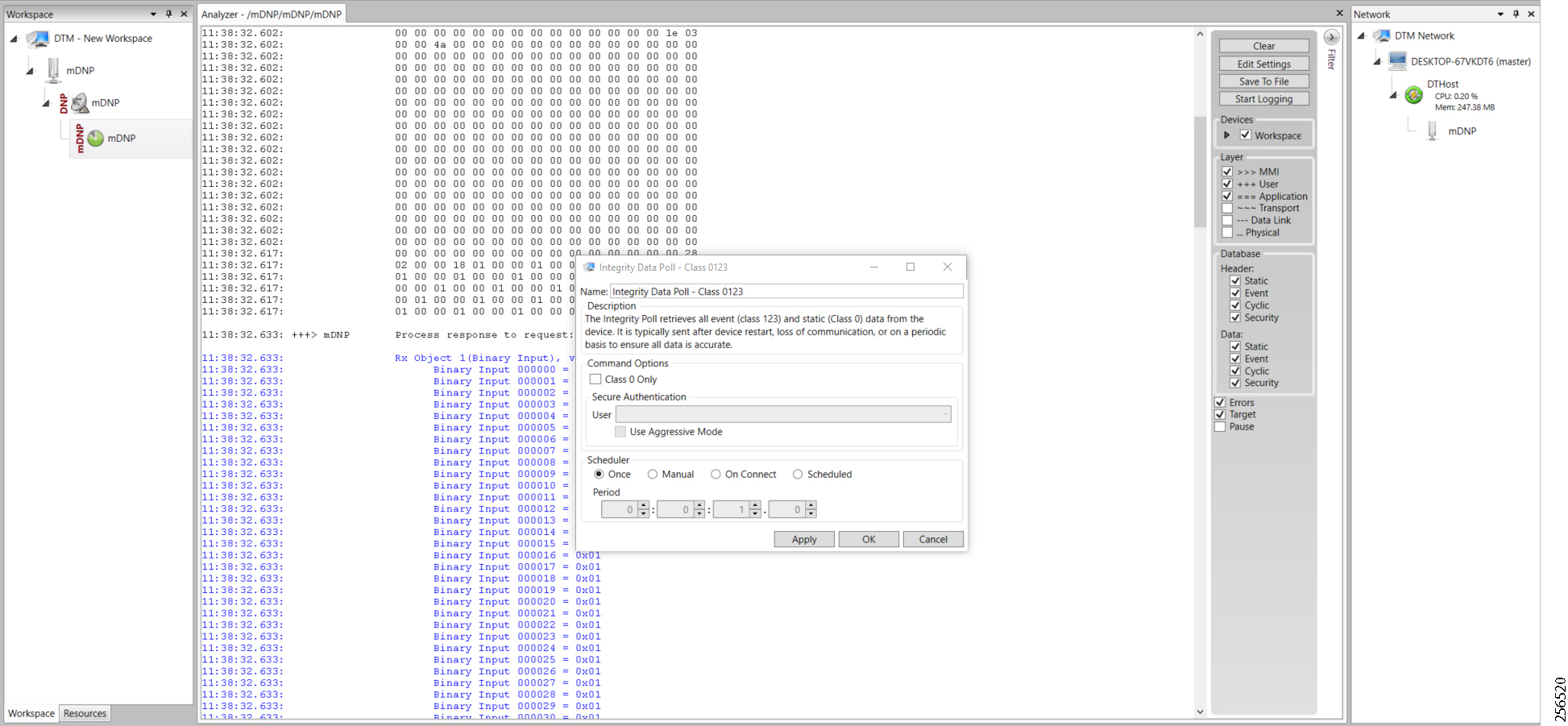

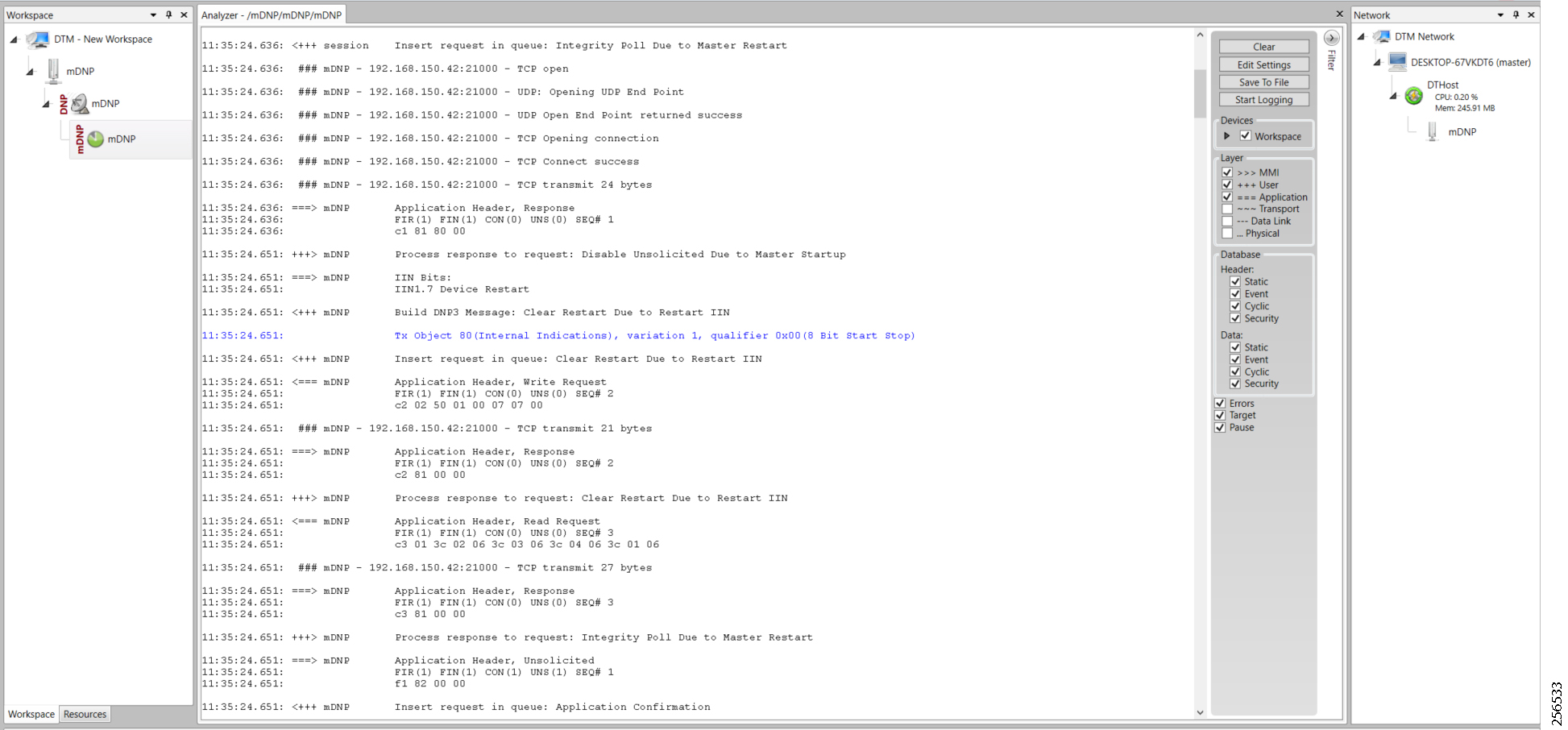

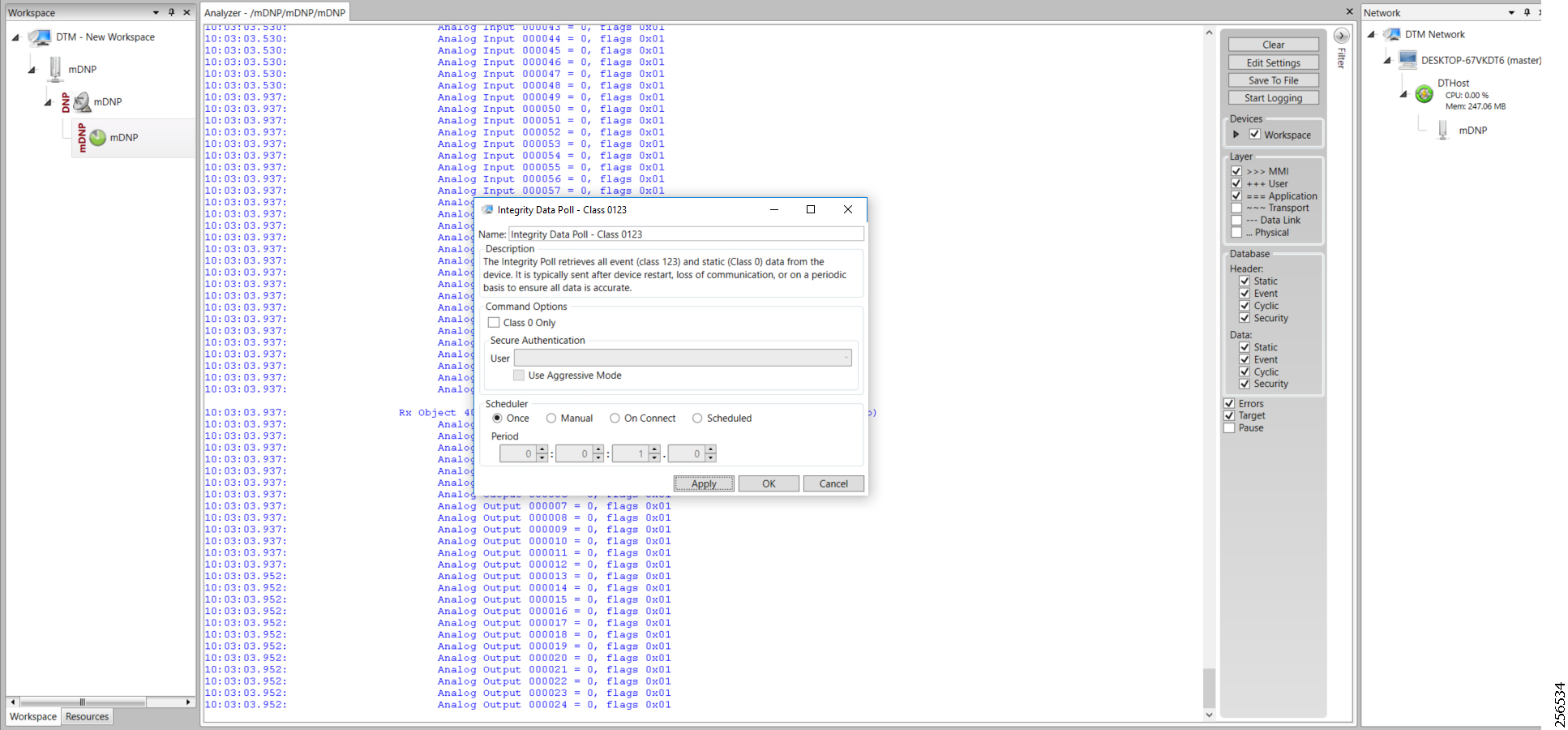

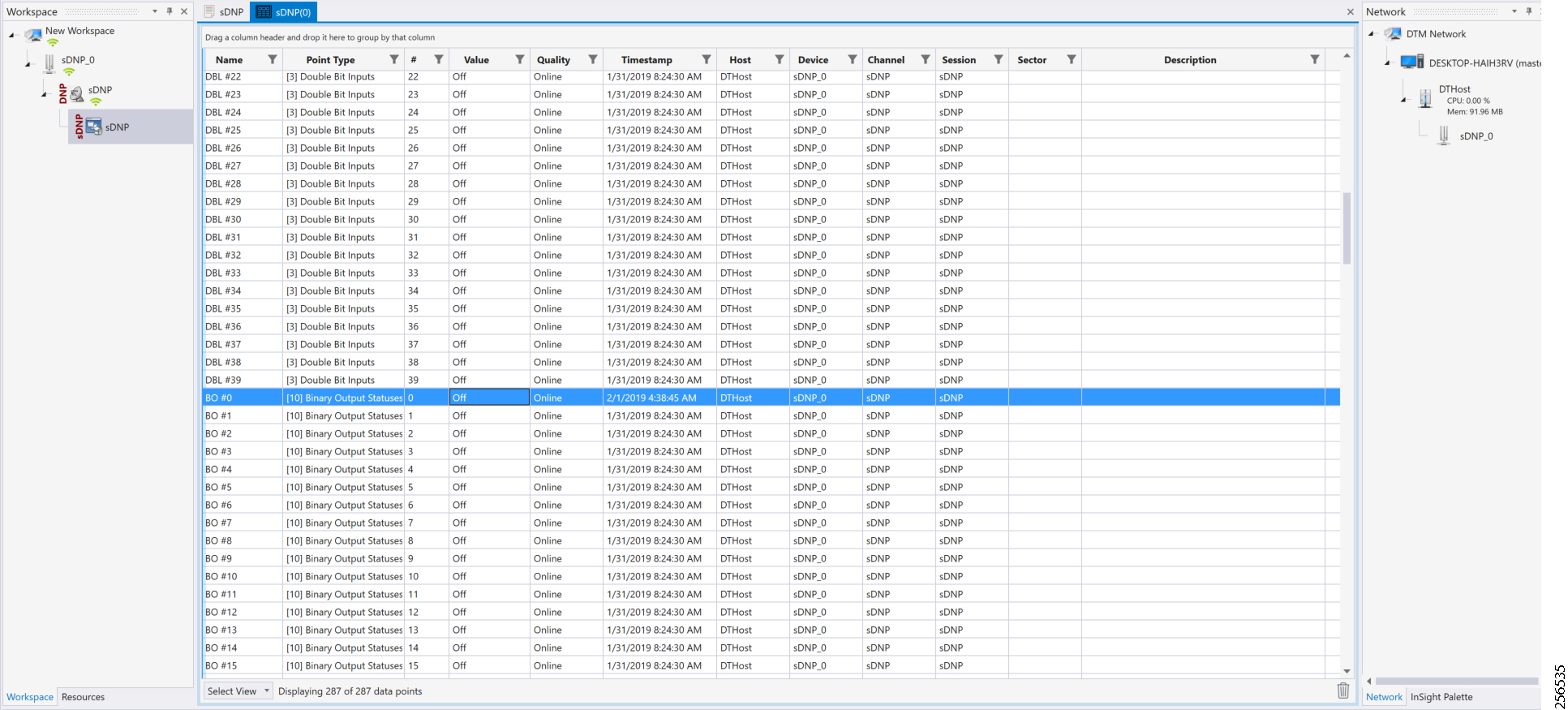

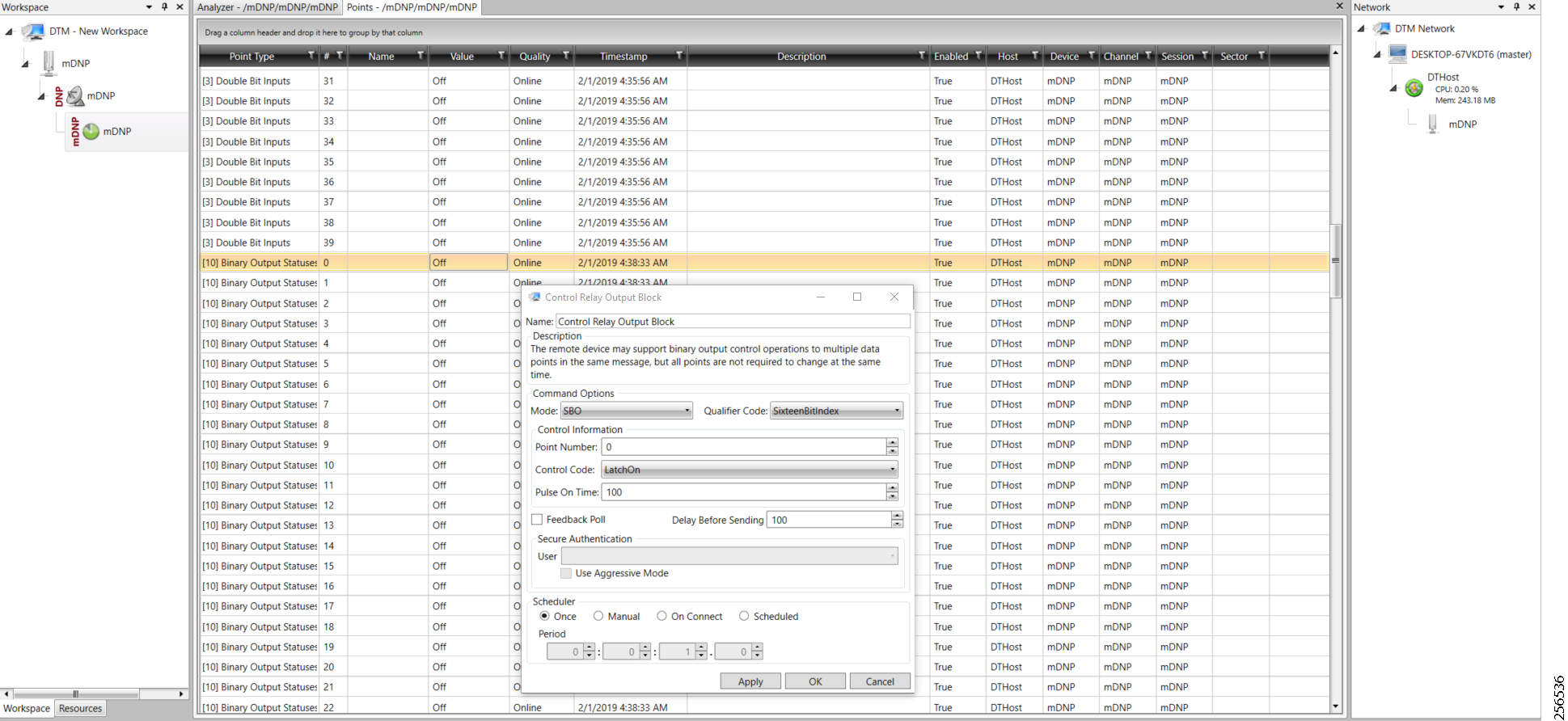

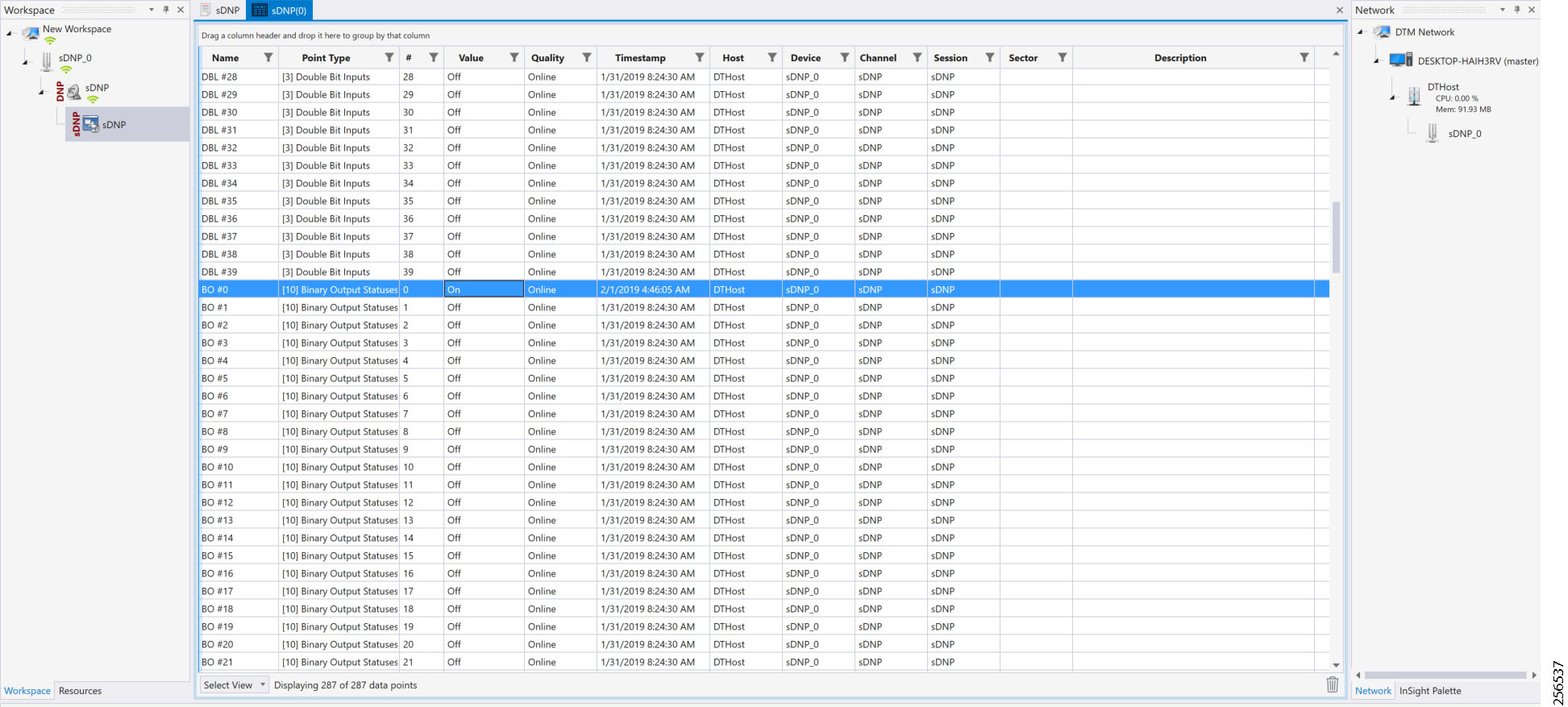

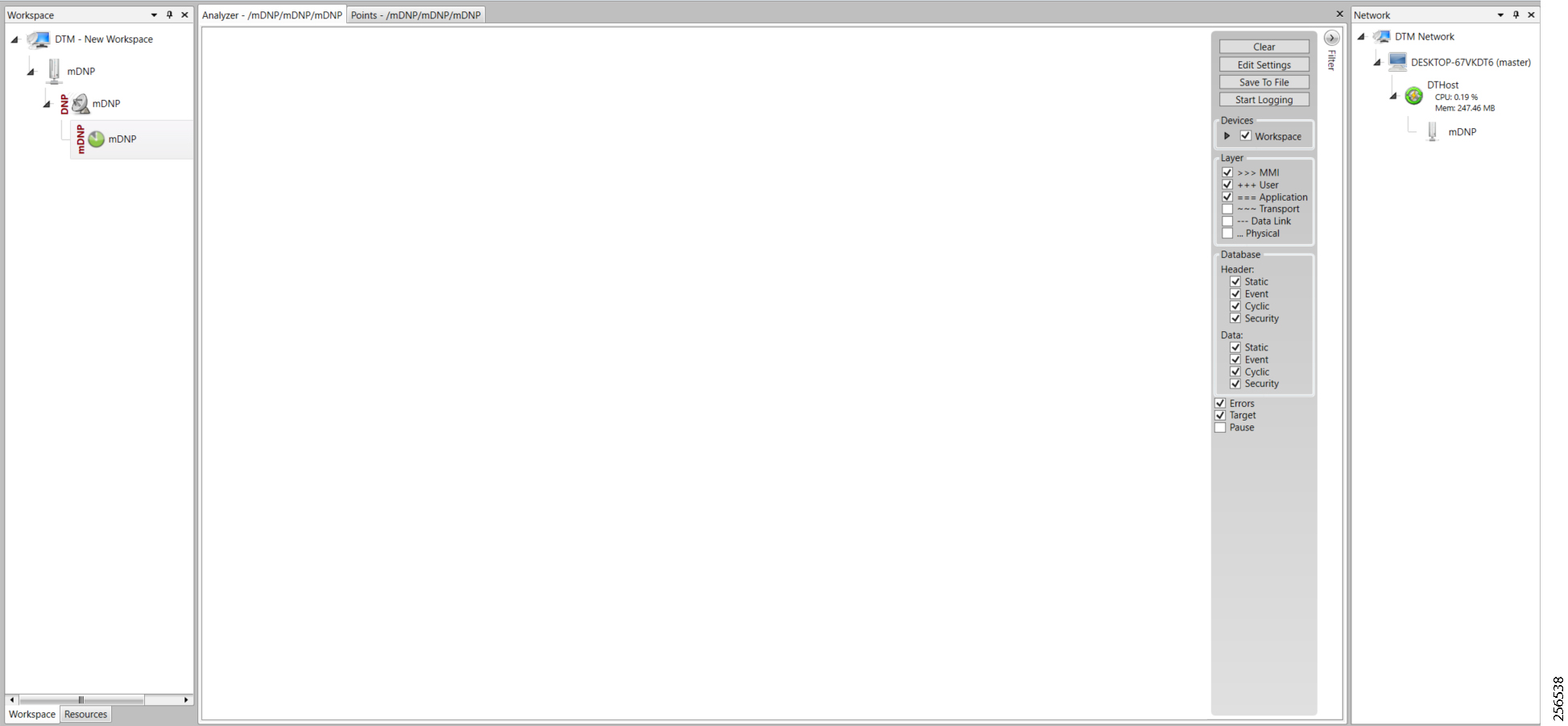

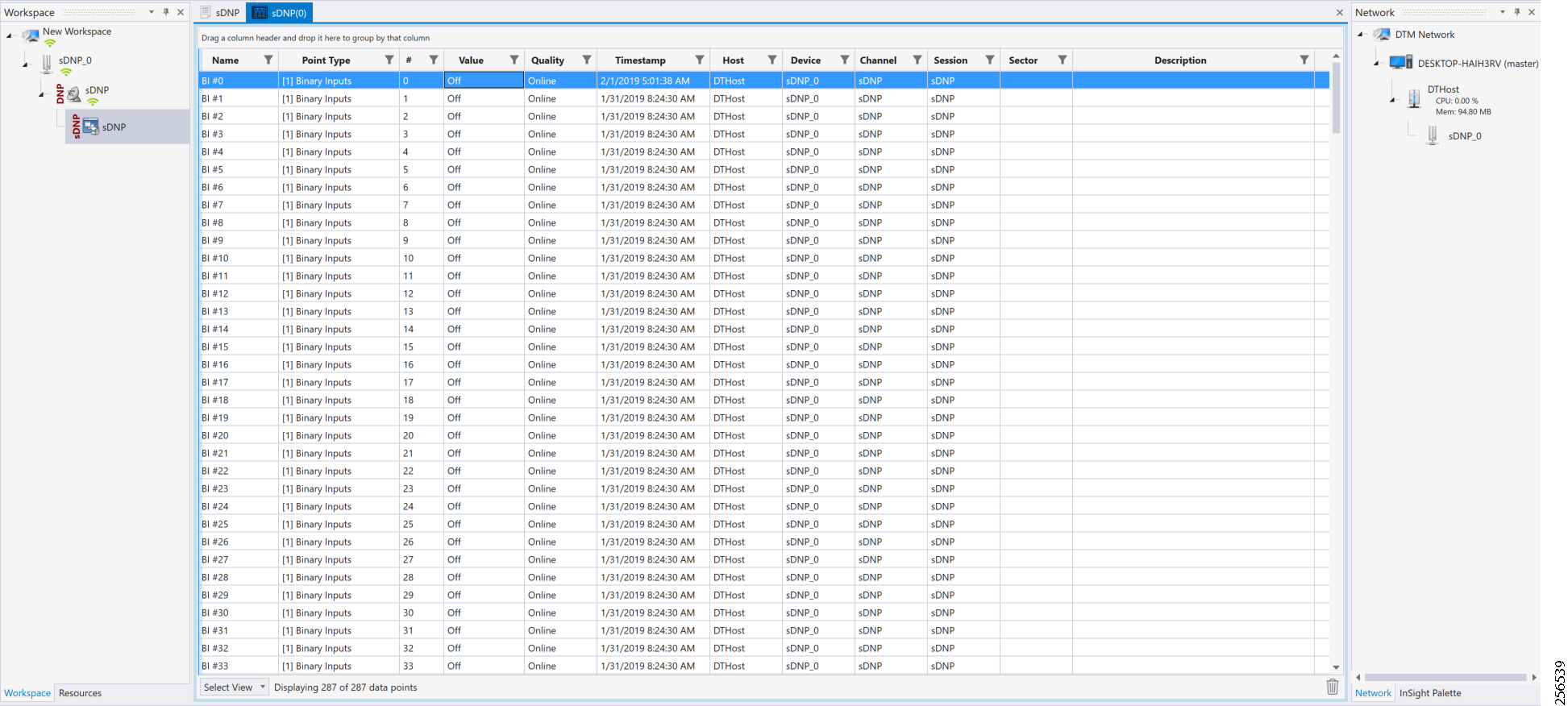

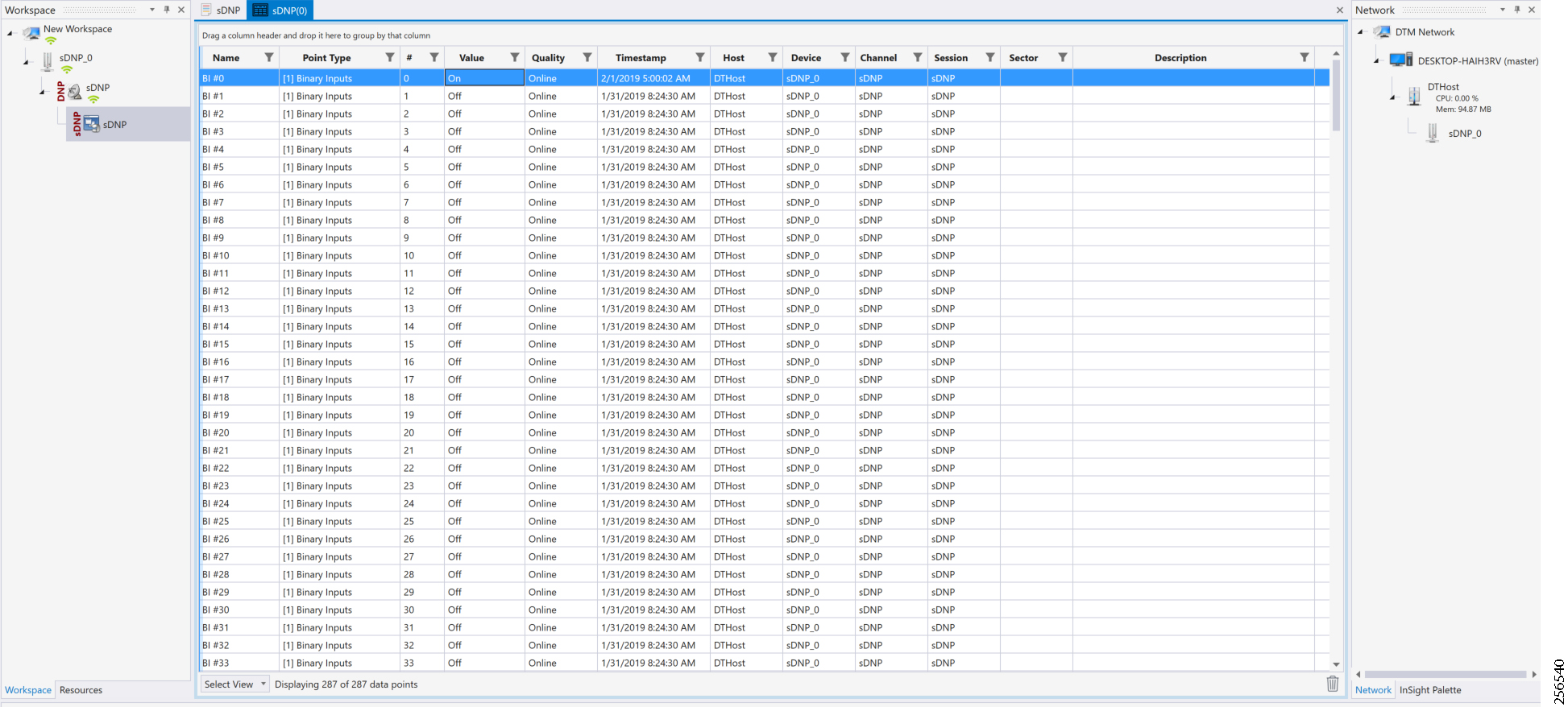

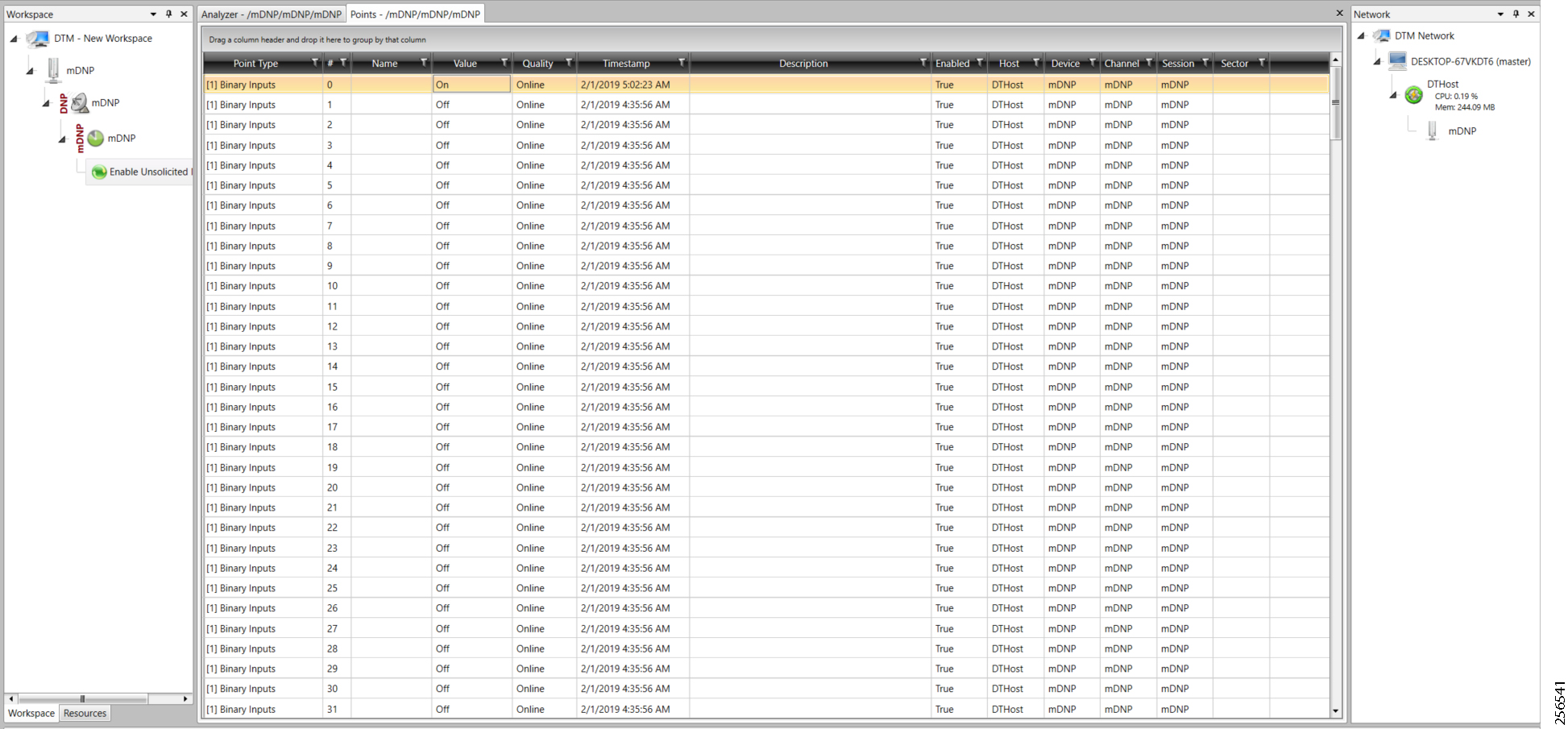

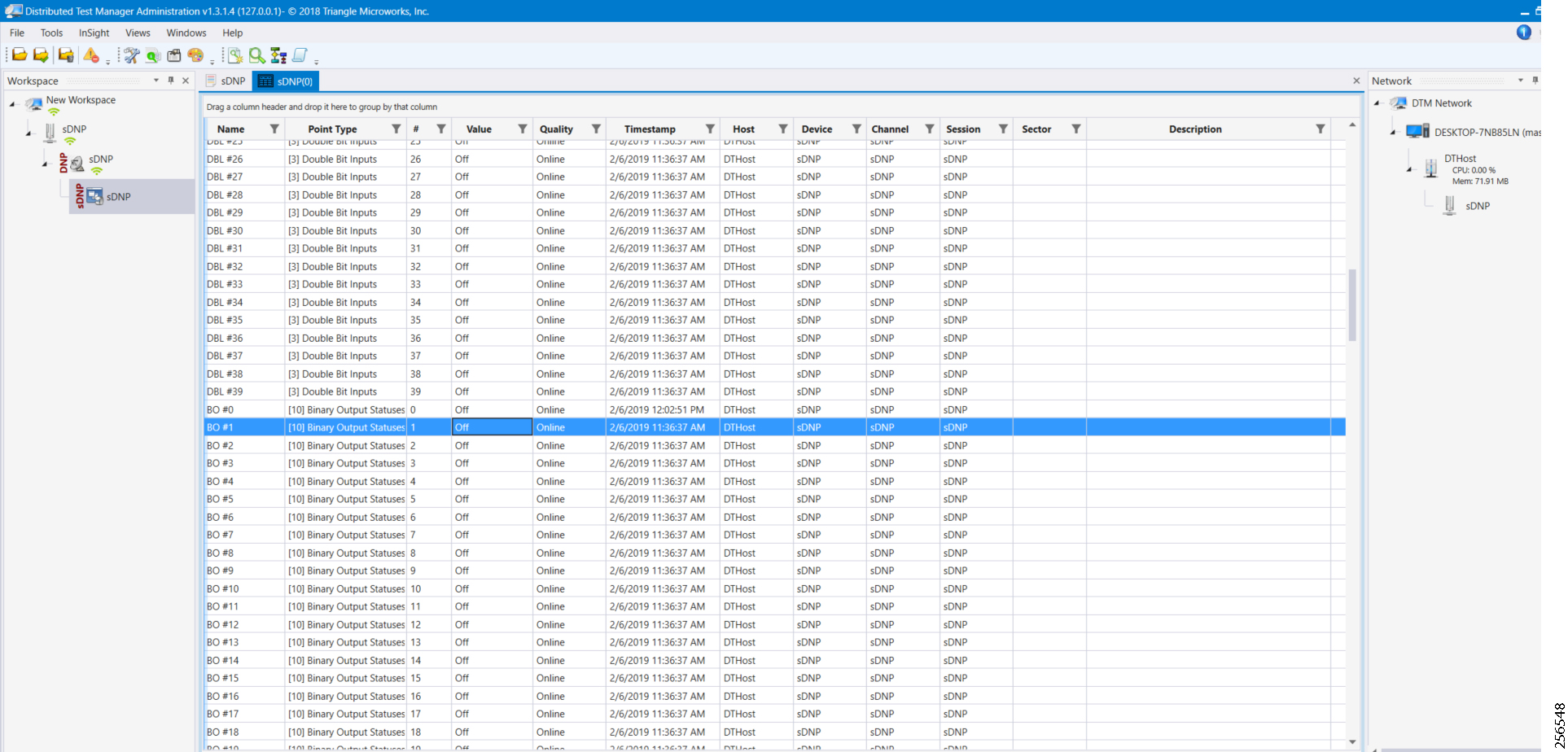

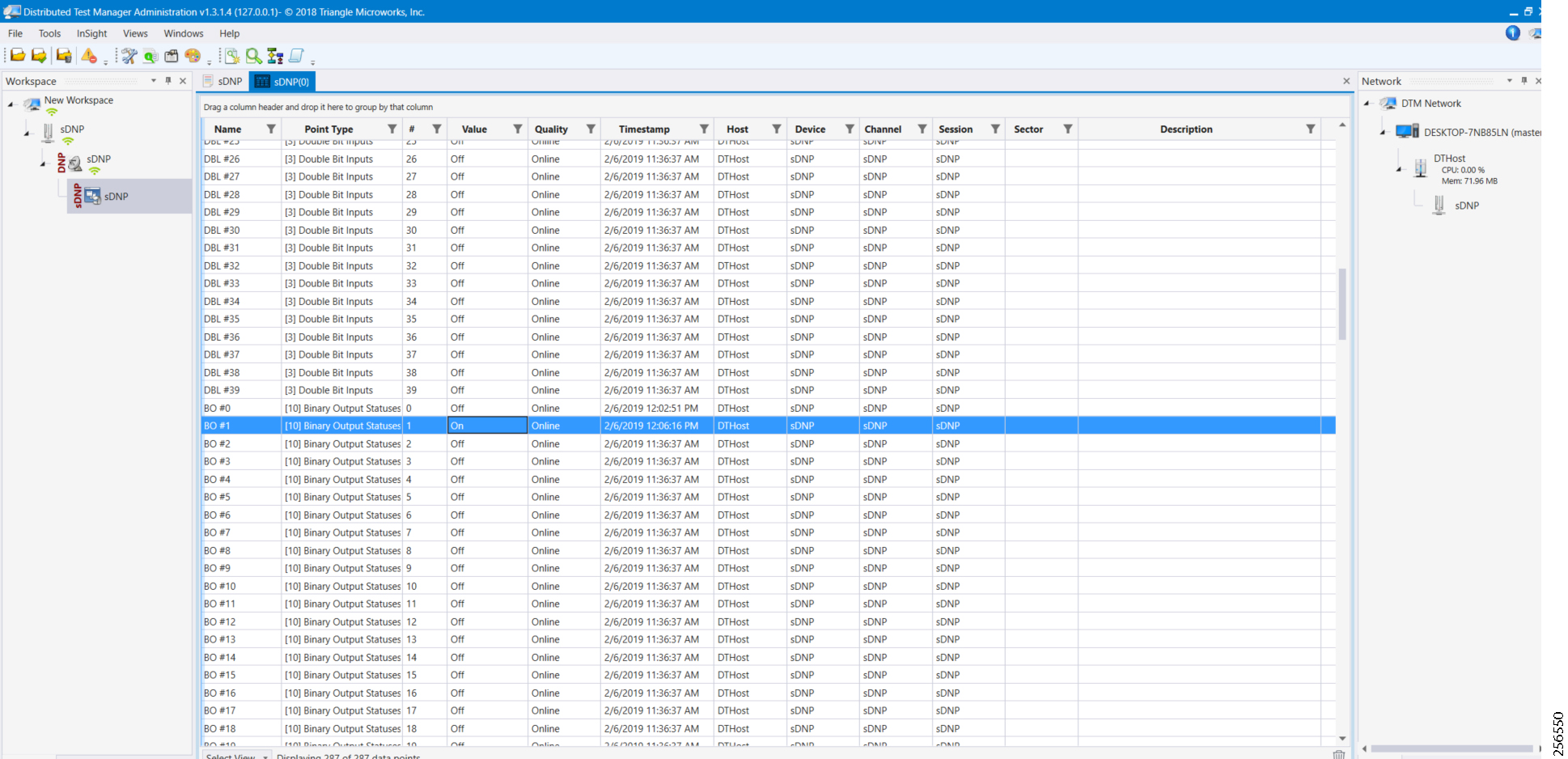

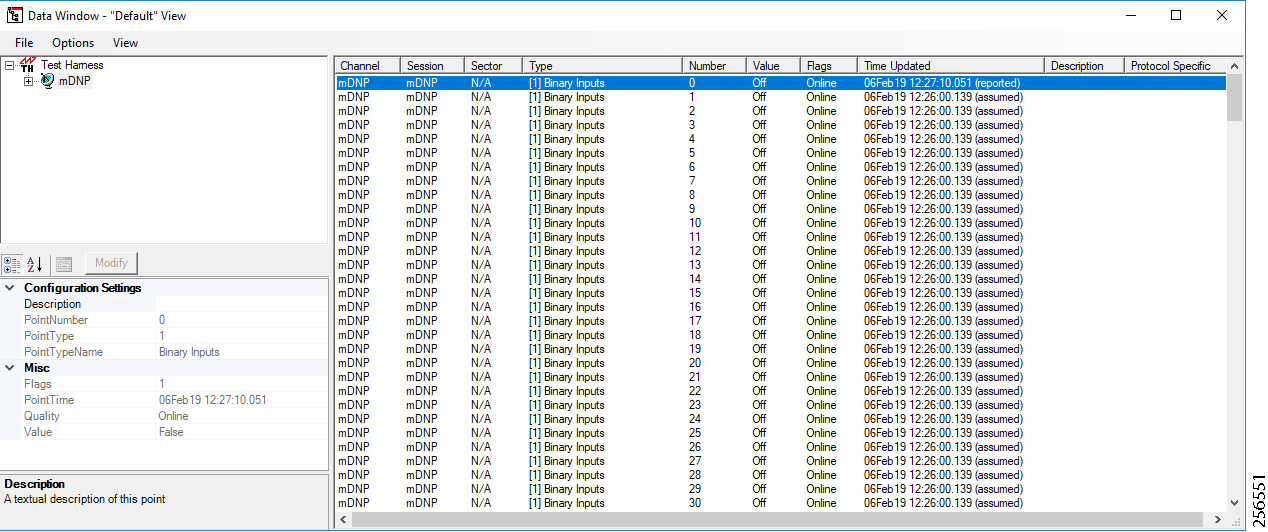

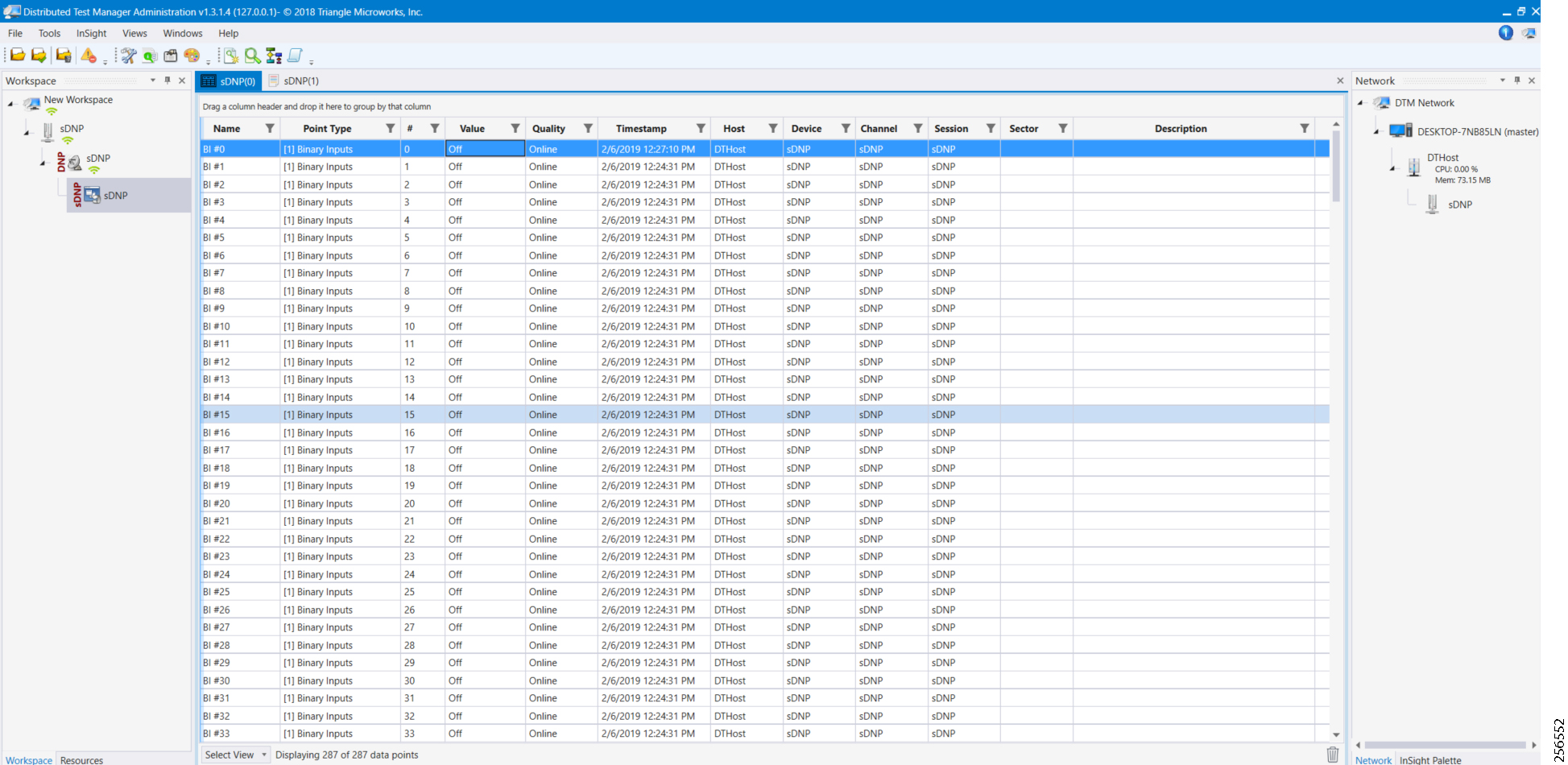

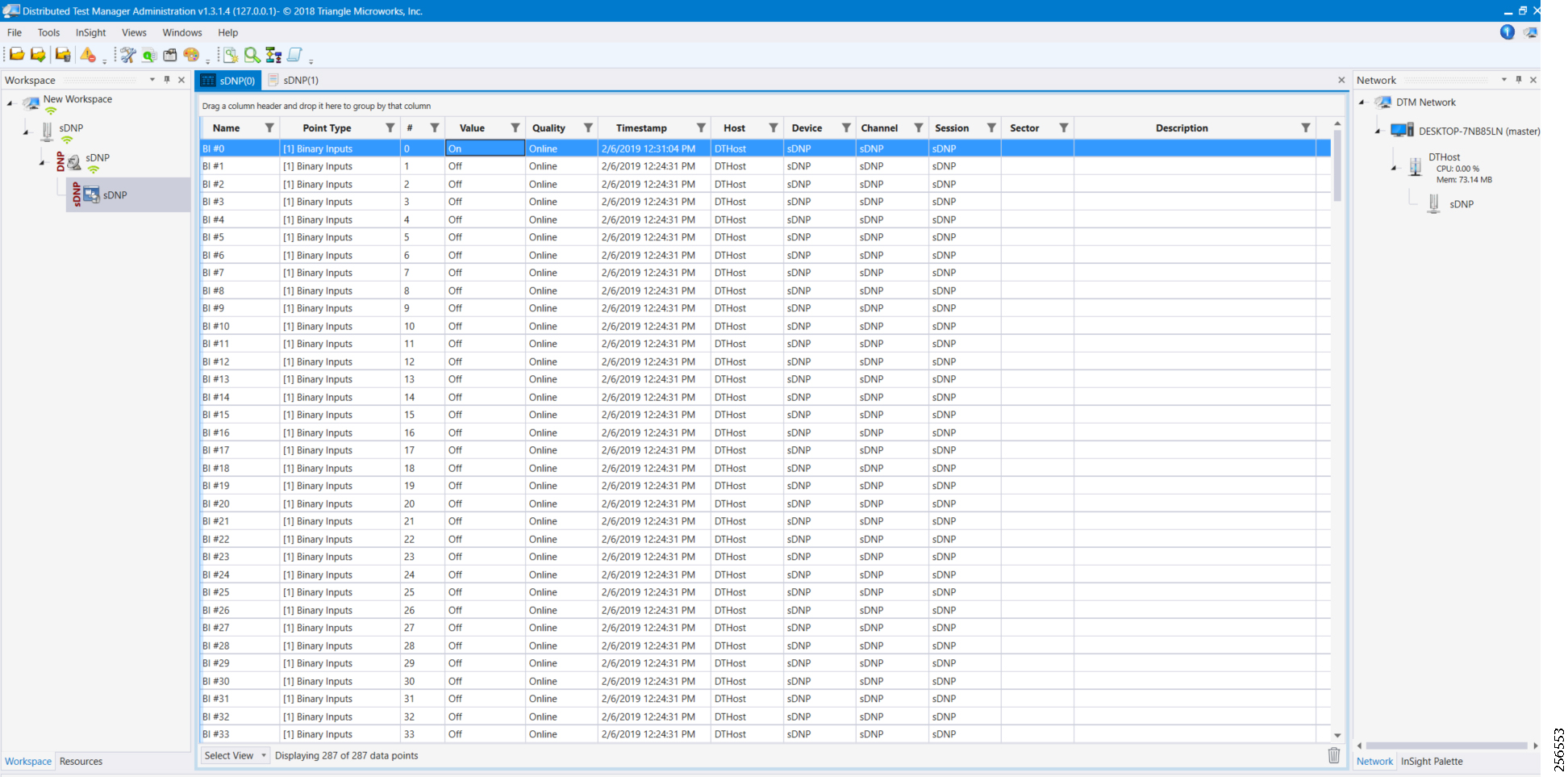

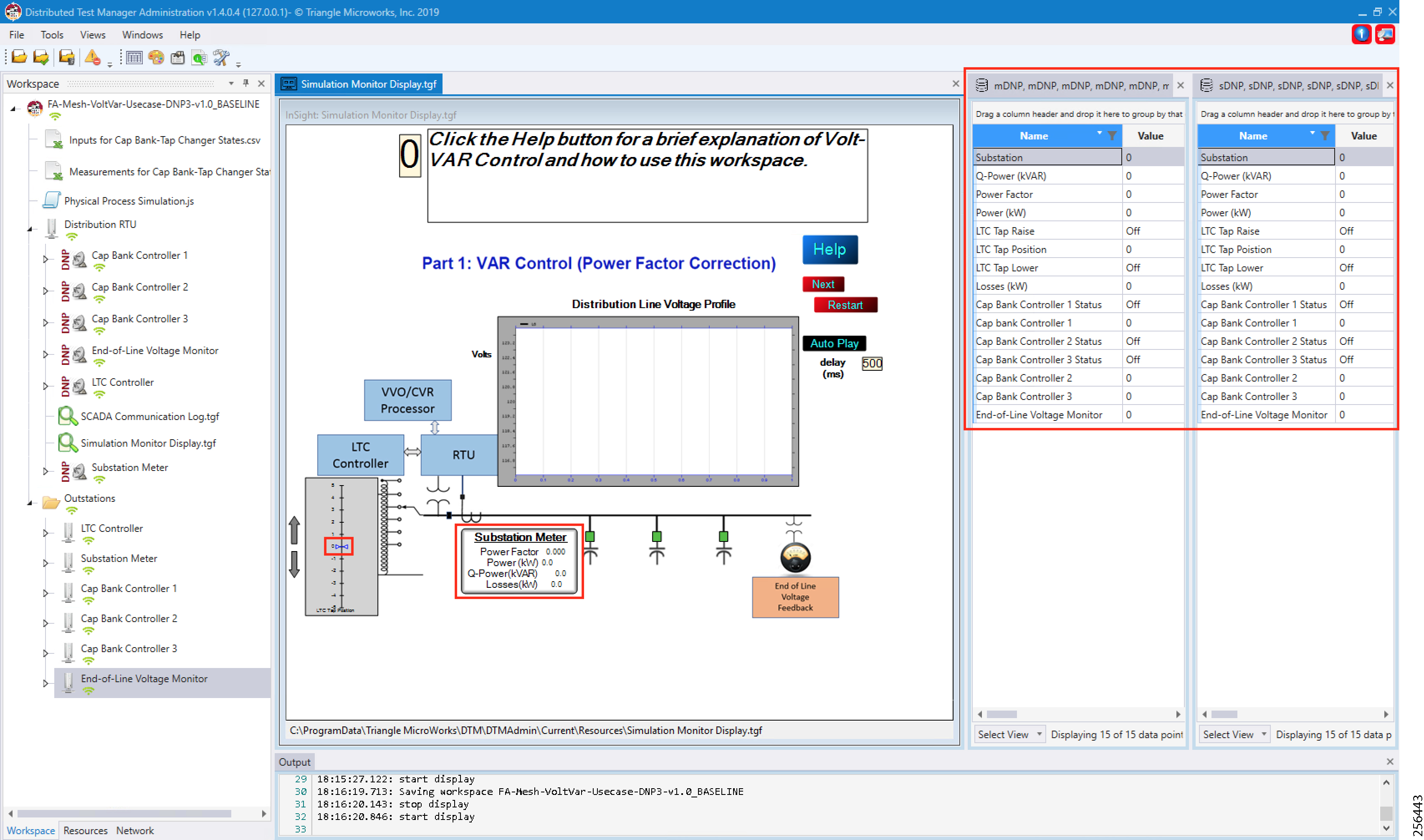

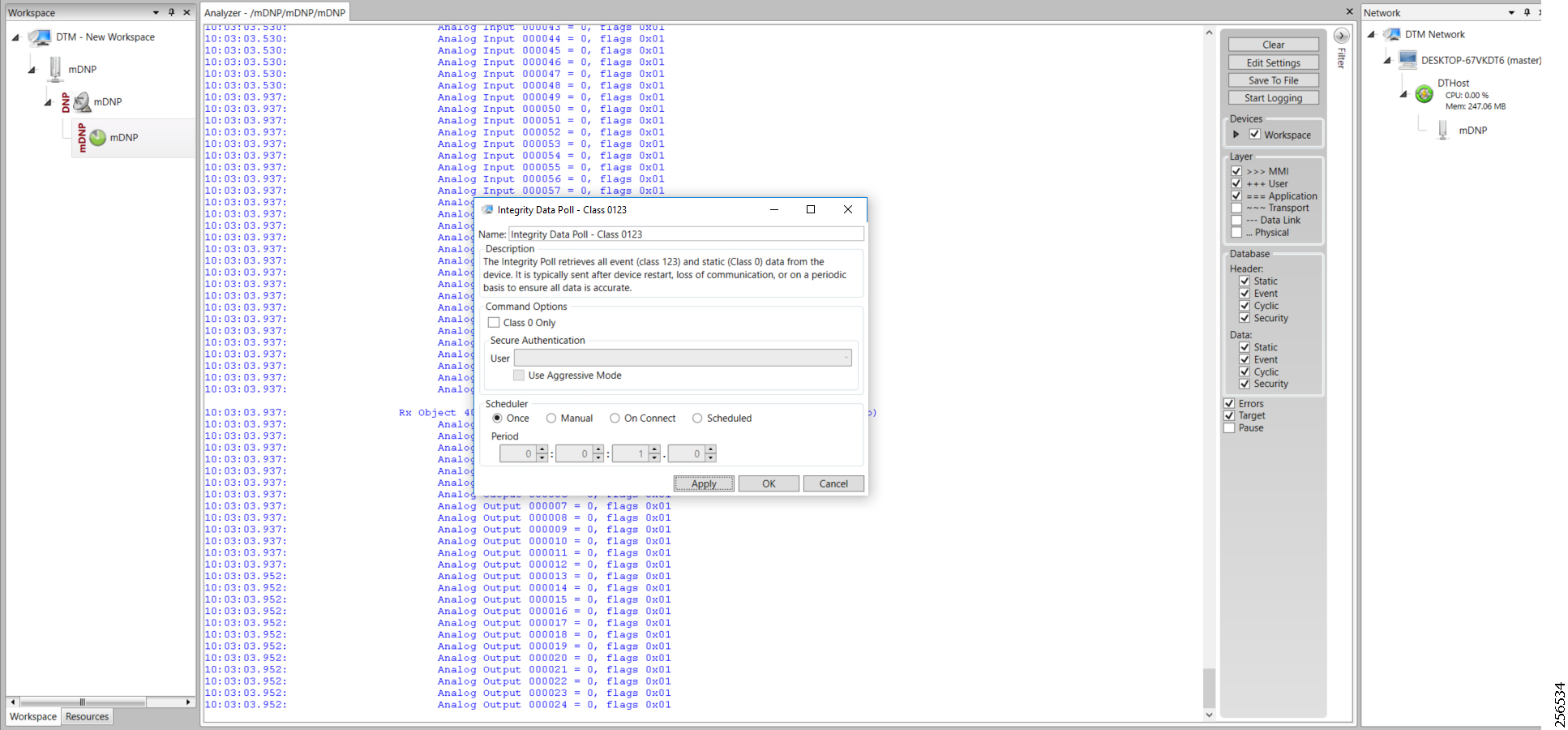

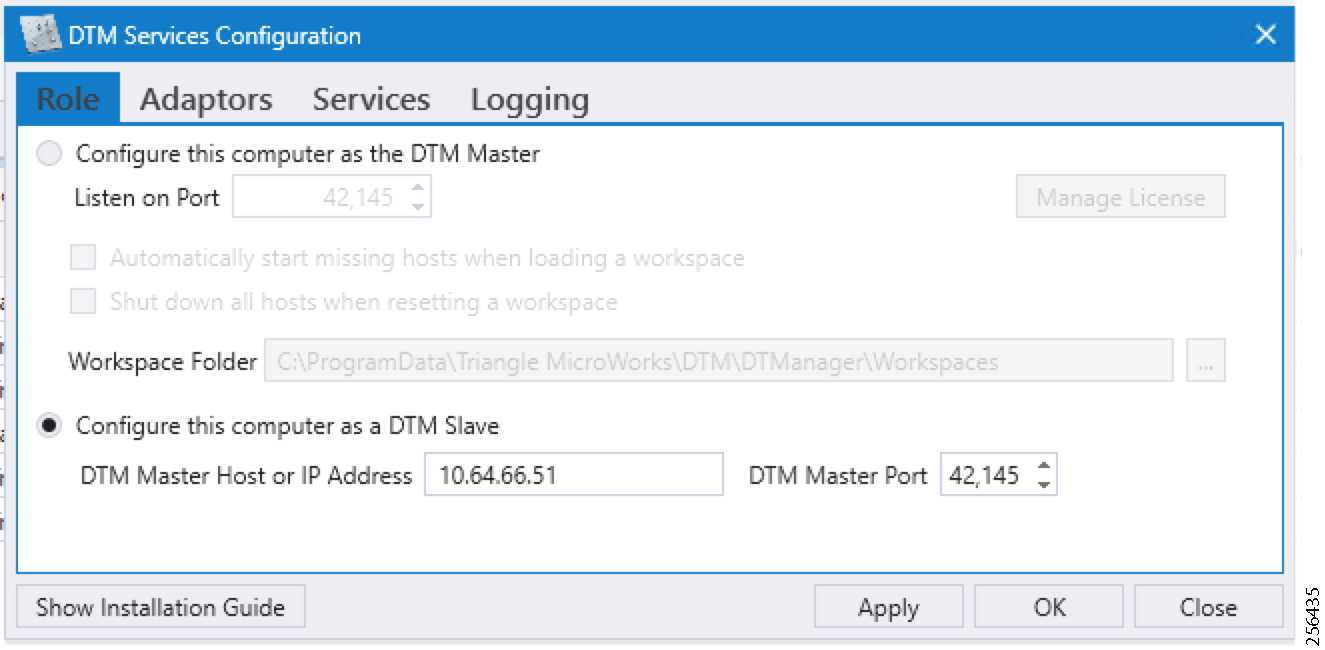

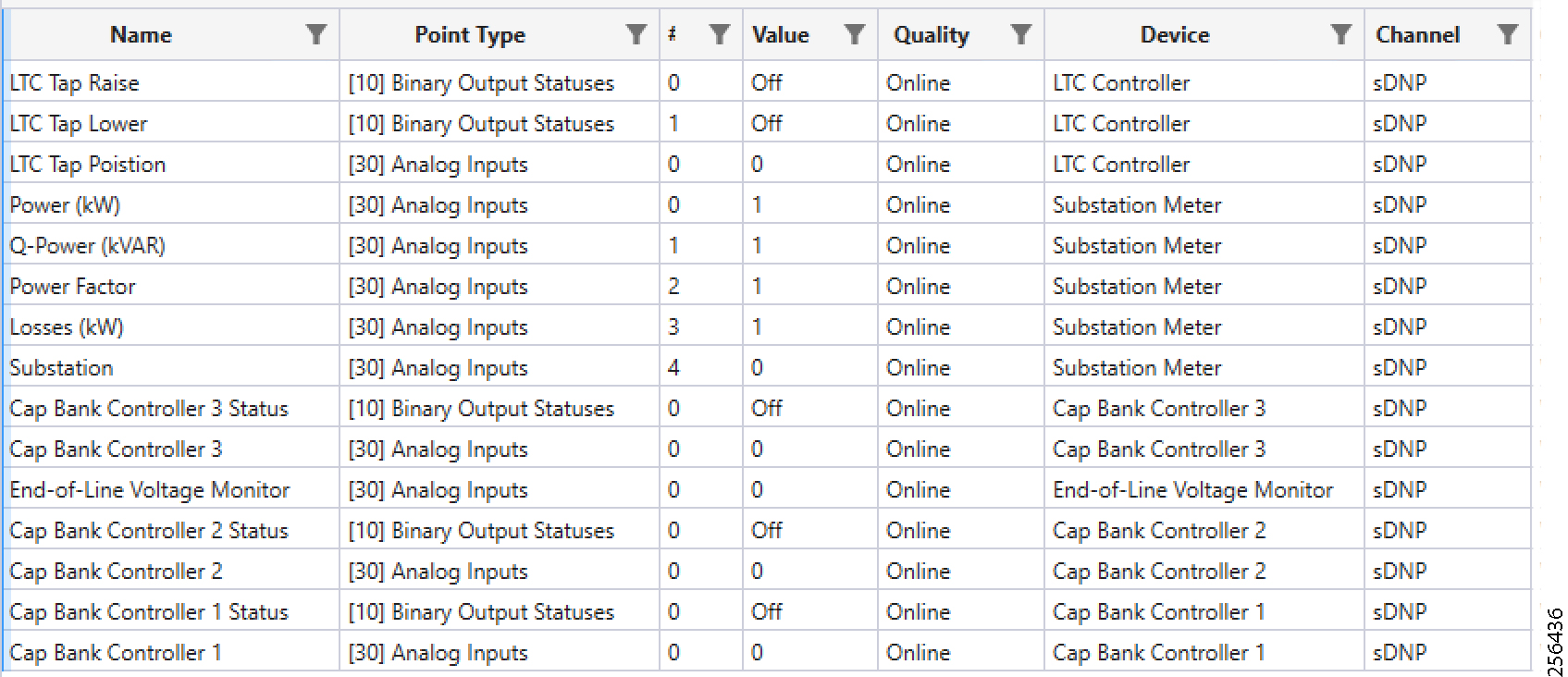

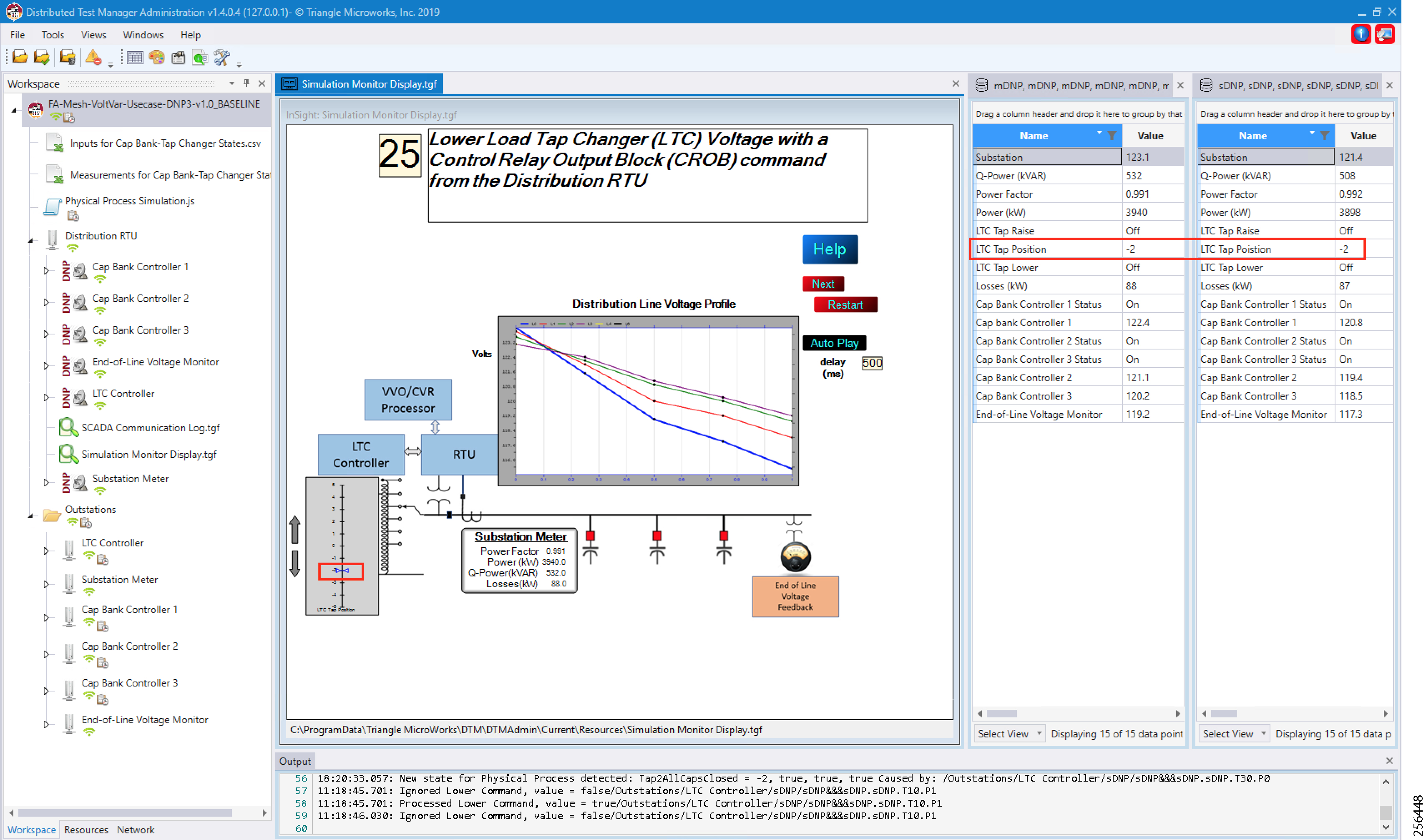

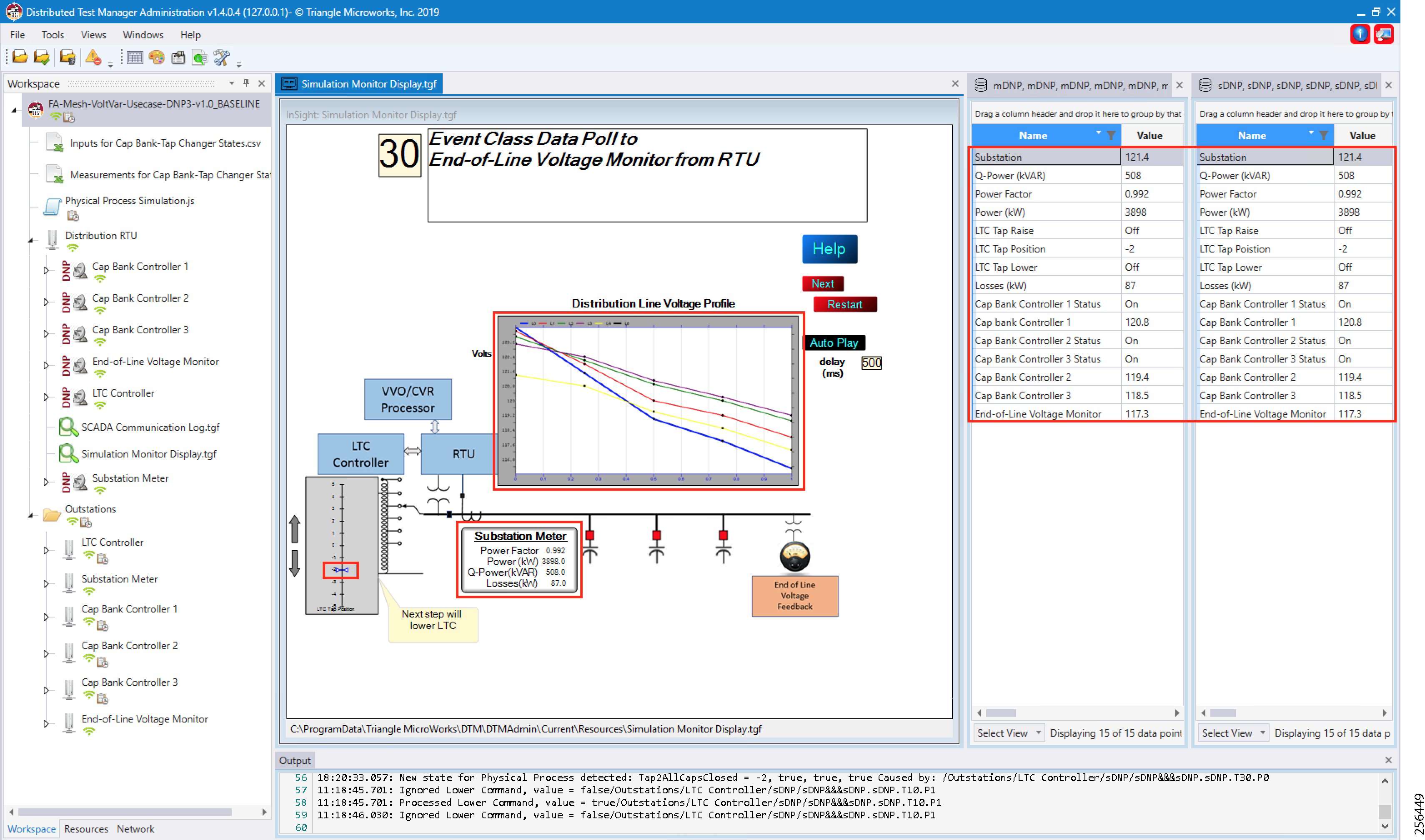

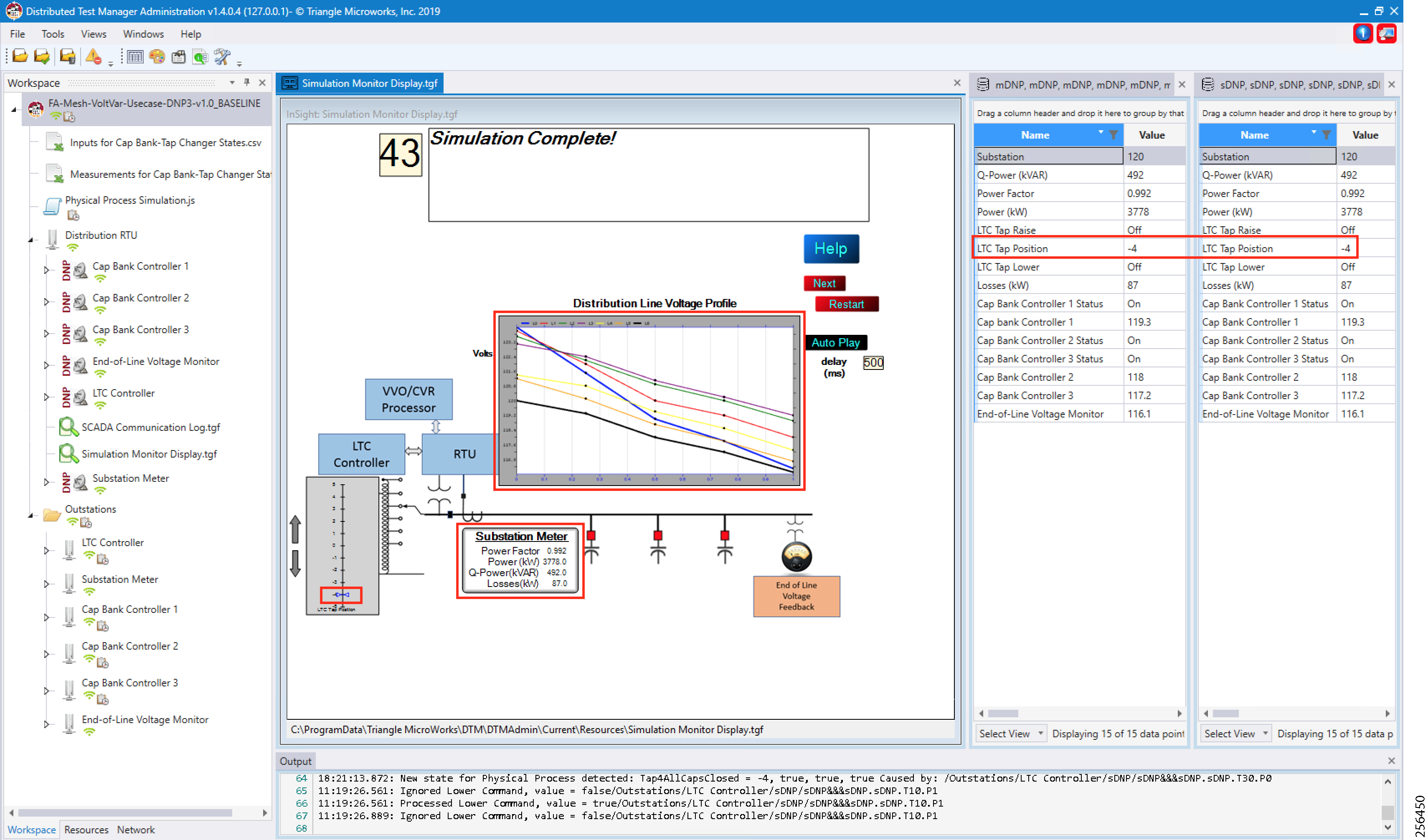

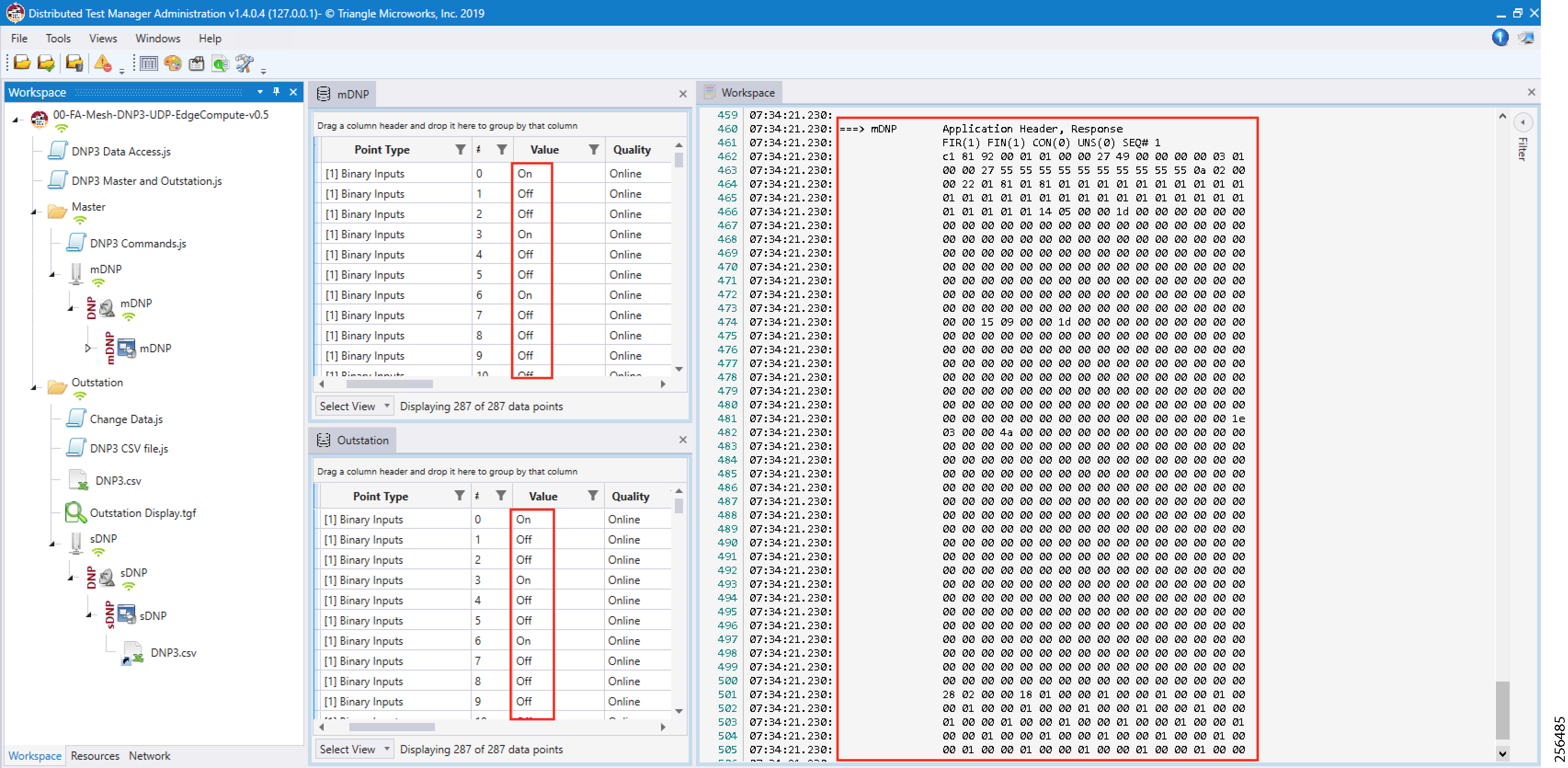

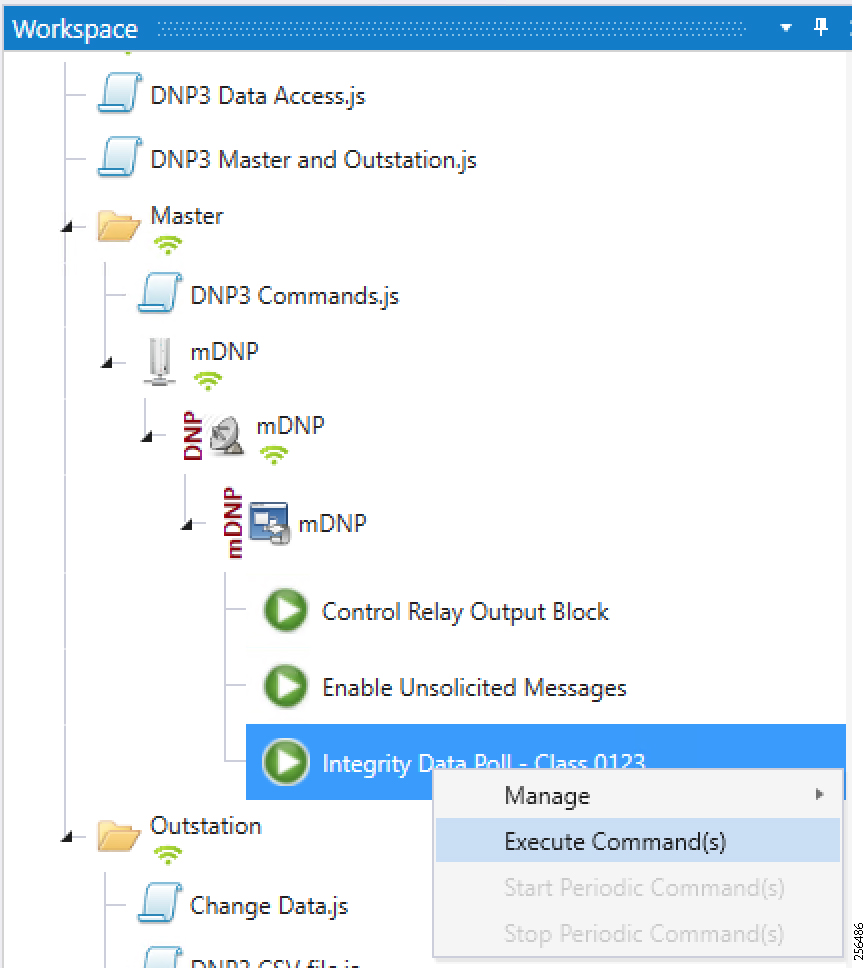

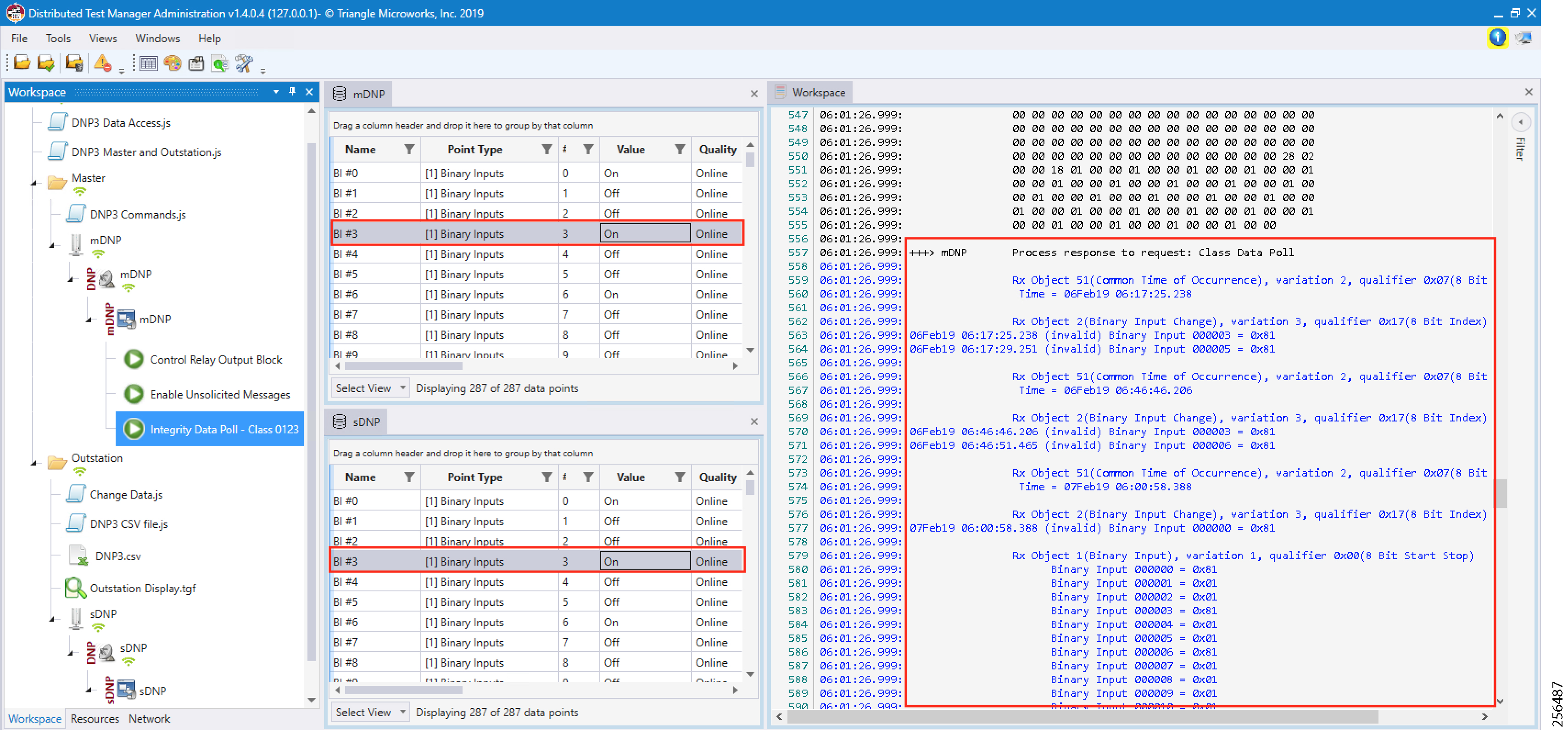

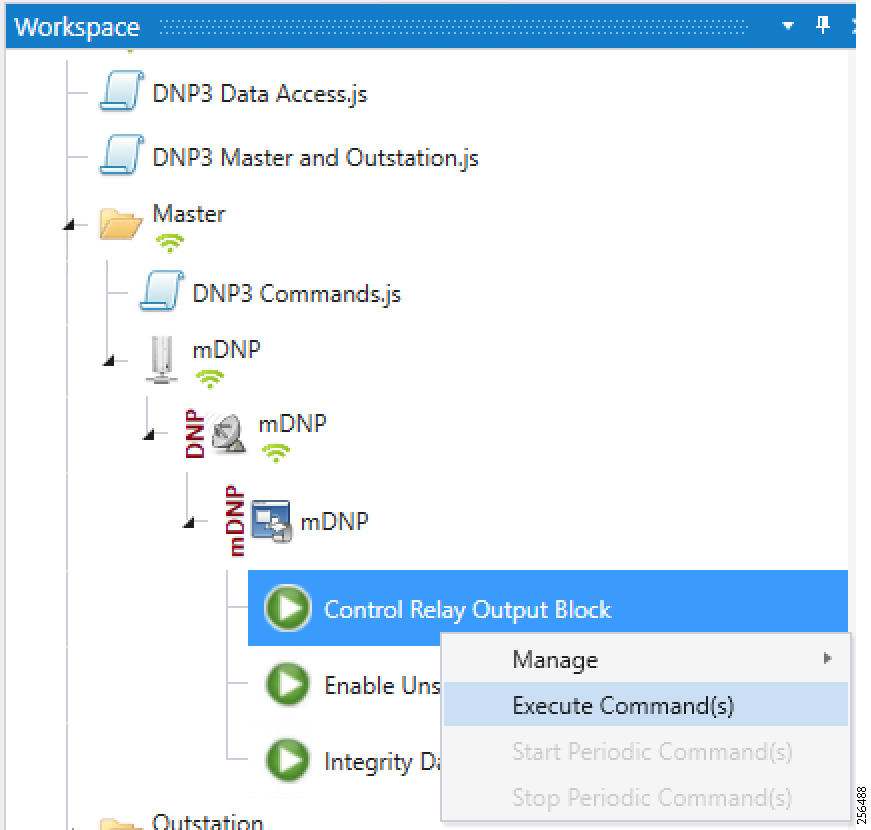

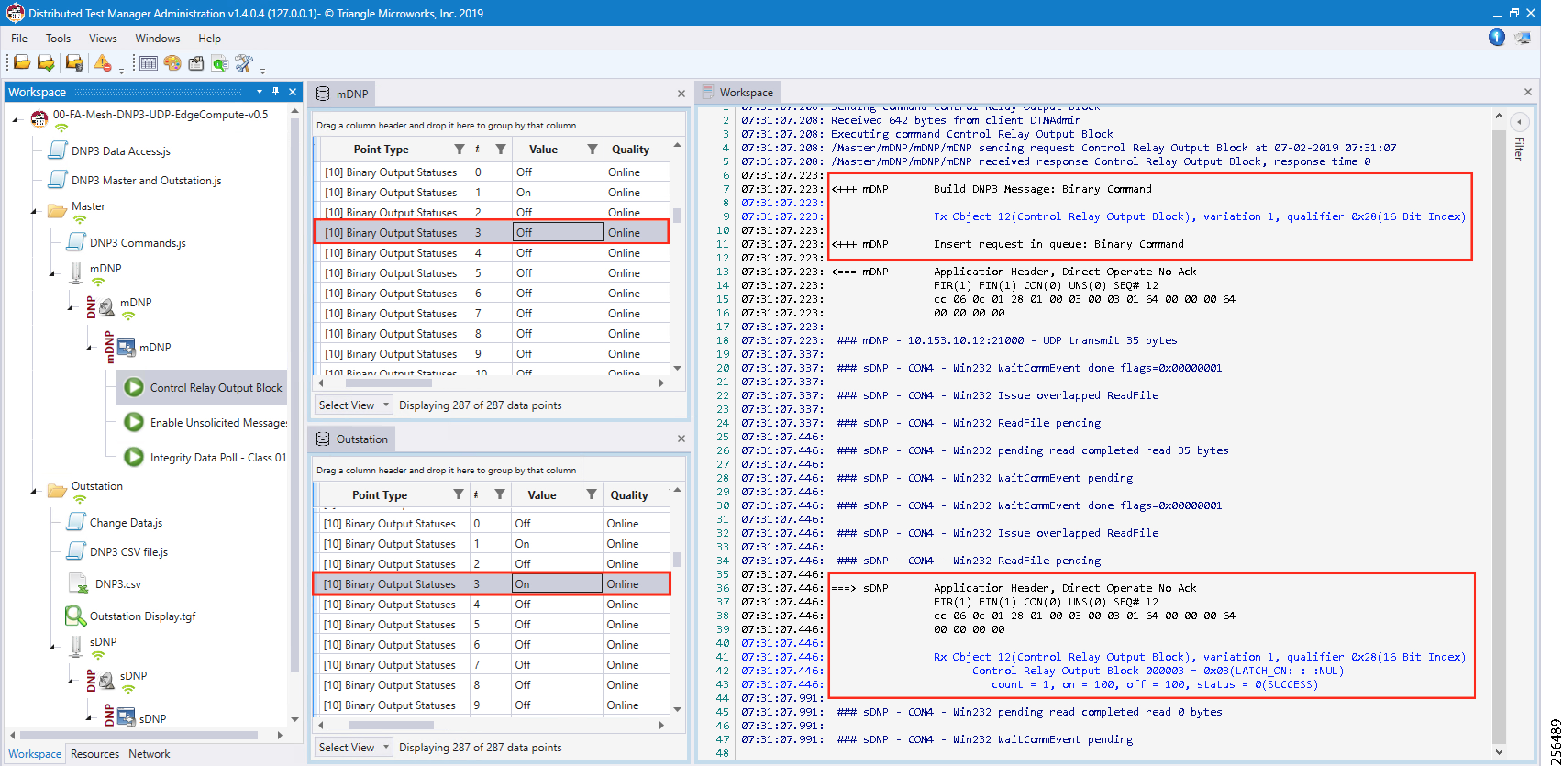

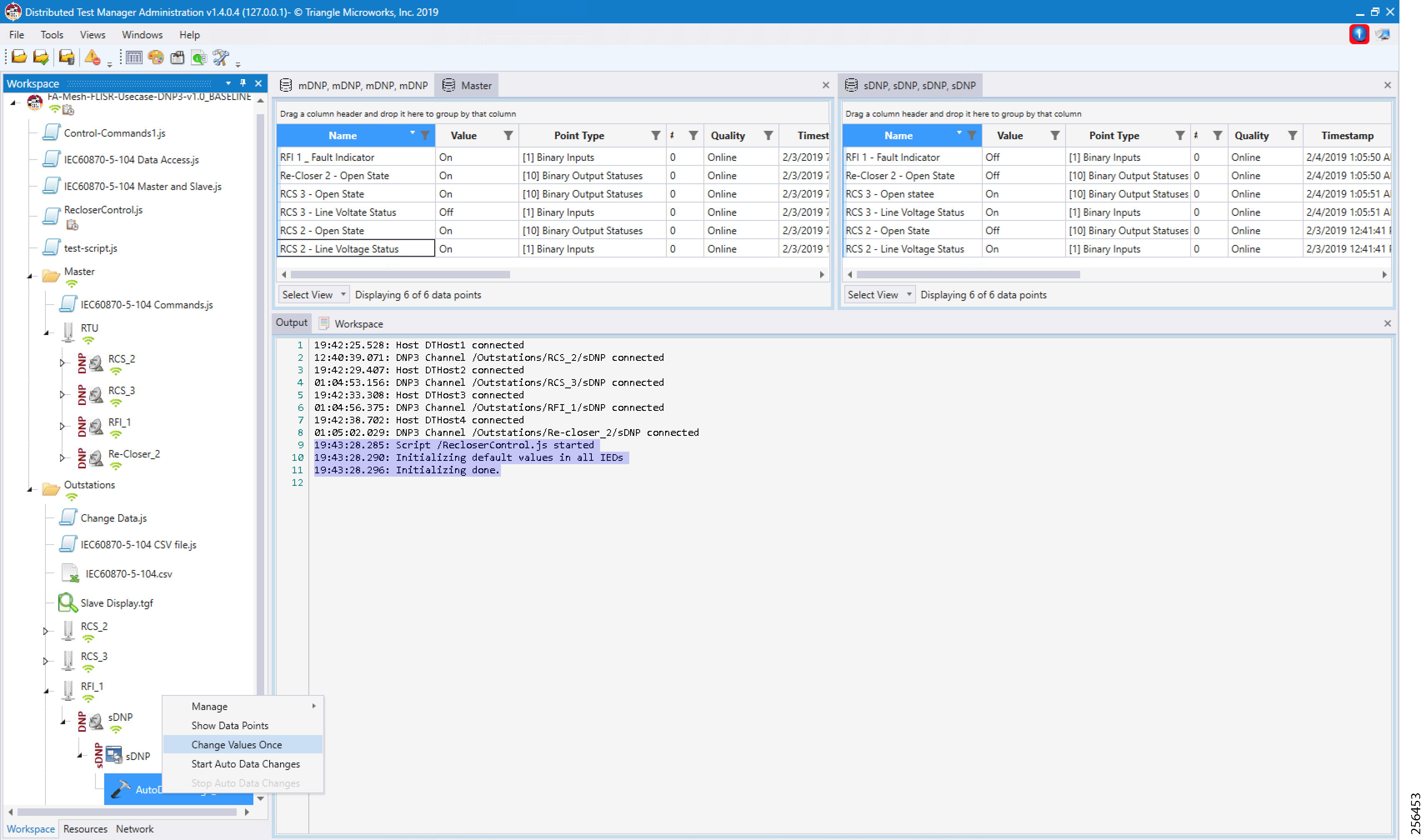

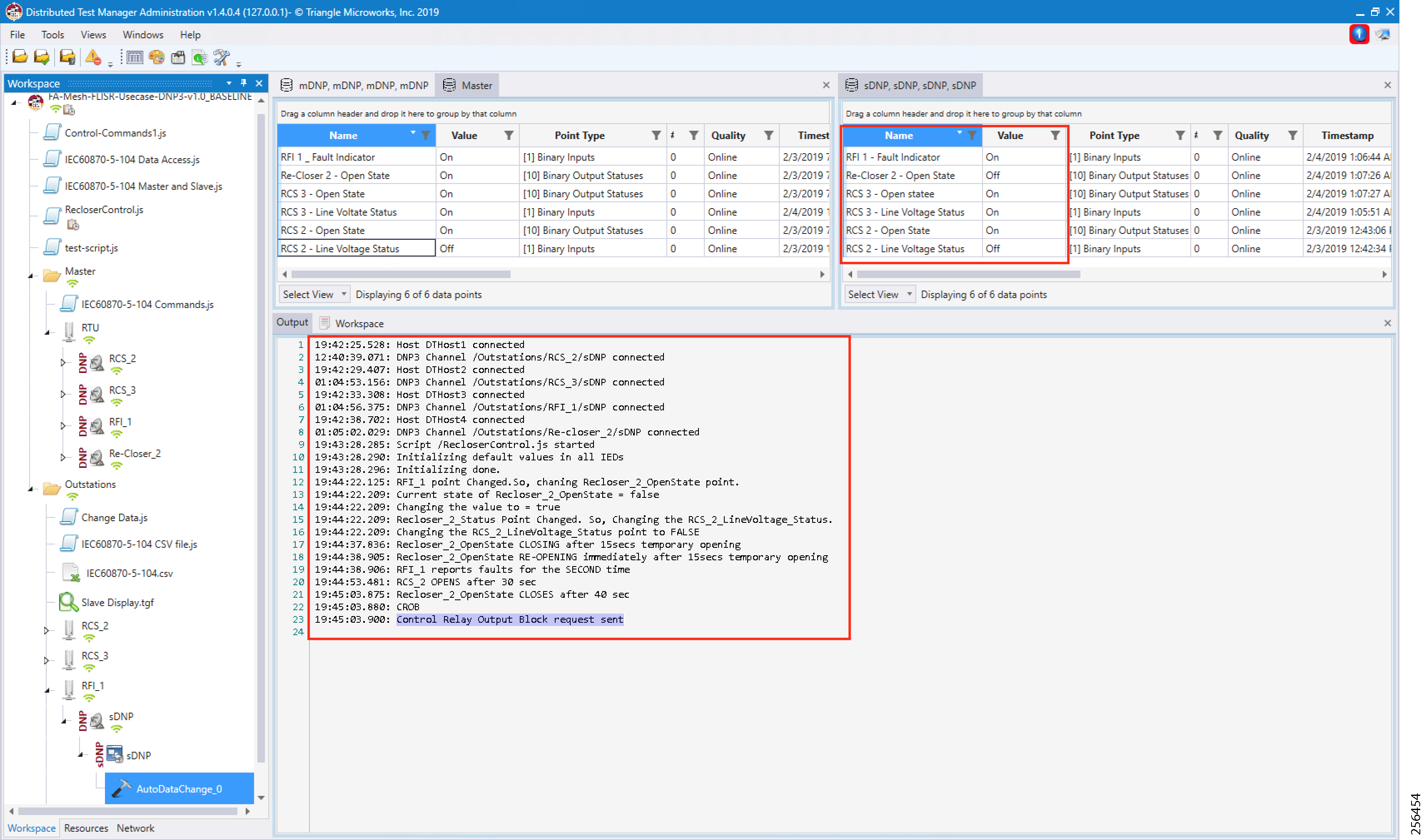

■![]() The Utility Controller Devices Block, in which the Utility controller devices (real/simulated) are connected to the Cisco DA Gateways (Cellular DA Gateway or Mesh DA Gateway) over an Ethernet/Serial interface. The following components are simulated using the Triangle Micro Works (Distributed Test Manager or DTM) tool:

The Utility Controller Devices Block, in which the Utility controller devices (real/simulated) are connected to the Cisco DA Gateways (Cellular DA Gateway or Mesh DA Gateway) over an Ethernet/Serial interface. The following components are simulated using the Triangle Micro Works (Distributed Test Manager or DTM) tool:

–![]() SCADA Master located in DSO Control Center

SCADA Master located in DSO Control Center

–![]() IEDs located in the Utility Controller Devices Block layer

IEDs located in the Utility Controller Devices Block layer

■![]() The NAN Block, which is comprised of three Personal Area Networks (PANs):

The NAN Block, which is comprised of three Personal Area Networks (PANs):

PAN3 has been validated over LTE backhaul. PAN1 and PAN2 have been validated over Ethernet backhaul. Cisco IOx Edge Compute functionality has been validated over PAN2. Fog Director (FD) located in the DSO control center has been used for the lifecycle management of Edge compute applications on the IOx platform of CR Mesh DA Gateway.

For implementation involving dual control scenarios, please refer to the Distribution Automation - Feeder Automation Implementation Guide.

IPv4 and IPv6 Addressing

This section, which provides detail about the addressing used at every layer of the Figure 1 Cisco DA Feeder Automation solution validation topology, includes the following sections:

■![]() Addressing in the DSO Control Center Block

Addressing in the DSO Control Center Block

Addressing in the DSO Control Center Block

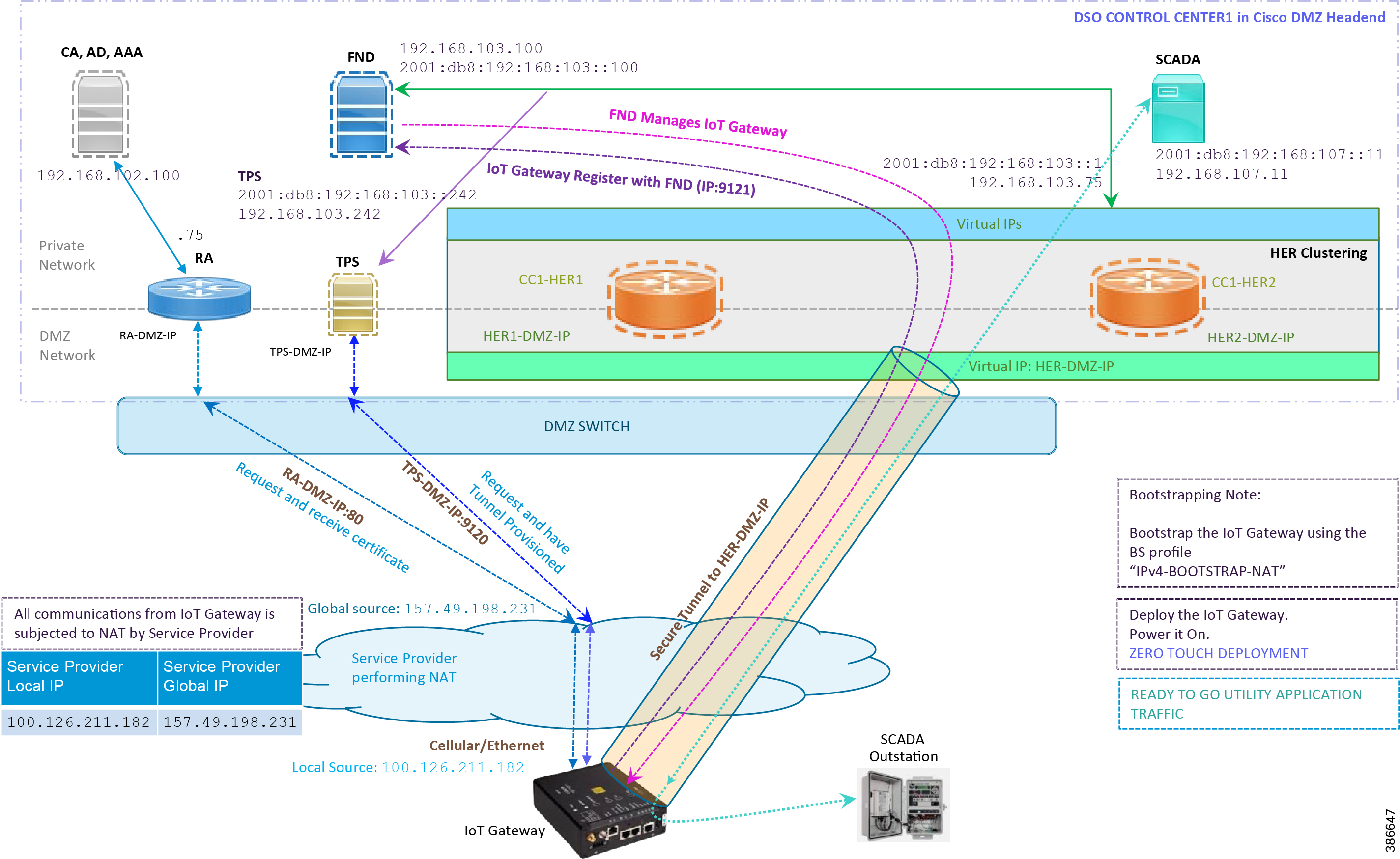

Figure 4 captures the granular details of the DSO Control Center.

Figure 4 DSO Control Center Block—Zoom In

The DSO Control Center is comprised of two types of network: the Private Network and the DMZ Network

■![]() The Private Network hosts an UCS server (with all the required head end components like FND, Certificate Authority, DHCP server, and so on), SCADA Master as well as Fog Director. Private Network leverages the Cisco NTP for time synchronization, as well as Cisco DNS servers for name resolution.

The Private Network hosts an UCS server (with all the required head end components like FND, Certificate Authority, DHCP server, and so on), SCADA Master as well as Fog Director. Private Network leverages the Cisco NTP for time synchronization, as well as Cisco DNS servers for name resolution.

■![]() The DMZ Network hosts a cluster of Headend Routers (ASR 1000), TPS, and Registration Authority. These components connect to the DMZ Network on one side and the Private Network on the other side.

The DMZ Network hosts a cluster of Headend Routers (ASR 1000), TPS, and Registration Authority. These components connect to the DMZ Network on one side and the Private Network on the other side.

For more details about implementing the headend in the DSO Control Center, please refer to the Cisco FAN-Headend Deep Dive Implementation and FAN Use Cases Guide.

Addressing in the Private Network

Table 1 captures the addressing details of the components located in the private network of DSO Control Center.

Addressing in the DMZ Network

The previous topology in Figure 4 shows that components that are located in the DMZ Network (reachable over WAN) include the following:

■![]() Tunnel Provisioning Server (TPS)

Tunnel Provisioning Server (TPS)

■![]() HER Cluster of ASR 1000 series of routers

HER Cluster of ASR 1000 series of routers

Table 2 captures the addressing details of the components located in the DMZ network of DSO Control Center.

Note: The Virtual IP for FAN-PHE-HER1, FAN-PHE-HER2, and FAN-PHE-HER3 is 10.10.100.100.

Addressing in the WAN Block

The Public IP WAN has been validated in this implementation guide. Addressing in the WAN block is typically service provider managed. As long as the Cisco FARs or Cisco Cellular IoT Gateways in the Distribution Block receive a dynamically-assigned IP address from the service provider and are able to reach the components in the DMZ network, the requirement would be met.

Addressing in the Distribution Block

Addressing in the Distribution blocks is discussed granularly in the following sections:

■![]() Addressing used in Cisco Cellular DA Gateways

Addressing used in Cisco Cellular DA Gateways

Addressing used in Cisco Cellular DA Gateways

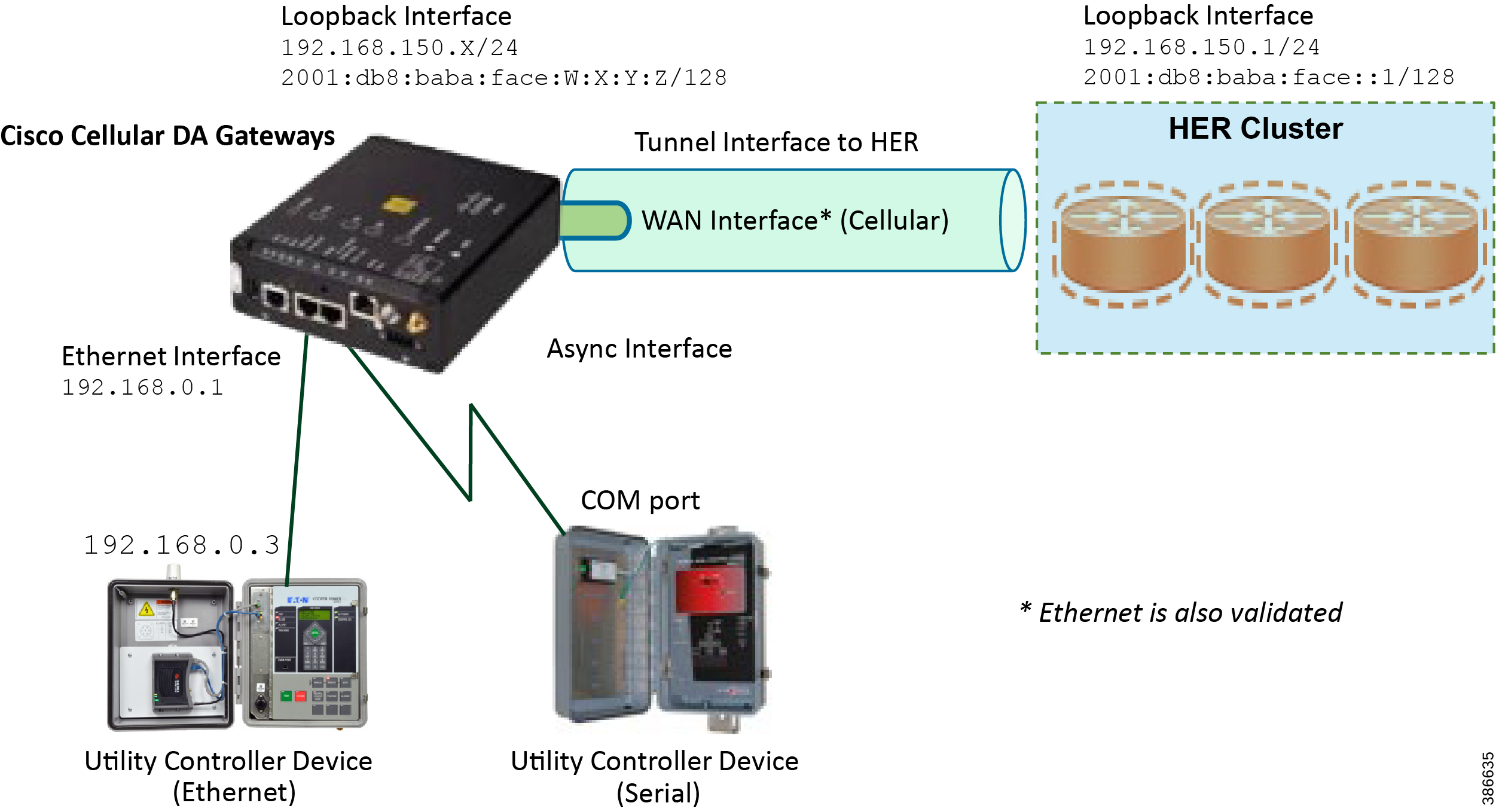

Figure 5 captures the various interfaces on the Cisco Cellular DA Gateways that are involved in the solution.

Figure 5 Addressing used in Cisco Cellular DA Gateways 256396

Table 3 captures the addressing used in Cisco Cellular DA Gateways.

Note: Some Cisco FAR devices available are CGR1120, CGR1240, IR1101 and IR807.

Addressing used in Cisco Field Area Routers

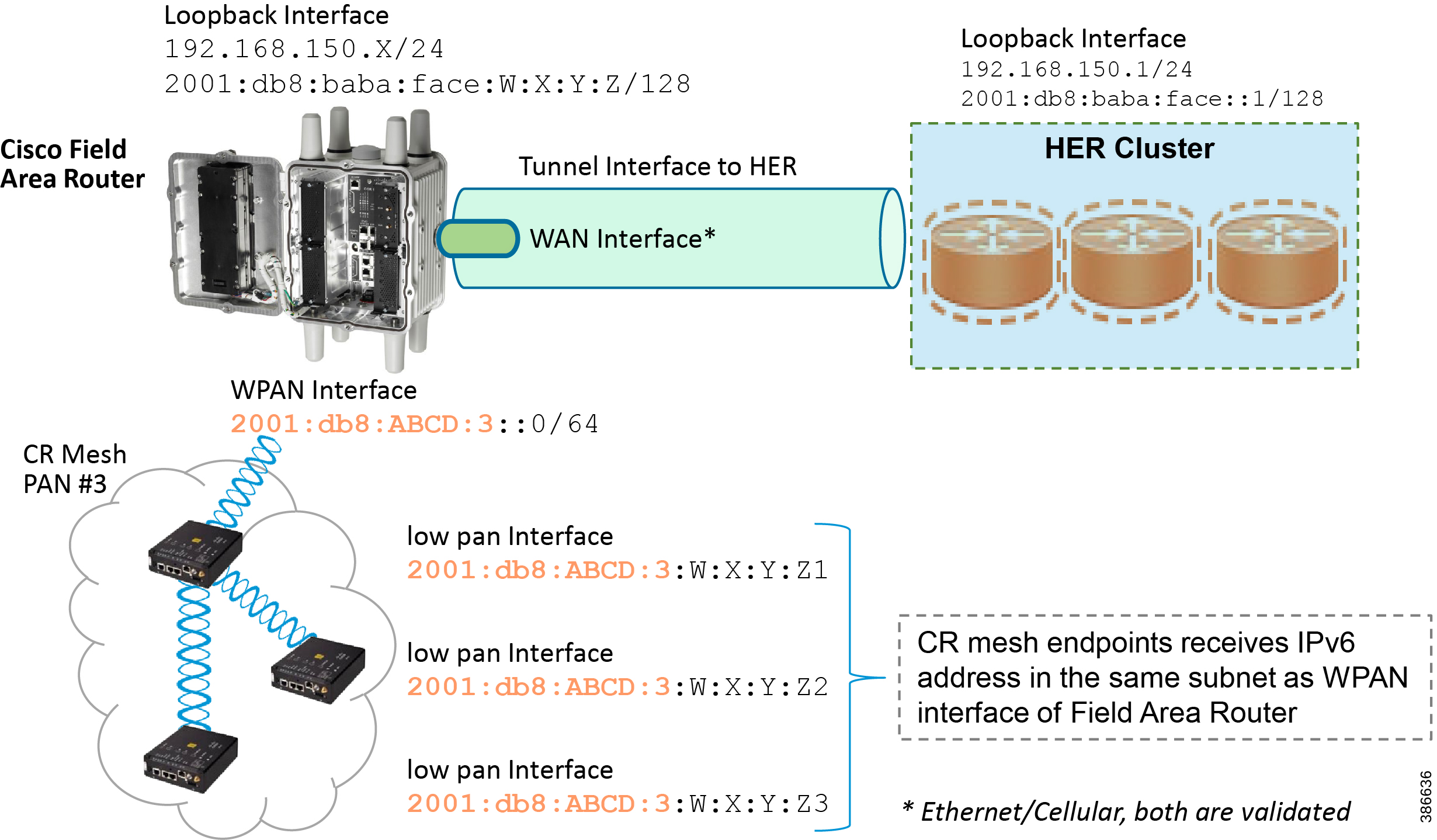

Figure 6 captures the various interfaces on the Cisco FARs that are involved in the solution.

Figure 6 Addressing used in Cisco Field Area Routers

Table 4 captures the various interfaces used in the Cisco FAR and its associated addressing.

Addressing used in Cisco Resilient Mesh DA Gateways

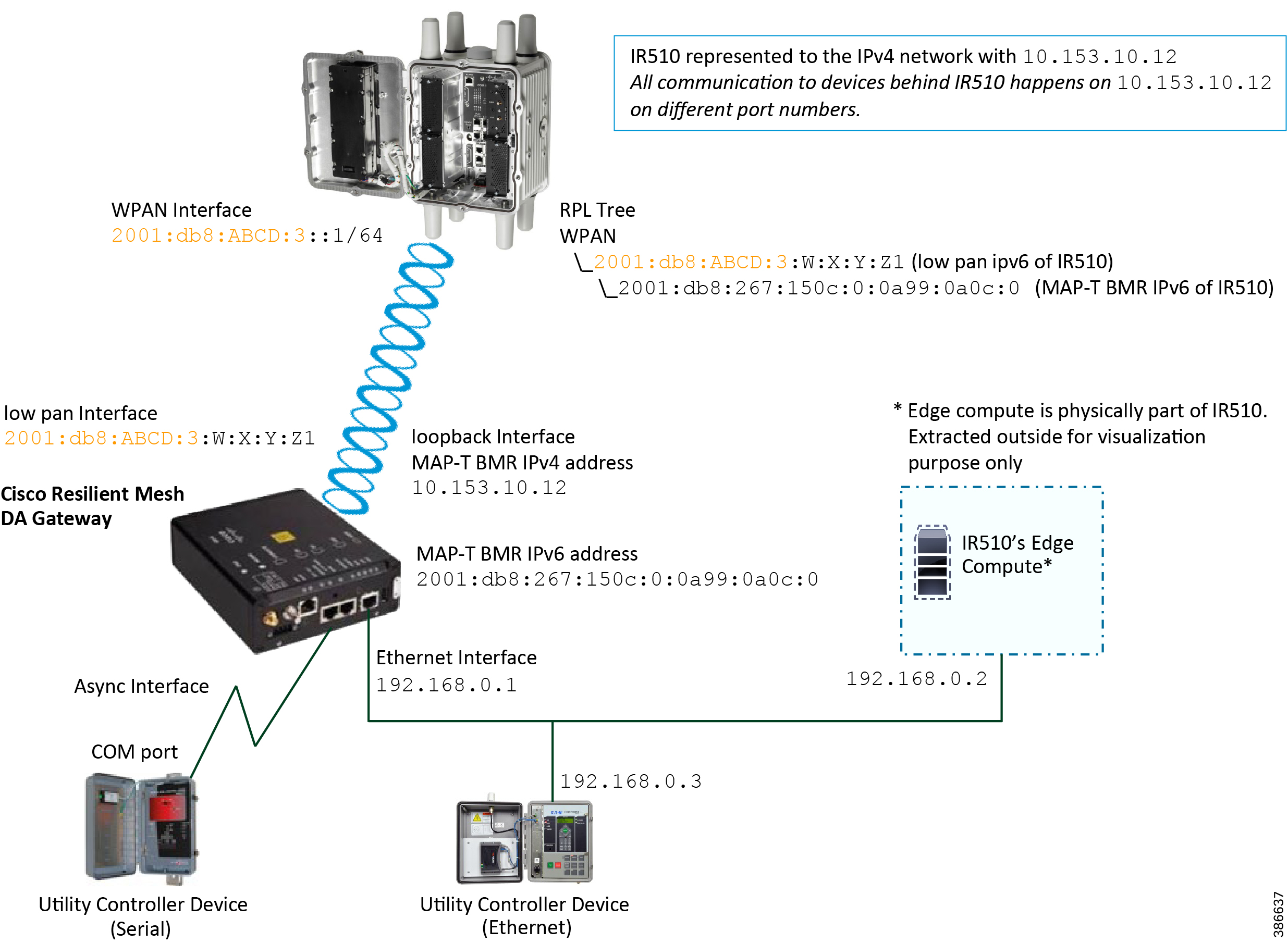

Figure 7 captures the various interfaces on the Cisco Resilient Mesh DA Gateways that are used in this solution.

Figure 7 Addressing used in Cisco Resilient Mesh DA Gateways

IR510 receives the IPv6 address for the LoWPAN interface from CGR. The IPv6 address of IR510 LoWPAN interface and the CGR WPAN interface are on the same IPv6 subnet. The CGR would serve as the default gateway for IR510.

Table 5 captures the various interfaces used in the CR Mesh DA Gateway and its associated addressing.

Addressing in the Utility Controller Devices Block

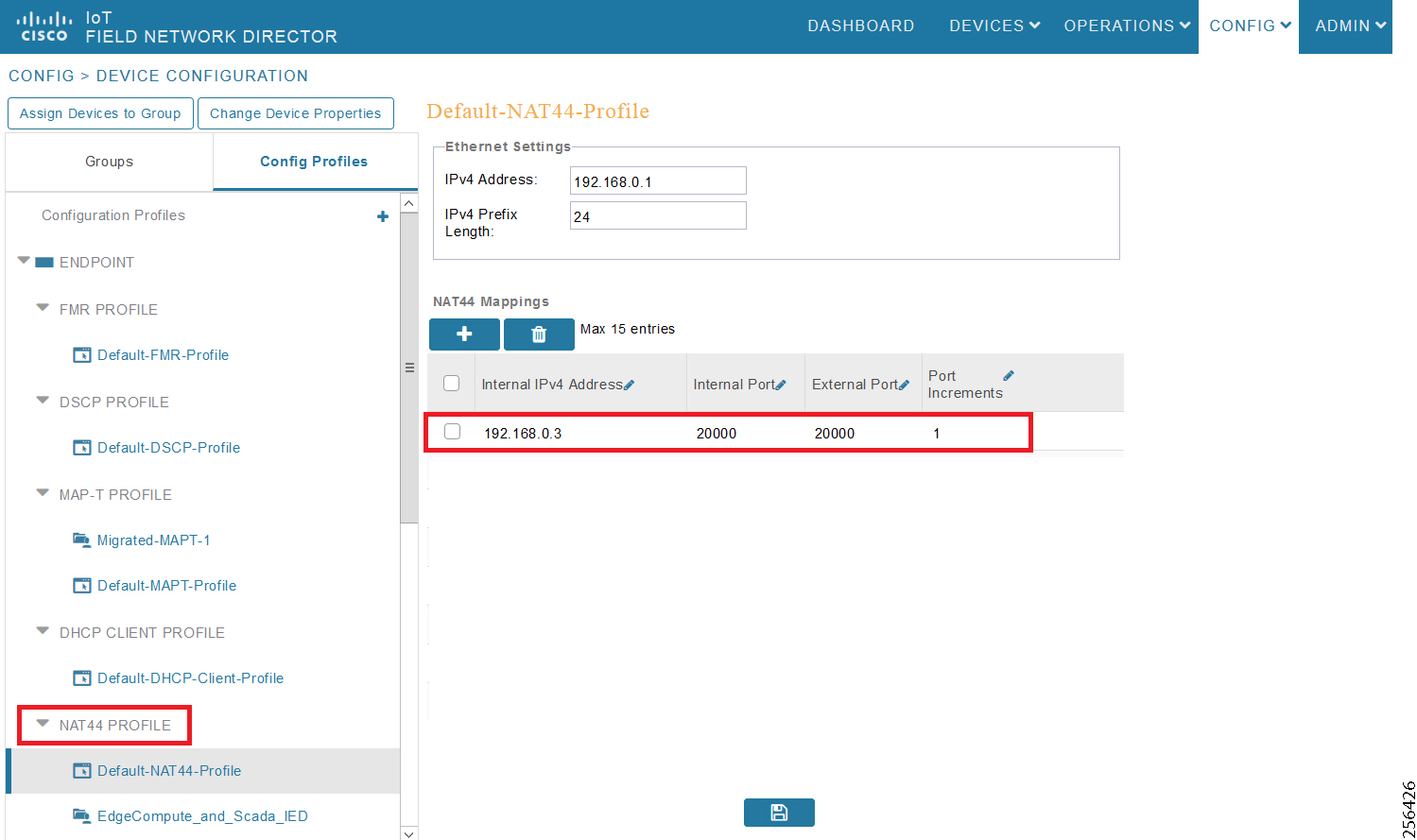

The Ethernet-based Utility Controller devices is to be configured with 192.168.0.3. It can be connected to the Ethernet ports of the Cisco Cellular DA Gateway or the CR Mesh DA Gateway. In this implementation, controller devices were simulated using Triangle Micro Works (Distributed Test Manager) tool. This simulated controller device is configured with 192.168.0.3 during this validation.

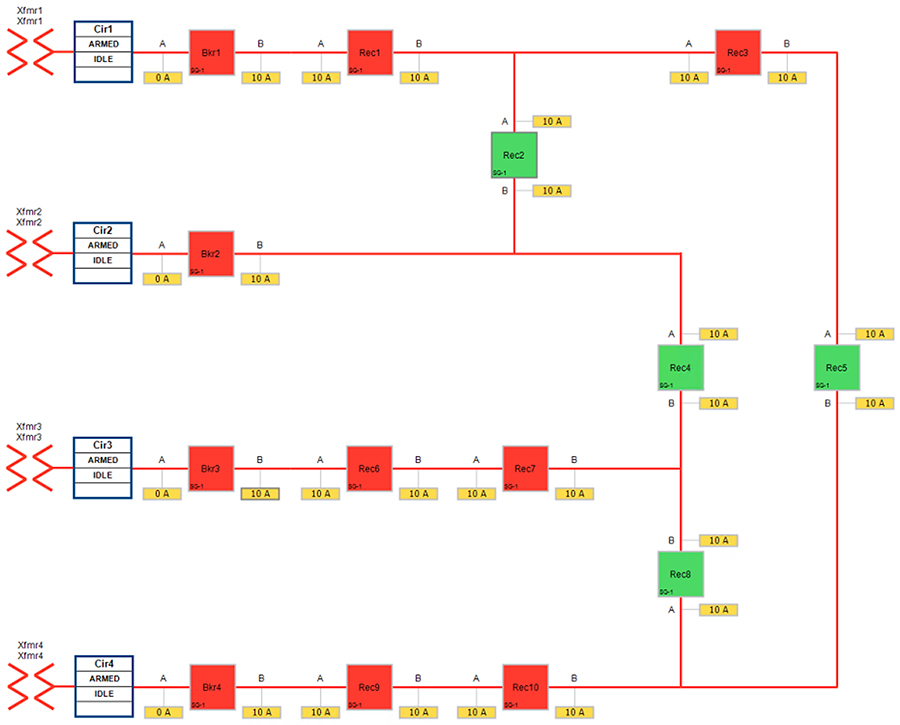

Solution Network Topology and Addressing for FLISR validation

This chapter, which focuses on the network topology used for solution validation and implementation of the Cisco DA 2.0 FLISR solution and the addressing (both IPv4 and IPv6) used in this implementation, includes the following major topics:

■![]() Topology Diagram for FLISR, page 5

Topology Diagram for FLISR, page 5

■![]() IPv4 and IPv6 Addressing, page6

IPv4 and IPv6 Addressing, page6

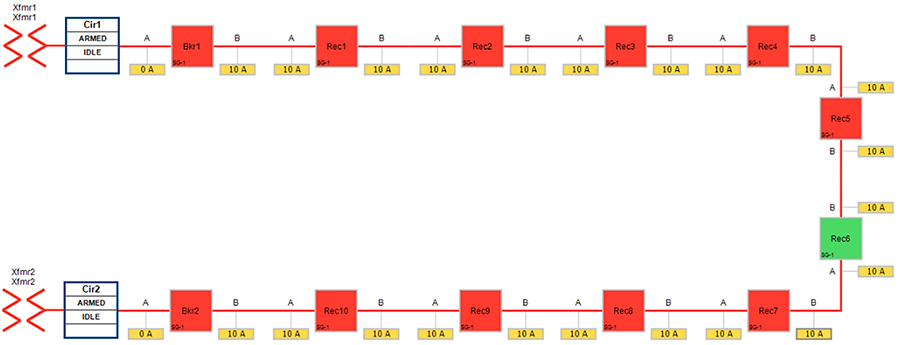

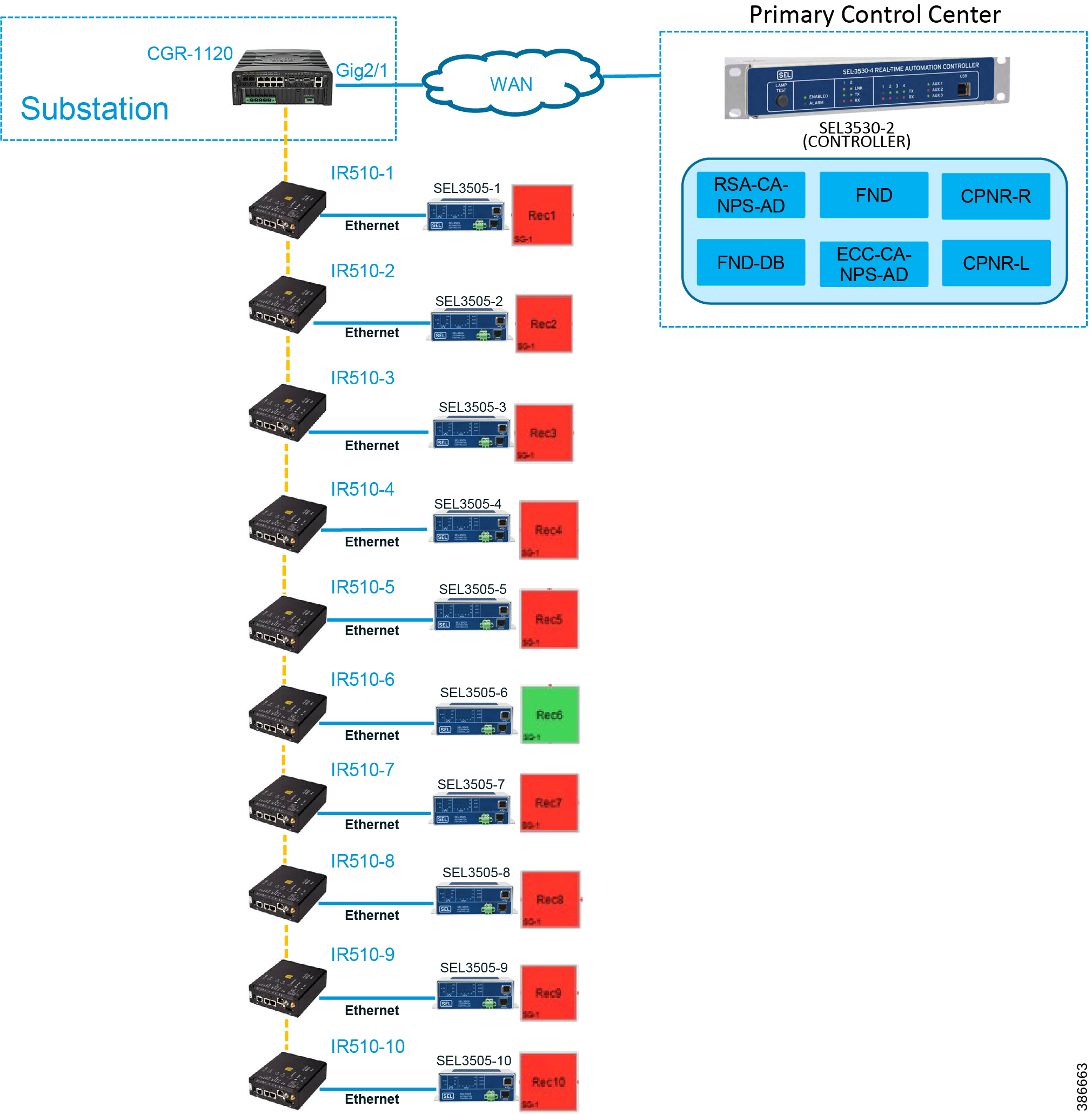

SEL FLISR solution is validated over Cisco Resilient Mesh on two different topologies. One is linear CR mesh with depth of 10 hops, which is typical rural deployment scenario and the second topology is aggregate CR mesh with depth of four rank nodes and four nodes connected at each rank level, Aggregate mesh is typically used in urban deployment scenario. For more details of these two types of deployment scenario, refer to Distribution Automation 2.0 – Feeder Automation Design Guide document.

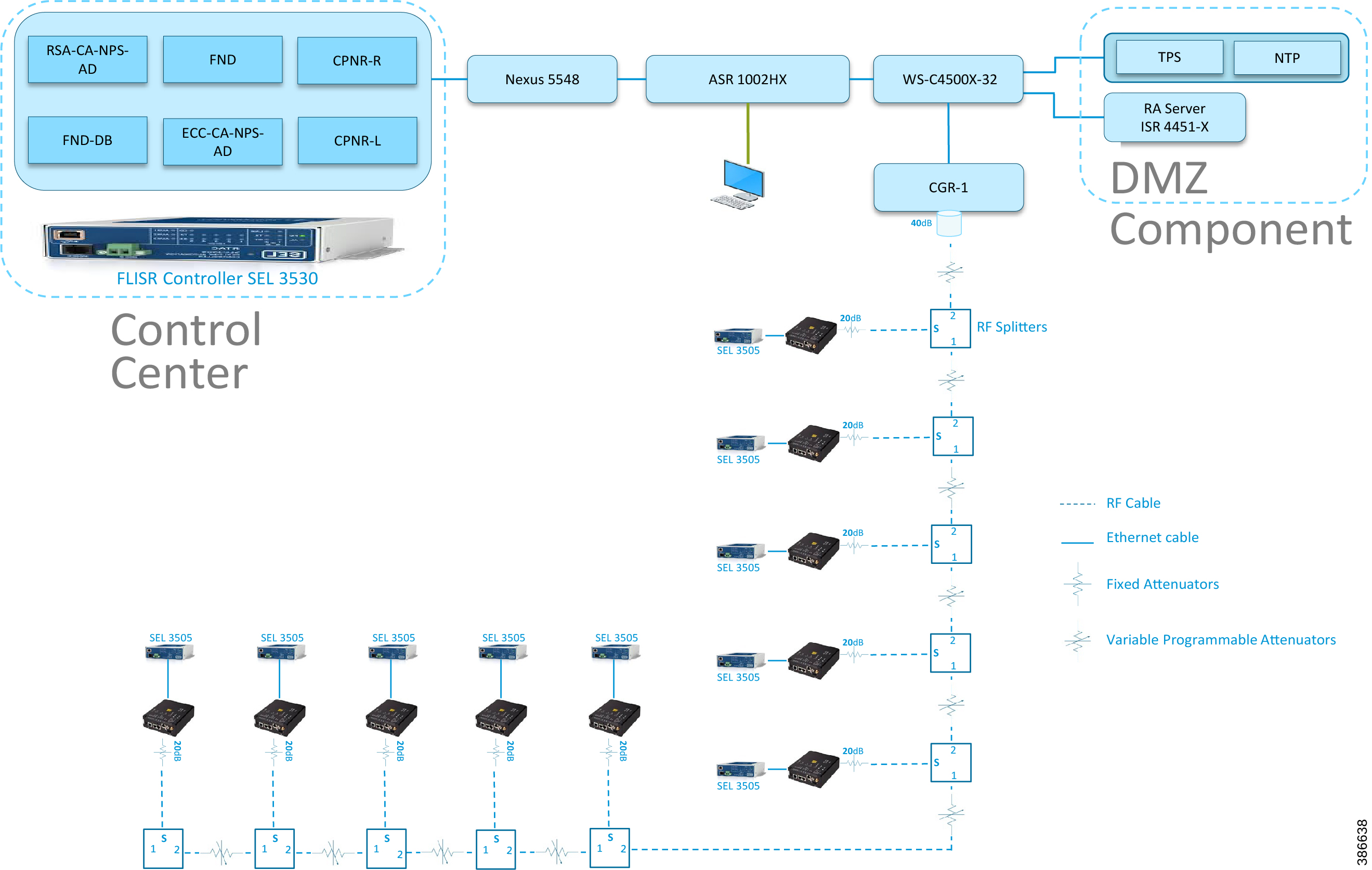

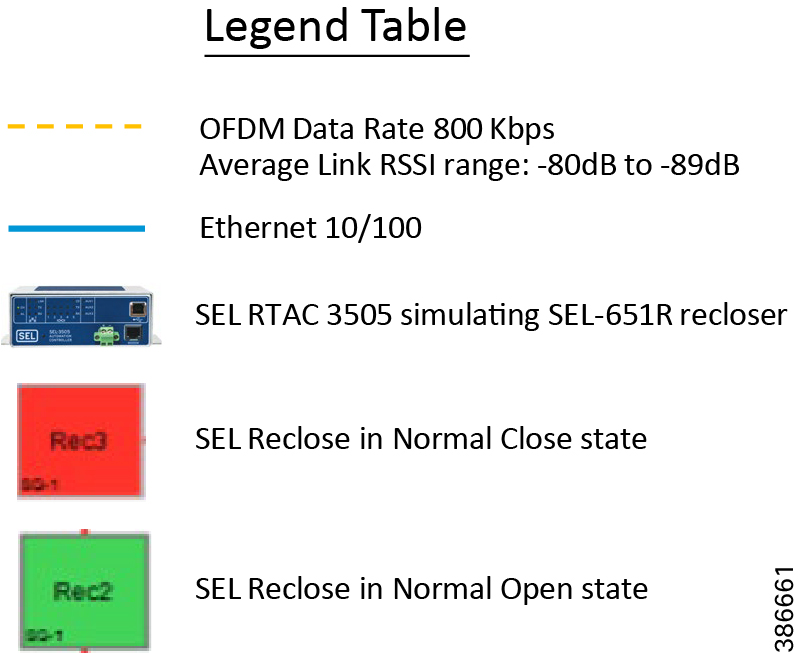

Topology Diagram for FLISR

This Linear and Aggregated Mesh topology constructed using RF coax cables, power splitters and attenuators, enabling signal variations to construct a 10-hop linear and 23 nodes aggregated mesh network. In mesh network nodes that can hear each other, in that the RSSI (Reverse Signal Strength Indication) is within the acceptable range for a specific modulation (OFDM) fixed modulation and data rate established between parent, child, and neighbor nodes.

The RF connectivity between the DA gateways designed for IEEE 802.15.4 Option 2 (OFDM fixed modulation PHY mode149 on Cisco Resilient Mesh) which corresponds to a physical layer data rate of 800kbps. The OFDM 800kbps maximum Receive Signal Strength Indicator (RSSI) is -101db. To avoid node flapping and instability in the network a new node joining the mesh network for the first time must have minimum RSSI of -91db with respect to its neighbor. So, for a best practice design rule that the link between DA devices is designed the average link RSSI range between -70db to -90db.

The mesh radio parameter configured using IEEE 802.15.4g and Routing Protocol for Low Power and Lossy Networks (RPL) timers. Mesh is also configured to operate in Storing Mode to support peer to peer communication.

This section describes the solution validation topology that has been used in this DA 2.0 FLISR Implementation Guide.

Linear Mesh lab topology for FLISR

In linear topology each node has two neighbors, one parent from upper rank close to CGR and one child from lower rank. The RSSI also designed for same RSSI range as showing in the topology. On lower ranks, as the hop counts increase, the latency values also increase due to each node adds its own processing delays. So the end to end, i.e. each hop to control center path delay will be longer.

Figure 8 depicts the DA 2.0 Linear Mesh Lab Topology.

Figure 8 Linear Mesh lab topology diagram

In the linear topology, fixed and variable attenuators are added to achieve an RSSI range of -70 to -90dB. RF Splitters are added at appropriate RF links, as shown in above lab topology figure, for creating a linear CR mesh.

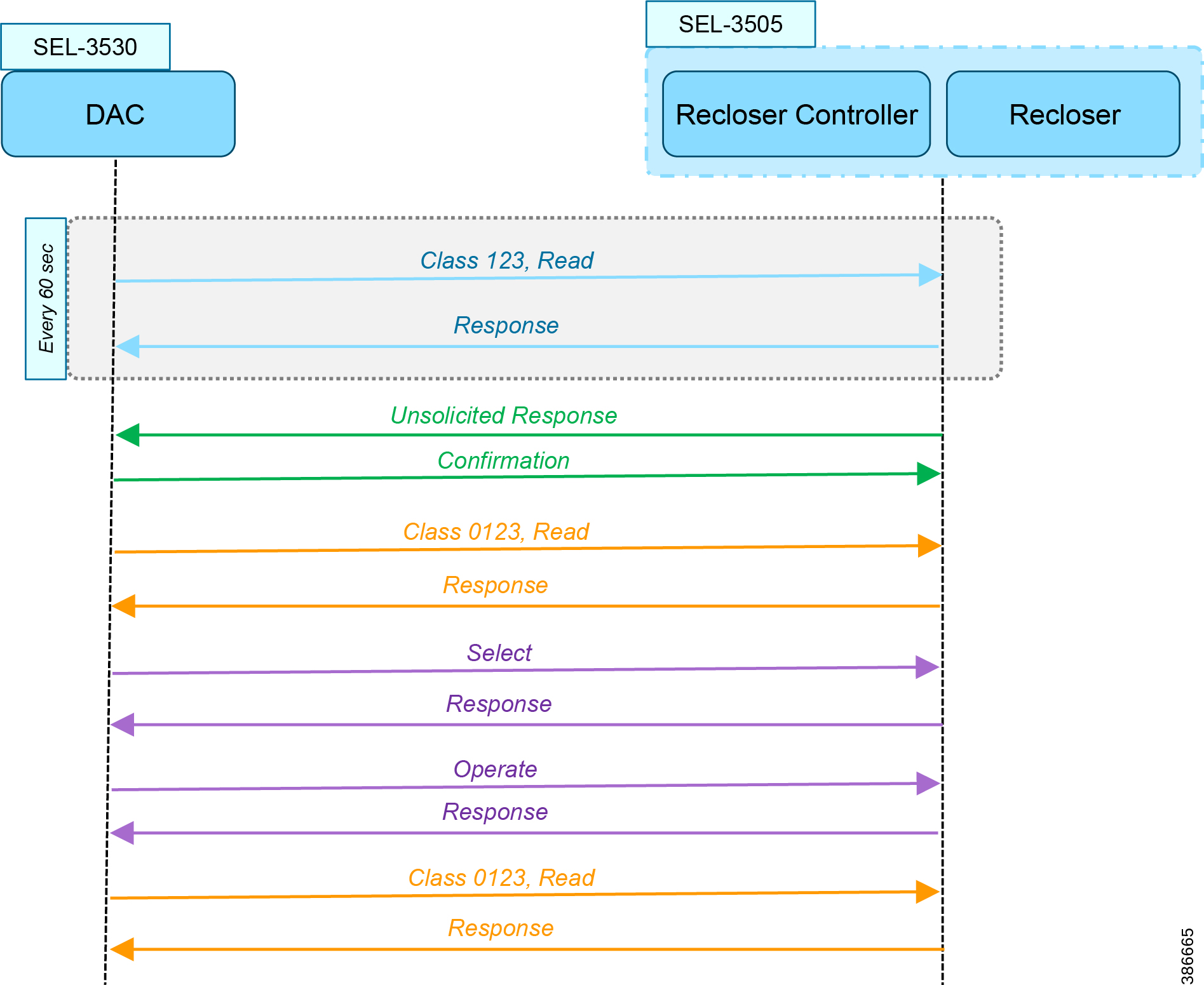

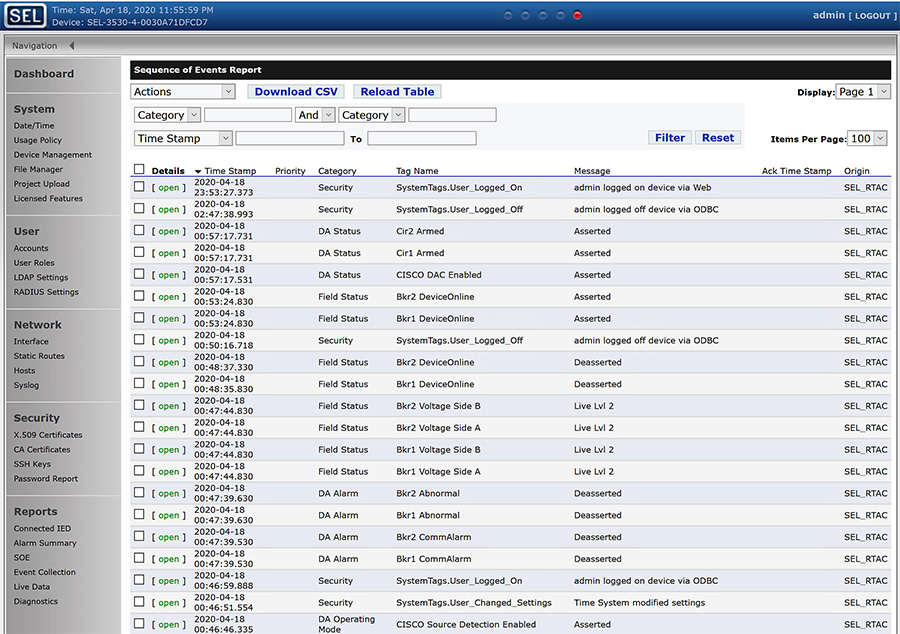

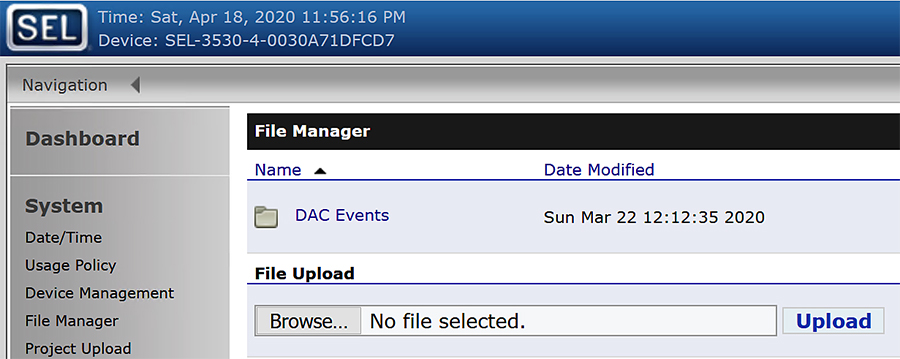

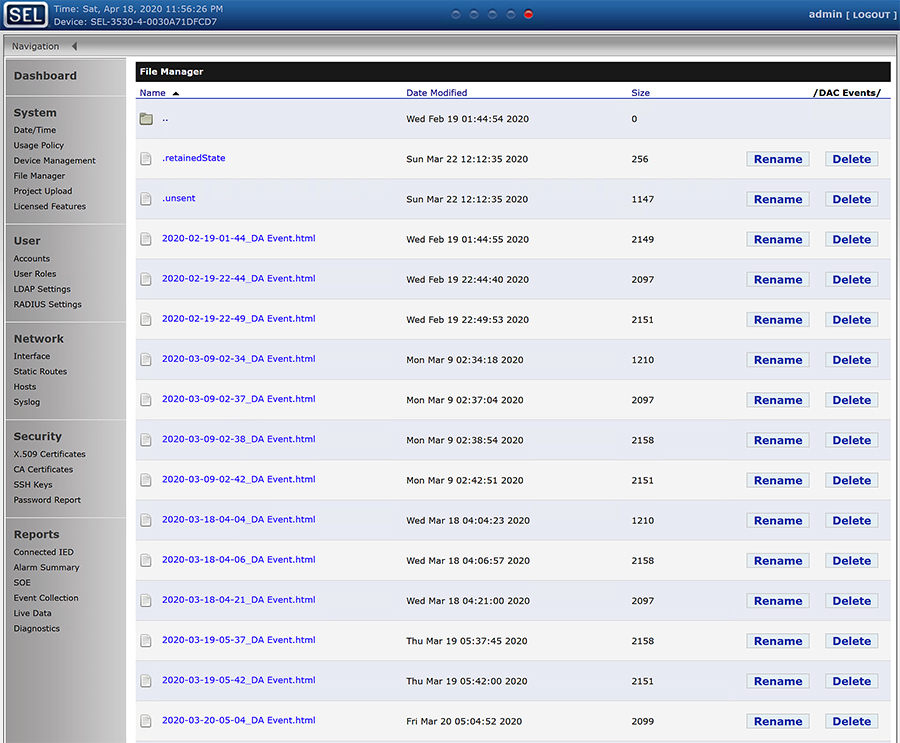

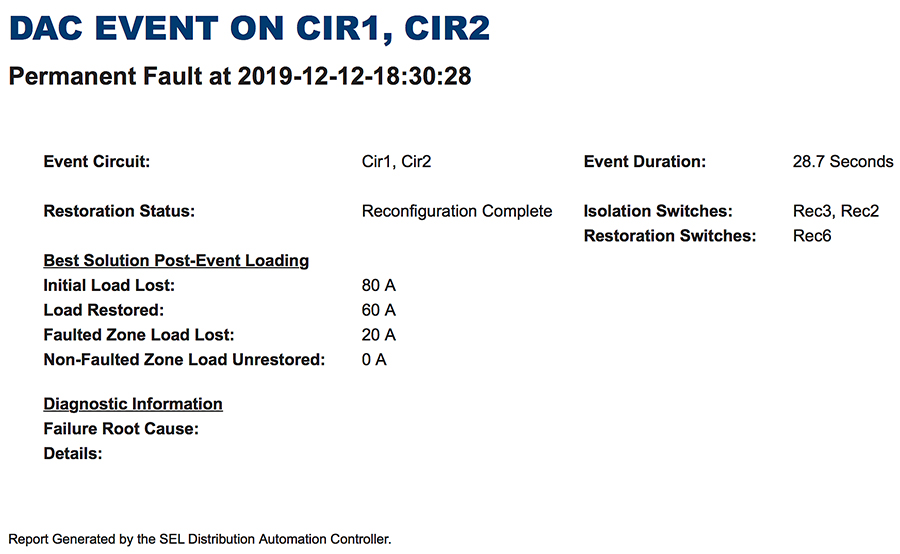

Each SEL-3505 RTAC is connected to each IR510 device via Ethernet connection. SEL-3530 RTAC, which act as a SCADA Master and DAC Controller is located in Control Center.

Refer to Addressing in the DSO Control Center Block section for the Control Center details.

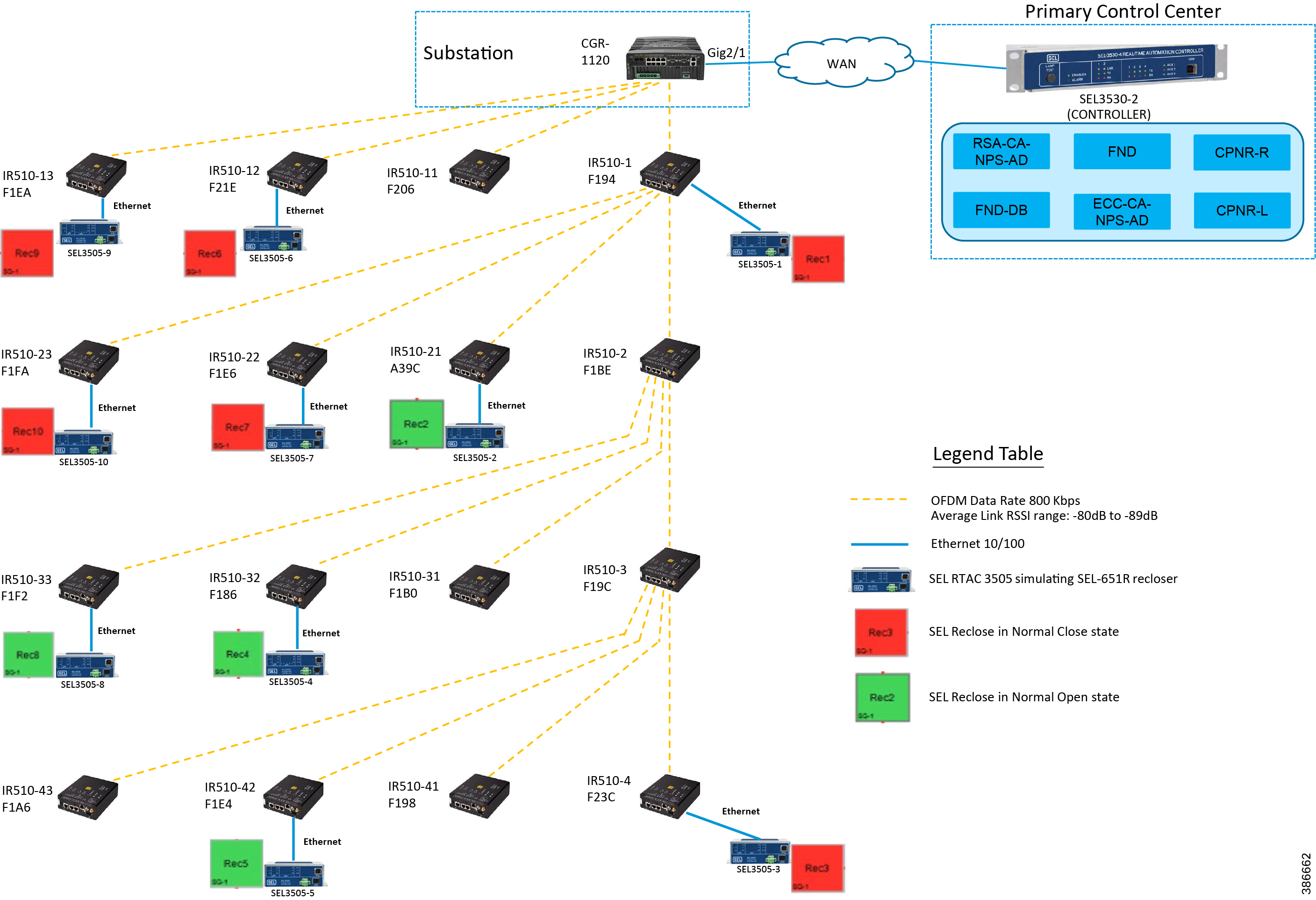

Aggregated Mesh lab topology for FLISR

In aggregate topology the distance between DA Grid device is shorter and nodes can aggregate traffic from multiple children. The ratio of child to parent is higher and the parent available bandwidth is shared among the children. To simulate this network the 2nd, 3rd, and 4th rank nodes were designed to establish physical layer 1 connection with first node of parent rank. The aggregation topology can be designed in multiple way to select their parent, limitations are applied due to lab environment and worst conditions. Refer to the topology for this implementation.

Note: This implementation is purely based on the topology provided in this section.

Figure 9 depicts the DA 2.0 Aggregated Mesh Lab Topology.

Figure 9 Aggregate Mesh lab topology diagram

In the aggregate topology, fixed and variable attenuators are added to achieve an RSSI range of -70 to -90dB. RF Splitters are added at appropriate RF links, as shown in above lab topology figure, for creating a linear CR mesh.

Each SEL-3505 RTAC is connected to each IR510 device via ethernet connection. SEL-3530 RTAC, which act as a SCADA Master and DAC Controller is located in Control Center.

Refer to DSO Control Center Block section for the Control Center details.

IPv4 and IPv6 Addressing

For general and complete IPv4 and IPv6 addressing please refer to the “Solution Network Topology and Addressing” section in this document. The specific FLISR configurations are shown below.

Table 6 Additional components for Field Block for FLISR

|

|

|

|

|---|---|---|

|

|

|

|

CGR 1240 Configuration

Please refer to Zero Touch Enrollment of Cisco Resilient Mesh Endpoints for IR510 device.

IoT Gateway Onboarding and Management

This chapter includes the following major topics:

■![]() Tunnel Provisioning Server/Field Network Director Categories

Tunnel Provisioning Server/Field Network Director Categories

■![]() Bootstrapping the IoT Gateway

Bootstrapping the IoT Gateway

■![]() Deployment of the Cisco IoT Gateway

Deployment of the Cisco IoT Gateway

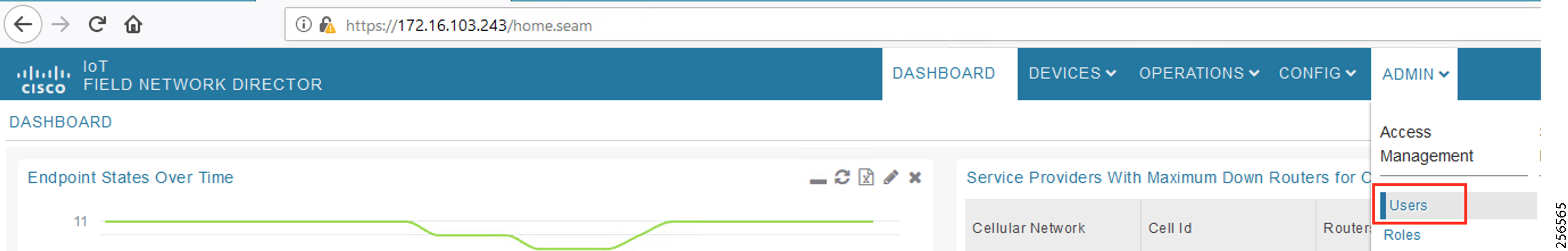

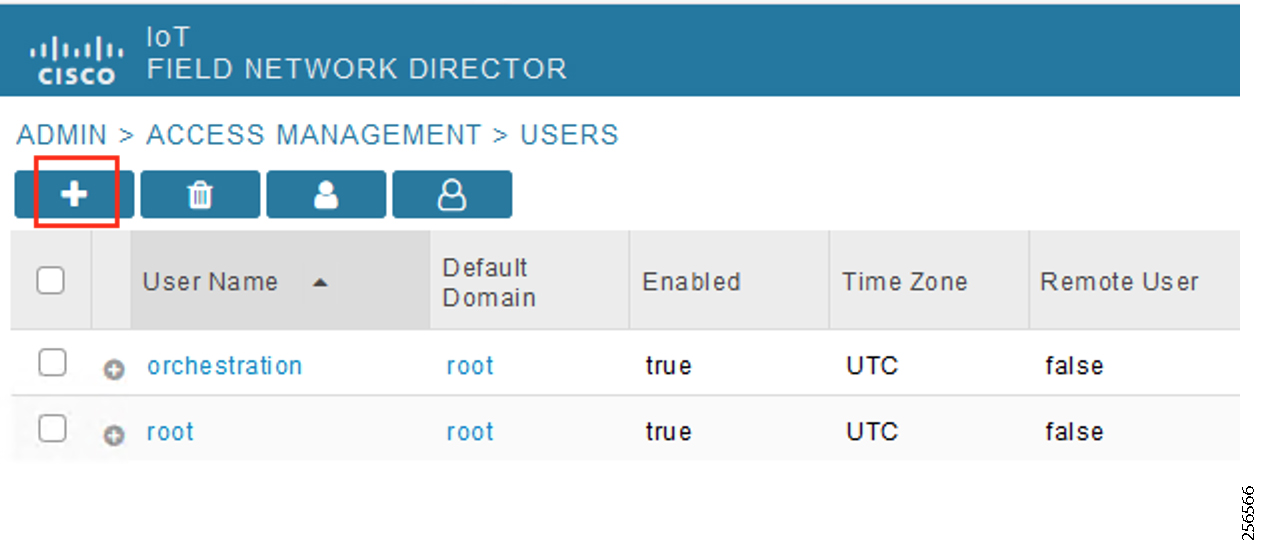

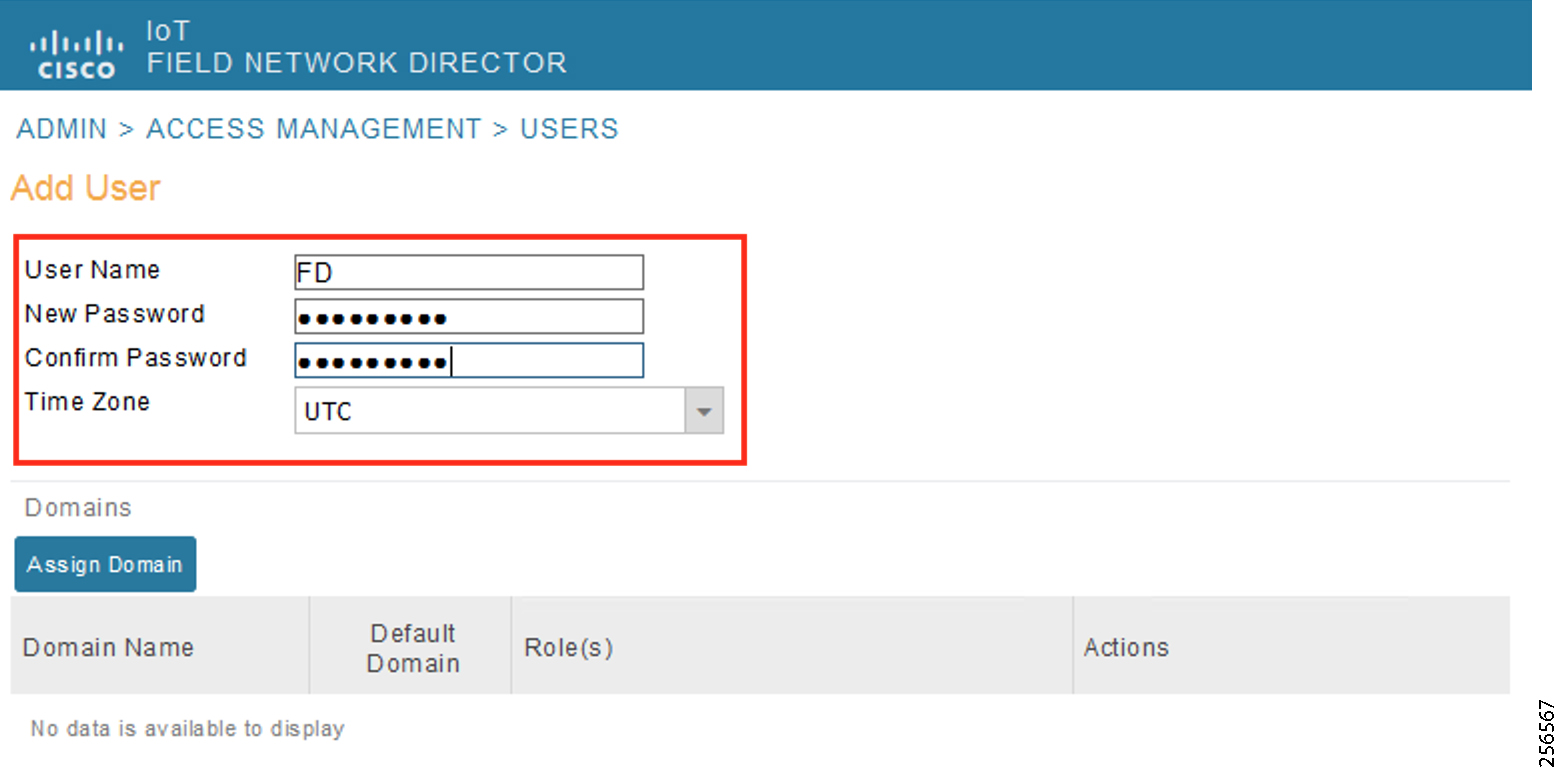

FND is used as the NMS in this solution. In this implementation guide, the terminology “IoT Gateway” is used to refer to both Cisco Cellular DA Gateways and Cisco FARs.

IoT Gateway Onboarding has been made very simple by following the steps below:

1.![]() Unpack the box containing the new IoT Gateway.

Unpack the box containing the new IoT Gateway.

2.![]() Use plug-and-play (PnP) infrastructure to bootstrap.

Use plug-and-play (PnP) infrastructure to bootstrap.

3.![]() After bootstrapping, power off the IoT Gateway and deploy at the desired location.

After bootstrapping, power off the IoT Gateway and deploy at the desired location.

4.![]() Power on the IoT Gateway for Zero Touch Deployment (ZTD).

Power on the IoT Gateway for Zero Touch Deployment (ZTD).

5.![]() The device is fully operational.

The device is fully operational.

As part of IoT Gateway onboarding with ZTD, the IoT Gateways are registered with the FND. From that point on, the FND located in the Control Center is used to remotely monitor/manage/troubleshoot the IoT Gateways, which are spread across the entire Distribution Automation network. This process has three phases:

3.![]() Remote Monitor/Manage/Troubleshoot the IoT Gateway.

Remote Monitor/Manage/Troubleshoot the IoT Gateway.

The two different approaches to bootstrapping and deployment of the IoT Gateway are:

■![]() Approach 1—IoT Gateway bootstrapped in staging location, deployed in a different location

Approach 1—IoT Gateway bootstrapped in staging location, deployed in a different location

■![]() Approach 2—IoT Gateway bootstrapped in deployment location

Approach 2—IoT Gateway bootstrapped in deployment location

Both approaches are now supported by Cisco IoT Gateways and this guide.

With Approach 1, bootstrapping of the IoT Gateways is done at the dedicated staging location. Once the devices are bootstrapped successfully, they are powered off and transported to the final deployment locations, where the devices are deployed and powered on.

With Approach 2, bootstrapping of the IOT Gateways is done at the deployment location. Once the devices are bootstrapped successfully, the ZTD process begins and no manual intervention is required.

Tunnel Provisioning Server/Field Network Director Categories

Bootstrapping TPS/FND

The TPS/FND located in the staging/bootstrapping environment that helps with PnP bootstrapping of the IoT Gateways are referred to as the bootstrapping TPS and bootstrapping FND.

Network Operating Center

The TPS/FND located in the NOC/Control Center environment that helps with ZTD of IoT Gateways is referred to as the NOC or Control Center TPS/FND. This TPS/FND located in the DSO Control Center helps with management of the IoT Gateways.

Note: The bootstrapping TPS/FND could be the same as or different from the NOC TPS/FND depending on the chosen approach.

Since Approach 1 is chosen for implementation in this guide, two different pairs of TPS/FND have been implemented:

For general implementation of TPS/FND, please refer to the detailed steps covered in the following sections of the Cisco FAN-Headend Deep Dive Implementation and FAN Use Cases Guide:

■![]() Implementing Tunnel Provisioning Server

Implementing Tunnel Provisioning Server

■![]() Implementing Field Network Director

Implementing Field Network Director

The Cisco IoT Field Network Director Installation Guide could also be referred to for implementation of TPS/FND.

Note: This guide focuses on the implementation details for enhancing the TPS/FND servers to also serve the functionality of Bootstrapping TPS and Bootstrapping FND.

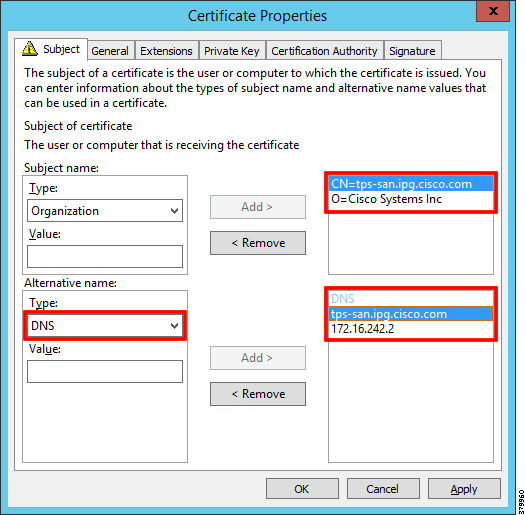

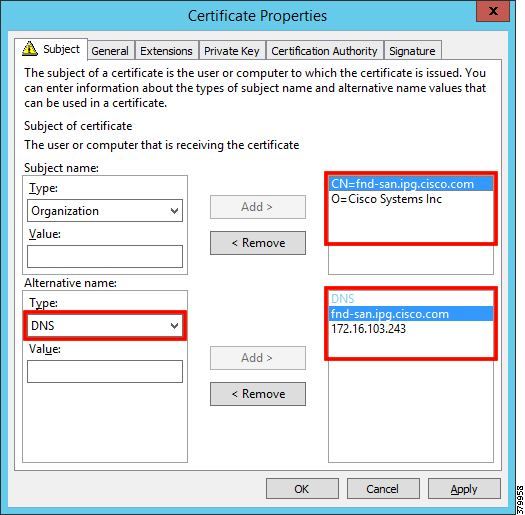

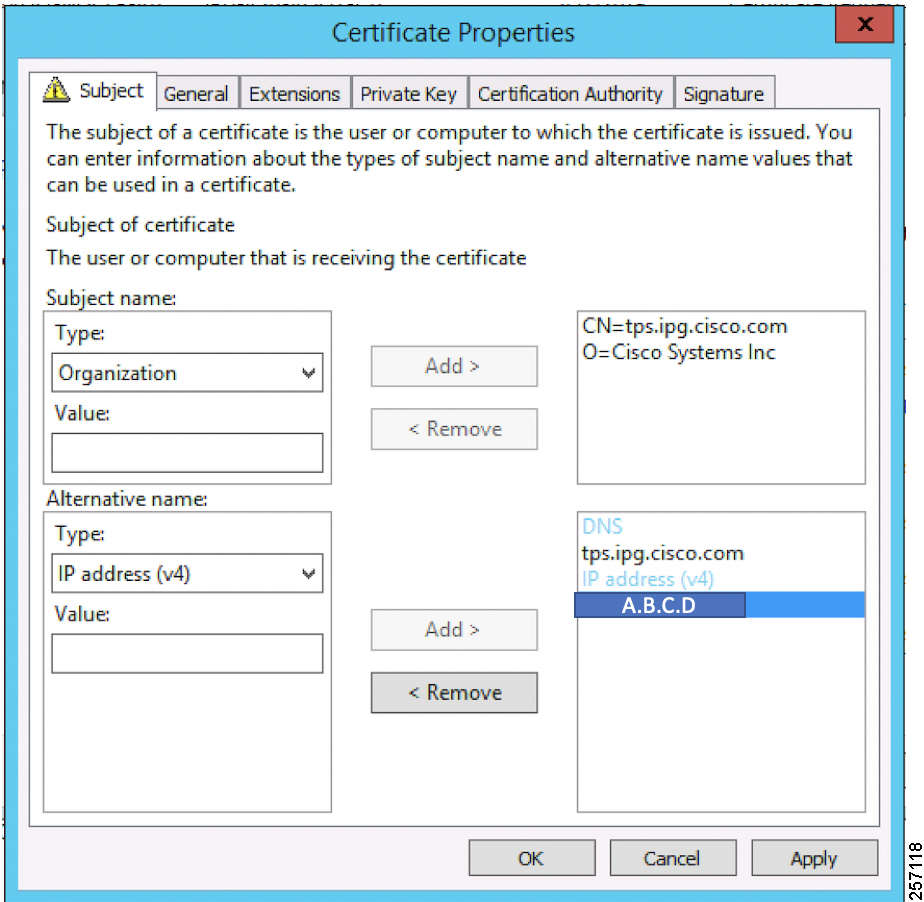

Certificate Considerations for PnP and ZTD

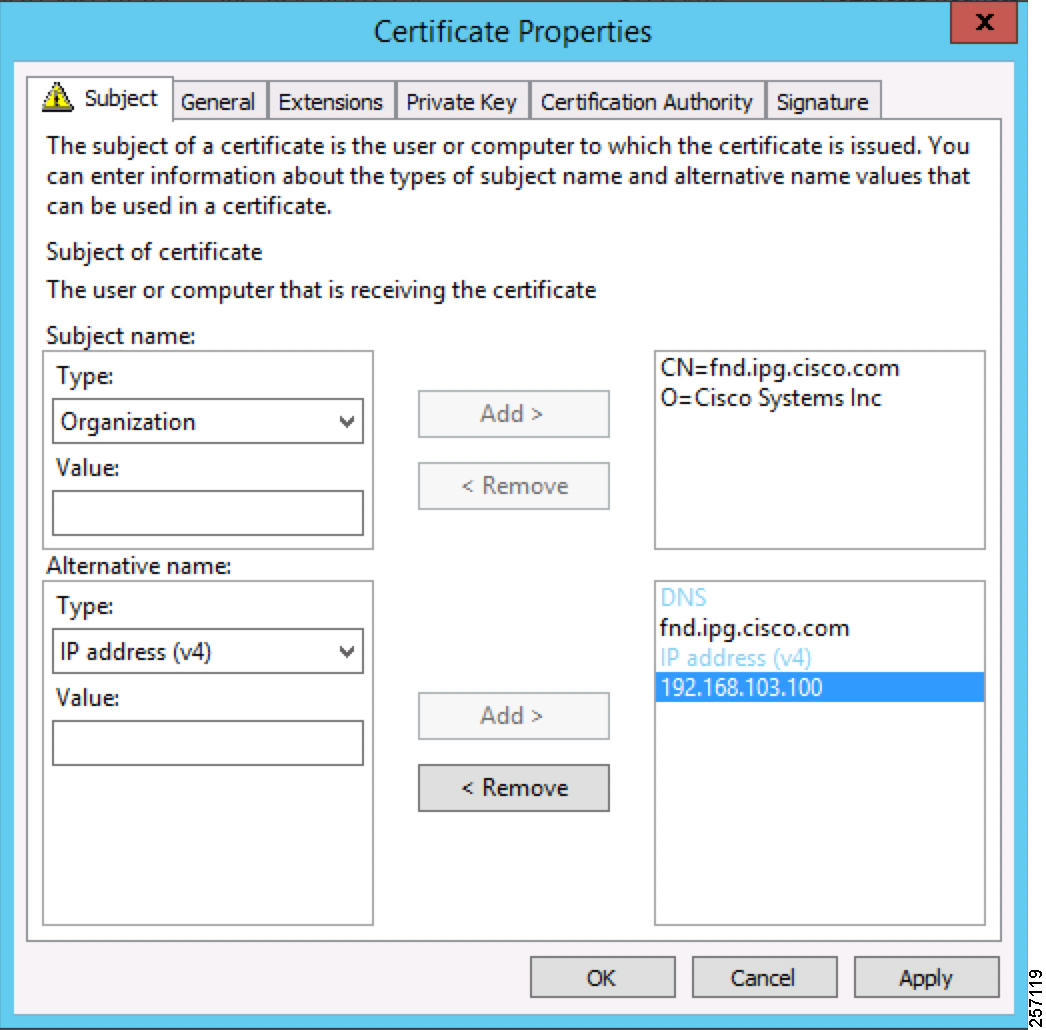

Common Name and Subject Alternate Name requirements must be considered while creating certificates for the Bootstrapping TPS/FND and NOC TPS/FND. Table 7 captures the sample certificate parameter requirements of the certificate that are to be installed on the TPS/FND server.

PnP TPS and FND need to have their subject alternative name (and optionally their corresponding IP addresses) set to FQDN. Also, the Common Name must match the hostname FQDN used in the URL during a https communication from the IoT Gateways. ZTD, TPS, and FND must have Common Name entries match the hostname FQDN used in the URL during https communication from the IoT Gateways.

Note: If https communication is attempted on https://tps-san.ipg.cisco.com:9120, then the Common Name of the certificate installed on the target server must match the FQDN ( tps-san.ipg.cisco.com) accessed in the URL.

Note: If https communication is attempted on https://10.10.242.242:9120, and if the Common Name of the certificate installed on the target server only has FQDN (and not IP), the SSL connection may not establish.

Bootstrapping the IoT Gateway

Bootstrapping can also be referred to with the following terminology:

■![]() Application of manufacturing configuration onto IoT Gateway

Application of manufacturing configuration onto IoT Gateway

■![]() Generation of Express Configuration

Generation of Express Configuration

On the bootstrapping FND, import the bootstrapping csv file and then assign the IoT Gateways to the correct bootstrapping group. Bootstrapping will occur automatically when the IoT gateway is powered on.

Note: To bootstrap the IoT Gateway, in the case of Approach 1, just connect the IoT Gateway to the Ethernet PnP Staging switch, and then power it on. In the case of Approach 2, just insert the LTE SIM cards (or connect the Ethernet link) with internet access on the IoT Gateway and power it on.

Bootstrapping is achieved with the help of the Cisco Network PnP solution. This section focuses on building the infrastructure required for bootstrapping to happen. The “Cisco Network PnP - Available Methods" section of the Design Guide discusses multiple methods for PnP server discovery. Three PnP server discovery methods, which have been implemented as part of this guide, are:

■![]() PnP server discovery through Cisco PnP Connect—validated with Approach 2

PnP server discovery through Cisco PnP Connect—validated with Approach 2

■![]() PnP server discovery through DHCP server—validated with Approach 1

PnP server discovery through DHCP server—validated with Approach 1

■![]() PnP server discovery through manual PnP profile—validated with Approach 1

PnP server discovery through manual PnP profile—validated with Approach 1

Preparing the Bootstrapping Infrastructure

The bootstrapping infrastructure, which involves multiple actors, is captured in Table 8.

This section is discussed in the following phases:

■![]() Certificate Creation and Installation

Certificate Creation and Installation

■![]() Installation of Bootstrapping TPS

Installation of Bootstrapping TPS

■![]() Installation of Bootstrapping FND

Installation of Bootstrapping FND

Prerequisites

■![]() The TPS and FND server must be up and running.

The TPS and FND server must be up and running.

■![]() This section focuses only on the incremental portions to make the regular TPS/FND a bootstrapping TPS/FND.

This section focuses only on the incremental portions to make the regular TPS/FND a bootstrapping TPS/FND.

■![]() Routing reachability over IPv4 and/or IPv6 networks from IoT Gateways to TPS.

Routing reachability over IPv4 and/or IPv6 networks from IoT Gateways to TPS.

Certificate Creation and Installation

This section captures the parameters that need to be considered while creating the certificate for the TPS (PnP Proxy) and FND (PnP server).

Note: For detailed instructions about certificate creation, please refer to the section “Creation of Certificate Templates and Certificates” of the Cisco FAN-Headend Deep Dive Guide.

Certificate Creation for Bootstrapping TPS

The certificate for the TPS must be created with both the Subject Name and the Subject Alternative Name fields populated.

Figure 10 TPS Certificate Parameters for PnP Bootstrapping

The Subject Name is the Common Name that must be set to the FQDN of the PnP Proxy. The Subject Alternative Name must be set to the FQDN of the PnP Proxy, along with the optional IP address. The Subject Alternative Name is required for PnP to work. The enrolled certificate is exported as PnP-TPS.pfx and is protected with a password.

Certificate Creation for Bootstrapping FND

The FND certificate must be created with both the Subject Name and Subject Alternative Name fields populated.

Figure 11 FND Certificate Parameters for PnP Bootstrapping

The Subject Name is the Common Name that must be set to the FQDN of the PnP Server. The Subject Alternative Name must be set to the FQDN of the PnP Server, along with the optional IP address. The Subject Alternative Name is required for PnP to work. The enrolled certificate is exported as PnP-FND.pfx and is protected with a password.

Installation of Bootstrapping TPS

The bootstrapping procedure in this implementation considers the use of TPS as PnP Proxy.

Note: As TPS is used in this implementation, TPS would represent itself as the PnP server for the IoT Gateways. Therefore, TPS is referred to as the PnP Proxy. For installation of TPS, please refer to the detailed steps covered under the section “Implementing Tunnel Provisioning Server” of the Cisco FAN-Headend Deep Dive Implementation and FAN Use Cases Guide.

TPS Certificate Installation on the Bootstrapping TPS

For installation of the certificate on the Bootstrapping TPS, please refer to the detailed steps covered under the section “Certificate Enrollment Phase for TPS Proxy Server” of the Cisco FAN - Headend Deep Dive Implementation and FAN Use Cases Guide.

Note: Please use PnP-TPS.pfx while enrolling the certificate on the TPS.

The following are the brief steps:

# To view the content of the "Pnp-TPS.pfx" certificate:

Cisco SUDI Certificate Installation on the Bootstrapping TPS

Cisco SUDI CA can be installed into the cgms_keystore of TPS using the following command:

The Cisco SUDI CA file "cisco-sudi-ca.pem" can be fetched from the FND, from the following location “/opt/cgms/server/cgms/conf/ciscosudi/cisco-sudi-ca.pem”

Installation of Bootstrapping FND

For installation of FND, please refer to the detailed steps covered under the section “Implementing Field Network Director” of the Cisco FAN-Headend Deep Dive Implementation and FAN Use Cases Guide.

FND Certificate Installation on the Bootstrapping FND

For installation of the certificate on the Bootstrapping FND, please refer to the detailed steps covered under the section “Certificate Enrollment onto FND's Keystore” of the Cisco FAN Headend Deep Dive Implementation and FAN Use Cases Guide.

Note: Please use PnP-FND.pfx while enrolling the certificate on the FND.

Cisco SUDI Certificate Installation on the Bootstrapping FND

Cisco SUDI CA can be installed into the cgms_keystore of FND using the following command:

Configuration of Bootstrapping TPS

This section covers the configuration steps and the final verification steps on the TPS.

TPS Proxy Properties Configuration TPS

Proxy Properties file needs to be configured with the following details:

■![]() inbound-bsproxy-destination: Address to which the bootstrapping requests be forwarded.

inbound-bsproxy-destination: Address to which the bootstrapping requests be forwarded.

■![]() enable-bootstrap-service: Is bootstrapping service enabled/disabled?

enable-bootstrap-service: Is bootstrapping service enabled/disabled?

■![]() bootstrap-proxy-listen-port: Port on which the PnP Proxy must be listening for processing bootstrapping requests (default port is 9125).

bootstrap-proxy-listen-port: Port on which the PnP Proxy must be listening for processing bootstrapping requests (default port is 9125).

Name resolution entries have to be present for FND FQDN in the /etc/hosts file.

Mandatory Verification Checks on TPS Proxy

The verification checks include the following:

■![]() FND FQDN entry in /etc/hosts.

FND FQDN entry in /etc/hosts.

■![]() TPS must have three certificates installed into the cgms_keystore:

TPS must have three certificates installed into the cgms_keystore:

–![]() Certificate signed by Utility PKI for TPS (with private key)

Certificate signed by Utility PKI for TPS (with private key)

–![]() Public Certificate of the Utility PKI CA server

Public Certificate of the Utility PKI CA server

–![]() Public Certificate of the Cisco SUDI CA

Public Certificate of the Cisco SUDI CA

■![]() Hostname consistency with the certificate.

Hostname consistency with the certificate.

■![]() There shouldn't be any unreachable name servers in /etc/resolv.conf.

There shouldn't be any unreachable name servers in /etc/resolv.conf.

■![]() NTP daemon should be running. Time should be synchronized.

NTP daemon should be running. Time should be synchronized.

■![]() Necessary firewall ports must have been opened up, if the firewall/iptables/ip6tables are enabled:

Necessary firewall ports must have been opened up, if the firewall/iptables/ip6tables are enabled:

–![]() TCP Port 9125 to process http communication

TCP Port 9125 to process http communication

–![]() TCP port 9120 to process https communication FND FQDN entry in /etc/hosts:

TCP port 9120 to process https communication FND FQDN entry in /etc/hosts:

TPS must have three certificates installed into the cgms_keystore:

■![]() The certificate entry 'root' represents the Utility PKI CA certificate.

The certificate entry 'root' represents the Utility PKI CA certificate.

■![]() The certificate entry 'sudi' represents the Cisco SUDI CA certificate.

The certificate entry 'sudi' represents the Cisco SUDI CA certificate.

■![]() The certificate entry 'cgms' represents the private certificate of the TPS server signed by the (custom) Utility PKI CA server.

The certificate entry 'cgms' represents the private certificate of the TPS server signed by the (custom) Utility PKI CA server.

Hostname should match certificate Common Name/SAN:

Note: No unreachable name servers should exist. Either the name servers should be present and reachable or they should be empty. Any unreachable name server address entry must be taken care or removed under the network interface configuration.

NTP daemon should be running. Time should be synchronized:

Note: The TPS server should be time synchronized. Otherwise, the https communication from the IoT Gateway might not reach the TPS Proxy Application.

Configuration of Bootstrapping FND

This section covers the configuration steps and the final verification steps on the FND.

The CGMS Properties file needs to be configured with the following details:

■![]() proxy-bootstrap-ip—Address of the PnP Proxy from which the bootstrapping requests are processed

proxy-bootstrap-ip—Address of the PnP Proxy from which the bootstrapping requests are processed

■![]() enable-bootstrap-service—Enable/Disable the bootstrapping service

enable-bootstrap-service—Enable/Disable the bootstrapping service

■![]() bootstrap-fnd-alias—The trust point alias to be used during bootstrapping of the IoT Gateway

bootstrap-fnd-alias—The trust point alias to be used during bootstrapping of the IoT Gateway

■![]() ca-fingerprint—fingerprint of the 'root' trustpoint

ca-fingerprint—fingerprint of the 'root' trustpoint

Name resolution entries have to be present for TPS FQDN in the /etc/hosts file.

Mandatory Verification Checks on FND

Verification checks include the following:

■![]() TPS FQDN entry in the /etc/hosts file.

TPS FQDN entry in the /etc/hosts file.

■![]() FND must have three certificates installed into the cgms_keystore:

FND must have three certificates installed into the cgms_keystore:

–![]() Certificate signed by Utility PKI for FND (with private key)

Certificate signed by Utility PKI for FND (with private key)

–![]() Public Certificate of the Utility PKI CA server

Public Certificate of the Utility PKI CA server

–![]() Public Certificate of the Cisco SUDI CA

Public Certificate of the Cisco SUDI CA

■![]() Hostname must be consistent with the certificate.

Hostname must be consistent with the certificate.

■![]() No unreachable name servers in /etc/resolv.conf should exist.

No unreachable name servers in /etc/resolv.conf should exist.

■![]() NTP daemon should be running. Time should be synchronized.

NTP daemon should be running. Time should be synchronized.

■![]() Necessary firewall ports must have been opened up if the firewall/iptables/ip6tables are enabled:

Necessary firewall ports must have been opened up if the firewall/iptables/ip6tables are enabled:

–![]() TCP Port 9125 to process http communication

TCP Port 9125 to process http communication

–![]() TCP port 9120 to process https communication

TCP port 9120 to process https communication

TPS/FND FQDN entry in the /etc/hosts file:

FND must have three certificates installed into the cgms_keystore:

■![]() The certificate entry 'root' represents the Utility PKI CA certificate.

The certificate entry 'root' represents the Utility PKI CA certificate.

■![]() The certificate entry 'sudi' represents the Cisco SUDI CA certificate.

The certificate entry 'sudi' represents the Cisco SUDI CA certificate.

■![]() The certificate entry 'cgms' represents the private certificate of the FND server signed by the (custom) Utility PKI CA server.

The certificate entry 'cgms' represents the private certificate of the FND server signed by the (custom) Utility PKI CA server.

Hostname should match the certificate Common Name/SAN:

Note: No unreachable name servers should exist. Either the name servers should be present and reachable or they should be empty. Any unreachable name server address entry must be taken care or removed under the network interface configuration:

NTP daemon should be running. Time should be synchronized:

Note: The FND server should be time synchronized. Otherwise, the https communication from the IoT Gateway might not reach the FND (cgms) application.

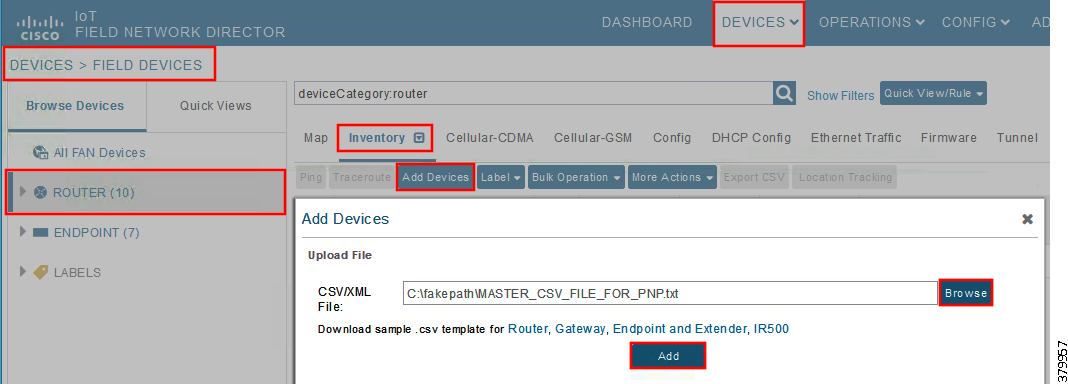

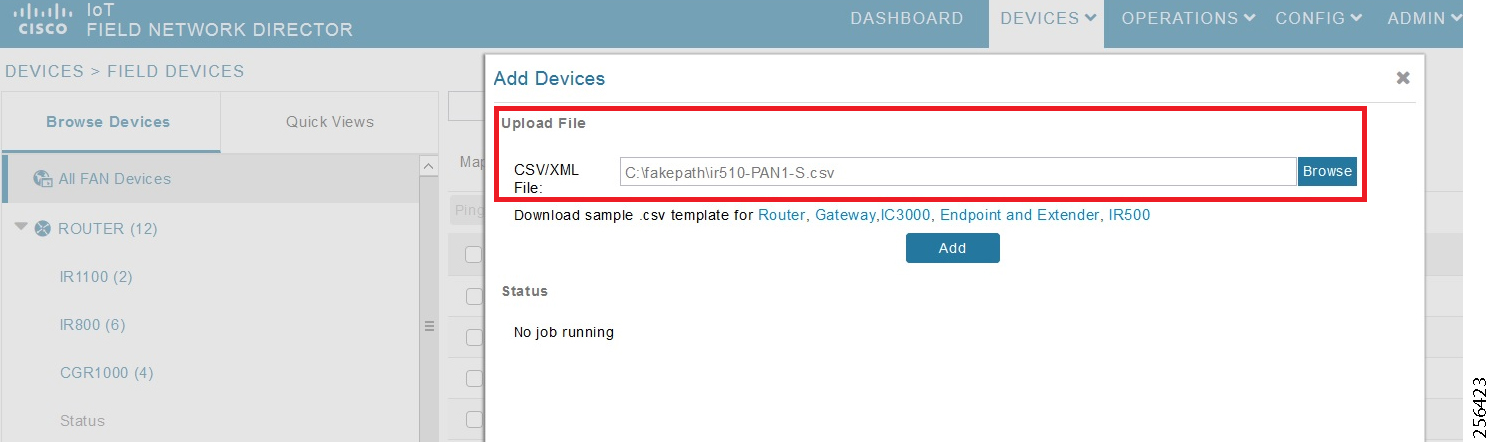

A sample csv file that can be imported into FND for bootstrapping of IoT Gateway is shown below:

administrator,<encrypted_pwd>,IR809_ JMX1941X00B,ipg.cisco.com,flash:/ir800-universalk9

Note: Ensure that there aren’t any blank spaces while using this csv file.

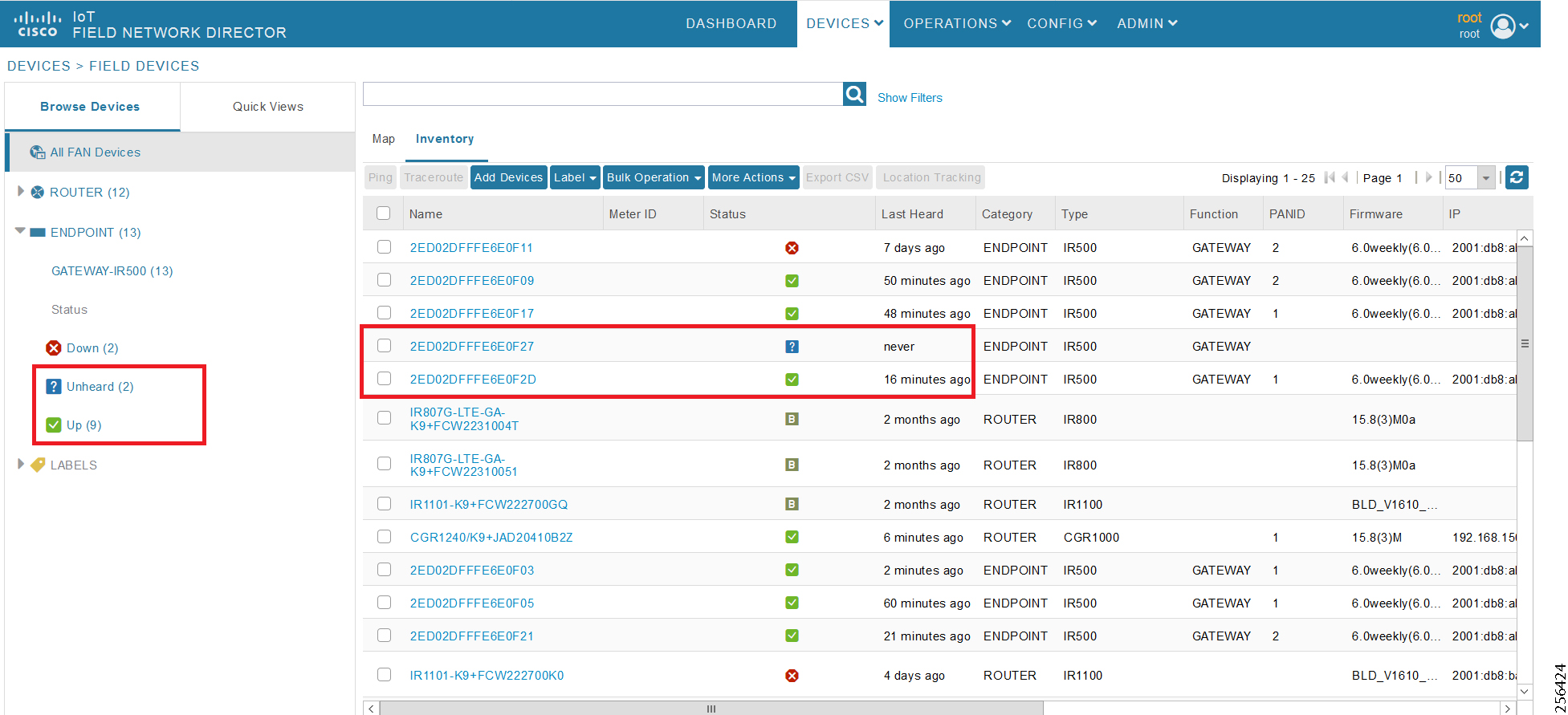

Figure 12 Bootstrapping CSV Import at Bootstrapping FND

1.![]() From Devices > Field Devices, click Router in the left pane.

From Devices > Field Devices, click Router in the left pane.

2.![]() Click the Inventory tab on the middle pane.

Click the Inventory tab on the middle pane.

4.![]() Browse the csv file created in the previous step.

Browse the csv file created in the previous step.

5.![]() Then click Add to import the IoT Gateway CSV list into the bootstrapping FND.

Then click Add to import the IoT Gateway CSV list into the bootstrapping FND.

DHCP Server-Assisted PnP Provisioning

This section is discussed in the following phases:

■![]() Bootstrapping in the IPv4 Network

Bootstrapping in the IPv4 Network

Prerequisites

PnP Proxy must be reachable either over the LAN or over the WAN/Internet. As TPS is used in this implementation, TPS acts as the PnP server for the IoT Gateways. The DHCP server advertises TPS details in place of the PnP server details.

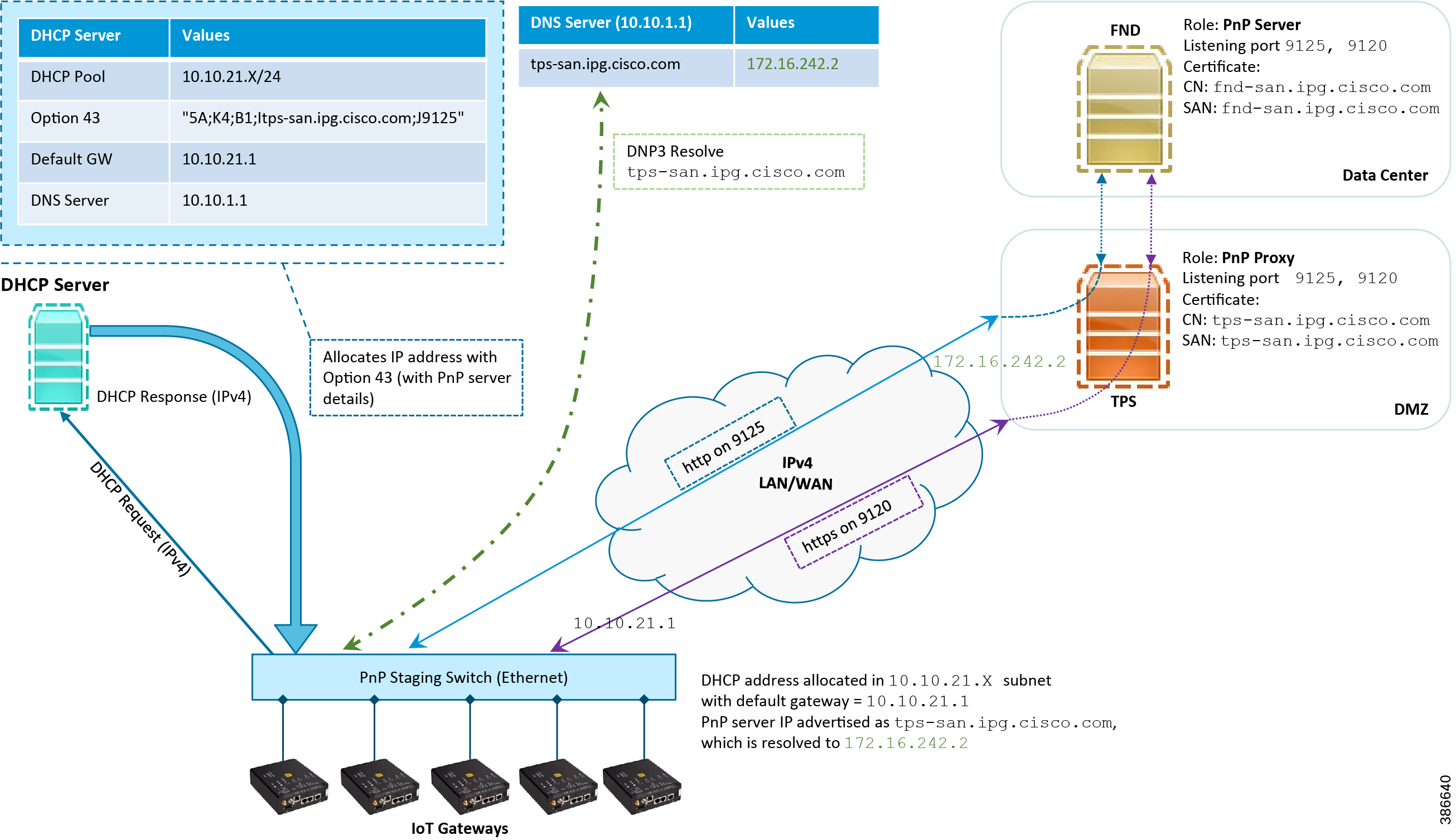

Bootstrapping in the IPv4 Network

This section discusses the DHCP server-assisted bootstrapping of the IoT Gateways over the IPv4 network. In Figure 13, IoT Gateways obtain the IP address dynamically from the DHCP server along with details of the PnP server (which, in this case, is actually that of PnP Proxy, as TPS is deployed).

■![]() The PnP server details are received using DHCP option 43.

The PnP server details are received using DHCP option 43.

■![]() The PnP agent (residing on the IoT Gateway) then reaches out to PnP Proxy over IPv4 LAN/WAN network over http on port 9125 and then over https on port 9120.

The PnP agent (residing on the IoT Gateway) then reaches out to PnP Proxy over IPv4 LAN/WAN network over http on port 9125 and then over https on port 9120.

Figure 13 DHCP Server-Assisted Bootstrapping of IoT Gateways over IPv4 Network

Bootstrapping in the IPv6 Network

This section discusses the DHCP server-assisted bootstrapping of the IoT Gateways over the IPv6 network.

■![]() IoT Gateways obtains the IP address dynamically from the DHCP server along with details of the PnP server (which, in this case, is actually that of PnP Proxy, as TPS is deployed).

IoT Gateways obtains the IP address dynamically from the DHCP server along with details of the PnP server (which, in this case, is actually that of PnP Proxy, as TPS is deployed).

■![]() The PnP server details are received using DHCP option 9.

The PnP server details are received using DHCP option 9.

■![]() The PnP agent (residing on the IoT Gateway) then reaches out to PnP Proxy over IPv6 LAN/WAN network over http on port 9125 and then over https on port 9120.

The PnP agent (residing on the IoT Gateway) then reaches out to PnP Proxy over IPv6 LAN/WAN network over http on port 9125 and then over https on port 9120.

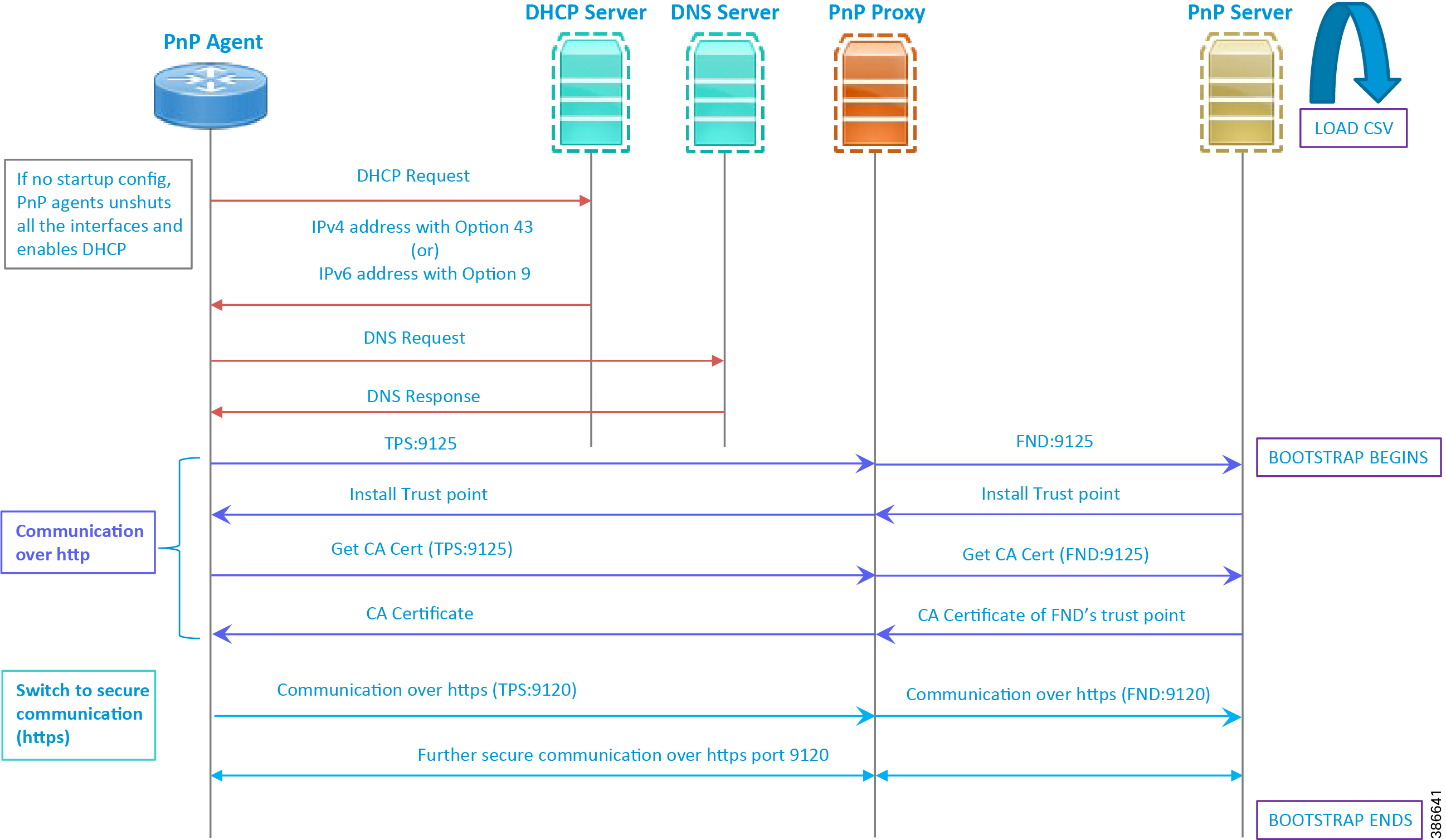

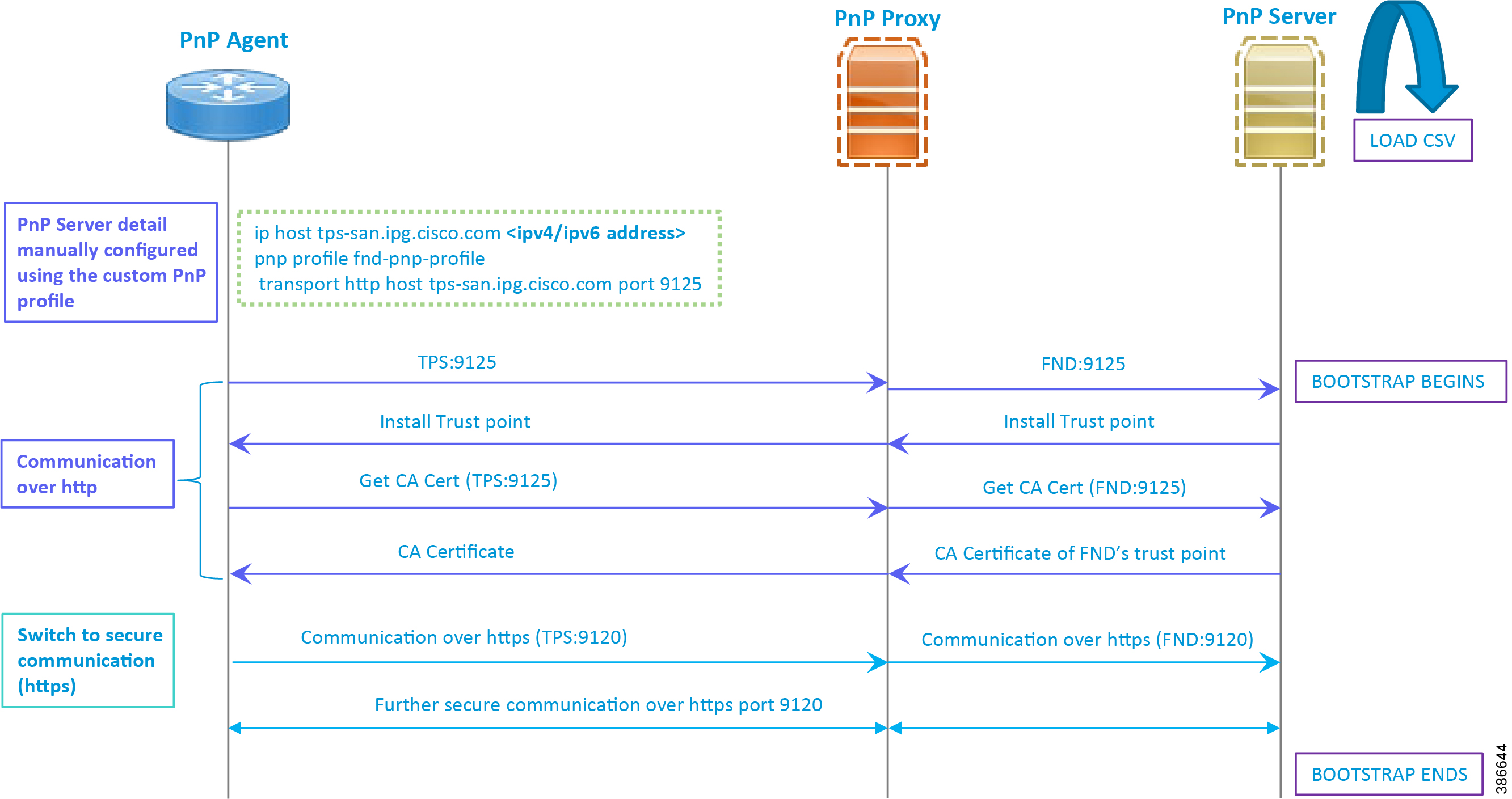

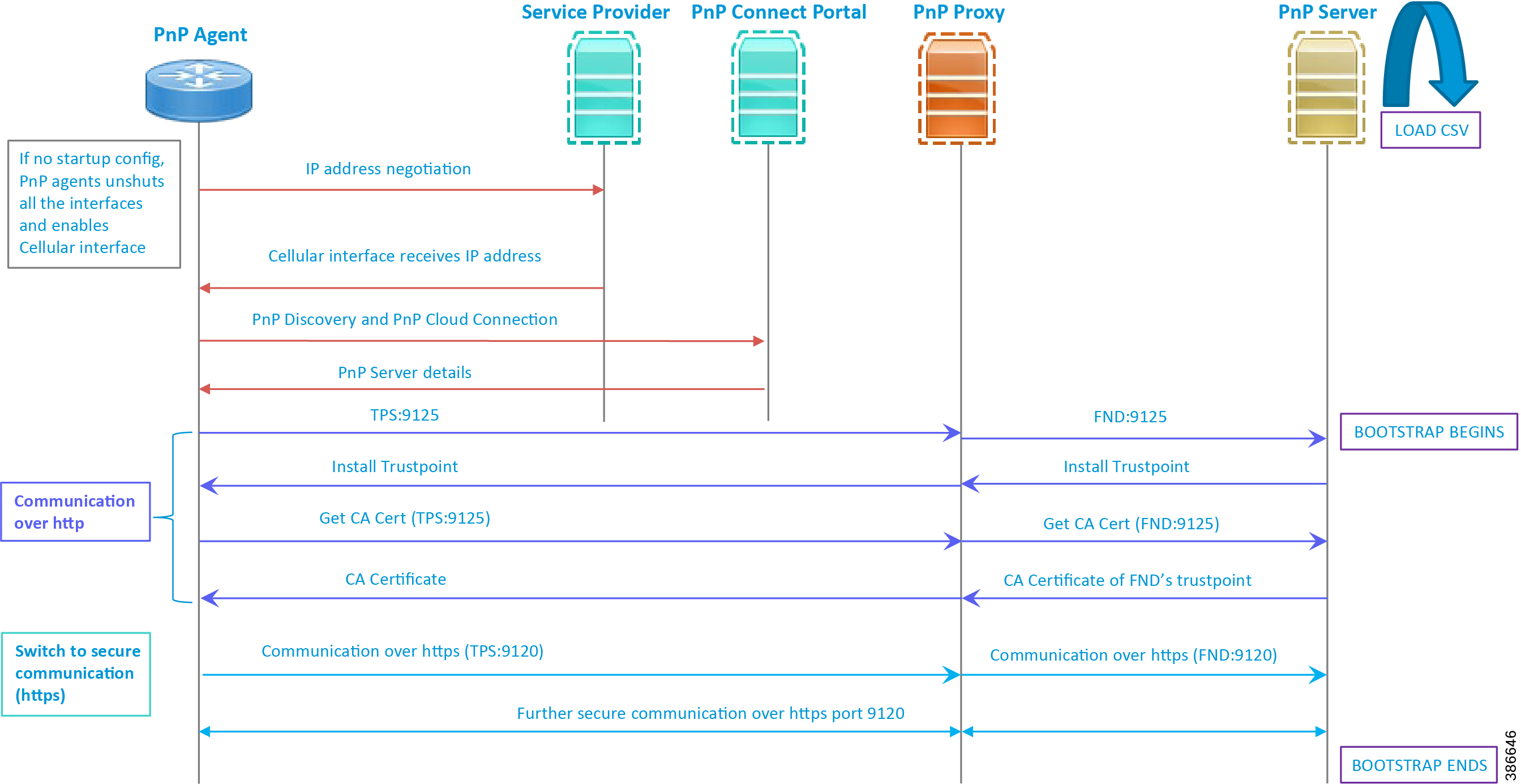

Logical Call Flow

This section discusses the logical call flow sequence with the DHCP server-assisted bootstrapping of the IoT Gateways over the IPv4/IPv6 network. Figure 14 shows the following actors:

Figure 14 DHCP Server-Assisted Bootstrapping of IoT Gateways—Logical Call Flow

1.![]() When the IoT Gateway is powered on, the PnP Agent on the IoT Gateway checks for the presence of the startup configuration. If the startup configuration is not found, then the PnP agent performs “no shut" and enables DHCP on all the interfaces.

When the IoT Gateway is powered on, the PnP Agent on the IoT Gateway checks for the presence of the startup configuration. If the startup configuration is not found, then the PnP agent performs “no shut" and enables DHCP on all the interfaces.

2.![]() The IOS on the IoT Gateway sends out a DHCP request, which reaches the DHCP server (either directly or with the help of DHCP relay agent).

The IOS on the IoT Gateway sends out a DHCP request, which reaches the DHCP server (either directly or with the help of DHCP relay agent).

3.![]() The DHCP server responds back with the IPv4 address along with option 43, or the IPv6 address along with option 9. The option contains the FQDN of the PnP server to talk to (for example, tps-san.ipg.cisco.com) and the port number (for example, 9125) on which the PnP Proxy/Server is expected to be listening. The PnP server detail advertised as part of the DHCP option is the IP address of the PnP Proxy instead of the actual PnP server (with TPS deployed as part of the solution).

The DHCP server responds back with the IPv4 address along with option 43, or the IPv6 address along with option 9. The option contains the FQDN of the PnP server to talk to (for example, tps-san.ipg.cisco.com) and the port number (for example, 9125) on which the PnP Proxy/Server is expected to be listening. The PnP server detail advertised as part of the DHCP option is the IP address of the PnP Proxy instead of the actual PnP server (with TPS deployed as part of the solution).

4.![]() The IoT Gateway then sends out a name resolution request to DNS server to resolve the FQDN to its corresponding IPv4/IPv6 address.

The IoT Gateway then sends out a name resolution request to DNS server to resolve the FQDN to its corresponding IPv4/IPv6 address.

5.![]() The PnP Agent attempts its communication with the PnP Proxy over port 9125 (over http). PnP Proxy, in turn, communicates with the FND on port 9125. Bootstrapping begins at the FND from this point. The prerequisite to processing this bootstrapping request from the IoT Gateway is the addition of IoT Gateway details into the FND with the loading of the csv file.

The PnP Agent attempts its communication with the PnP Proxy over port 9125 (over http). PnP Proxy, in turn, communicates with the FND on port 9125. Bootstrapping begins at the FND from this point. The prerequisite to processing this bootstrapping request from the IoT Gateway is the addition of IoT Gateway details into the FND with the loading of the csv file.

6.![]() The FND installs the trust point on the IoT Gateway.

The FND installs the trust point on the IoT Gateway.

7.![]() The IoT Gateway sends out a Get CA Certificate request to PnP Proxy, which, in turn, proxies the communication to the FND. The FND would respond back with the CA certificate of the FND's trust point, which would then be installed on the IoT Gateway.

The IoT Gateway sends out a Get CA Certificate request to PnP Proxy, which, in turn, proxies the communication to the FND. The FND would respond back with the CA certificate of the FND's trust point, which would then be installed on the IoT Gateway.

The following PnP States would have transitioned at the FND:

8.![]() From this point onwards, the further communication switches over to https on port 9120. The IoT Gateway would communicate with the TPS IP on port 9120, which, in turn, is sent to the FND IP on port 9120. The rest of the IoT Gateway bootstrapping happens over this secure https communication established on port 9120.

From this point onwards, the further communication switches over to https on port 9120. The IoT Gateway would communicate with the TPS IP on port 9120, which, in turn, is sent to the FND IP on port 9120. The rest of the IoT Gateway bootstrapping happens over this secure https communication established on port 9120.

Note: Since the communication is over https, time synchronization and certificate parameters matching must be taken care of:

–![]() For example, if https://<TPS_FQDN>:9120 is attempted, then the certificate installed on the TPS must have CN/SAN configured with <TPS_FQDN>.

For example, if https://<TPS_FQDN>:9120 is attempted, then the certificate installed on the TPS must have CN/SAN configured with <TPS_FQDN>.

–![]() Similarly, if the https://<TPS_IP>:9120 is attempted, then the certificate installed on the TPS must also have CN/SAN configured with <TPS_IP>. Otherwise, SSL failure might occur and the https message from IoT Gateway might not reach the TPS Proxy Application on port 9120.

Similarly, if the https://<TPS_IP>:9120 is attempted, then the certificate installed on the TPS must also have CN/SAN configured with <TPS_IP>. Otherwise, SSL failure might occur and the https message from IoT Gateway might not reach the TPS Proxy Application on port 9120.

FND would transition through the following PnP states while the bootstrapping progresses:

–![]() PUSHING_BOOTSTRAP_CONFIG_FILE

PUSHING_BOOTSTRAP_CONFIG_FILE

–![]() PUSHING_BOOTSTRAP_CONFIG_VERIFY_HASH

PUSHING_BOOTSTRAP_CONFIG_VERIFY_HASH

9.![]() Bootstrapping would be complete with the "BOOTSTRAP_DONE" PnP State.

Bootstrapping would be complete with the "BOOTSTRAP_DONE" PnP State.

Custom PnP Profile for PnP Server

This section is discussed in the following phases:

■![]() Bootstrapping over IPv4 Network

Bootstrapping over IPv4 Network

■![]() Bootstrapping over IPv6 Network

Bootstrapping over IPv6 Network

As a gateway of last resort, if dynamic ways of learning the PnP Server are not an option, an option does exist to enable learning about the PnP server with minimal manual configuration.

Manual PnP profile configuration with PnP server details:

Note: Only the PnP Server detail is manually configured. Bootstrapping and Deployment (the rest of ZTD) still happens dynamically.

Prerequisites

■![]() The PnP server must be reachable either over the LAN or over the WAN/Internet.

The PnP server must be reachable either over the LAN or over the WAN/Internet.

■![]() As TPS is used in this implementation, TPS acts as a PnP server for the IoT Gateways.

As TPS is used in this implementation, TPS acts as a PnP server for the IoT Gateways.

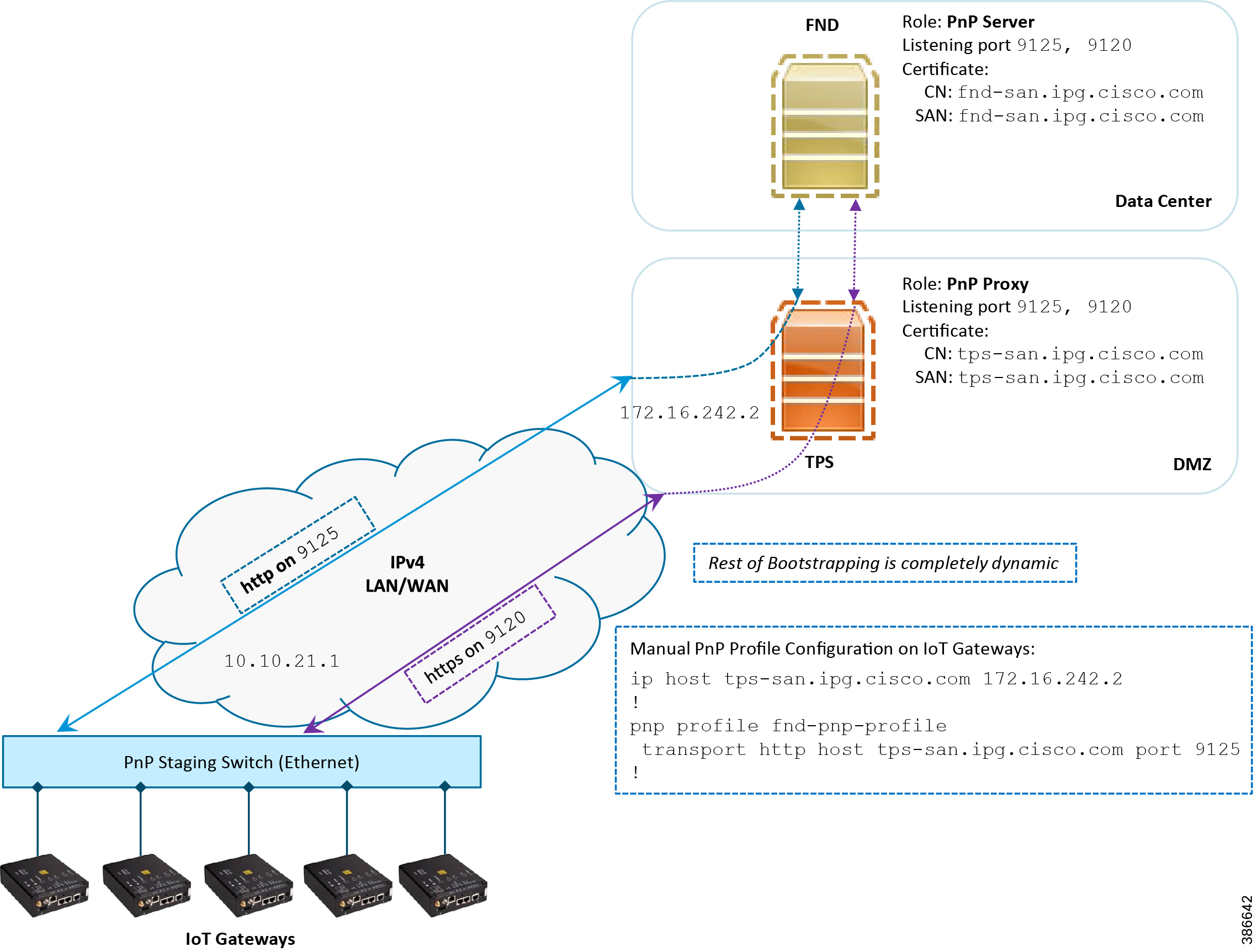

Bootstrapping over IPv4 Network

This section focuses on the bootstrapping of the IoT Gateways over the IPv4 network in the absence of the DHCP server, DNS server, and Cisco Cloud redirector server to provide the PnP server details. IoT Gateways are informed about the PnP server detail directly through the Cisco IOS configuration commands.

In Figure 15, the manual PnP profile configuration on the IoT Gateways lets the IoT Gateways learn about the PnP server that should be reached out to and the desired PnP port number. For example, the custom PnP profile is configured to reach out to the PnP server ( tps-san.ipg.cisco.com) over the http on port 9125.

Figure 15 Custom PnP Profile-Assisted Bootstrapping of IoT Gateways over IPv4 Network

Based on the manual PnP profile configuration on the IoT Gateways, communication is initially established with PnP Proxy on http://tps-san.ipg.cisco.com:9125. Later, the communication is established with the PnP Proxy on https://tps-san.ipg.cisco.com:9120.

Note: Only the PnP server discovery is made manual. The rest of the bootstrapping procedure is the same as the DHCP server-assisted PnP provisioning discussed above.

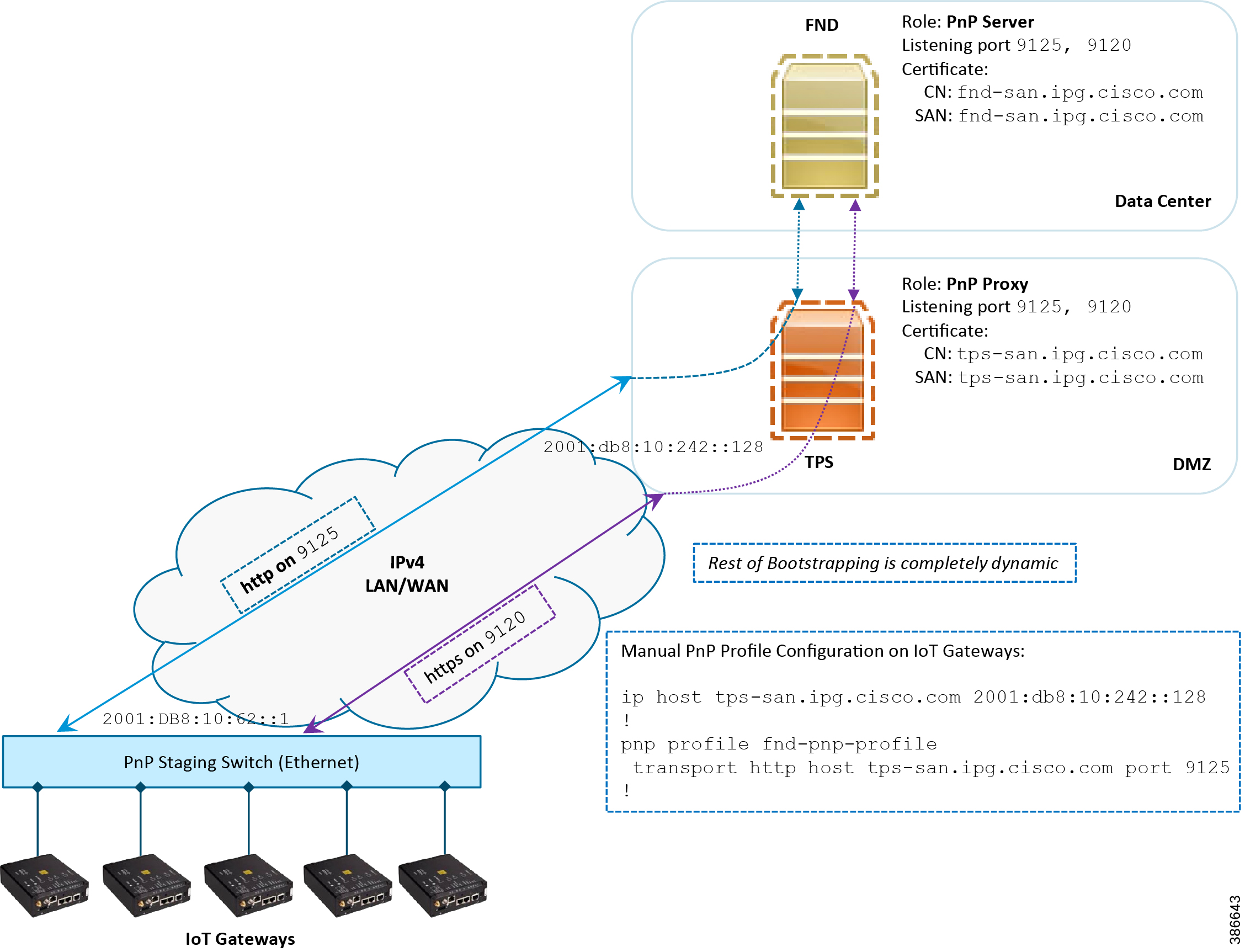

Bootstrapping over IPv6 Network

This section focuses on the bootstrapping of the IoT Gateways over the IPv6 network in the absence of the DHCP server, DNS server, and Cisco Cloud Redirector Server to provide the PnP server details. IoT Gateways are informed about the PnP server detail directly through the Cisco IOS configuration commands in order to enable bootstrapping of the IoT Gateways over the IPv6 network.

In Figure 16, based on the manual PNP profile configuration on the IoT Gateways, initially communication is established with the PnP Proxy on http://tps-san.ipg.cisco.com:9125. Later, the communication is established with PnP Proxy on https://tps-san.ipg.cisco.com:9120.

Name resolution happens to an IPv6 address, and the bootstrapping happens over an IPv6 network.

Note: Only the PnP server discovery is made manual. The rest of the bootstrapping procedure (PnP communication on port 9120 and 9125) is still dynamic.

Figure 16 Custom PnP Profile-Assisted Bootstrapping of IoT Gateways over IPv6 Network

Logical Call Flow

This section discusses the logical call flow sequence with the Custom PnP profile-assisted bootstrapping of the IoT Gateways over the IPv4/IPv6 network.

Figure 17 Custom PnP Profile-Assisted Bootstrapping of IoT Gateways—Logical Call Flow

In Figure 17:

■![]() PnP server detail is learned out of the custom PnP profile, configured manually.

PnP server detail is learned out of the custom PnP profile, configured manually.

■![]() The IoT Gateway reaches out to the PnP server in the configuration, which is http://tps- san.ipg.cisco.com:9125.

The IoT Gateway reaches out to the PnP server in the configuration, which is http://tps- san.ipg.cisco.com:9125.

■![]() The communication reaches TPS, and is then sent to FND. Bootstrapping of the IoT Gateway begins at the FND.

The communication reaches TPS, and is then sent to FND. Bootstrapping of the IoT Gateway begins at the FND.

■![]() The rest of the procedure is exactly the same as the bootstrapping steps discussed as part of DHCP server-assisted PnP Provisioning.

The rest of the procedure is exactly the same as the bootstrapping steps discussed as part of DHCP server-assisted PnP Provisioning.

–![]() Initial communication happens on http://tps-san.ipg.cisco.com:9125

Initial communication happens on http://tps-san.ipg.cisco.com:9125

–![]() Later communication happens on https://tps-san.ipg.cisco.com:9120

Later communication happens on https://tps-san.ipg.cisco.com:9120

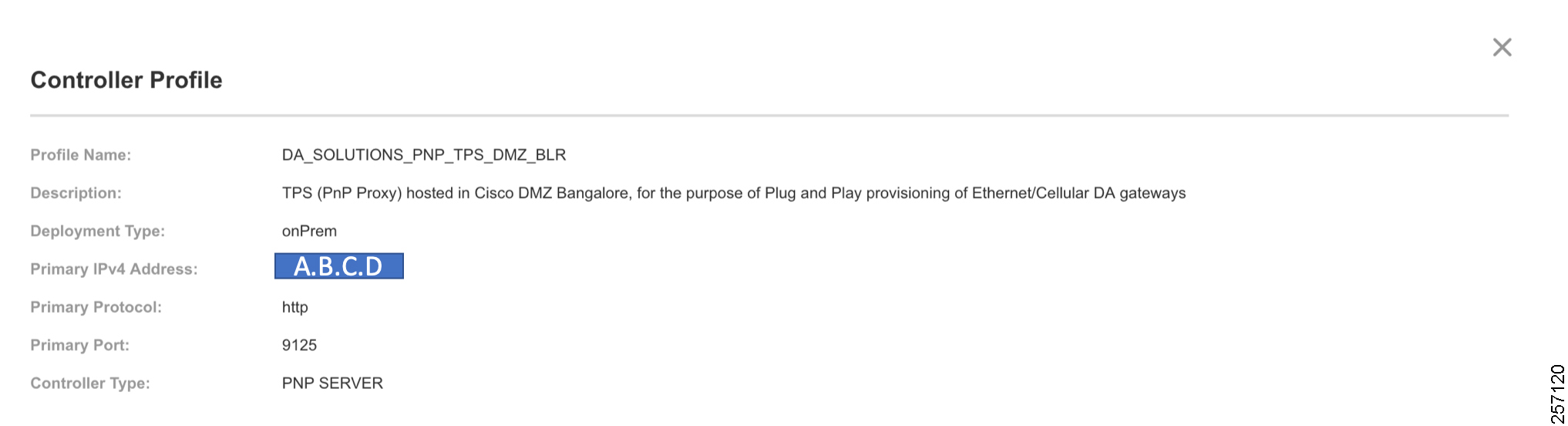

PnP Server Discovery through Cisco PnP Connect and Bootstrapping

Prerequisites

PnP Proxy must be reachable either over the WAN/Internet. As TPS is used in this implementation, TPS acts as the PnP server for the IoT Gateways. The controller profile on "software.cisco.com" should be configured with the correct TPS address. The controller profile advertises TPS details in place of the PnP server details.

To create the controller profile, login to software.cisco.com. Go to Network Plug and Play > Select controller profile from the toolbar and add the details.

Figure 18 shows the controller profile added on software.cisco.com.

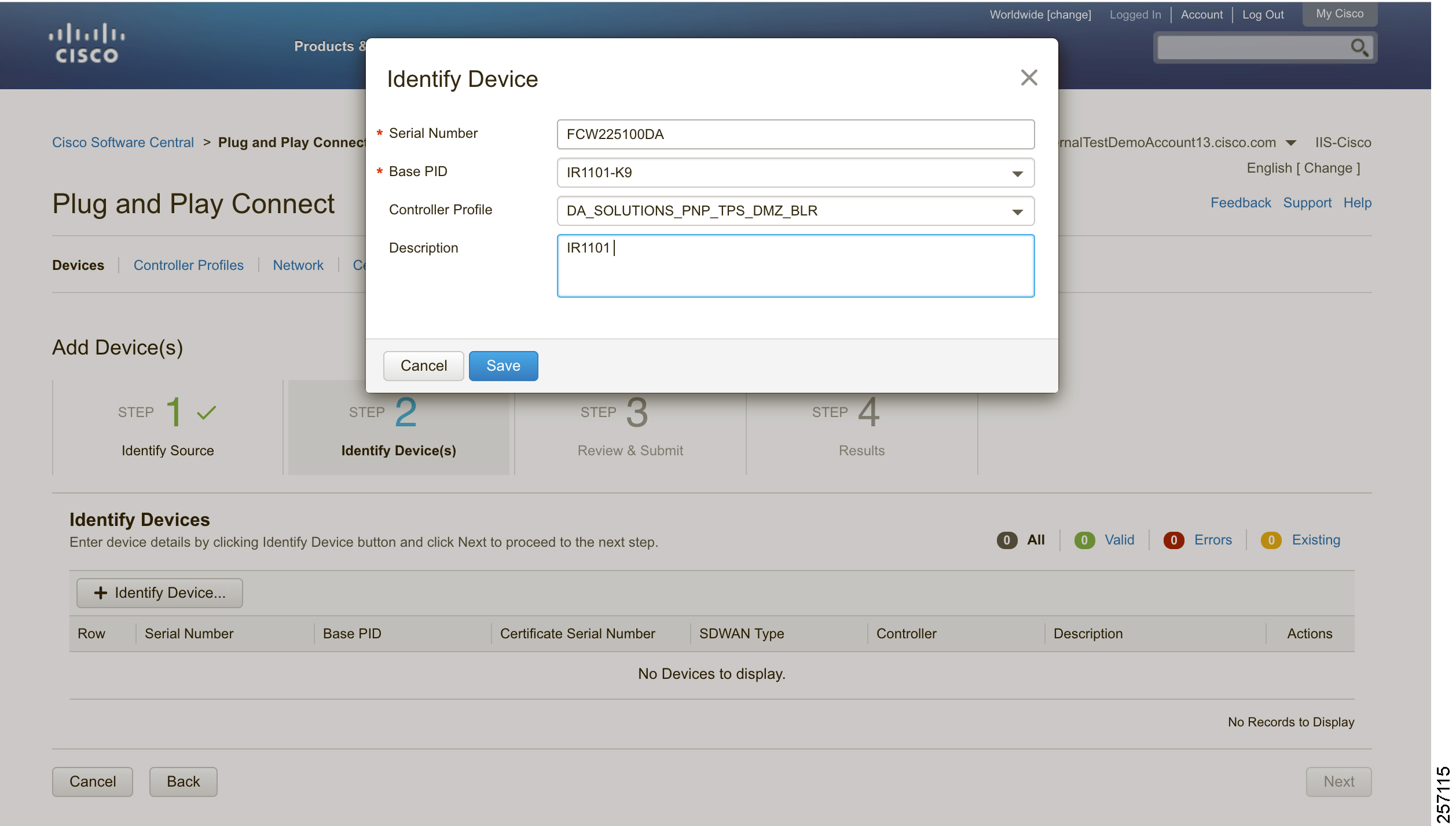

When a device is ordered through CCW, the device must be attached with the Smart account. For the PnP discovery to be successful using PnP Connect, a device must be added on the software.cisco.com portal. The device can be added either manually or by uploading a csv file. You can refer to "PnP Server Discovery Through Cisco PnP Connect" in the Cisco Distribution Automation Feeder Automation Design Guide. Figure 19 shows adding a device manually.

Figure 19 Manual Addition of Device

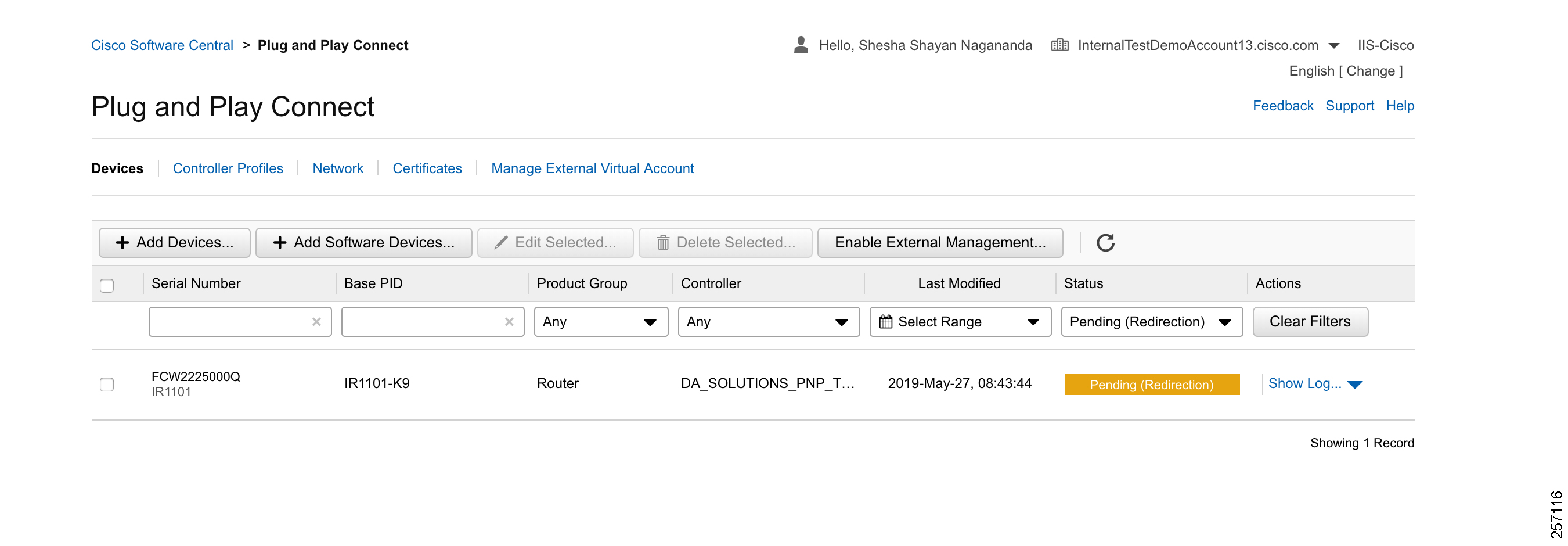

After manually adding the device in the PnP Connect portal, the request is yet to received from the device and the status for PnP redirection will be pending. This is shown in Figure 20.

Figure 20 PnP Redirect Pending after Manual Device Addition

Finally, when the device is added successfully, it should be populated in the devices list as shown in Figure 20, which lists the devices for when the Redirect was successful.

Bootstrapping

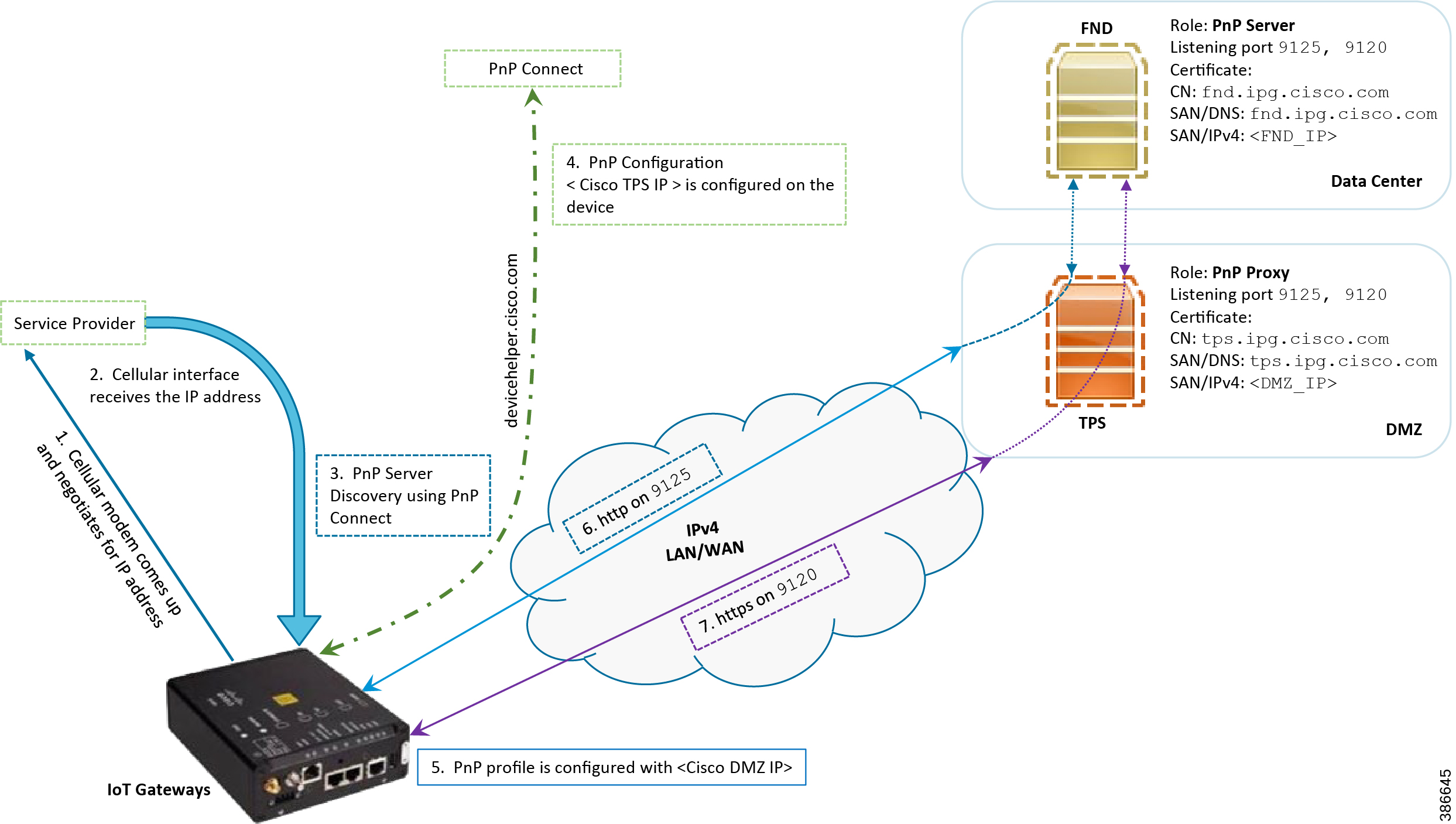

This section discusses the PnP Connect-Assisted bootstrapping of the IoT Gateways over the IPv4 network.

In Figure 21, IoT Gateways obtain the IP address dynamically from the service provider.

■![]() The PnP agent (residing on the IoT Gateway) then reaches out to PnP Proxy over IPv4 LAN/WAN network over http on port 9125 and then over https on port 9120.

The PnP agent (residing on the IoT Gateway) then reaches out to PnP Proxy over IPv4 LAN/WAN network over http on port 9125 and then over https on port 9120.

Figure 21 PnP Connect—Assisted Bootstrapping of IoT Gateways

Logical Call Flow

This section discusses the logical call flow sequence with the DHCP server-assisted bootstrapping of the IoT Gateways over the IPv4/IPv6 network.

The actors shown in Figure 22 are the following:

■![]() PnP Cloud Re-direction Service PnP Connect Portal

PnP Cloud Re-direction Service PnP Connect Portal

Figure 22 PnP Connect-Assisted Bootstrapping of IoT Gateways -Logical Call Flow

1.![]() When the IoT Gateway is powered on, the PnP Agent on the IoT Gateway checks for the presence of the startup configuration. If the startup configuration is not found, then the PnP agent performs "no shut" on all the cellular interfaces.

When the IoT Gateway is powered on, the PnP Agent on the IoT Gateway checks for the presence of the startup configuration. If the startup configuration is not found, then the PnP agent performs "no shut" on all the cellular interfaces.

2.![]() The IOS on the IoT Gateway sends out a request to the service provider.

The IOS on the IoT Gateway sends out a request to the service provider.

3.![]() The service provider responds back with the IPv4 address.

The service provider responds back with the IPv4 address.

4.![]() The IOT gateway proceeds for PnP server discovery and connects to the PnP cloud re-direction service connect portal. After successfully connecting the server devicehelper.cisco.com, the server PnP Connect portal sends the publicly reachable TPS DMZ IP(A.B.C.D) PnP proxy IP and the port number (9125) on which the proxy server is listening. The serial number of the gateway should be added to the Cisco Cloud PnP Connect portal for the re-direction service to be successful.

The IOT gateway proceeds for PnP server discovery and connects to the PnP cloud re-direction service connect portal. After successfully connecting the server devicehelper.cisco.com, the server PnP Connect portal sends the publicly reachable TPS DMZ IP(A.B.C.D) PnP proxy IP and the port number (9125) on which the proxy server is listening. The serial number of the gateway should be added to the Cisco Cloud PnP Connect portal for the re-direction service to be successful.

5.![]() Once the PnP discovery is successful, the PnP profile is configured on the device with the publicly reachable TPS DMZ IP. Once the profile is configured, the bootstrapping begins.

Once the PnP discovery is successful, the PnP profile is configured on the device with the publicly reachable TPS DMZ IP. Once the profile is configured, the bootstrapping begins.

6.![]() The rest of the procedure is exactly the same as the bootstrapping steps discussed as part of PnP server discovery through DHCP server.

The rest of the procedure is exactly the same as the bootstrapping steps discussed as part of PnP server discovery through DHCP server.

Bootstrapping Configuration Template on Bootstrapping FND

The bootstrapping template is a configuration template residing on the bootstrapping FND. As part of the bootstrapping procedure, when the bootstrapping request is received from the IoT Gateway, this bootstrap configuration template is used to derive the Cisco IOS configuration, which is then pushed onto the IoT Gateway.

Once this Cisco IOS configuration is pushed onto the IoT Gateway and copied onto a running configuration successfully, the bootstrapping is said to be SUCCESSFUL.

This bootstrapping of Cisco IoT Gateways from Cisco IoT FND (PnP Server) is entirely Zero Touch. This implementation section includes the following sections:

Creation of Bootstrap Configuration Template Group

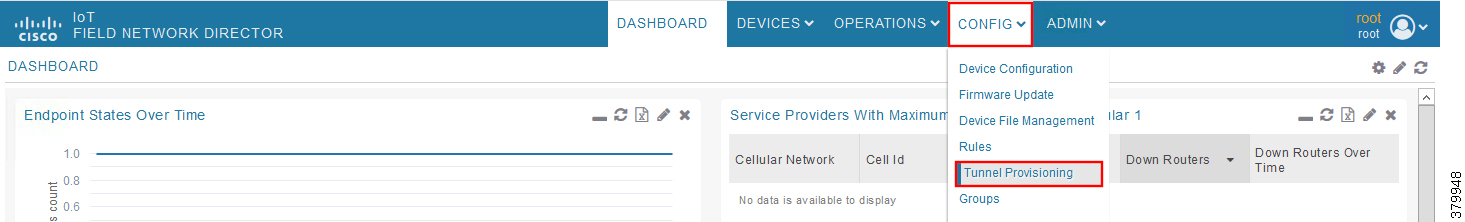

This section covers the steps required for configuring the bootstrapping group.

Figure 23 CREATE Bootstrap—CONFIG—Tunnel Provisioning

1.![]() From the CONFIG Menu, select the Tunnel Provisioning option.

From the CONFIG Menu, select the Tunnel Provisioning option.

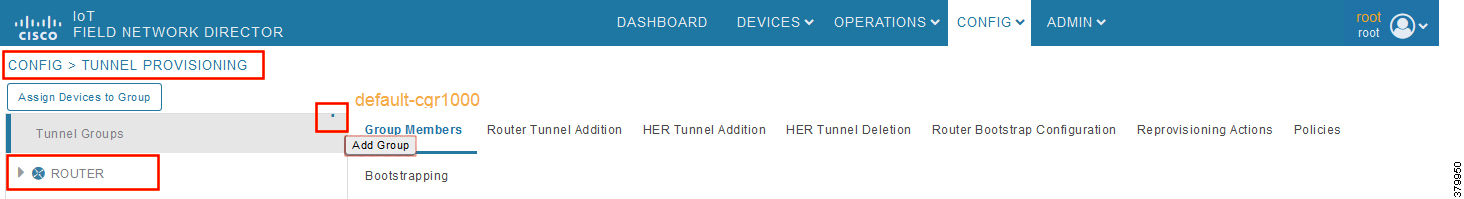

Figure 24 CREATE Bootstrap—Add Group

2.![]() With the Router Group selected in the left pane, click the "+" sign (Add Group icon) located on the top right of the left pane.

With the Router Group selected in the left pane, click the "+" sign (Add Group icon) located on the top right of the left pane.

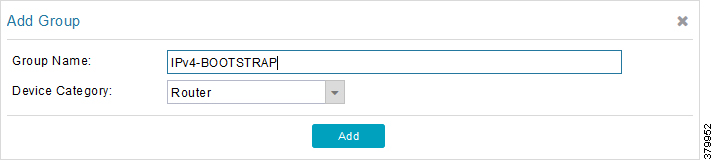

Figure 25 CREATE Bootstrap—Add IPv4 Group

3.![]() Configure the group name IPv4-BOOTSTRAP, and click Add.

Configure the group name IPv4-BOOTSTRAP, and click Add.

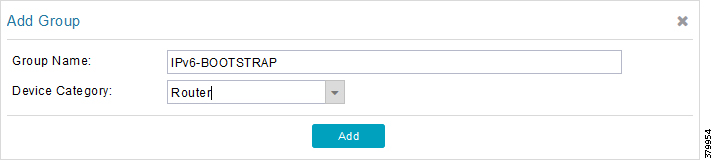

Figure 26 CREATE Bootstrap—Add IPv6 Group

4.![]() Similarly, configure another group name IPv6-BOOTSTRAP for bootstrapping over the IPv6 network. Click Add.

Similarly, configure another group name IPv6-BOOTSTRAP for bootstrapping over the IPv6 network. Click Add.

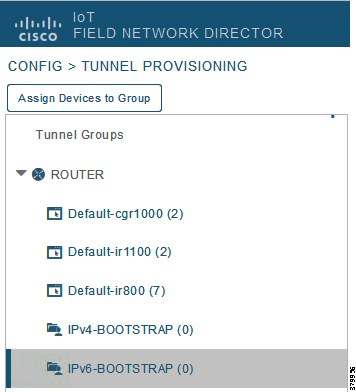

Figure 27 CREATE Bootstrap—List of Bootstrap Groups

The two newly created bootstrapping groups are displayed in the left pane:

■![]() IPv4-BOOTSTRAP (Created to handle bootstrapping over the IPv4 network)

IPv4-BOOTSTRAP (Created to handle bootstrapping over the IPv4 network)

■![]() IPv6-BOOTSTRAP (Created to handle bootstrapping over the IPv6 network)

IPv6-BOOTSTRAP (Created to handle bootstrapping over the IPv6 network)

Moving Devices under the Bootstrapping Group

Multiple bootstrapping groups could be configured on the bootstrapping FND. IoT Gateways have to be moved under the correct group in order to have it bootstrapped with the appropriate configuration.

Complete the following steps to move IoT Gateways under the correct bootstrapping group.

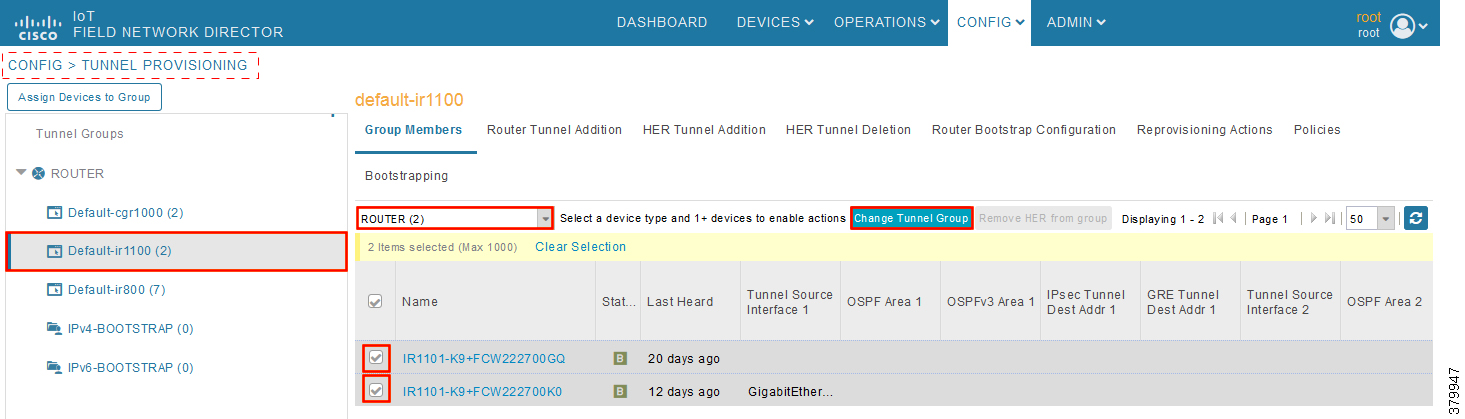

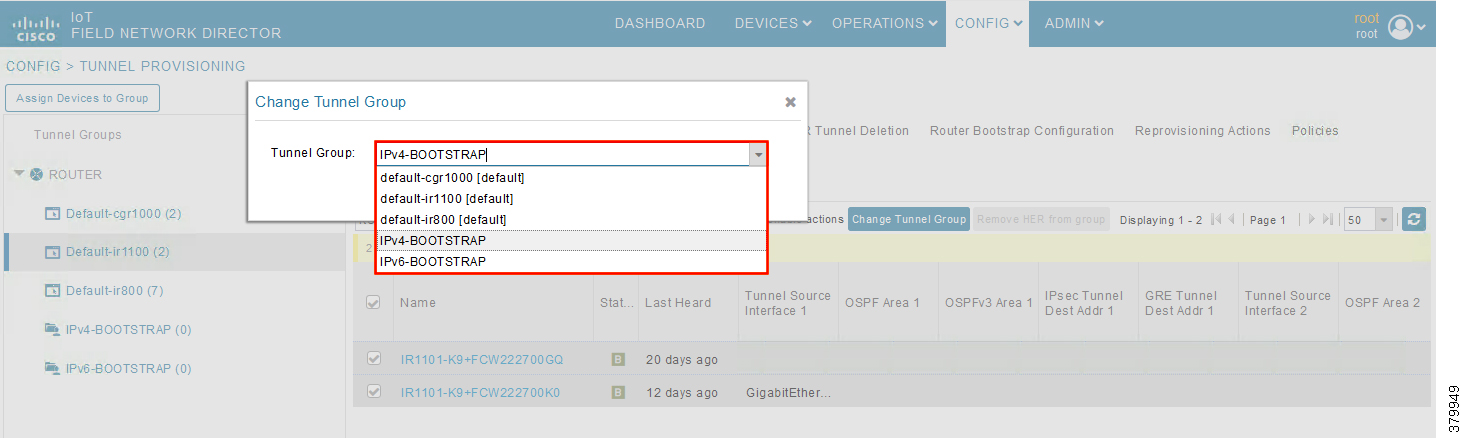

Figure 28 CHANGE Tunnel Group—Device Under Default Group

1.![]() In Figure 28, two IoT Gateways are under the default group. The devices need to be moved to the newly created IPv4-BOOTSTRAP group. In the middle pane, select the Router in the pull-down menu, select the IoT Gateways to be moved under the new bootstrapping group, and then click Change Tunnel Group.

In Figure 28, two IoT Gateways are under the default group. The devices need to be moved to the newly created IPv4-BOOTSTRAP group. In the middle pane, select the Router in the pull-down menu, select the IoT Gateways to be moved under the new bootstrapping group, and then click Change Tunnel Group.

Figure 29 CHANGE Tunnel Group—Pull-Down Menu

2.![]() Choose the correct bootstrap group IPv4-BOOTSTRAP. To perform bootstrapping over the IPv6 network, choose the IPv6-BOOTSTRAP tunnel group.

Choose the correct bootstrap group IPv4-BOOTSTRAP. To perform bootstrapping over the IPv6 network, choose the IPv6-BOOTSTRAP tunnel group.

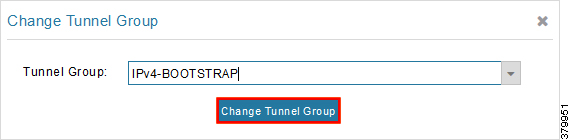

Figure 30 CHANGE Tunnel Group—Select IPv4 Group

3.![]() With the appropriate bootstrap group chosen, click Change Tunnel Group to move the IoT Gateway from the default group to the desired group.

With the appropriate bootstrap group chosen, click Change Tunnel Group to move the IoT Gateway from the default group to the desired group.

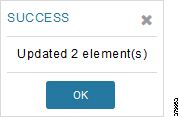

Figure 31 CHANGE Tunnel Group—Updated IPv4 Group

Device migration to the desired group was successful.

Figure 32 CHANGE Tunnel Group—Devices Moved under IPv4 Group

In Figure 30, it can be seen that IoT Gateways were moved under the correct bootstrapping group.

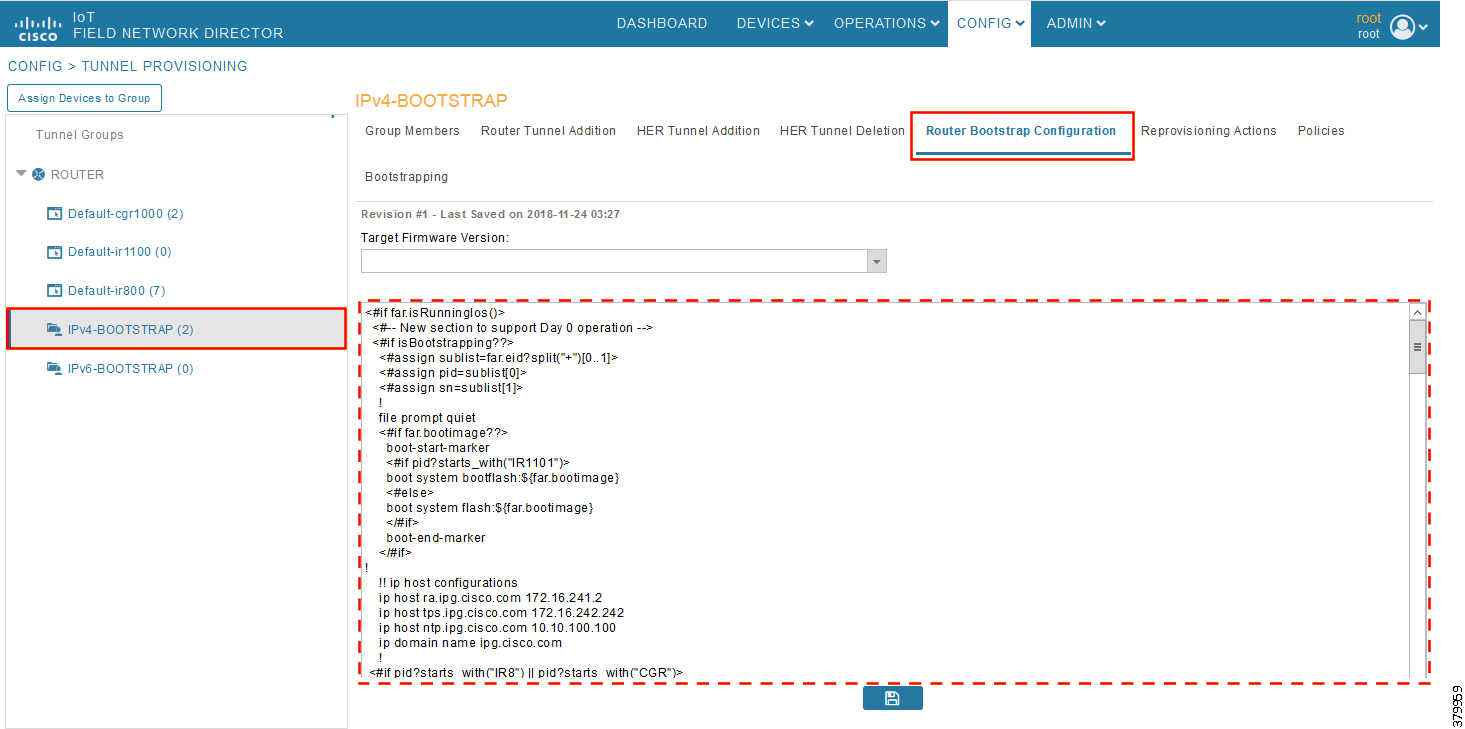

Router Bootstrap Configuration Groups—Populating Templates

This section shows where to populate the bootstrapping template in FND, and the template that needs to be chosen for bootstrapping of the IoT Gateways according to the network in which the IoT Gateway would be deployed (for example, IPv4/IPv6 network, located/not located behind NAT, etc).

Note: Working versions of bootstrapping templates can be found in Appendix A: PnP Profiles.

Figure 33 captures the Router Bootstrap Configuration section that needs to be populated for the purpose of bootstrapping.

Figure 33 Router Bootstrap Configuration

Every bootstrap group (referred as Tunnel Group in the left pane) can be populated with a unique Router bootstrap configuration.

With reference to Table 10, for bootstrapping the IoT Gateways for deployment over the IPv4 network:

■![]() If IoT Gateways are located behind NAT, then the bootstrapping template IPv4- BOOTSTRAP-NAT could be used.

If IoT Gateways are located behind NAT, then the bootstrapping template IPv4- BOOTSTRAP-NAT could be used.

■![]() If IoT Gateways are not located behind NAT, then the bootstrapping template IPv4- BOOTSTRAP could be used.

If IoT Gateways are not located behind NAT, then the bootstrapping template IPv4- BOOTSTRAP could be used.

Similarly, for bootstrapping the IoT Gateways for deployment over IPv6 network:

■![]() If IoT Gateways are located behind NAT, then the bootstrapping template IPv6- BOOTSTRAP-NAT could be used.

If IoT Gateways are located behind NAT, then the bootstrapping template IPv6- BOOTSTRAP-NAT could be used.

■![]() If IoT Gateways are not located behind NAT, then the bootstrapping template IPv6- BOOTSTRAP could be used.

If IoT Gateways are not located behind NAT, then the bootstrapping template IPv6- BOOTSTRAP could be used.

Deployment of the Cisco IoT Gateway

This section includes the following topics:

■![]() Deployment over IPv4 Cellular Network with NAT

Deployment over IPv4 Cellular Network with NAT

Prerequisites for Deployment

■![]() Cisco IoT Gateway should have gone through the bootstrapping procedure mentioned in Bootstrapping the IoT Gateway, with the device being part of the appropriate bootstrapping group.

Cisco IoT Gateway should have gone through the bootstrapping procedure mentioned in Bootstrapping the IoT Gateway, with the device being part of the appropriate bootstrapping group.

■![]() Bootstrapping is said to be complete, when the Cisco IOS Routers received the bootstrapping configuration from the Bootstrapping FND.

Bootstrapping is said to be complete, when the Cisco IOS Routers received the bootstrapping configuration from the Bootstrapping FND.

■![]() The bootstrapping status for the router on the Bootstrapping FND must be in ‘Bootstrapped’ state.

The bootstrapping status for the router on the Bootstrapping FND must be in ‘Bootstrapped’ state.

Deployment Infrastructure Readiness

■![]() Cisco IoT Gateway should be assigned an IPv4/IPv6 address dynamically over Ethernet/Cellular. If a static address needs to be used on the Cisco IoT Gateway, then assignment of address to the Cisco IoT Gateway's interface needs to be taken care as part of Bootstrapping.

Cisco IoT Gateway should be assigned an IPv4/IPv6 address dynamically over Ethernet/Cellular. If a static address needs to be used on the Cisco IoT Gateway, then assignment of address to the Cisco IoT Gateway's interface needs to be taken care as part of Bootstrapping.

Tip: If any extra configuration is required to receive IP address dynamically, the delta configuration should be fed back into the bootstrapping profile, that was used to bootstrap the IoT Gateway.

■![]() Cisco Field Area Network—Headend (DSO Control Center1) should be UP and running.

Cisco Field Area Network—Headend (DSO Control Center1) should be UP and running.

–![]() If it needs to be set up, the Cisco FAN-Headend Deep Dive Implementation and FAN Use Cases' guide could be referenced to set up the headend in the DSO Control Center or NOC.

If it needs to be set up, the Cisco FAN-Headend Deep Dive Implementation and FAN Use Cases' guide could be referenced to set up the headend in the DSO Control Center or NOC.

■![]() All the required headend components like the CA server (RSA), AAA, AD, Registration Authority, NOC TPS/FND, DHCP server, and HERs are expected to be up and running in the DSO Control Center.

All the required headend components like the CA server (RSA), AAA, AD, Registration Authority, NOC TPS/FND, DHCP server, and HERs are expected to be up and running in the DSO Control Center.

■![]() NOC TPS, RA, and HERs must have static IP addresses configured and should be reachable from the Cisco IoT Gateways that are located along the Distribution network.

NOC TPS, RA, and HERs must have static IP addresses configured and should be reachable from the Cisco IoT Gateways that are located along the Distribution network.

Note: If the prerequisites for deployment are addressed, ZTD of the IoT Gateways should happen successfully after the gateway is deployed at the desired location and powered on, with the Ethernet cable connected or the LTE SIM card inserted.

Deployment over IPv4 Cellular Network with NAT

Note: This section has no implementation steps. As the term "ZTD" states, it's a zero touch deployment. As long as bootstrapping happened successfully by having the IoT Gateway part of the correct bootstrapping group, this deployment should happen successfully with no manual steps.

Figure 34 captures the deployment steps for IoT Gateway over LTE Cellular.

Figure 34 Deployment over IPv4 Cellular Network

Note: This scenario has been validated with the headend located in the Cisco DMZ.

The following is the summary sequence of steps that occurs during the deployment:

1.![]() The IoT Gateway is powered on. When up, it obtains the IP address over LTE Cellular interface.

The IoT Gateway is powered on. When up, it obtains the IP address over LTE Cellular interface.

2.![]() The EEM Script for ZTD kicks in and waits for the time to be synchronized. Then, SCEP enrollment happens over port 80 with RA-DMZ-IP.

The EEM Script for ZTD kicks in and waits for the time to be synchronized. Then, SCEP enrollment happens over port 80 with RA-DMZ-IP.

3.![]() Once the certificate is received for the IoT Gateway (from the RA/CA), the ZTD script disables itself and activates the CGNA profile for tunnel provisioning (cgna initiator-profile cg-nms-tunnel).

Once the certificate is received for the IoT Gateway (from the RA/CA), the ZTD script disables itself and activates the CGNA profile for tunnel provisioning (cgna initiator-profile cg-nms-tunnel).

Note: "cgna initiator-profile cg-nms-tunnel" must be used when the IoT Gateway is behind NAT, whereas "cgna profile cg-nms-tunnel" must be used when no NAT exists between IoT Gateway and TPS. This CGNA profile is configured as part of bootstrapping.

4.![]() TPS/FND provisions the secure FlexVPN tunnel with the HER Cluster located in the DSO Control Center1.

TPS/FND provisions the secure FlexVPN tunnel with the HER Cluster located in the DSO Control Center1.

5.![]() As an overlay routing, FND and SCADA routes are advertised (by the HER) to the IoT Gateway through the secure FlexVPN tunnel.

As an overlay routing, FND and SCADA routes are advertised (by the HER) to the IoT Gateway through the secure FlexVPN tunnel.

6.![]() The IoT Gateway sends out a registration request to FND on port 9121. Once registered successfully, the IOT Gateway is remotely manageable from the FND.

The IoT Gateway sends out a registration request to FND on port 9121. Once registered successfully, the IOT Gateway is remotely manageable from the FND.

7.![]() As part of the device registration with the FND, FND also pushes ICT enablement configurations to the IoT Gateway, which enables the communication between the SCADA Master in the Control Center and the SCADA Outstation located in the Feeder Automation/Distribution Network.

As part of the device registration with the FND, FND also pushes ICT enablement configurations to the IoT Gateway, which enables the communication between the SCADA Master in the Control Center and the SCADA Outstation located in the Feeder Automation/Distribution Network.

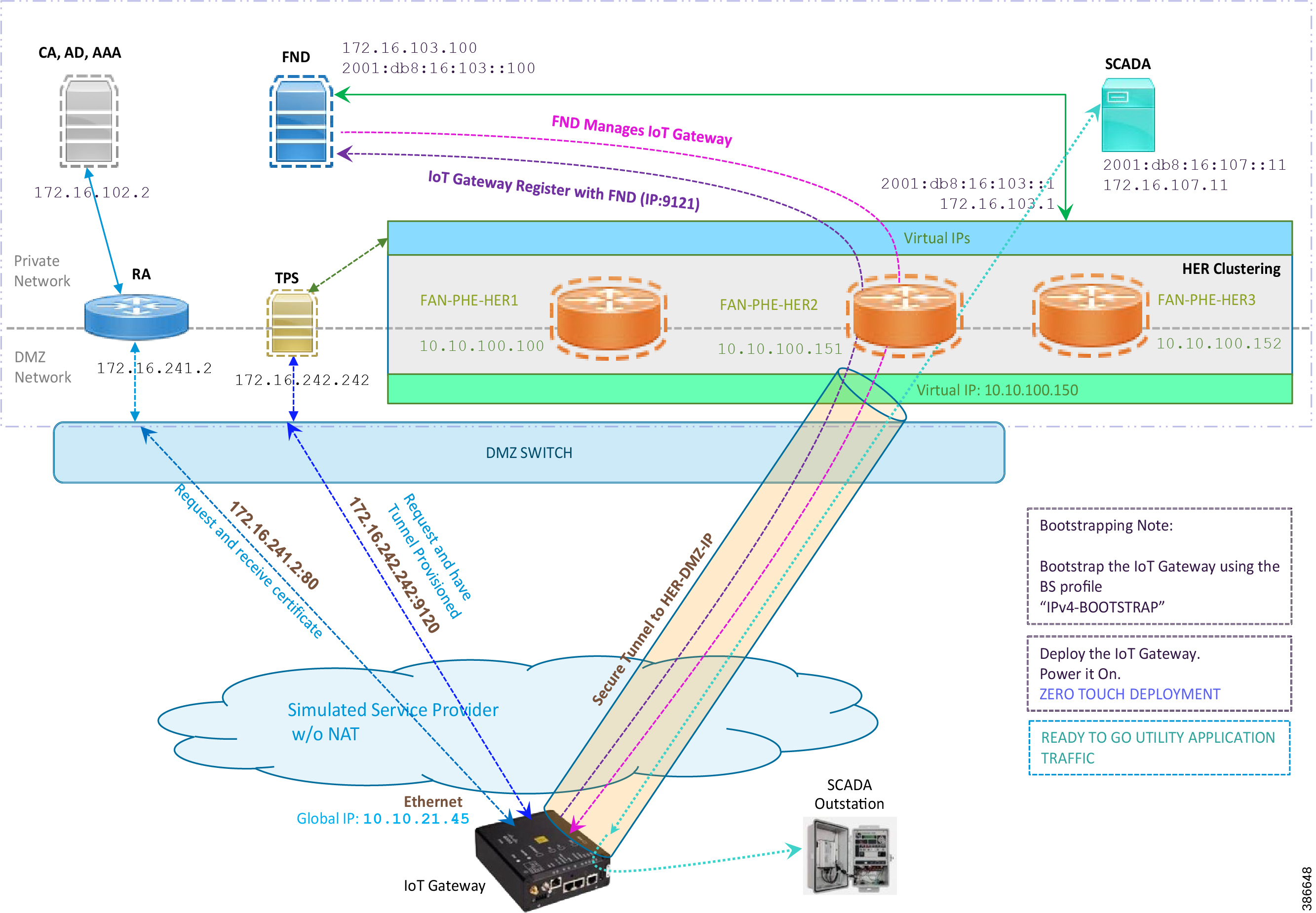

Deployment over IPv4 Network without NAT

Note: This section has no implementation steps. As the term "ZTD" states, it's a zero touch deployment. As long as bootstrapping happened successfully by having the IoT Gateway part of the right bootstrapping group, this deployment should happen successfully with no manual steps.

Figure 33 captures the deployment steps for IoT Gateway without NAT over the IPv4 network.

Figure 35 Deployment over IPv4 Ethernet Network

Note: This scenario has been validated with the headend located in the Engineering Lab.

The following is the summary sequence of steps that happens during the deployment:

1.![]() The IoT Gateway is powered on. When up, it obtains the IP address over the Ethernet interface.

The IoT Gateway is powered on. When up, it obtains the IP address over the Ethernet interface.

2.![]() The EEM Script for ZTD kicks in and waits for the time to be synchronized. Then, SCEP enrollment happens with RA IP (172.16.241.2) on port 80.

The EEM Script for ZTD kicks in and waits for the time to be synchronized. Then, SCEP enrollment happens with RA IP (172.16.241.2) on port 80.

3.![]() Once the certificate is received for the IoT Gateway (from the RA/CA), the ZTD script disables itself, and activates the CGNA profile for tunnel provisioning (cgna profile cg-nms- tunnel).

Once the certificate is received for the IoT Gateway (from the RA/CA), the ZTD script disables itself, and activates the CGNA profile for tunnel provisioning (cgna profile cg-nms- tunnel).

Note: "cgna profile cg-nms-tunnel" must be used when there is no NAT between IoT Gateway and TPS. This CGNA profile has already been configured as part of IoT Gateway bootstrapping. TPS/FND provisions secure FlexVPN tunnel with the HER Cluster located in the DSO Control Center1.

4.![]() As an overlay routing, FND (172.16.103.100 and 2001:db8:16:103::100) and SCADA (172.16.107.11 and 2001:db8:16:107::11) routes are advertised (by HER) to the IoT Gateway through the secure FlexVPN tunnel.

As an overlay routing, FND (172.16.103.100 and 2001:db8:16:103::100) and SCADA (172.16.107.11 and 2001:db8:16:107::11) routes are advertised (by HER) to the IoT Gateway through the secure FlexVPN tunnel.

5.![]() IoT Gateway sends out a registration request to FND IPv4 address 172.16.103.100 (or) IPv6 address 2001:db8:16:103::100 on port 9121. Once registered successfully, the IOT Gateway is remotely manageable from the FND.

IoT Gateway sends out a registration request to FND IPv4 address 172.16.103.100 (or) IPv6 address 2001:db8:16:103::100 on port 9121. Once registered successfully, the IOT Gateway is remotely manageable from the FND.

6.![]() As part of the device registration with the FND, FND also pushes ICT enablement configurations to the IoT Gateway, which enables the communication between SCADA Master in the Control Center and the SCADA Outstation located in the Feeder Automation/Distribution Network.

As part of the device registration with the FND, FND also pushes ICT enablement configurations to the IoT Gateway, which enables the communication between SCADA Master in the Control Center and the SCADA Outstation located in the Feeder Automation/Distribution Network.

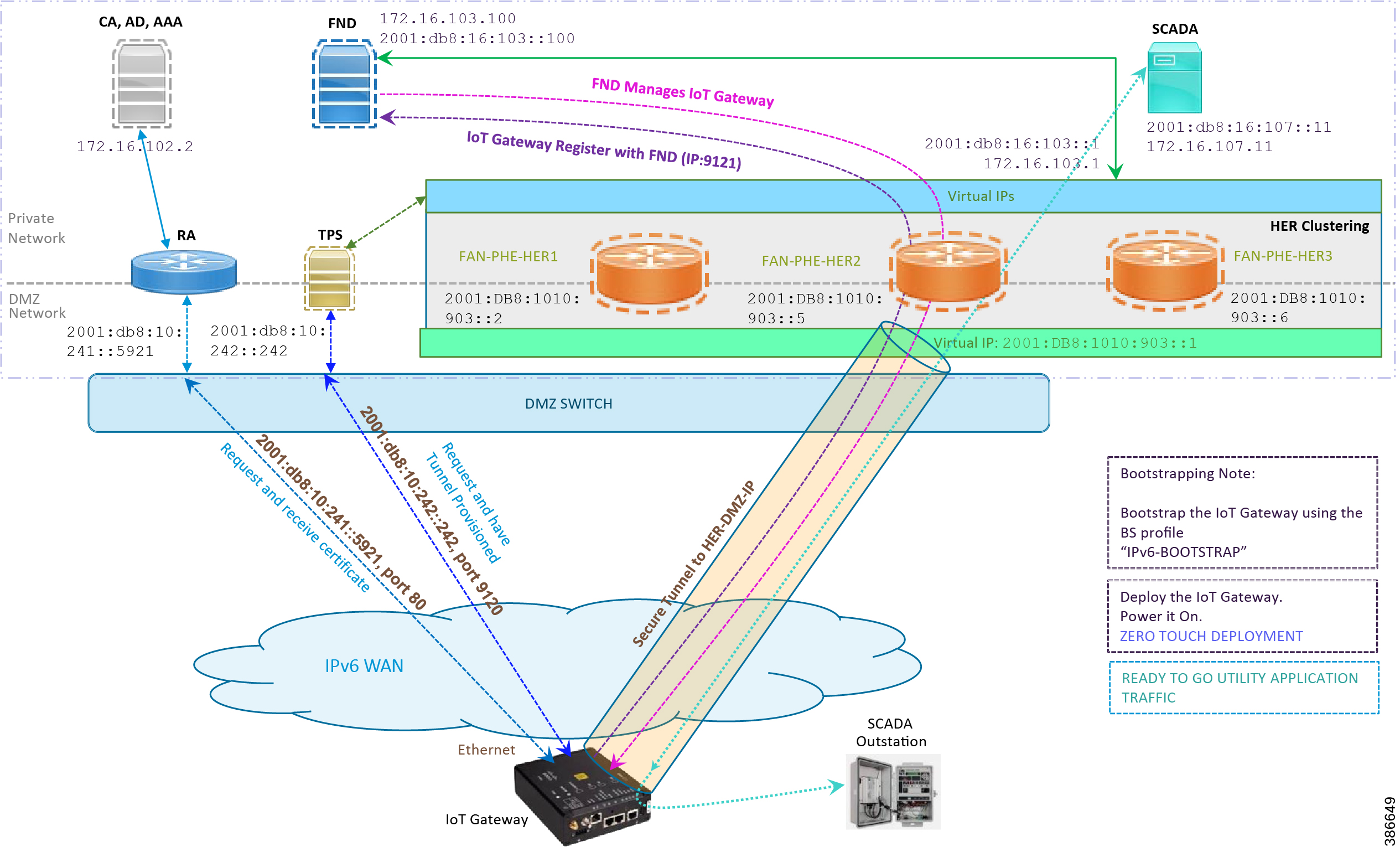

Deployment over Native IPv6 Ethernet Network

Note: This section has no implementation steps. As the term "ZTD" states, it's a zero touch deployment. As long as bootstrapping happened successfully by having the IoT Gateway part of the right bootstrapping group, this deployment should happen successfully with no manual steps.

Figure 36 captures the deployment steps for the IoT Gateway over the Native IPv6 network.

Figure 36 Deployment over Native IPv6 Ethernet Network

Note: This scenario has been validated with the headend located in the Engineering Lab over a native IPv6 network. It could be dual stack as well.

The following is the summary sequence of steps that happens during the deployment:

1.![]() The IoT Gateway is powered on. When up, it obtains the IPv6 address over the Ethernet interface.

The IoT Gateway is powered on. When up, it obtains the IPv6 address over the Ethernet interface.

2.![]() The EEM script for ZTD kicks in and waits for the time to be synchronized. Then, SCEP enrollment happens with RA IPv6 address (2001:db8:10:241::5921) on port 80.

The EEM script for ZTD kicks in and waits for the time to be synchronized. Then, SCEP enrollment happens with RA IPv6 address (2001:db8:10:241::5921) on port 80.

3.![]() IPv4 communication could be retained between RA and CA in the Control Center private network.

IPv4 communication could be retained between RA and CA in the Control Center private network.

4.![]() Once the certificate is received for the IoT Gateway (from the RA/CA), the ZTD script disables itself, and activates the CGNA profile for tunnel provisioning.

Once the certificate is received for the IoT Gateway (from the RA/CA), the ZTD script disables itself, and activates the CGNA profile for tunnel provisioning.

Note: "cgna initiator-profile cg-nms-tunnel" must be used when the IoT Gateway is behind NAT, whereas "cgna profile cg-nms-tunnel" must be used when there is no NAT between IoT Gateway and TPS. This CGNA profile has already been configured as part of the IoT Gateway bootstrapping.

5.![]() TPS/FND provisions secure the FlexVPN tunnel with the HER Cluster located in the DSO Control Center, over the Native IPv6 network.

TPS/FND provisions secure the FlexVPN tunnel with the HER Cluster located in the DSO Control Center, over the Native IPv6 network.

6.![]() As an overlay routing, FND (172.16.103.100 and 2001:db8:16:103::100) and SCADA (172.16.107.11 and 2001:db8:16:107::11) routes are advertised (by HER) to the IoT Gateway through the secure FlexVPN tunnel.

As an overlay routing, FND (172.16.103.100 and 2001:db8:16:103::100) and SCADA (172.16.107.11 and 2001:db8:16:107::11) routes are advertised (by HER) to the IoT Gateway through the secure FlexVPN tunnel.

7.![]() IoT Gateway sends out a registration request to FND IPv4 address 172.16.103.100 (or) IPv6 address 2001:db8:16:103::100 on port 9121. Once registered successfully, IOT Gateway is remotely manageable from the FND.

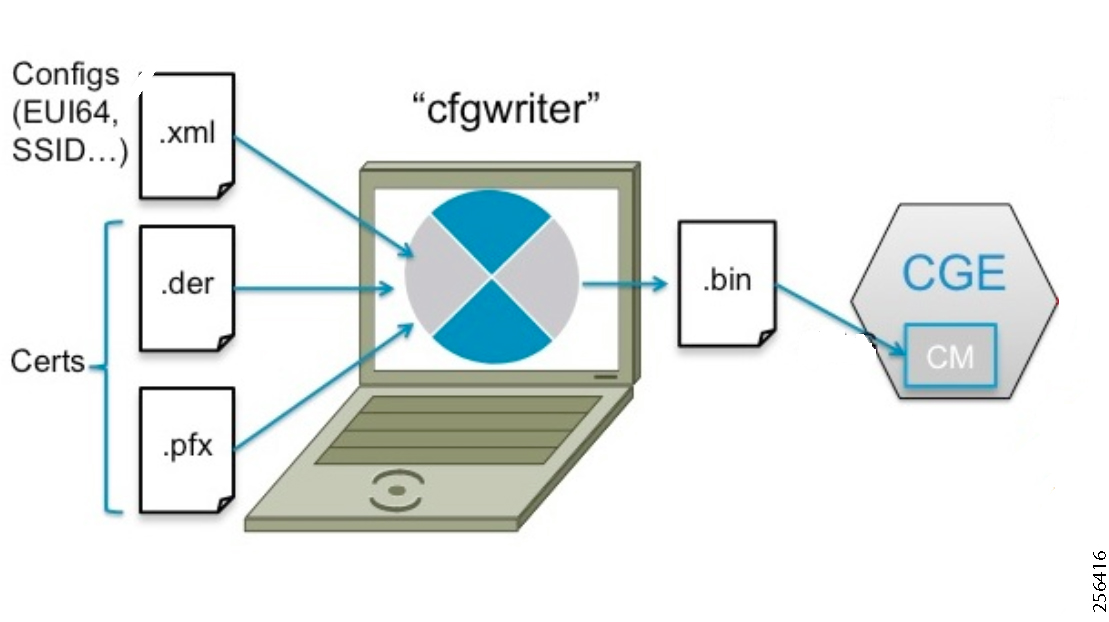

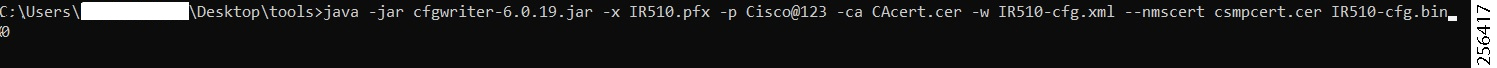

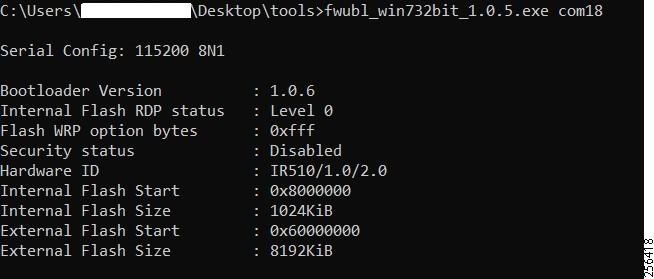

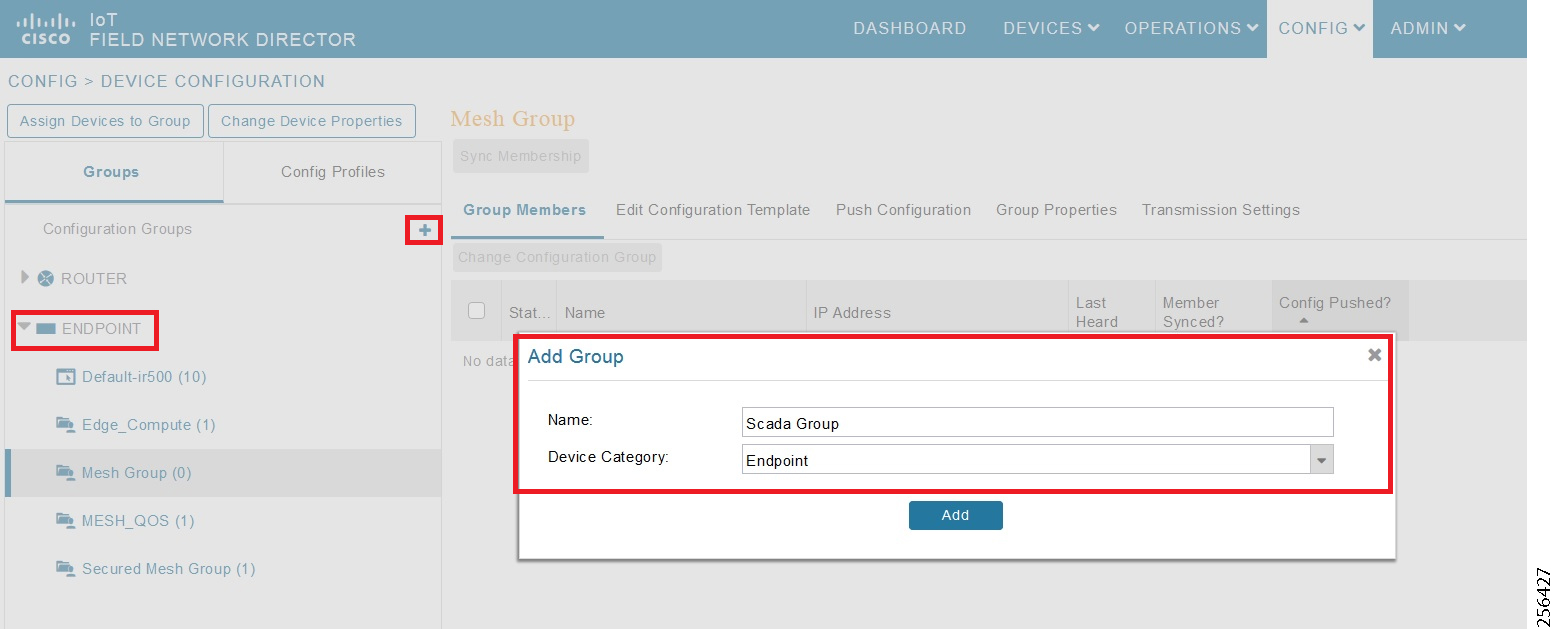

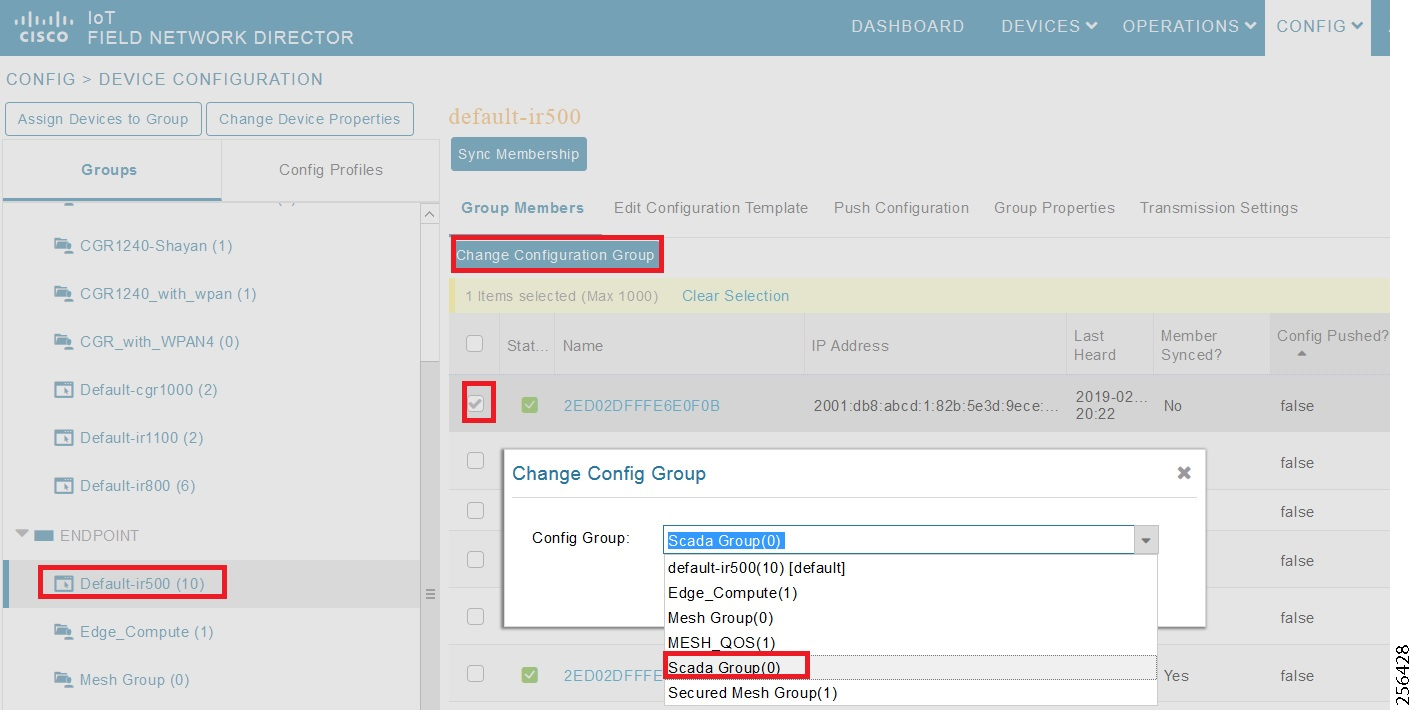

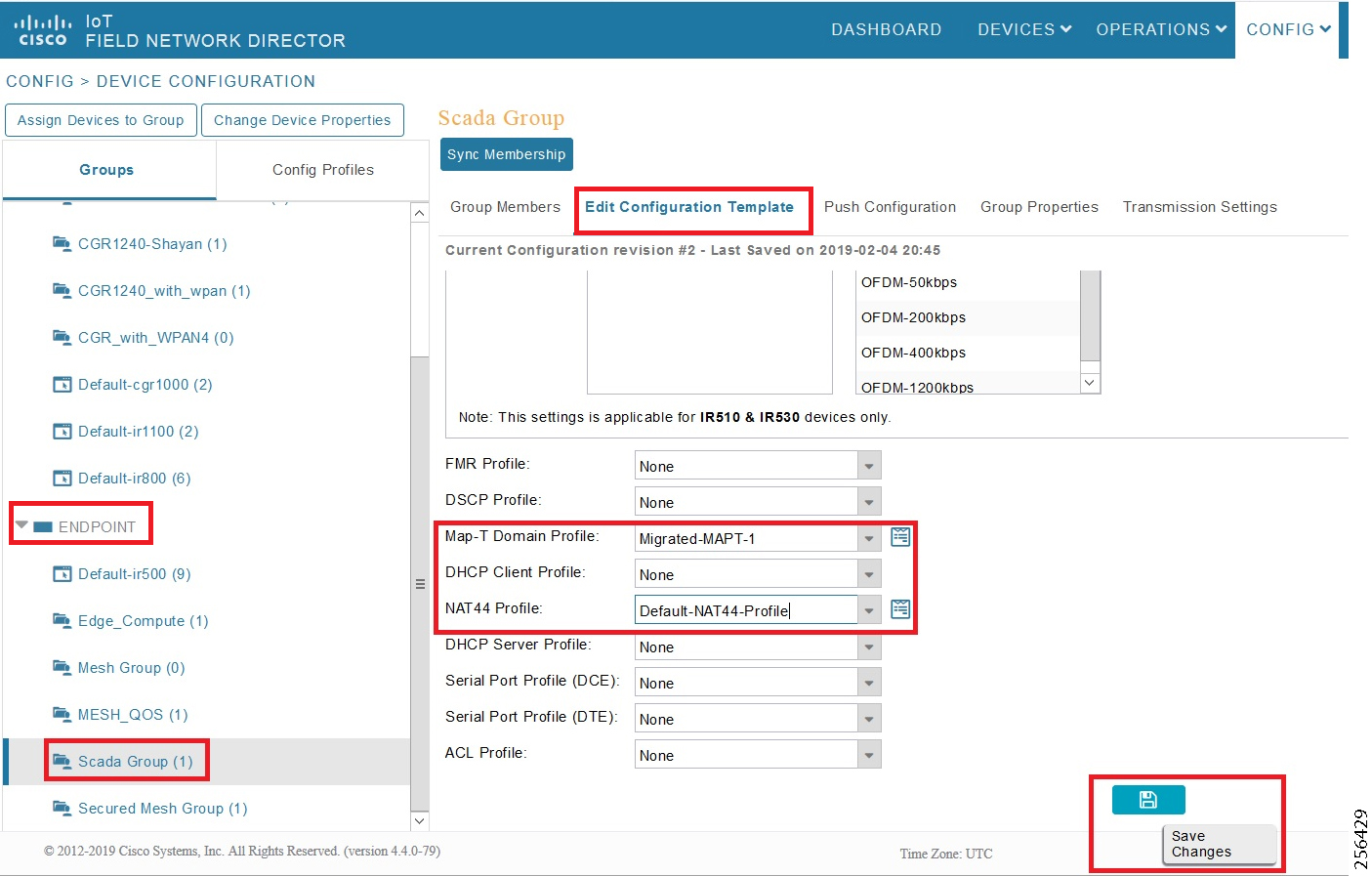

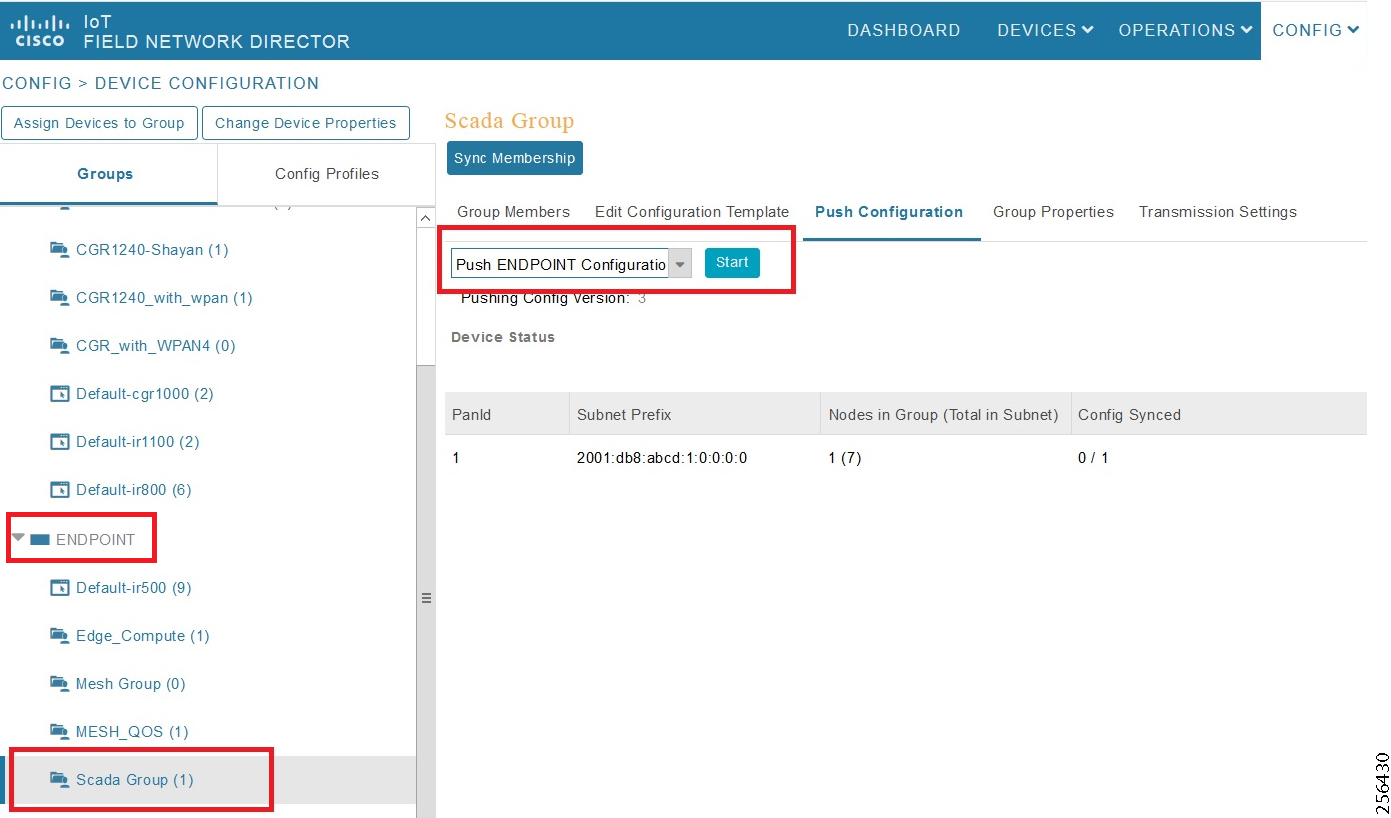

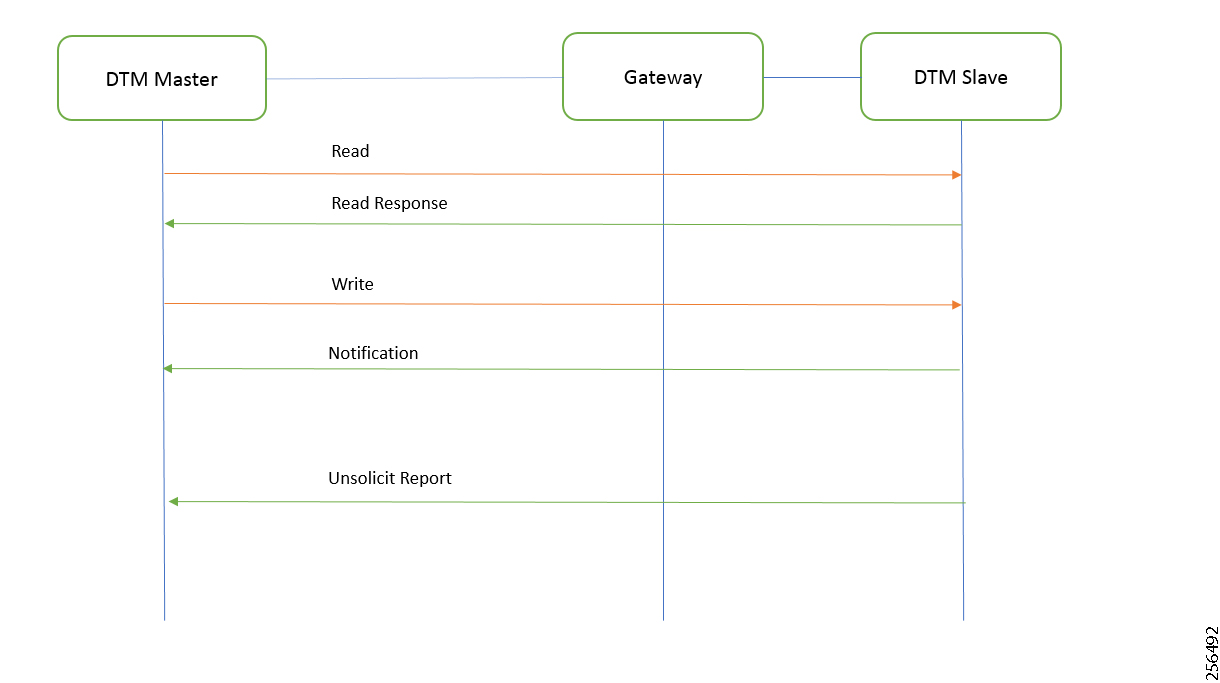

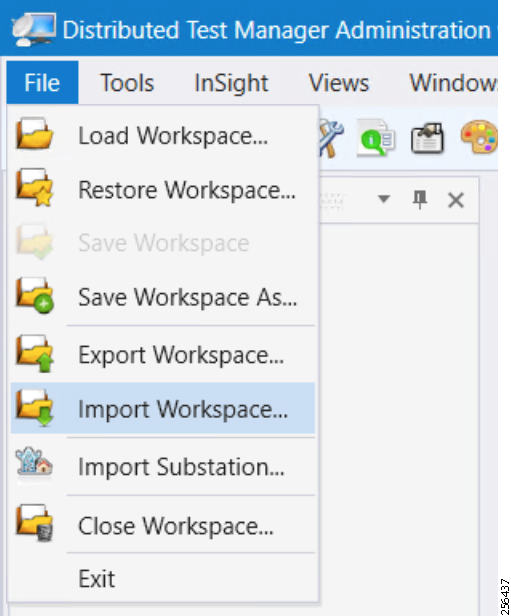

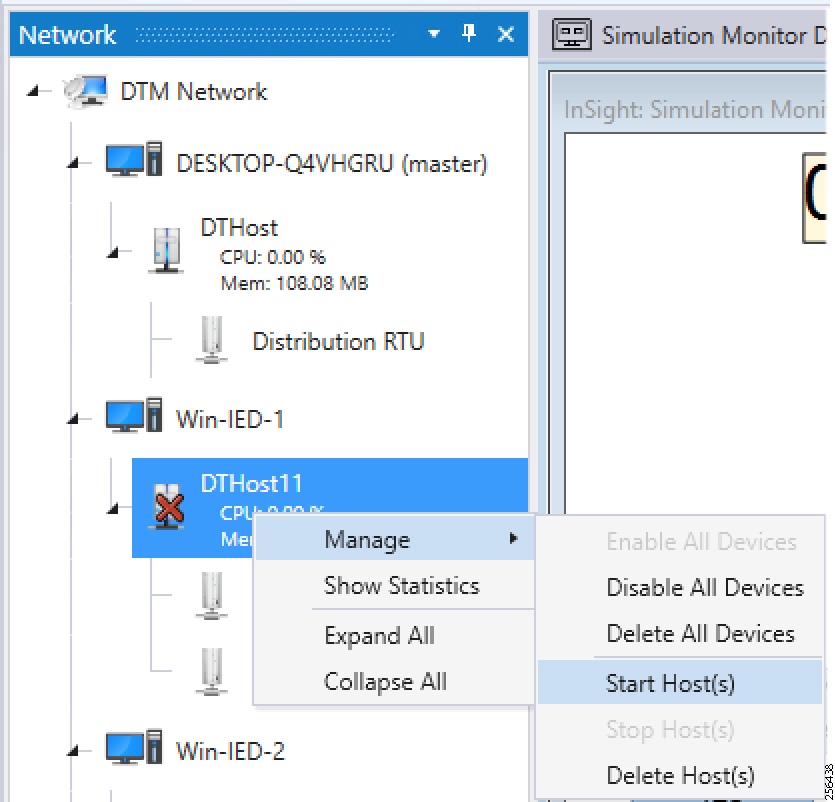

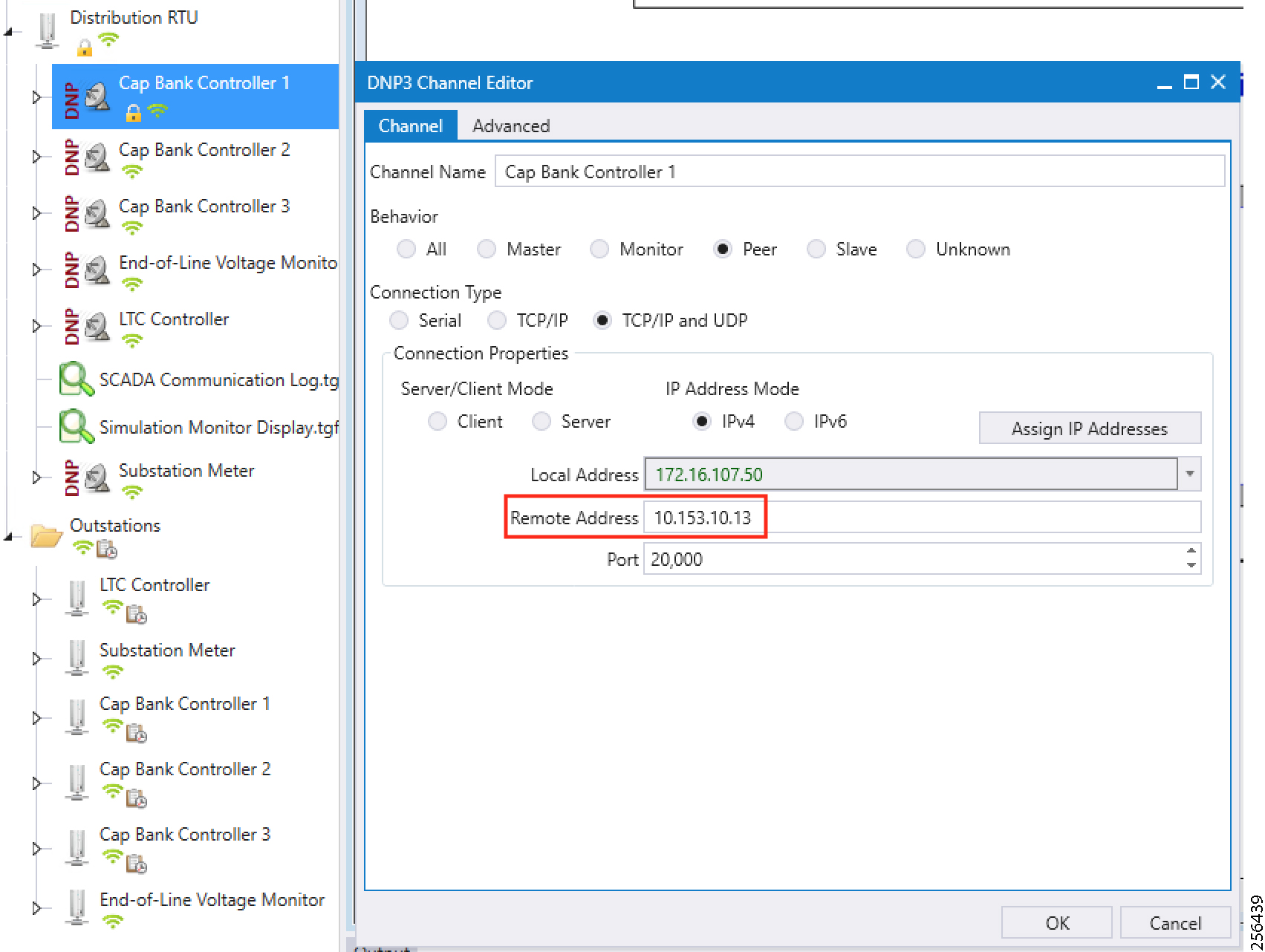

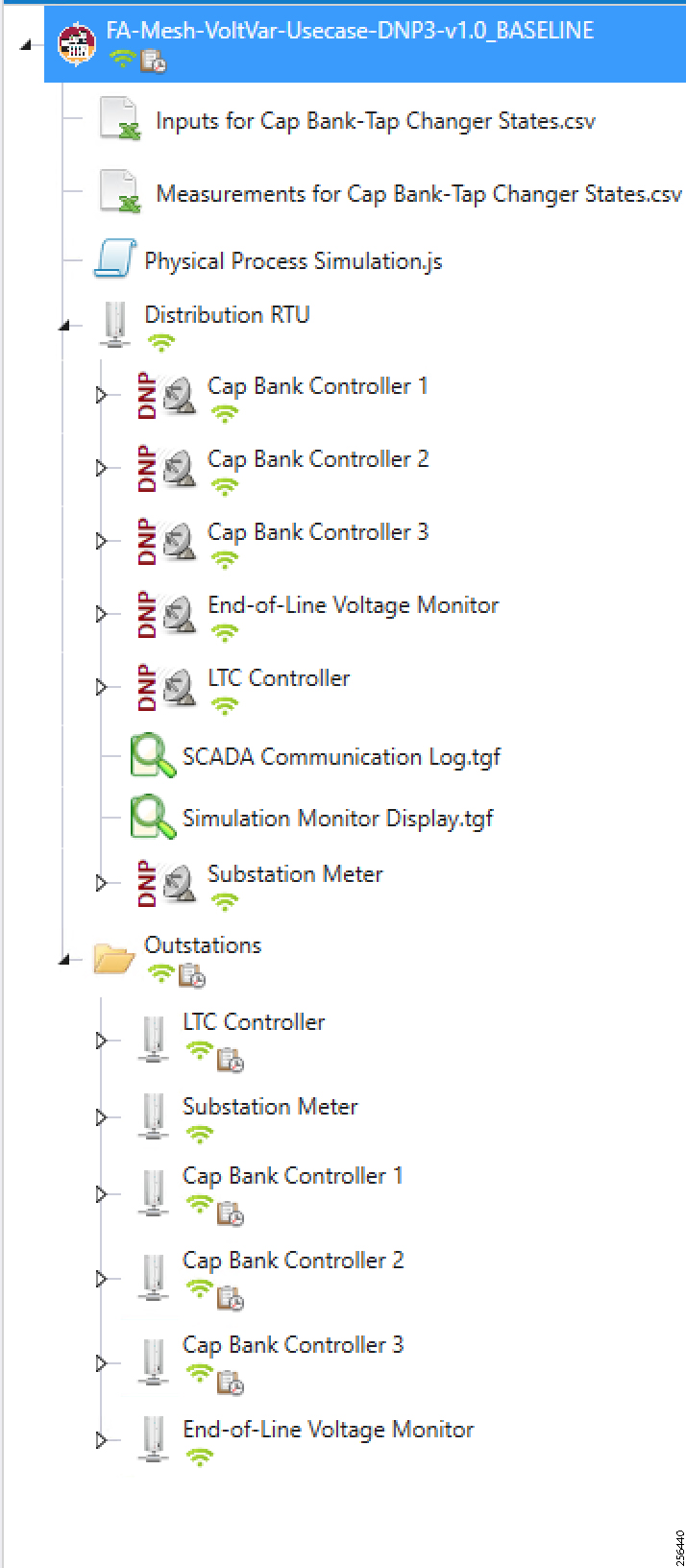

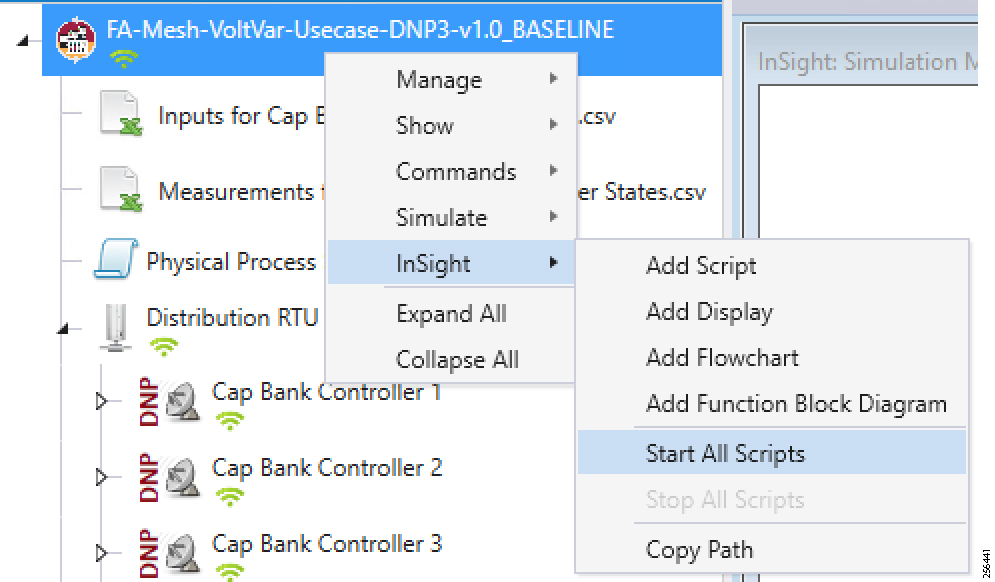

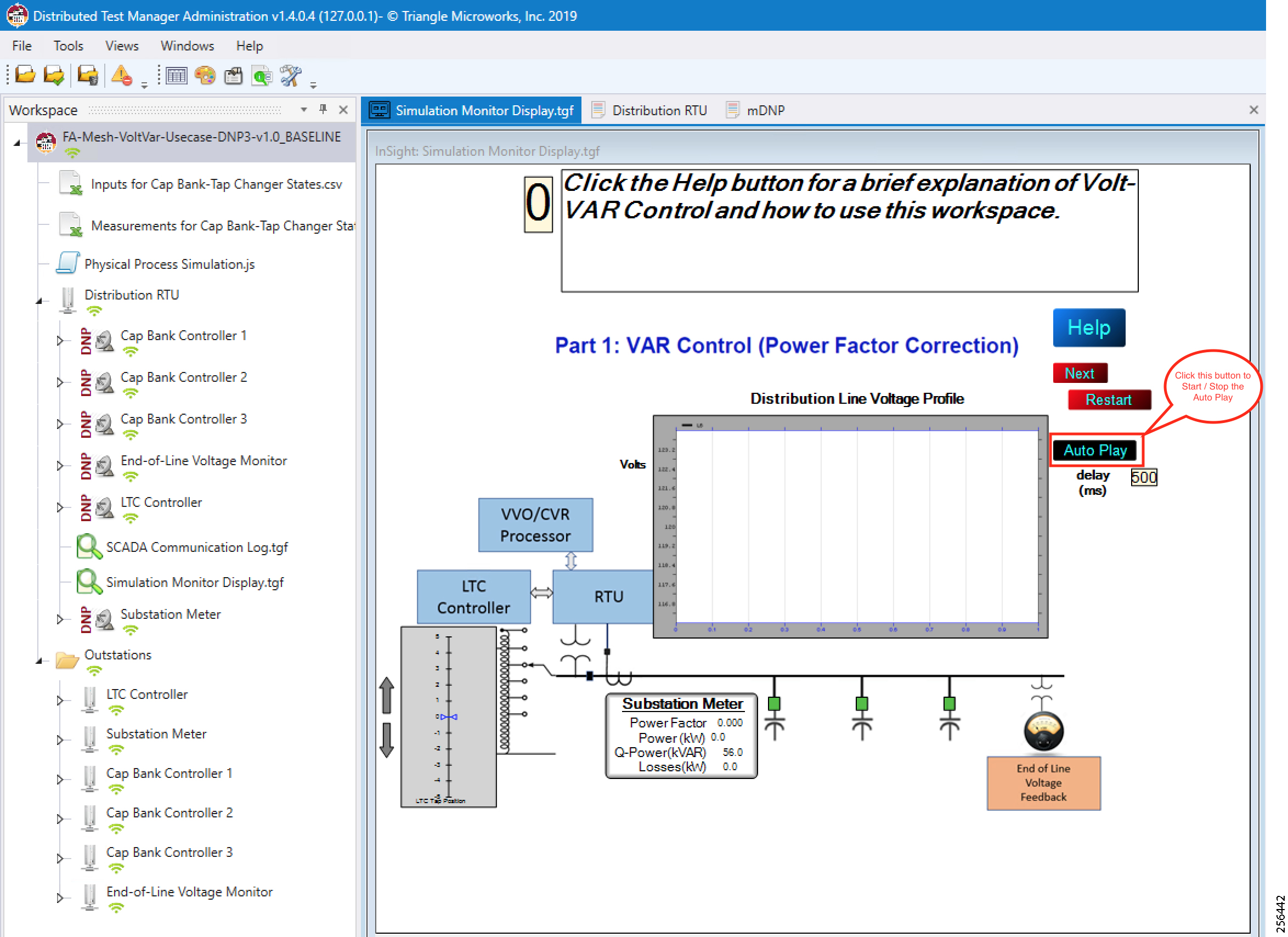

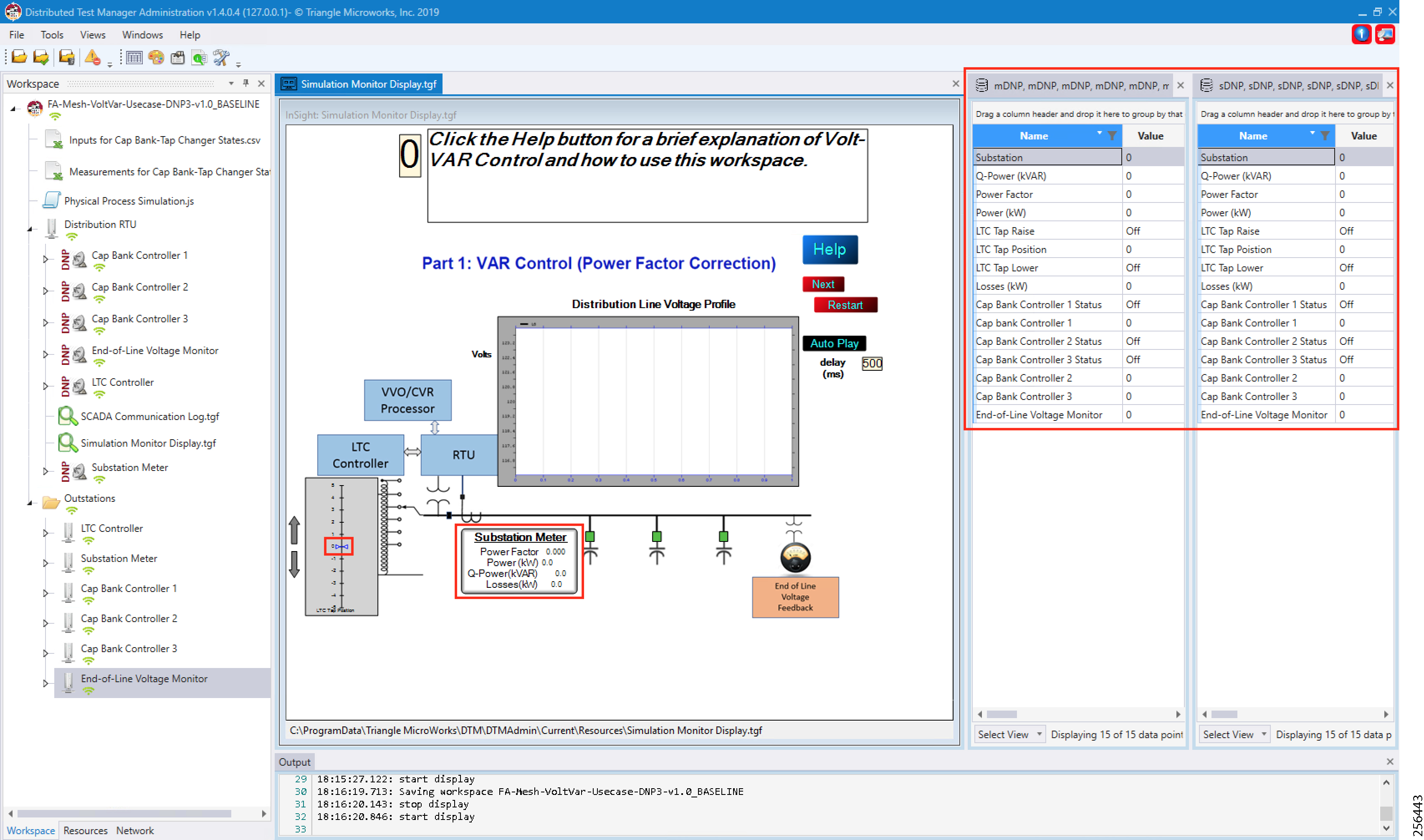

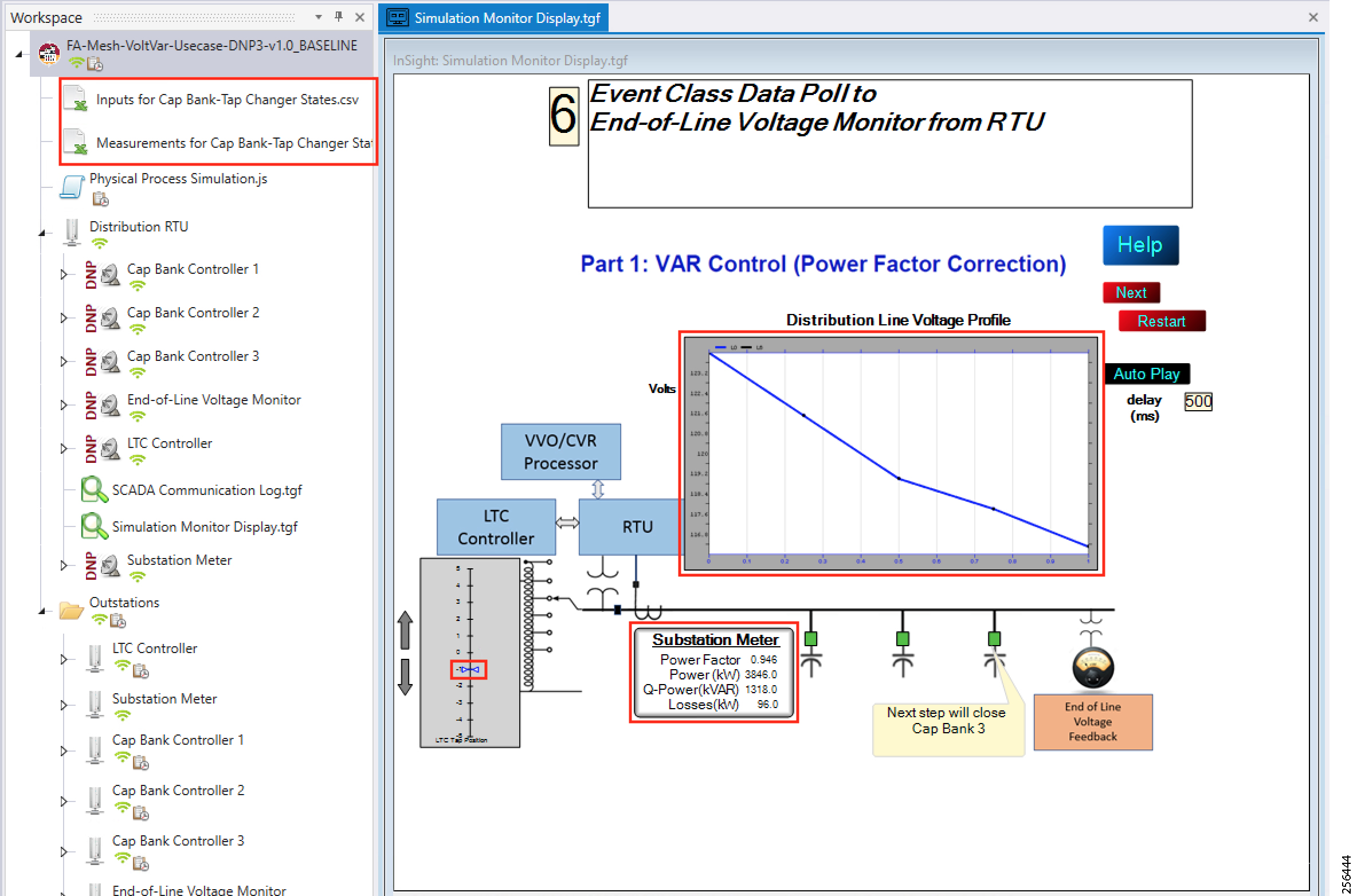

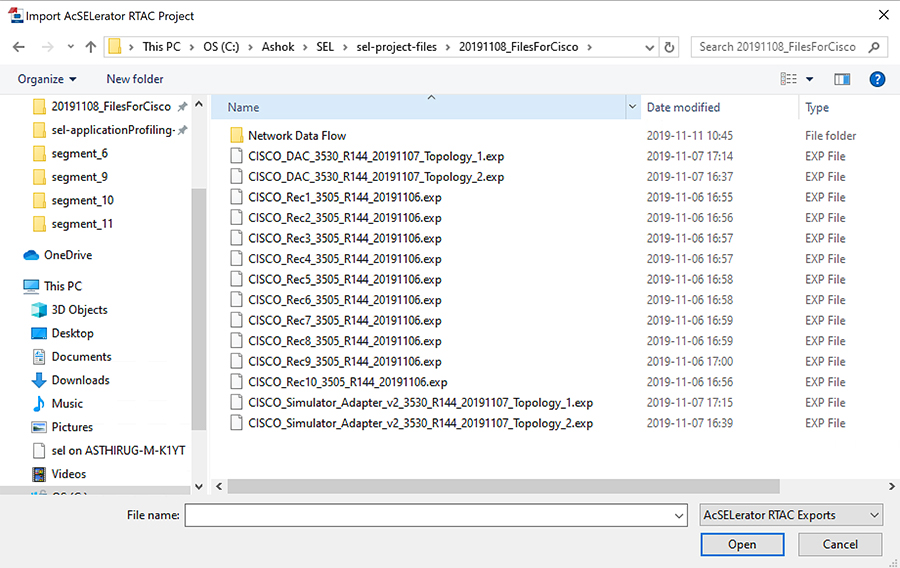

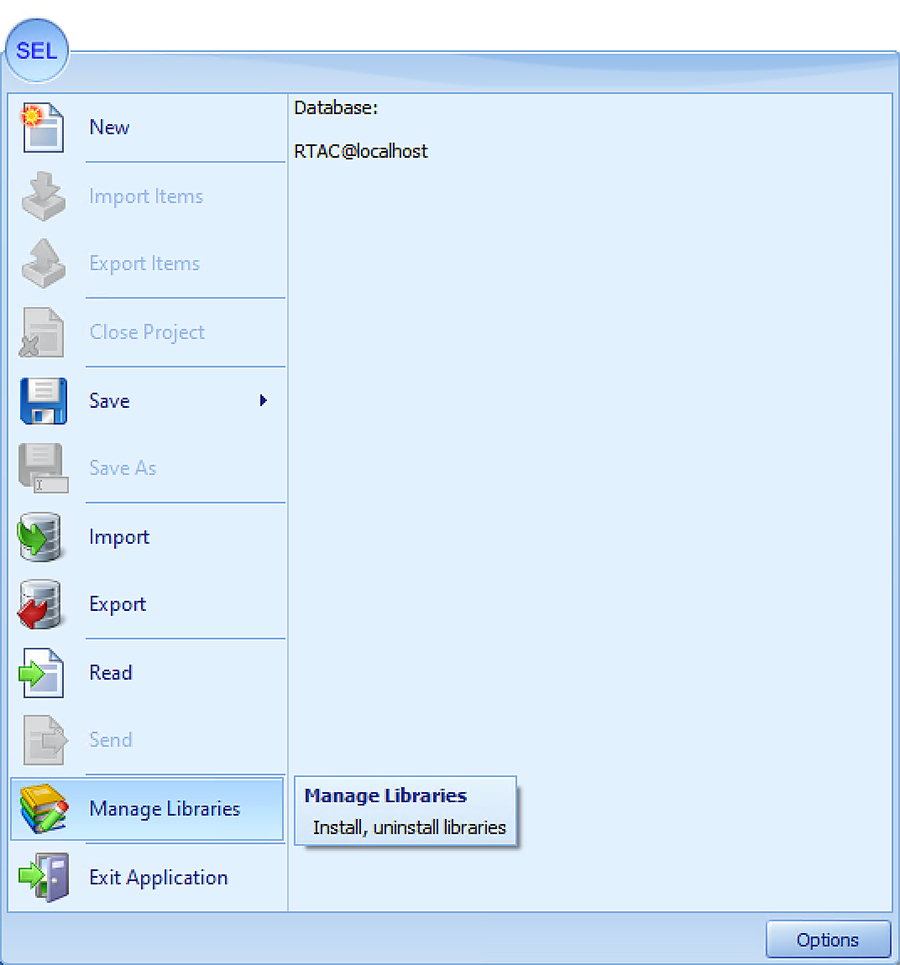

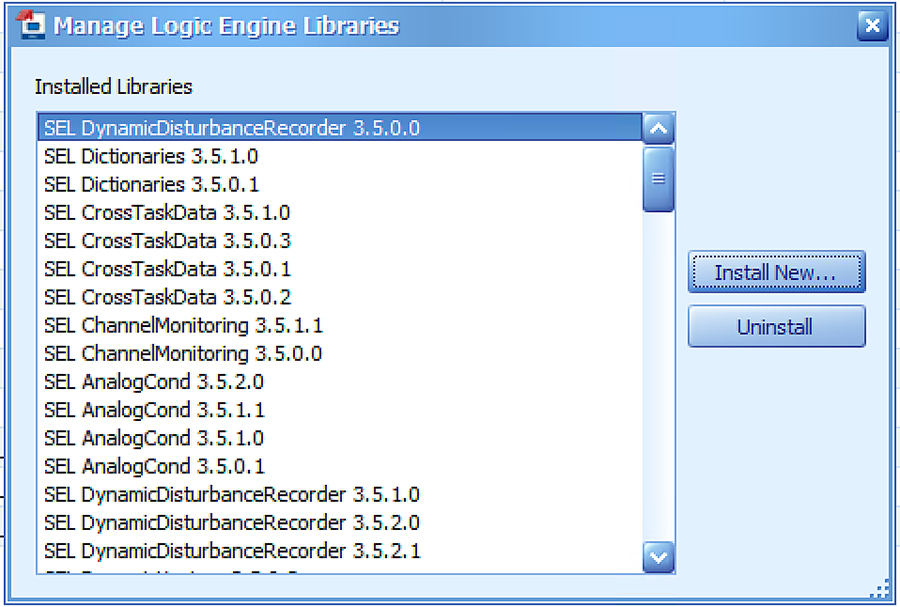

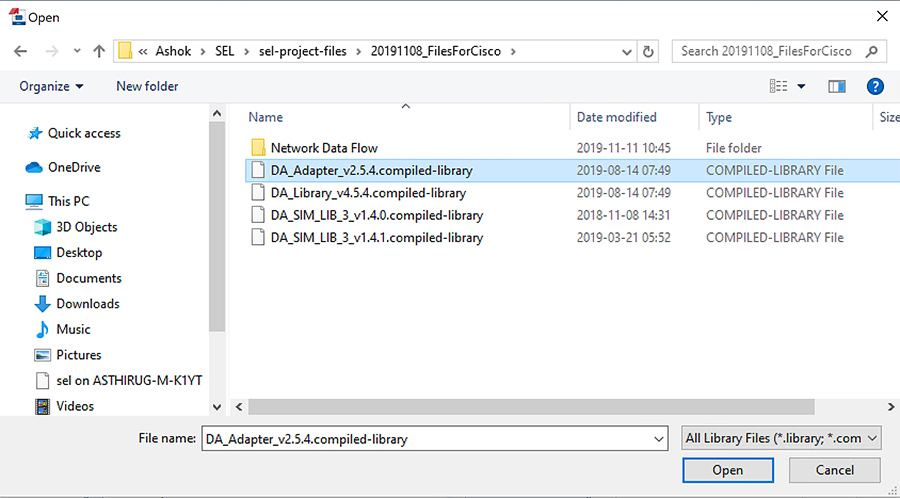

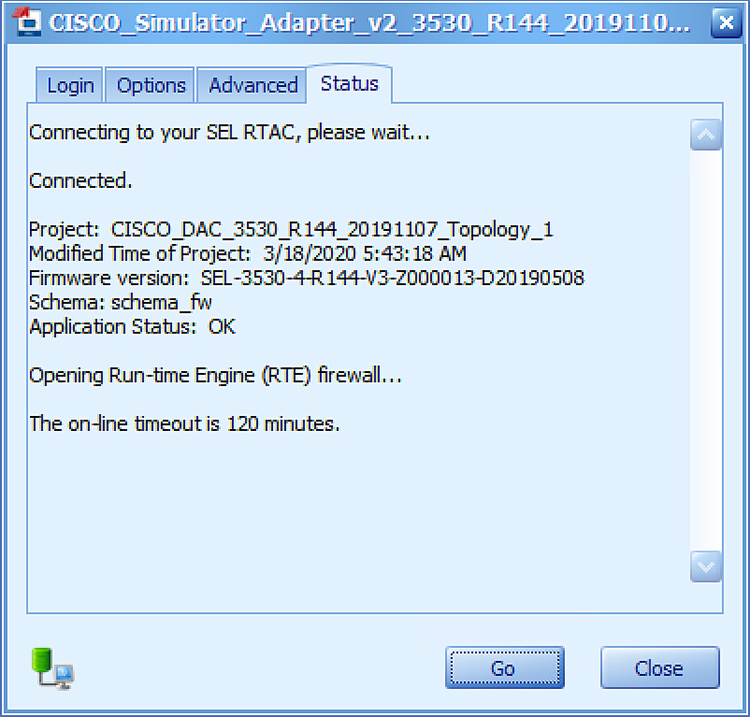

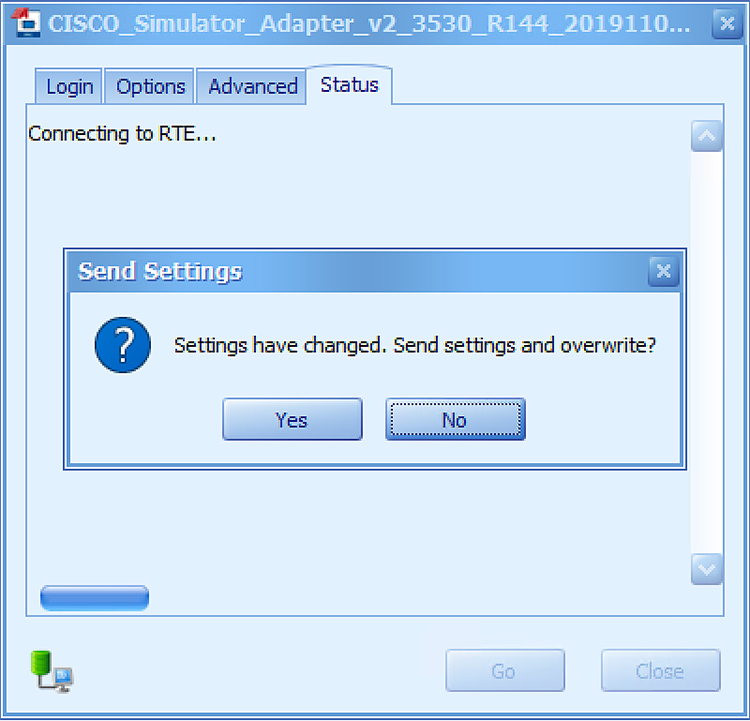

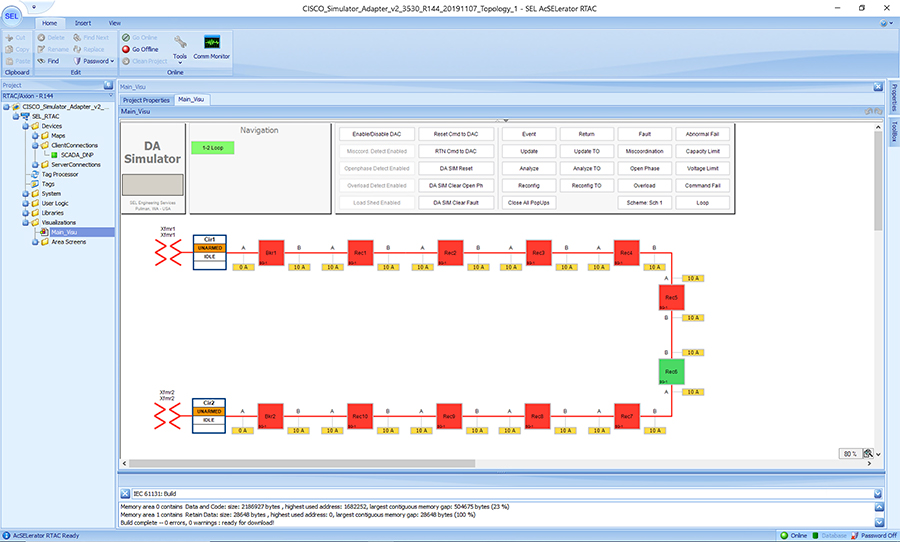

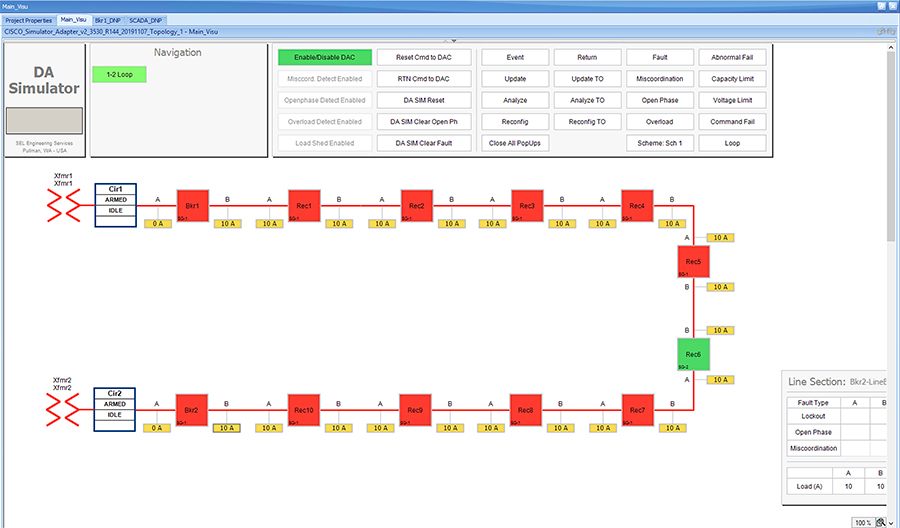

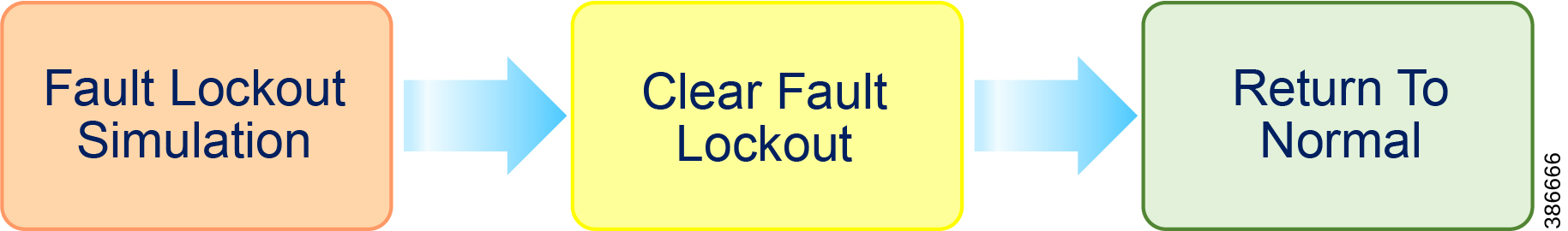

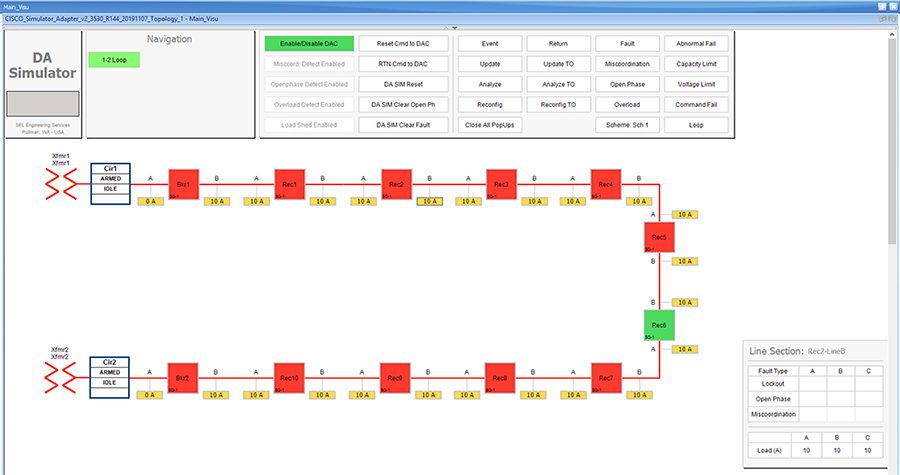

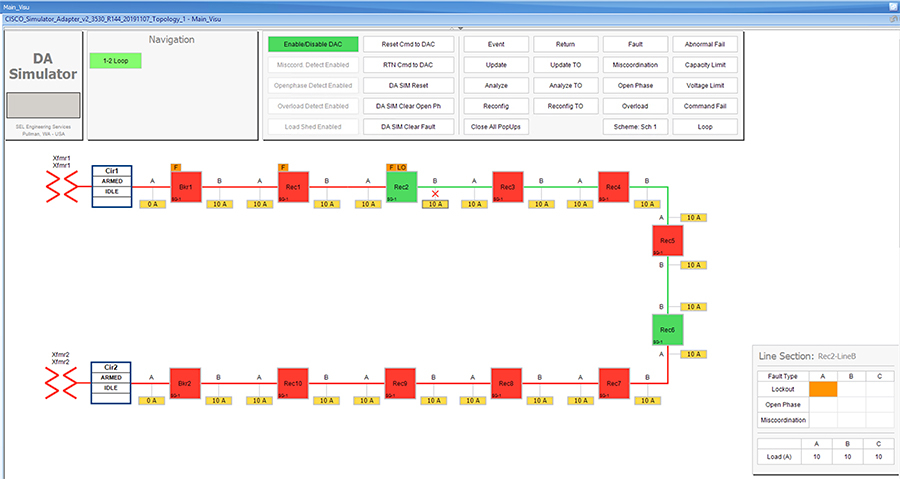

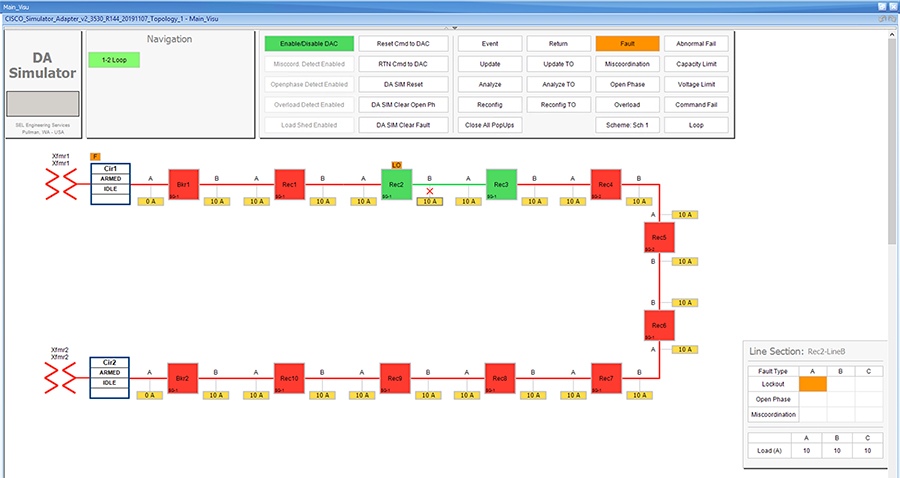

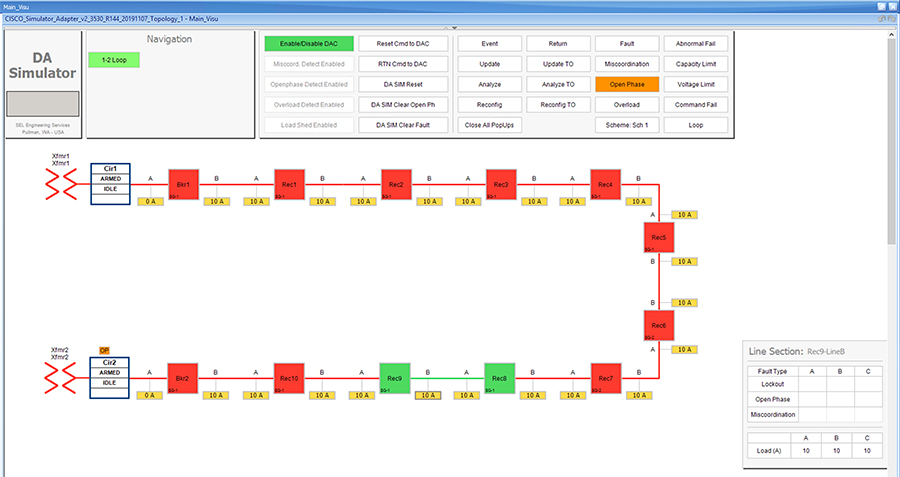

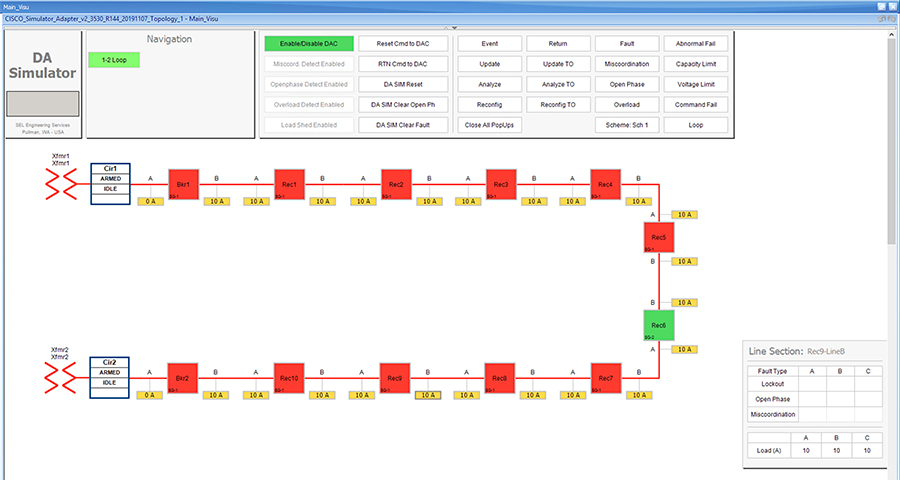

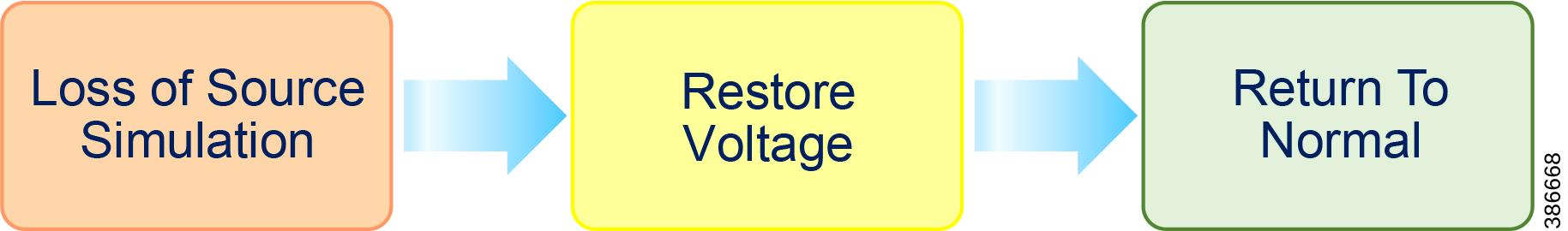

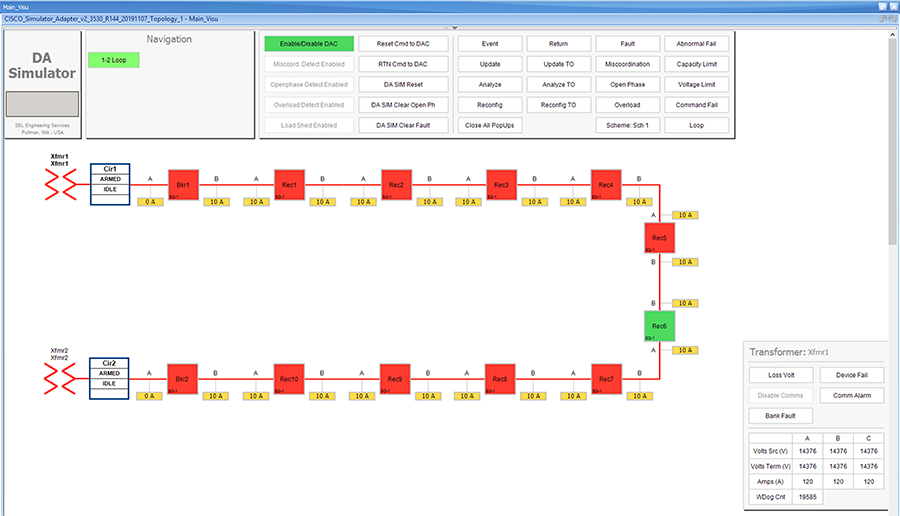

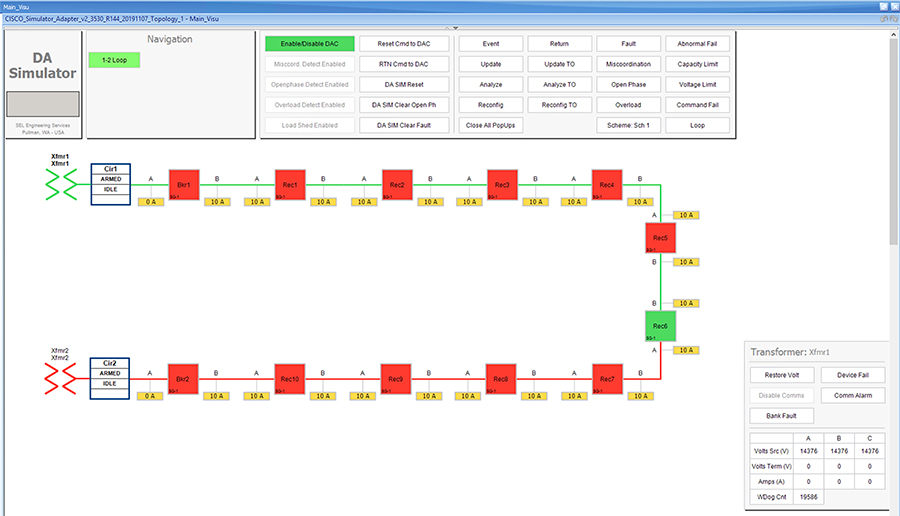

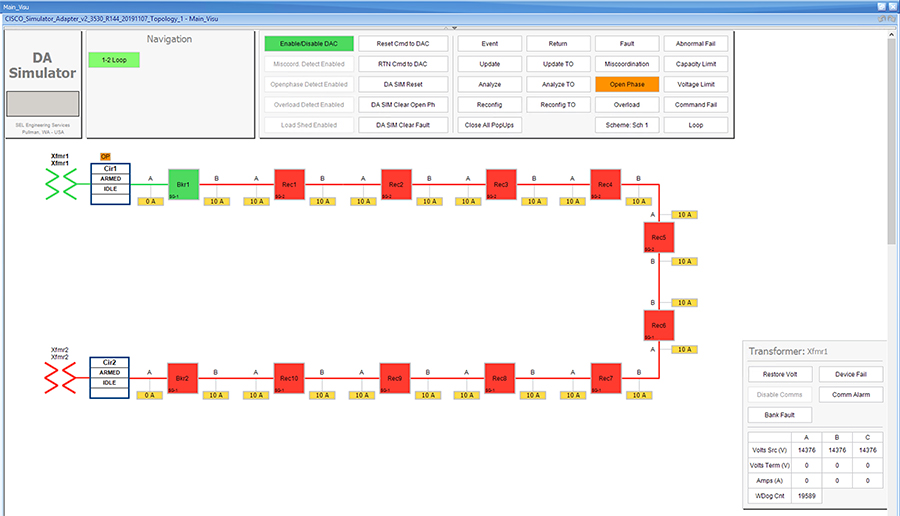

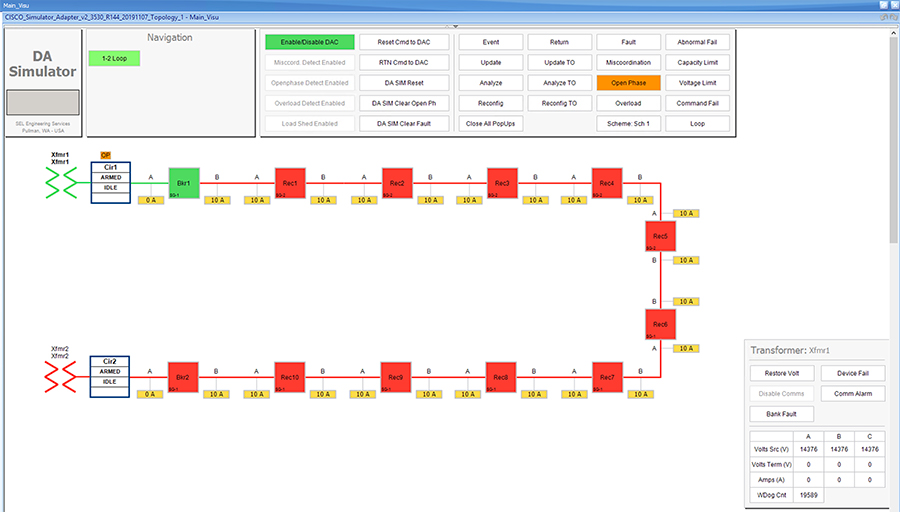

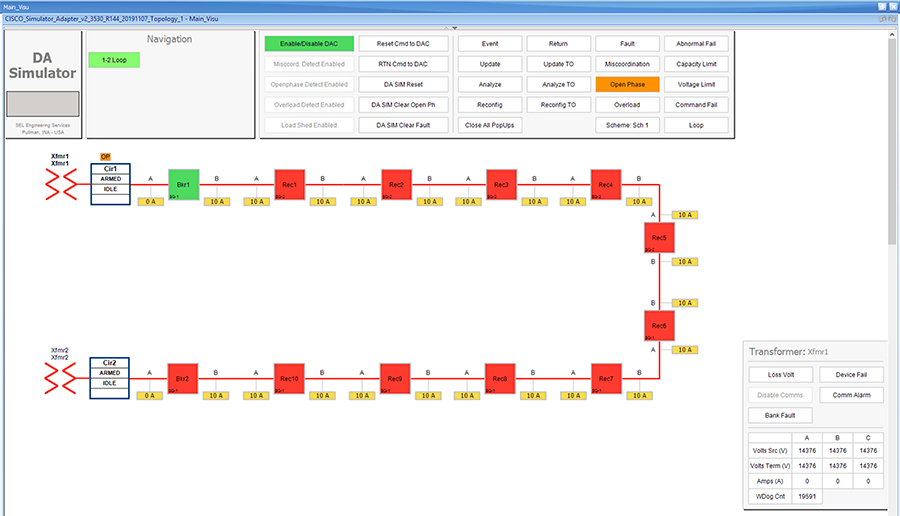

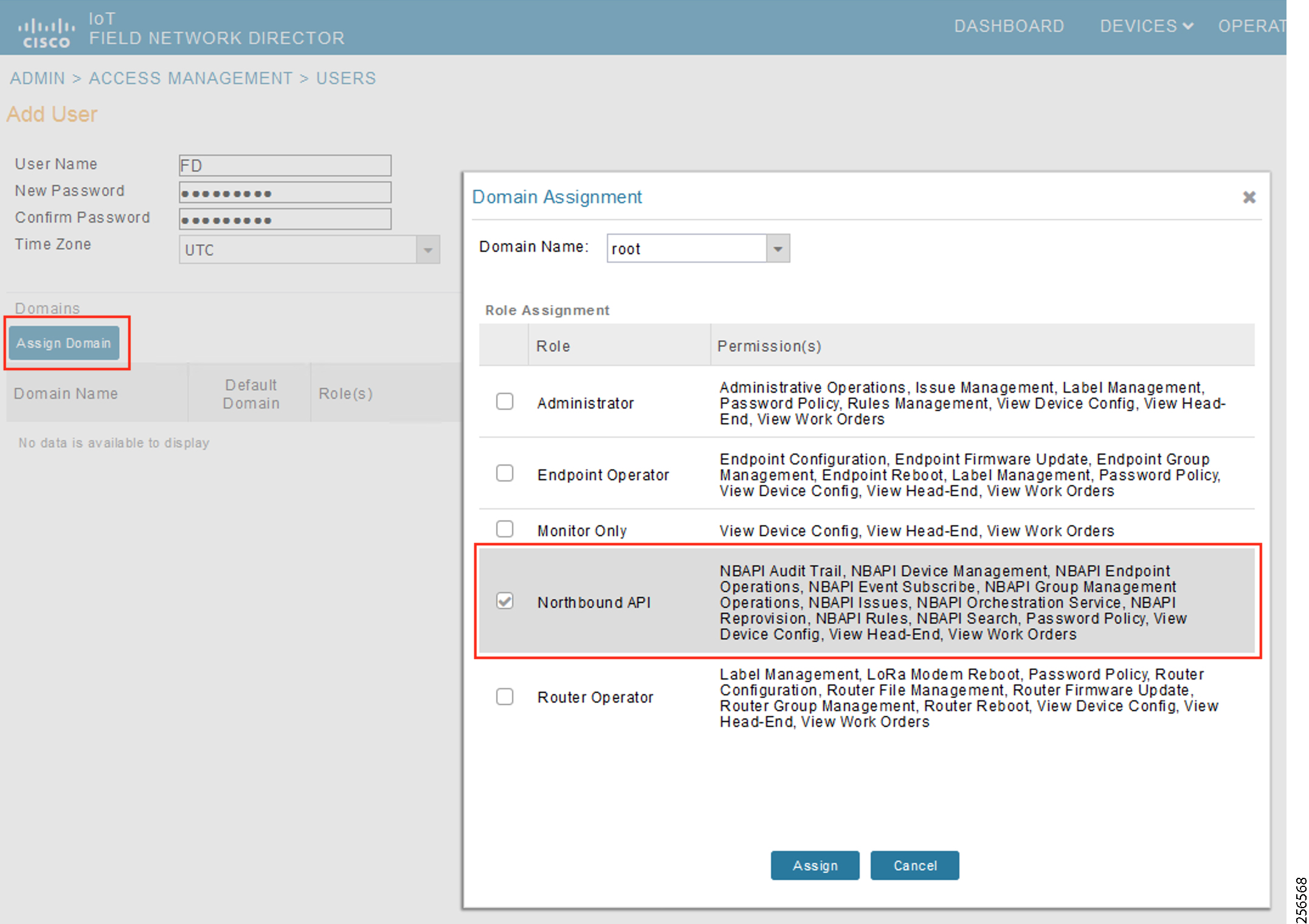

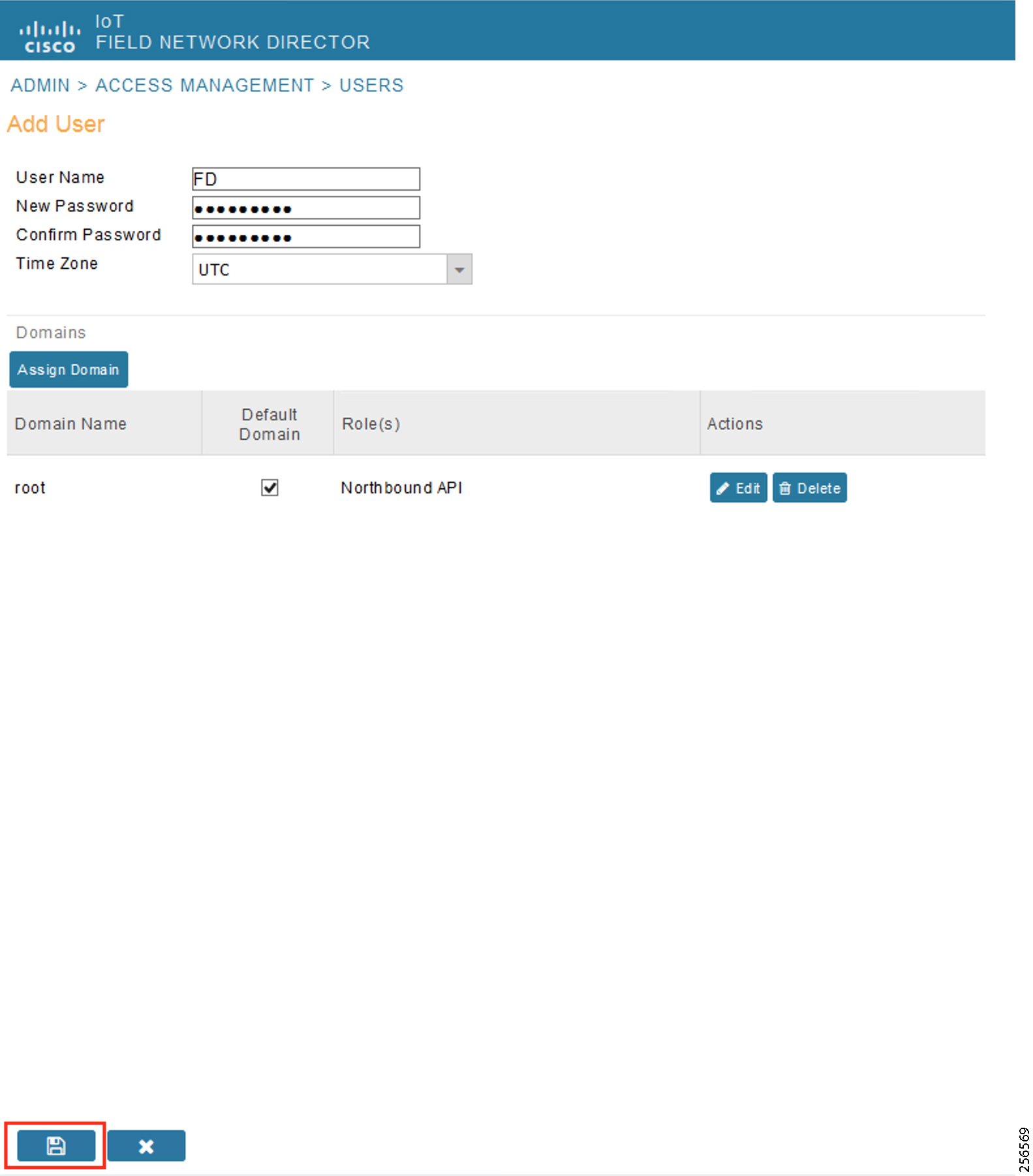

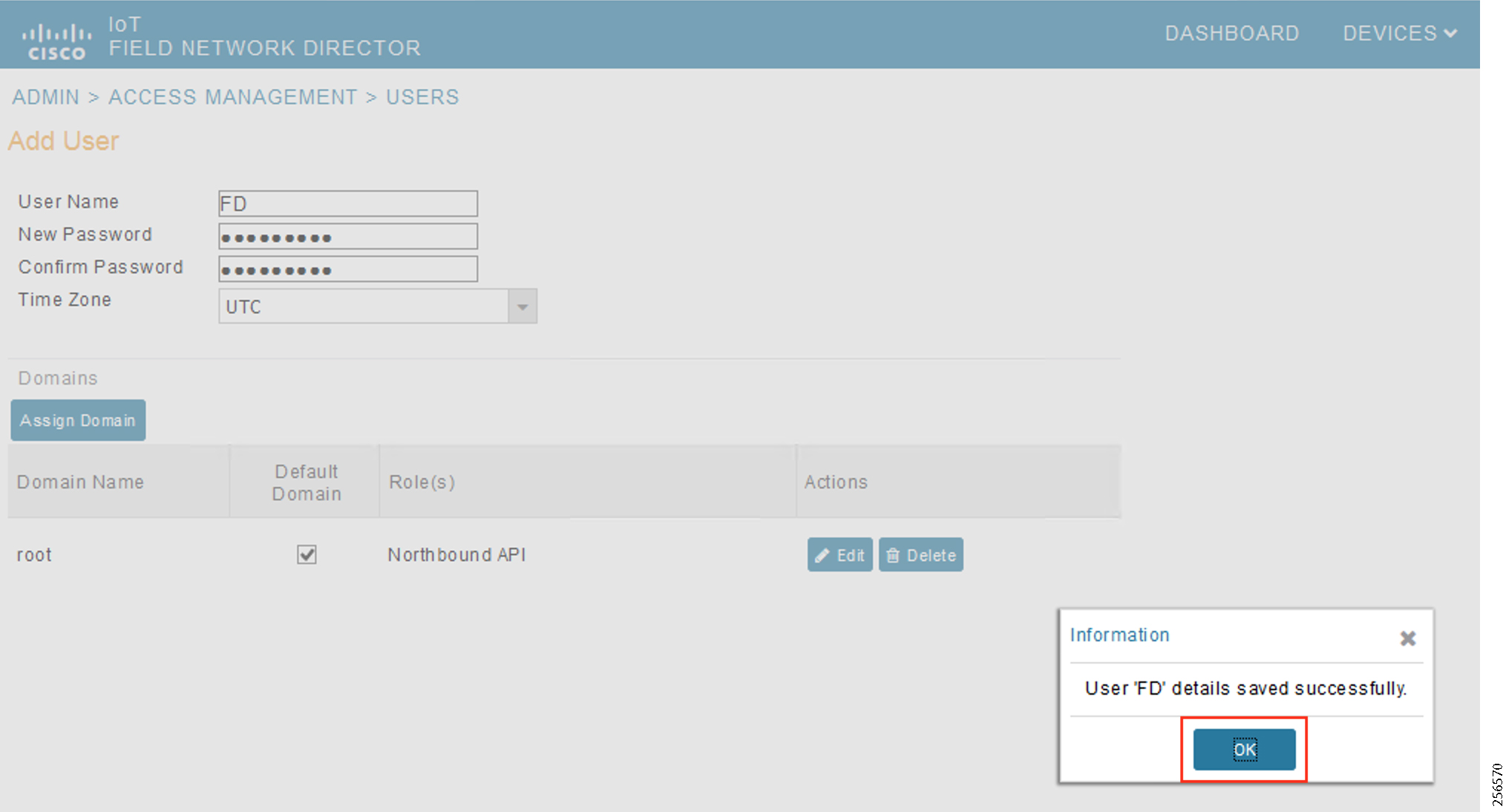

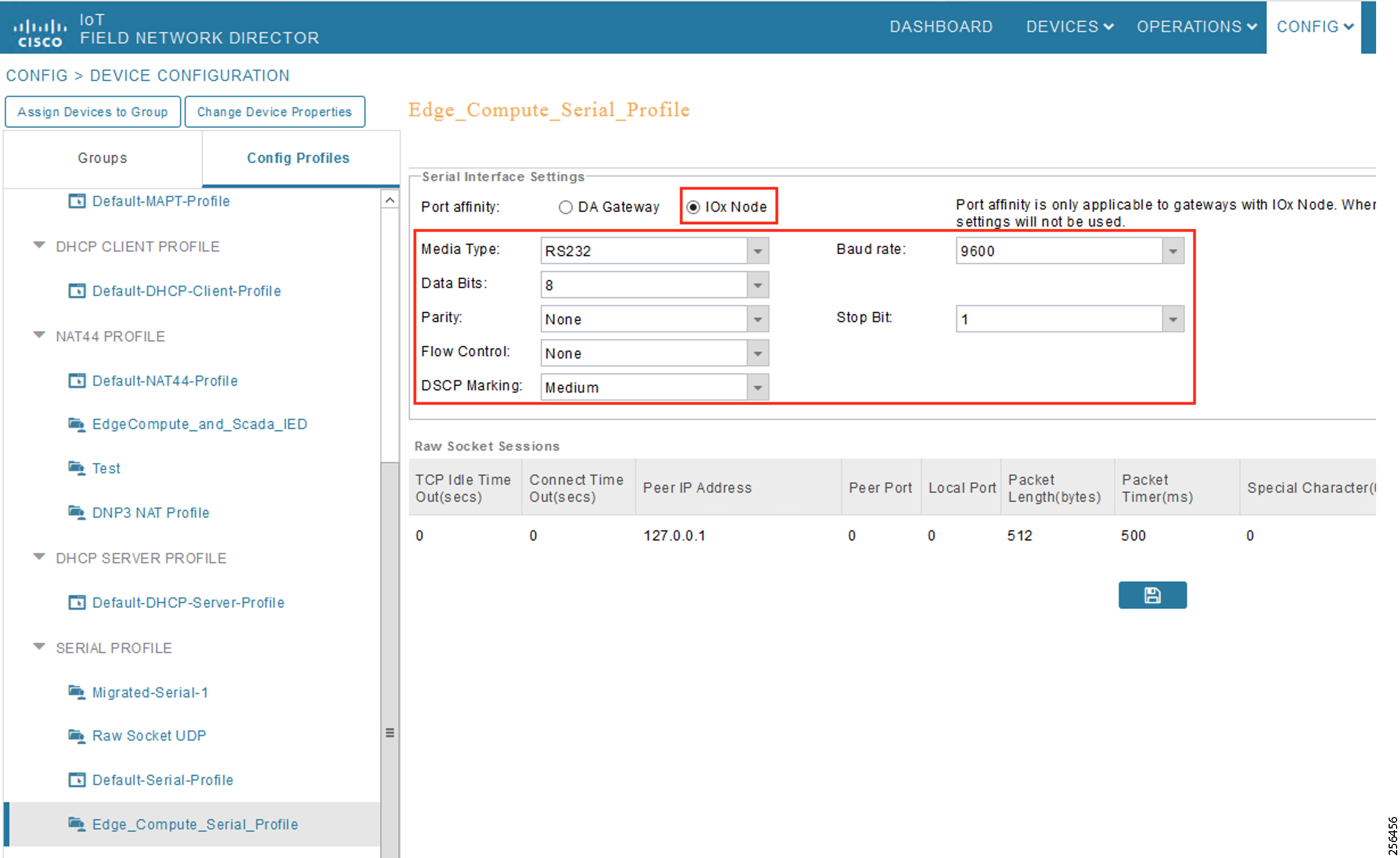

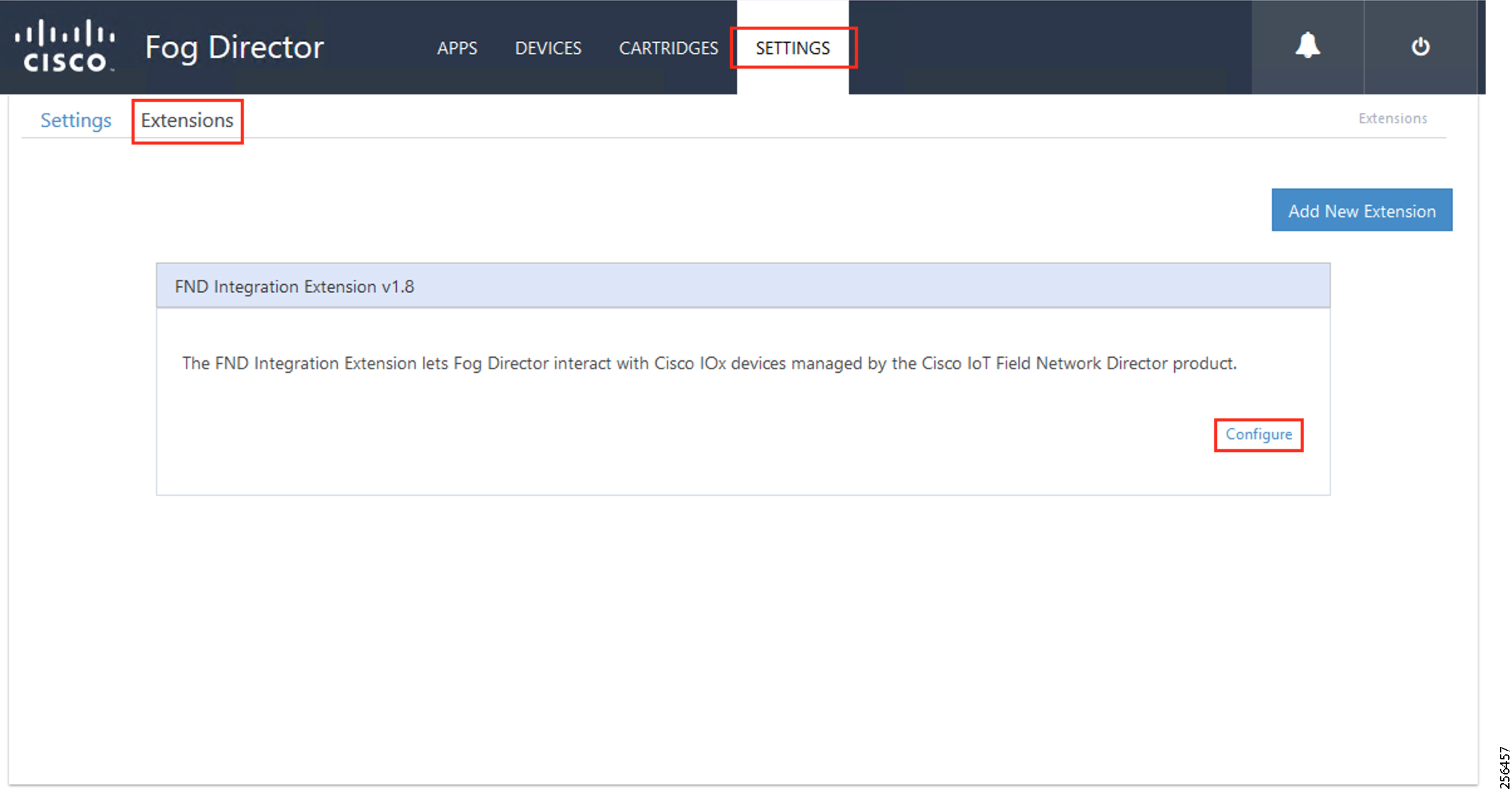

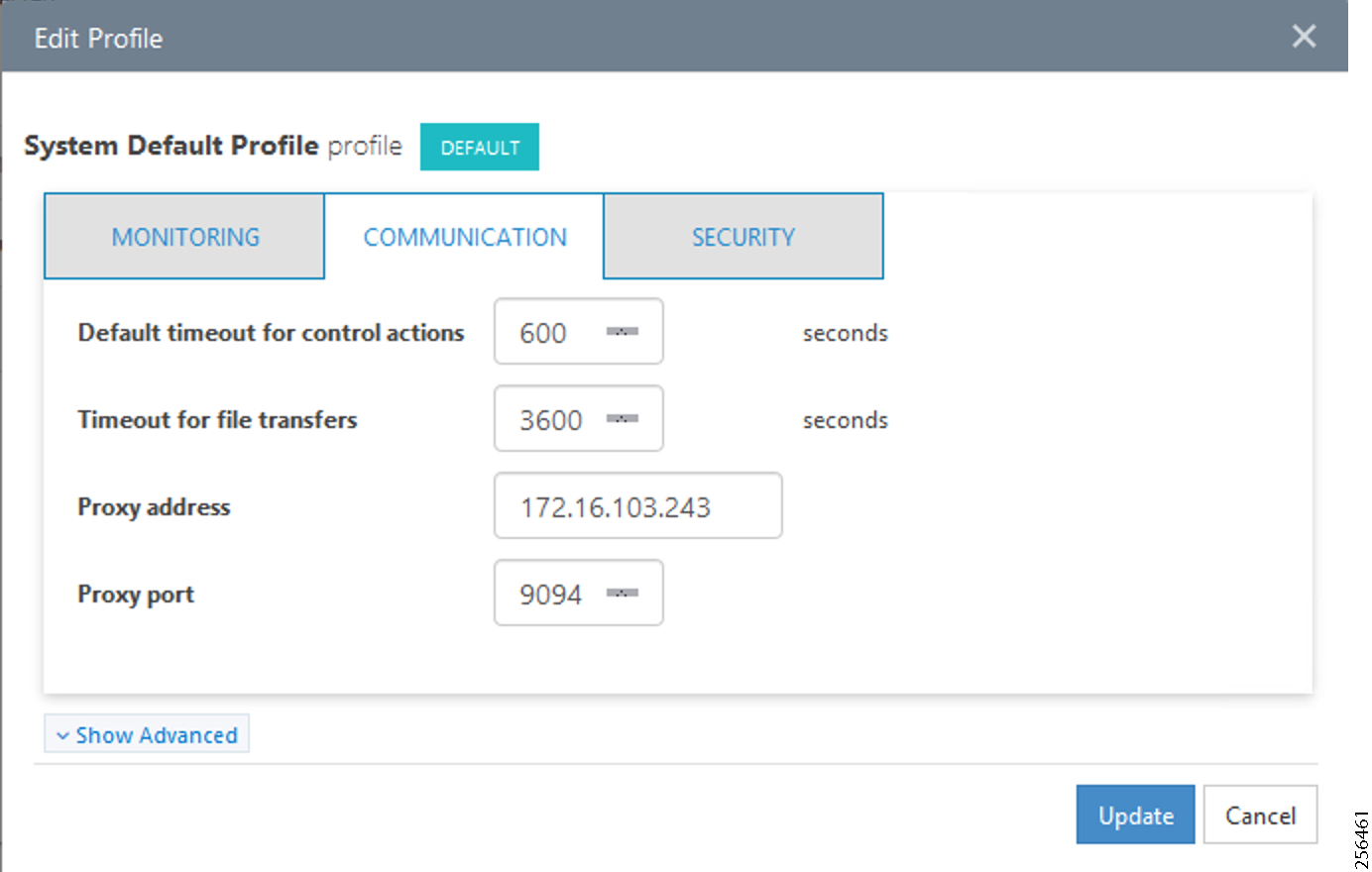

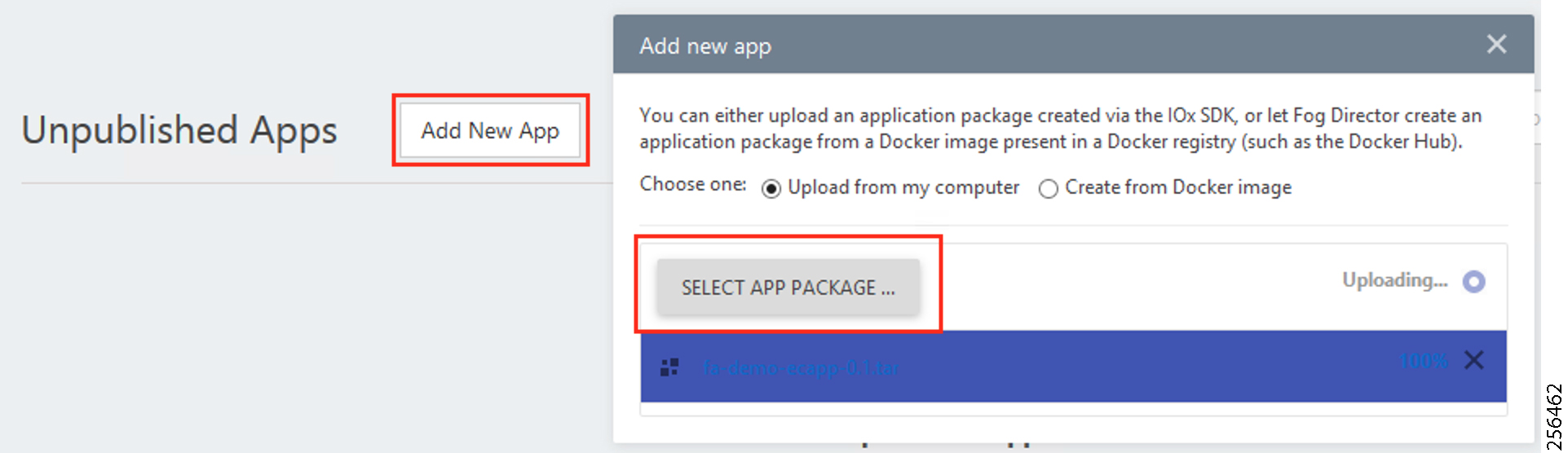

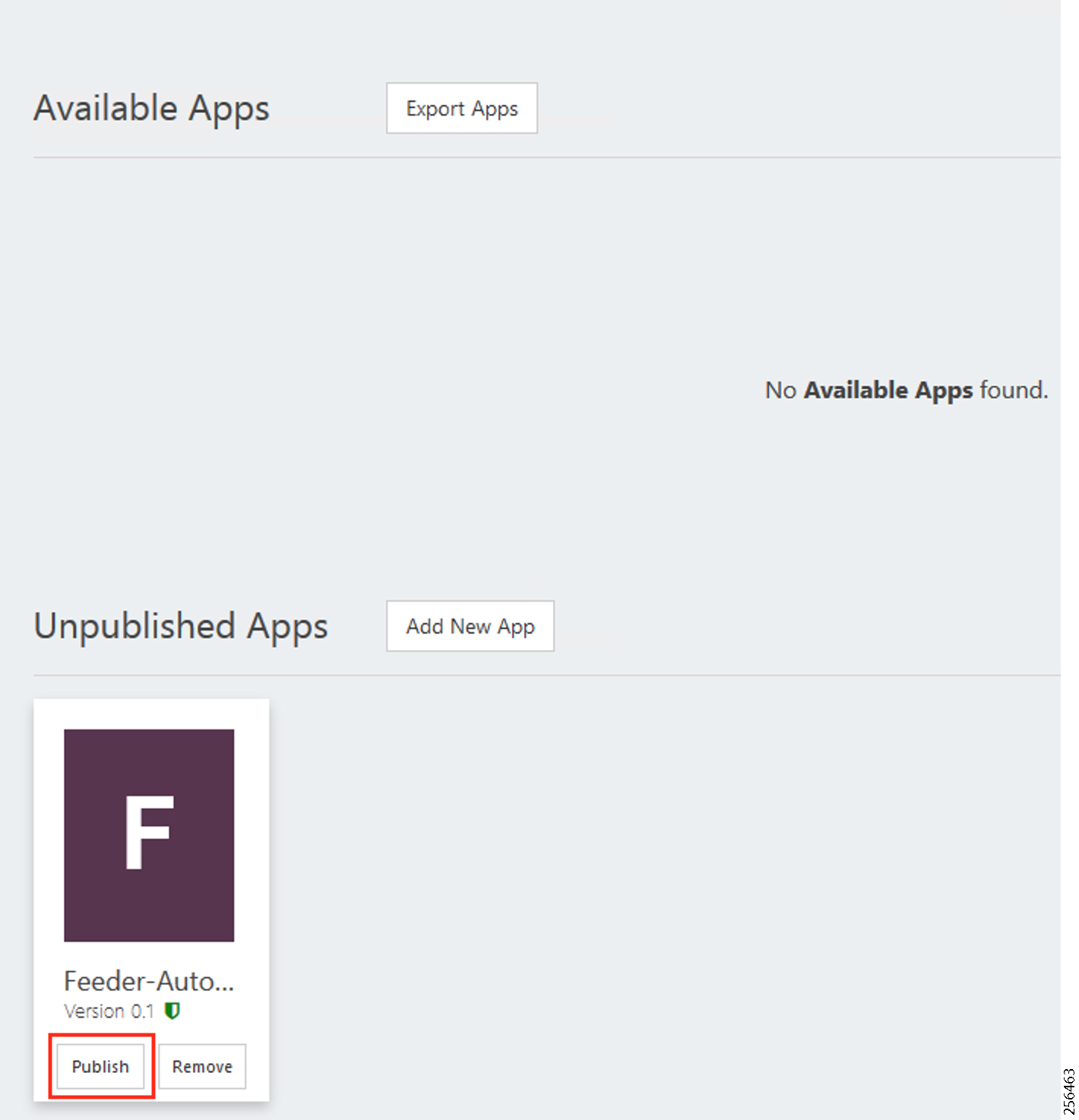

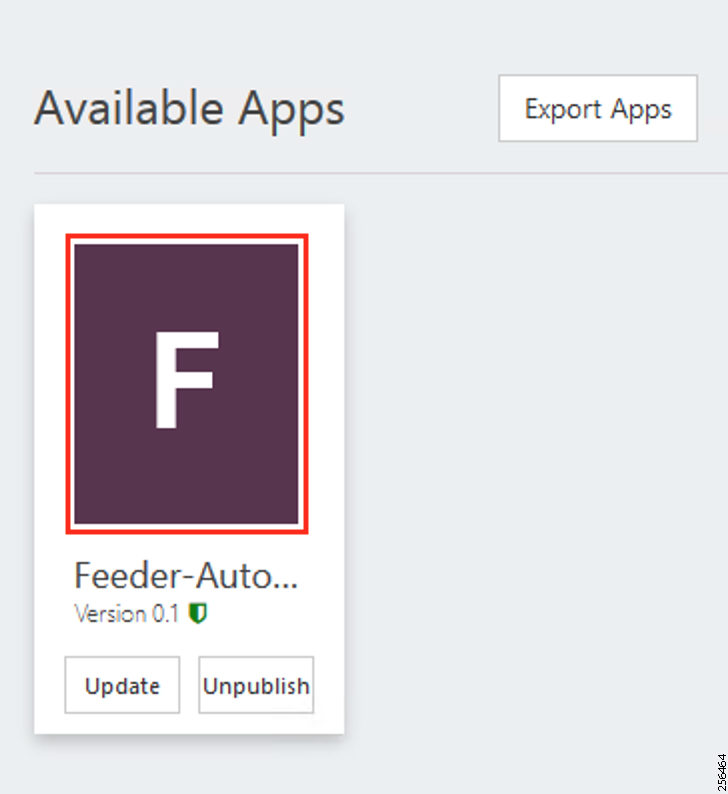

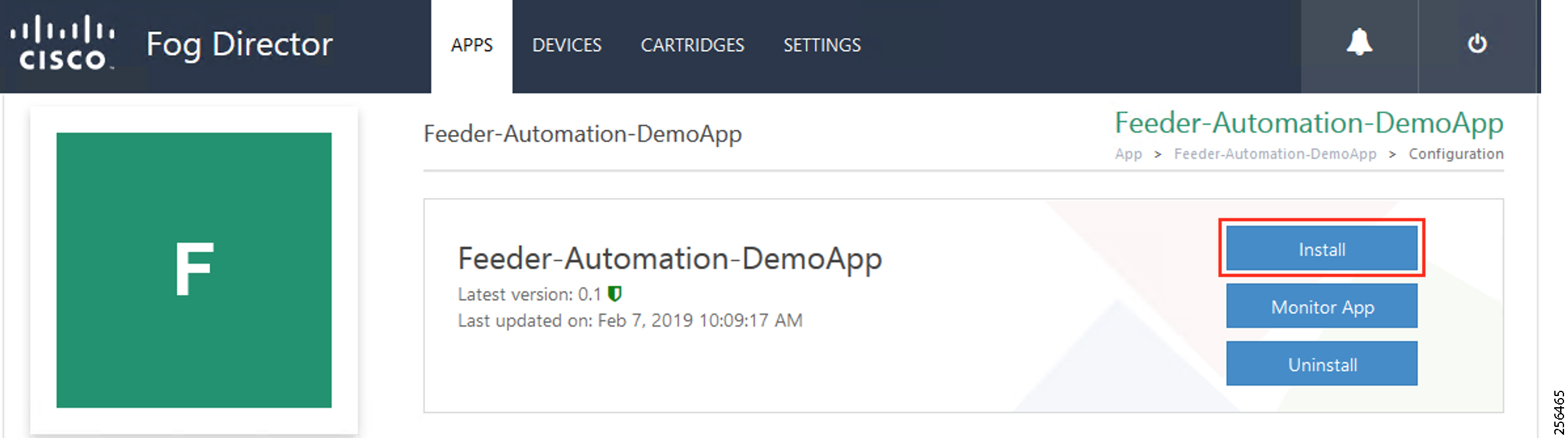

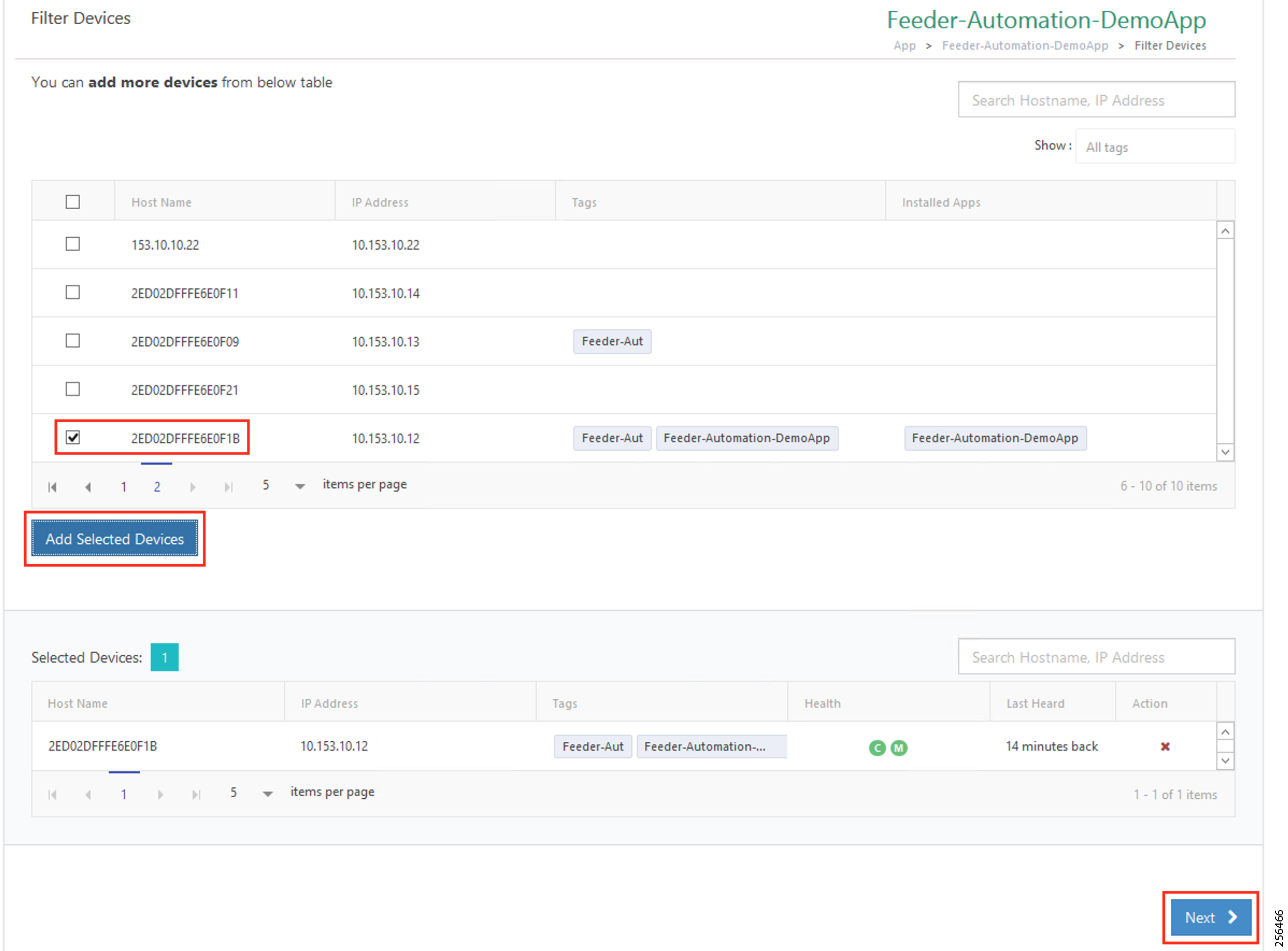

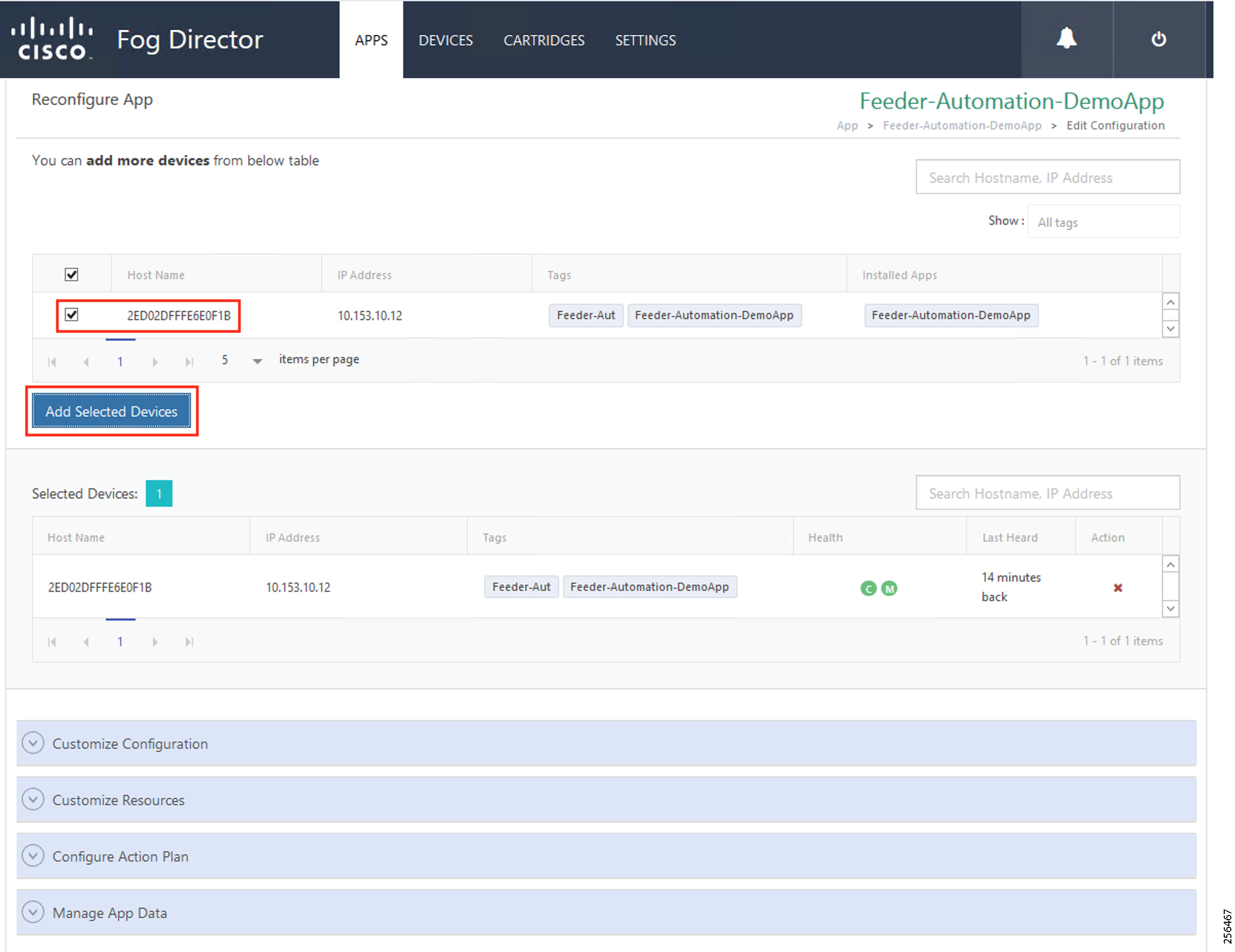

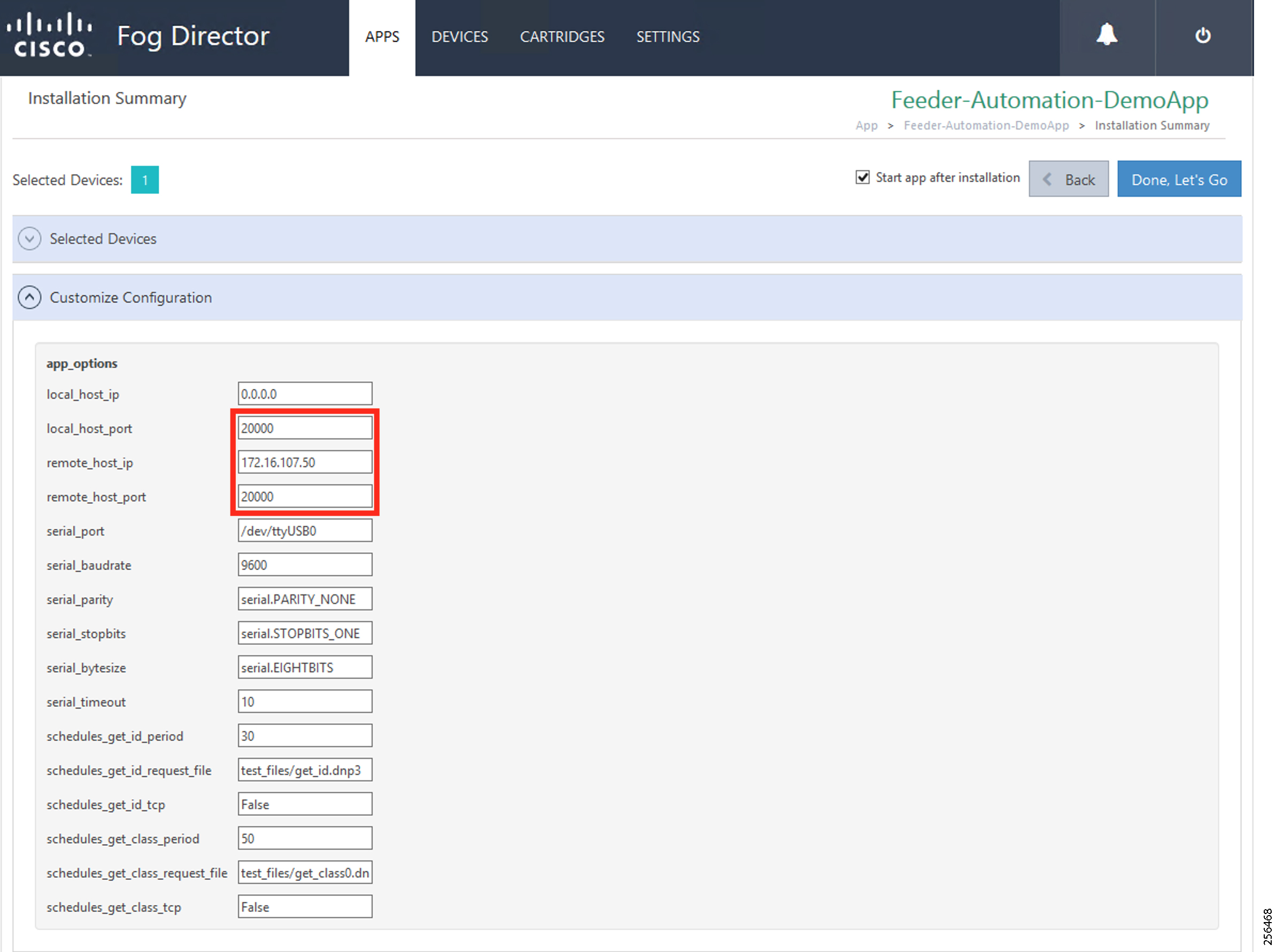

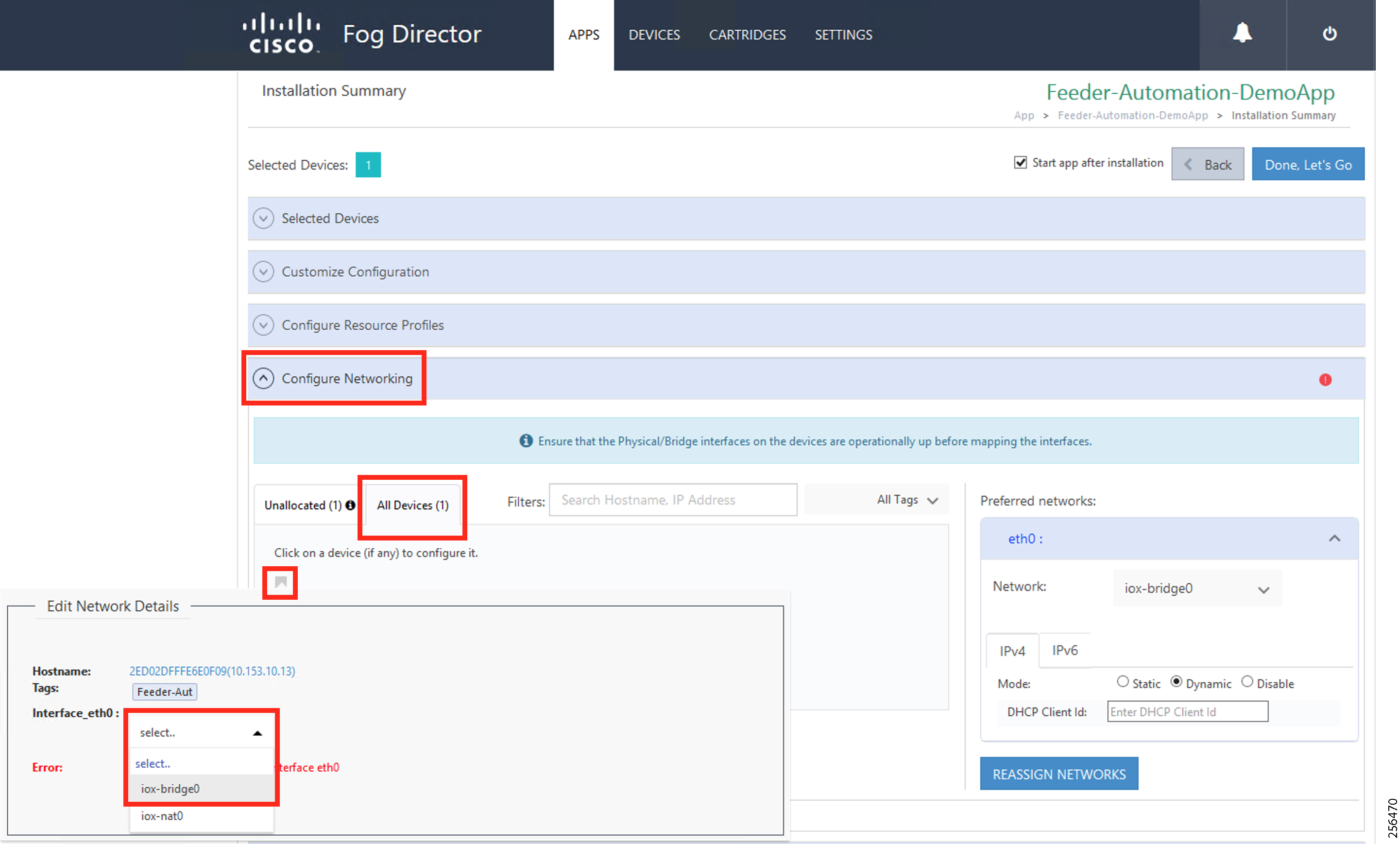

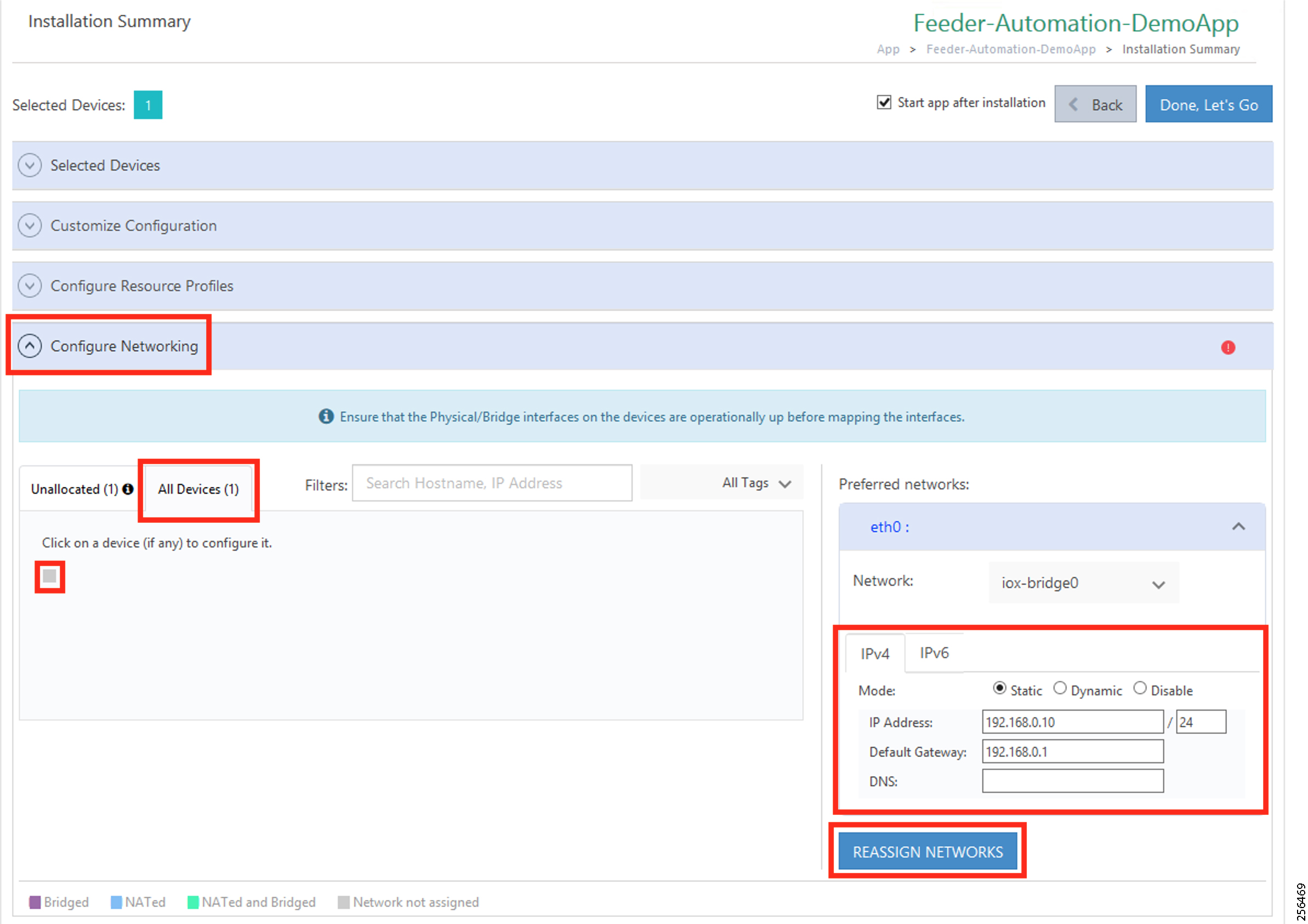

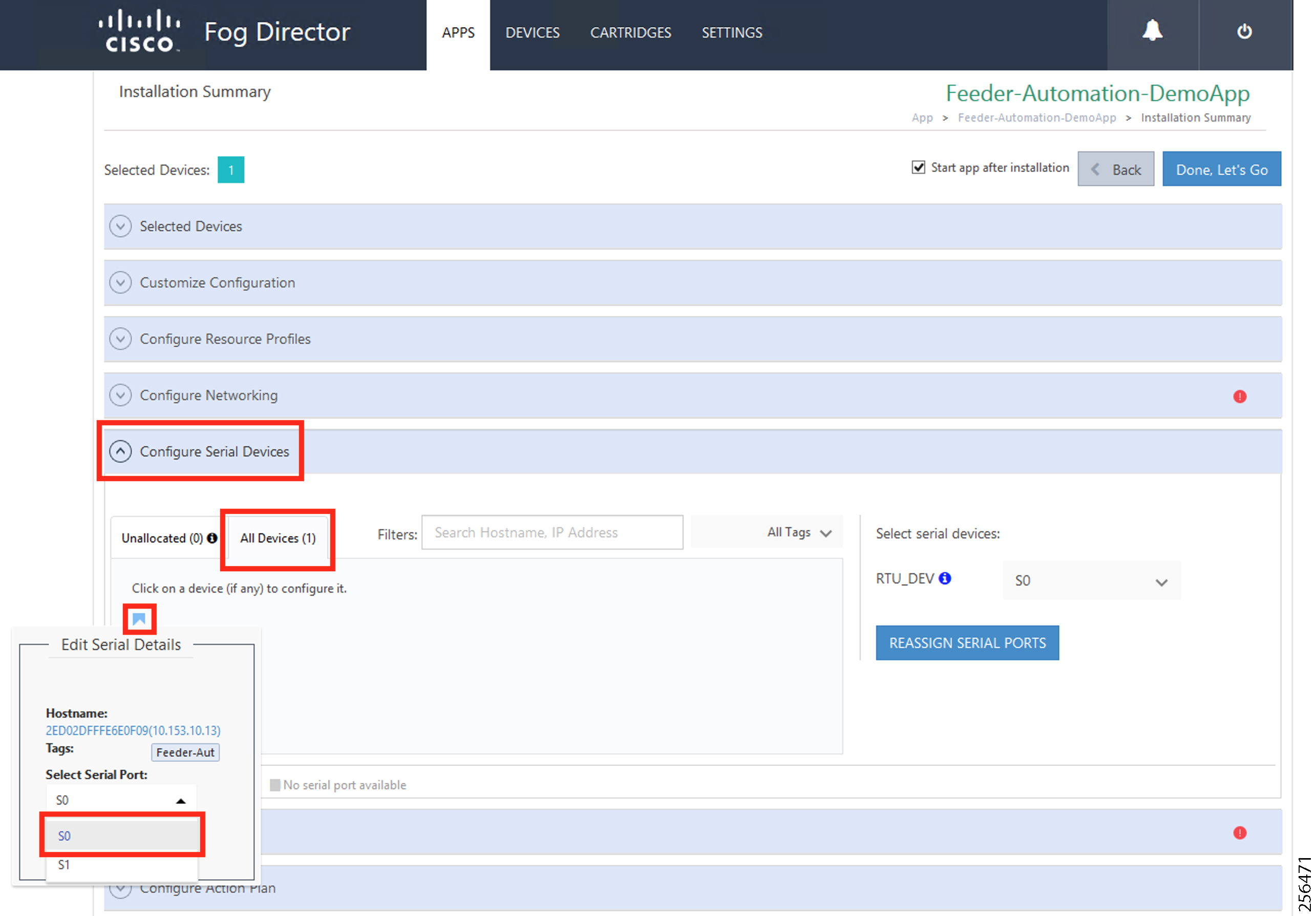

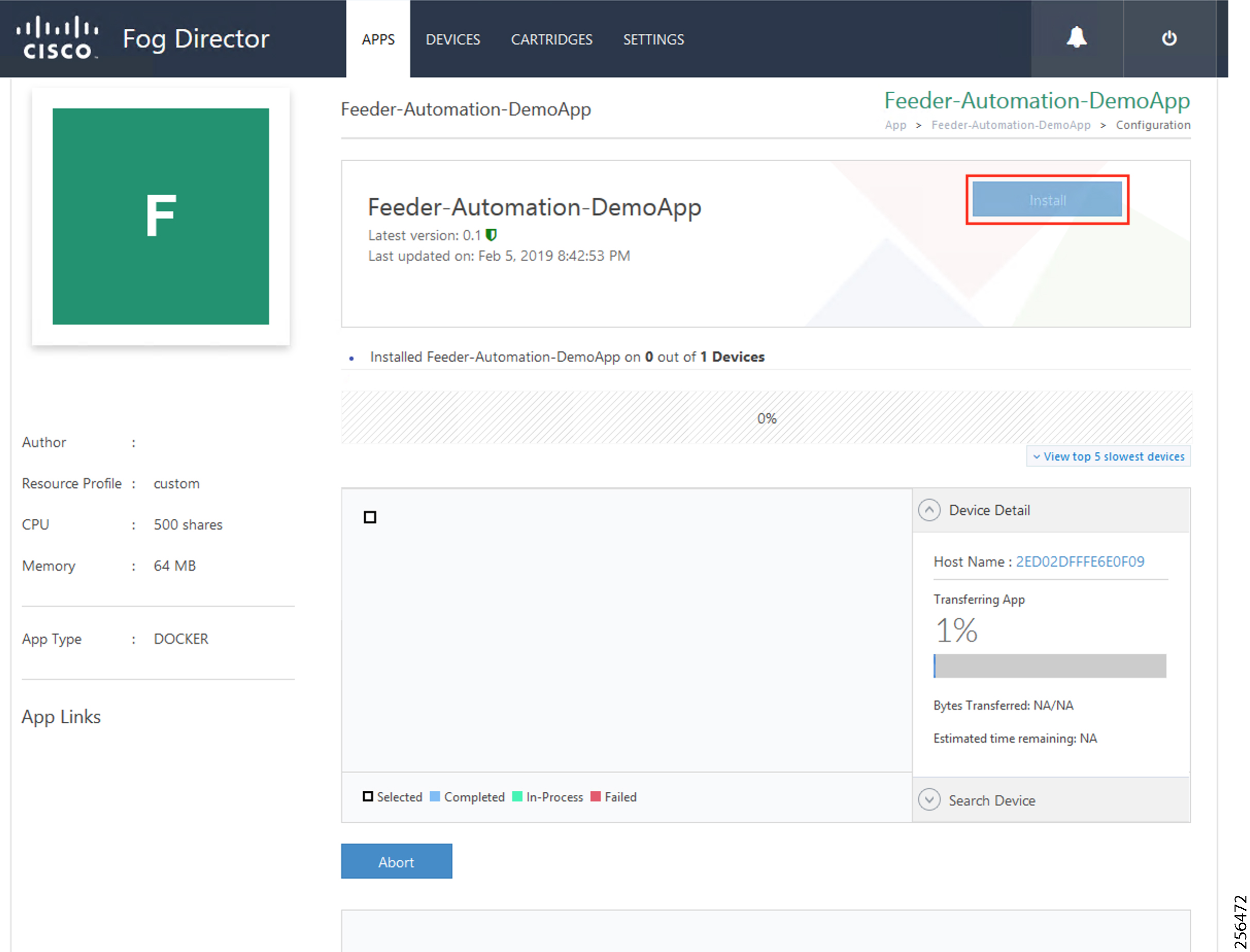

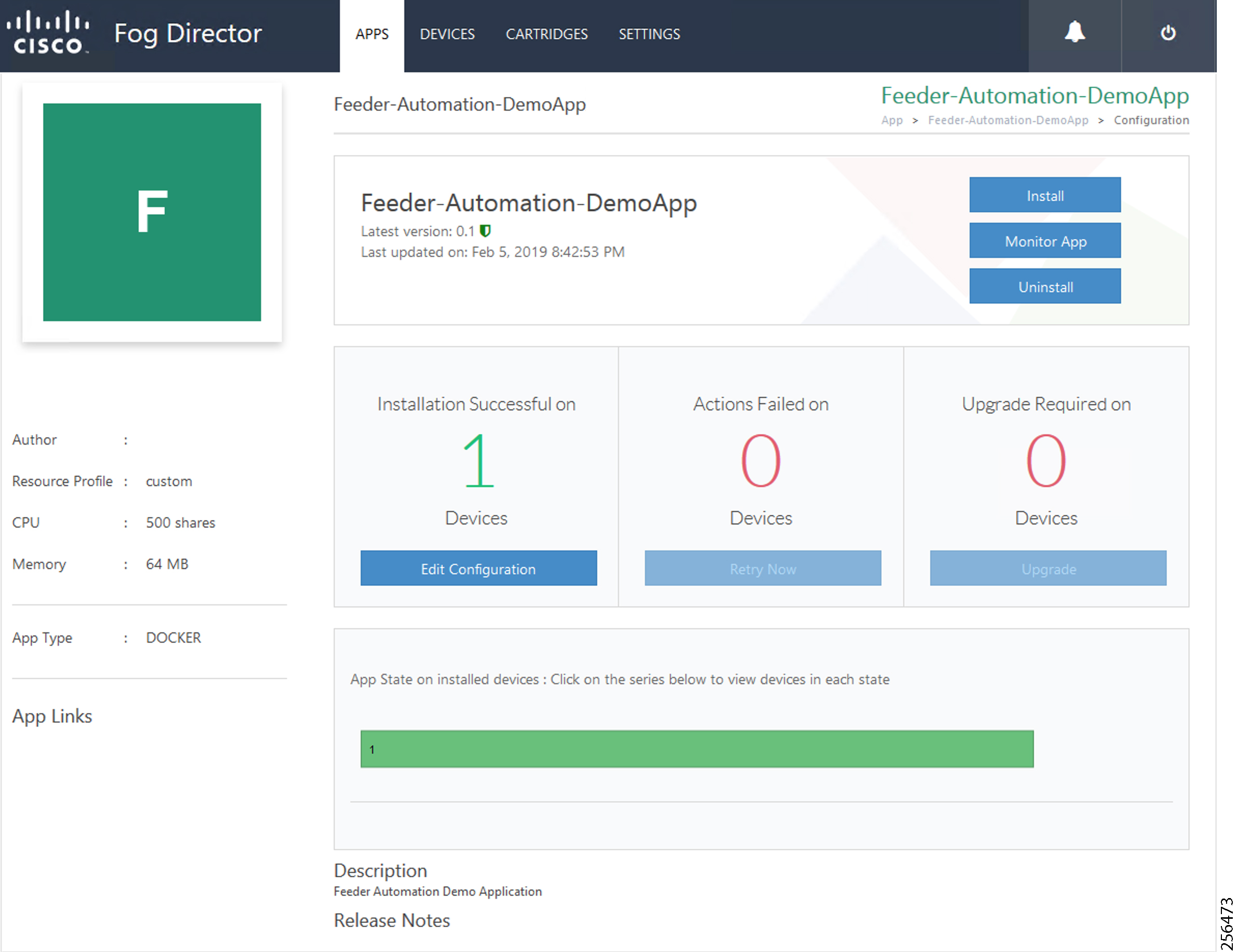

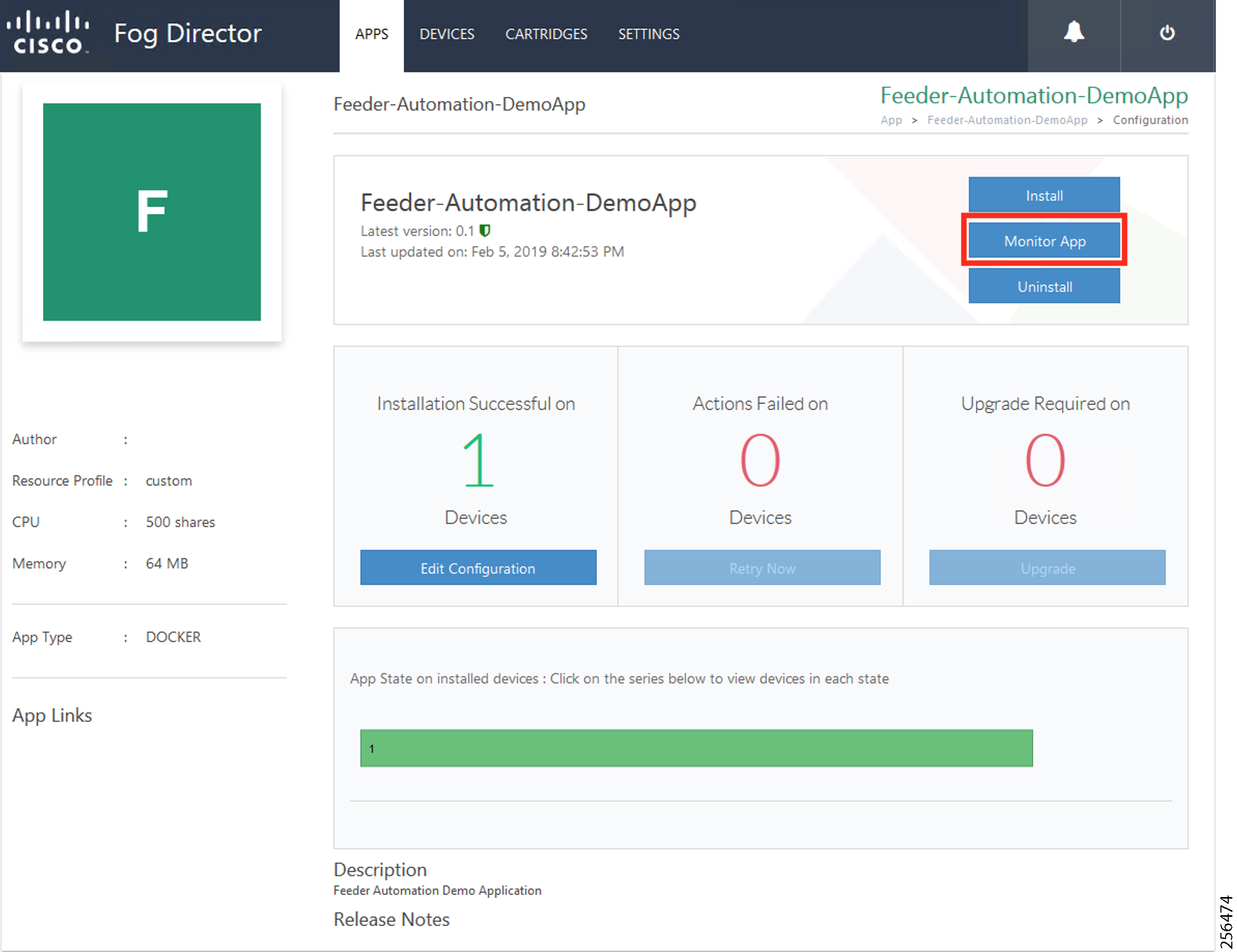

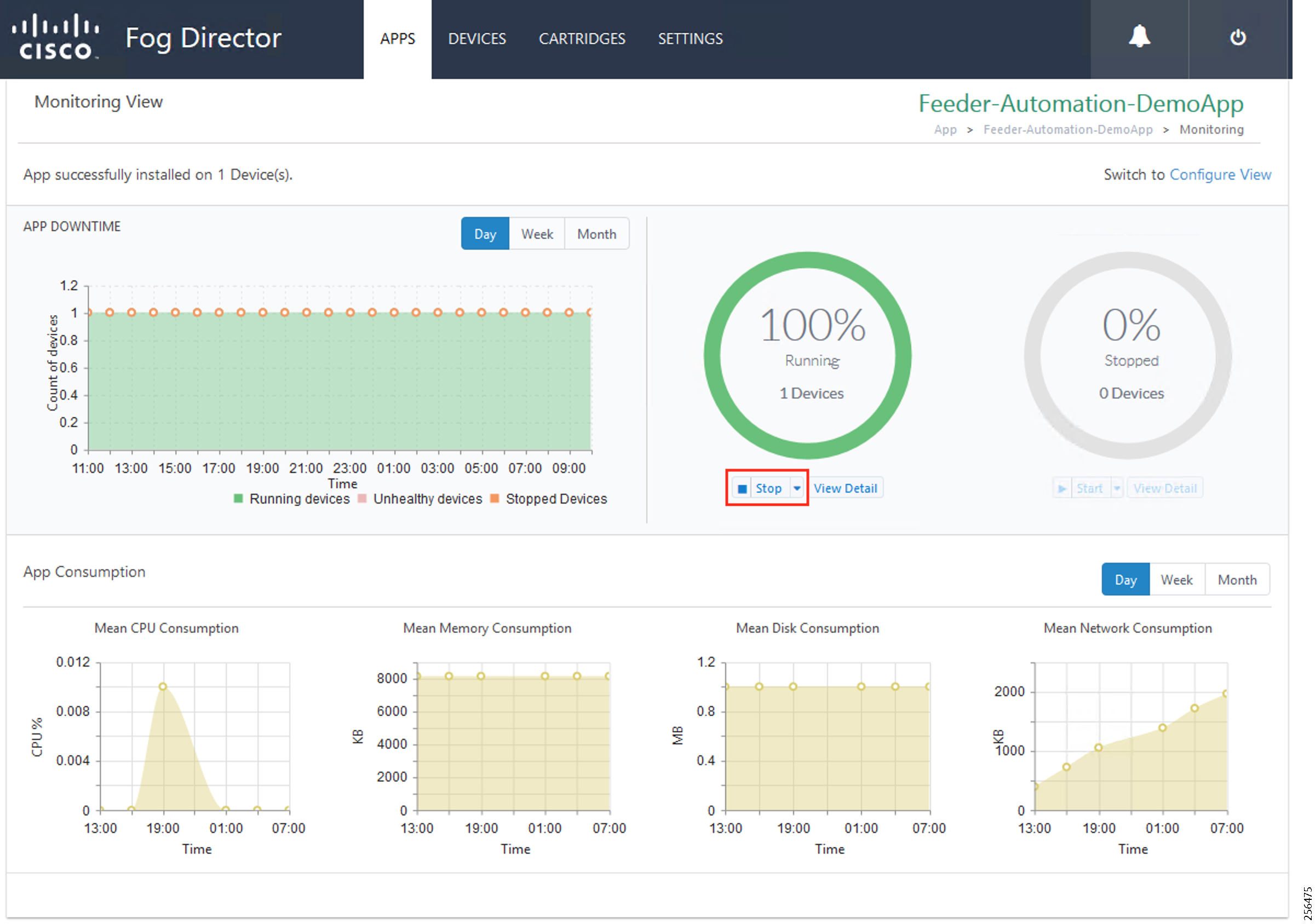

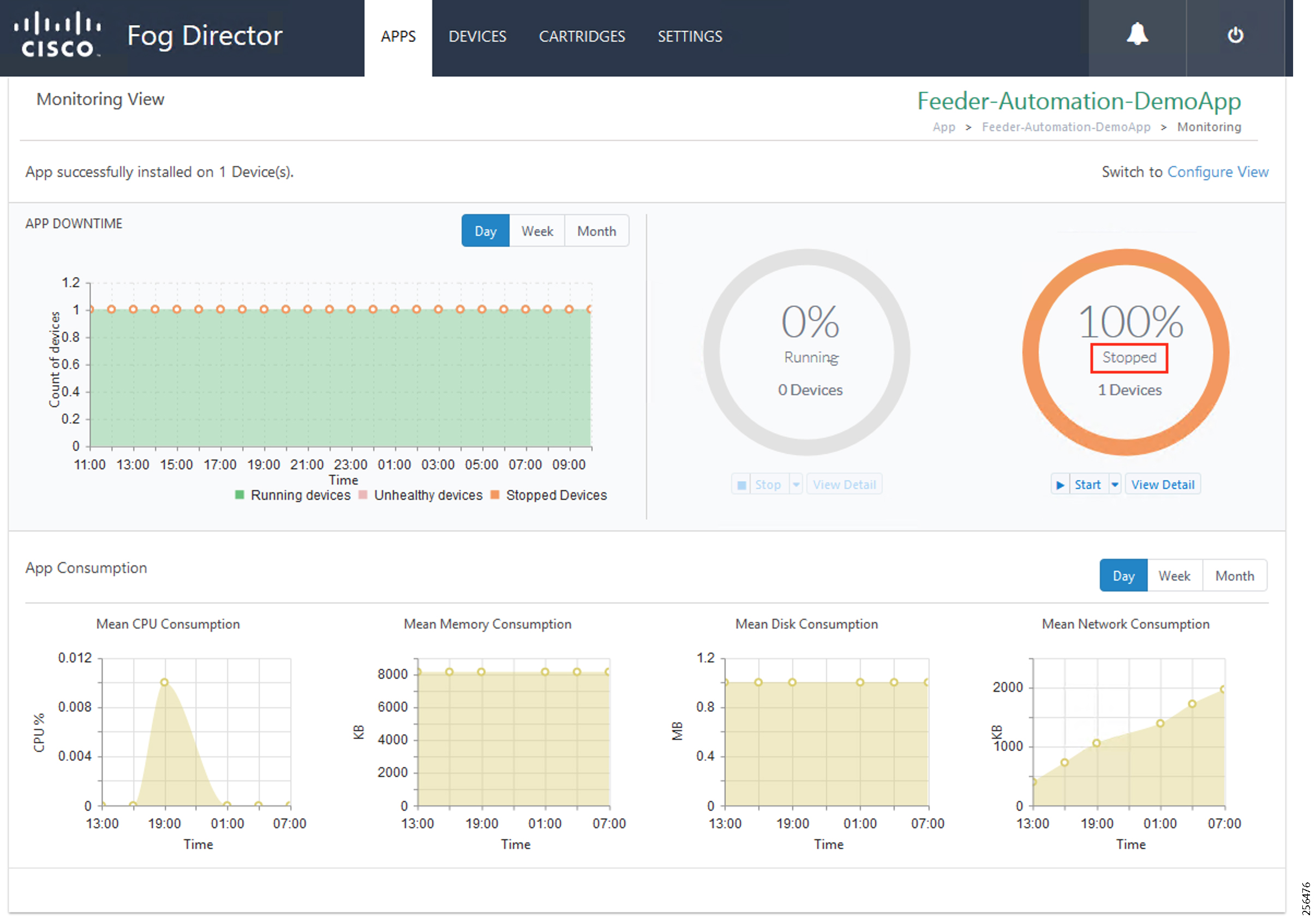

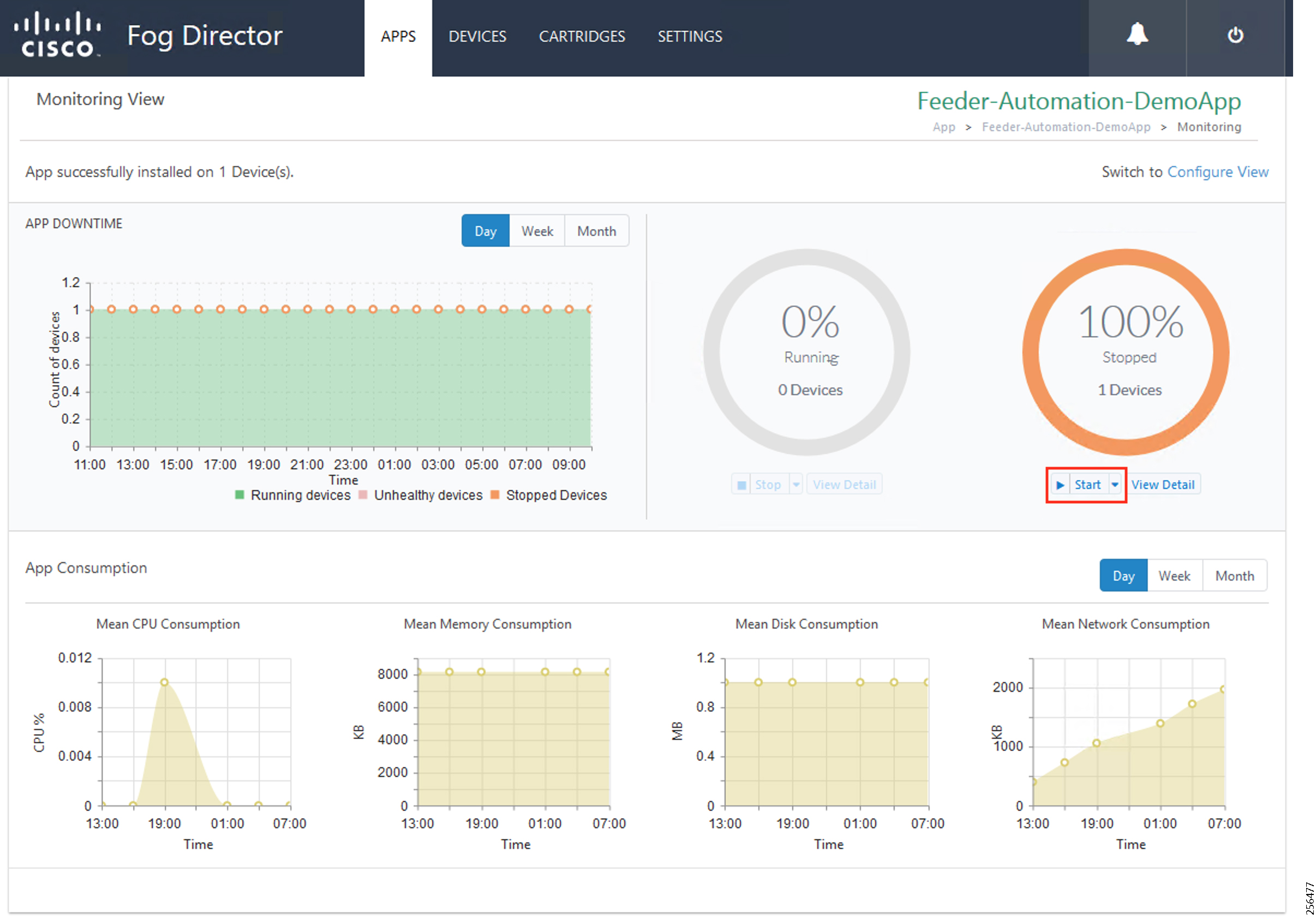

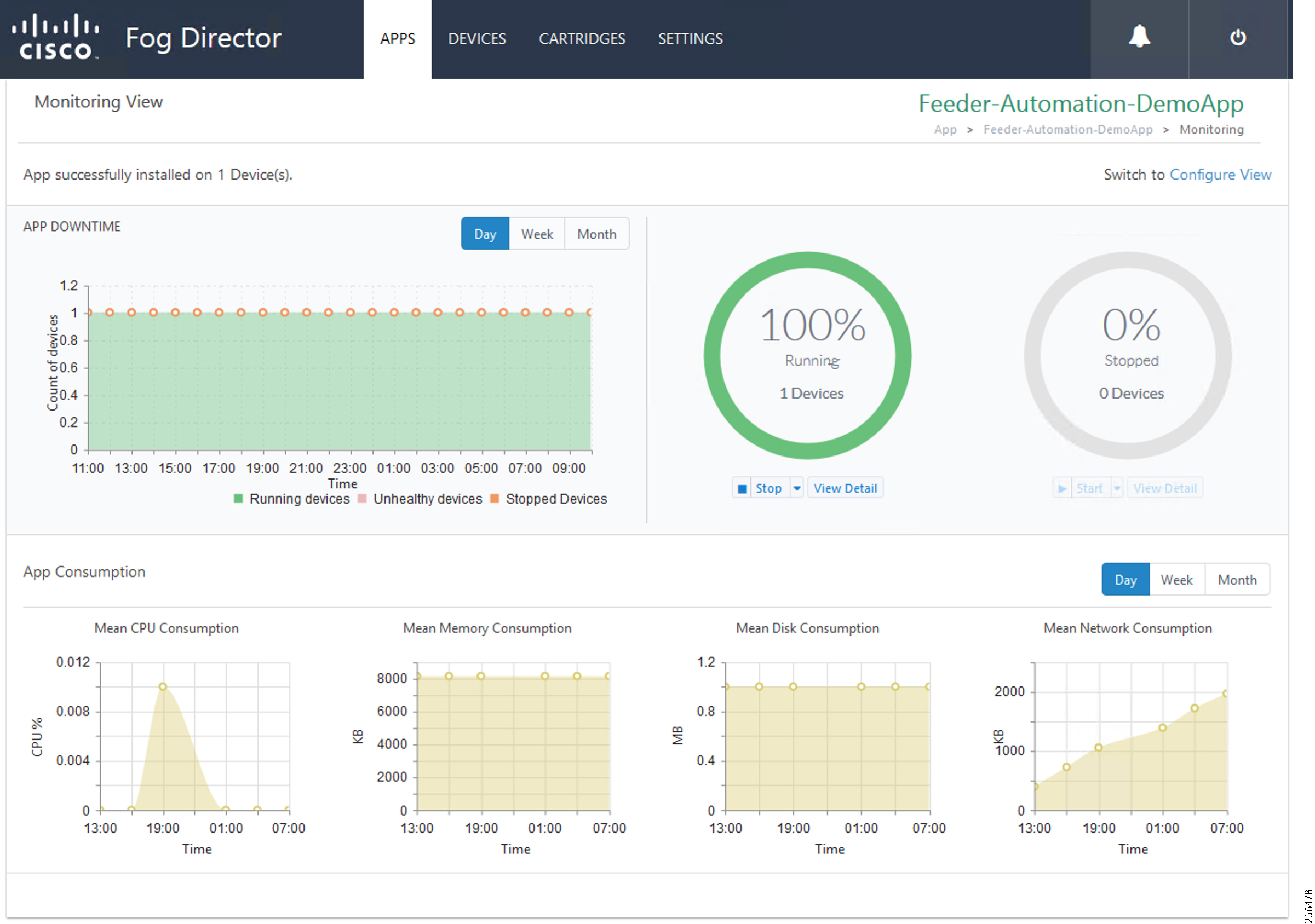

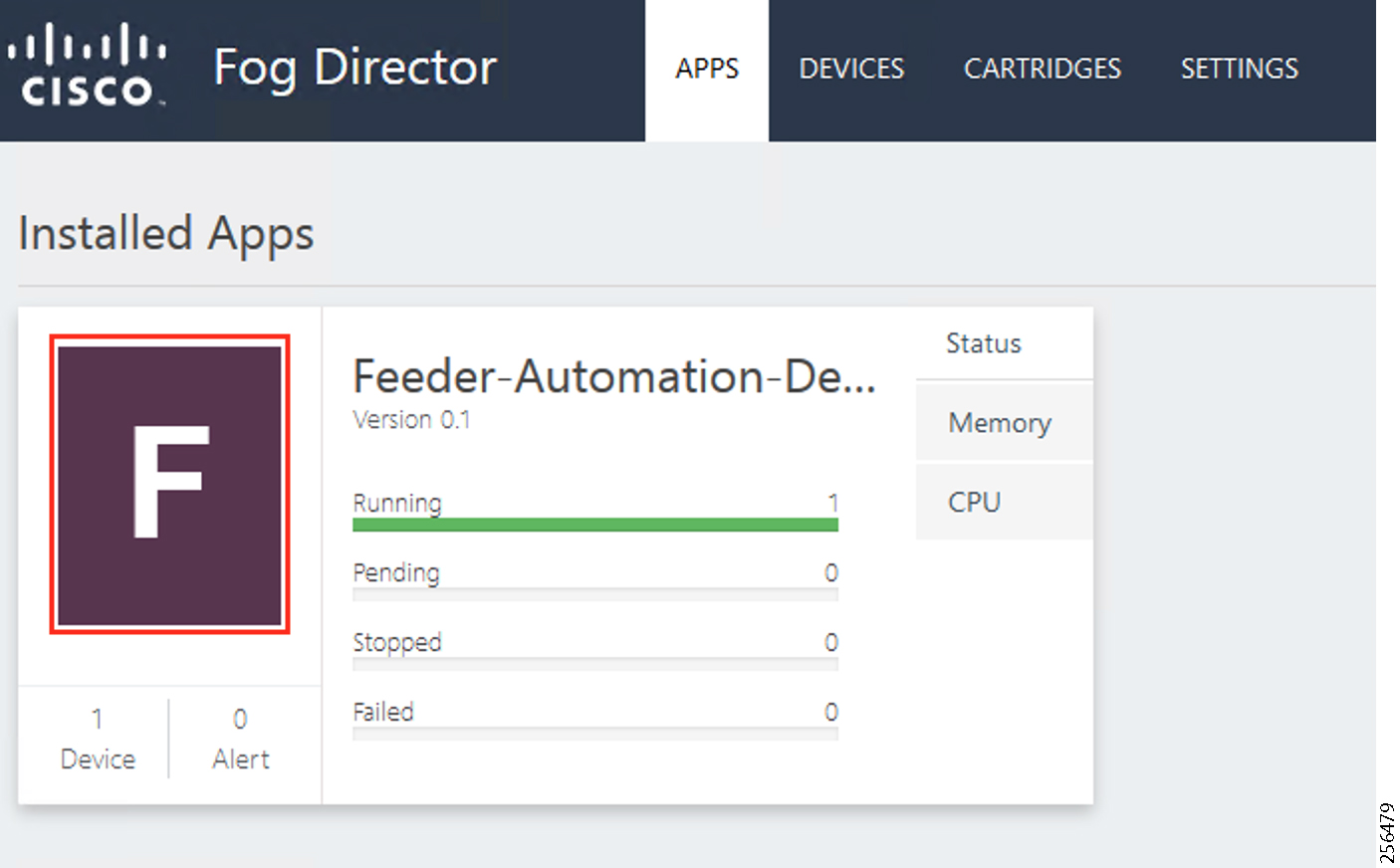

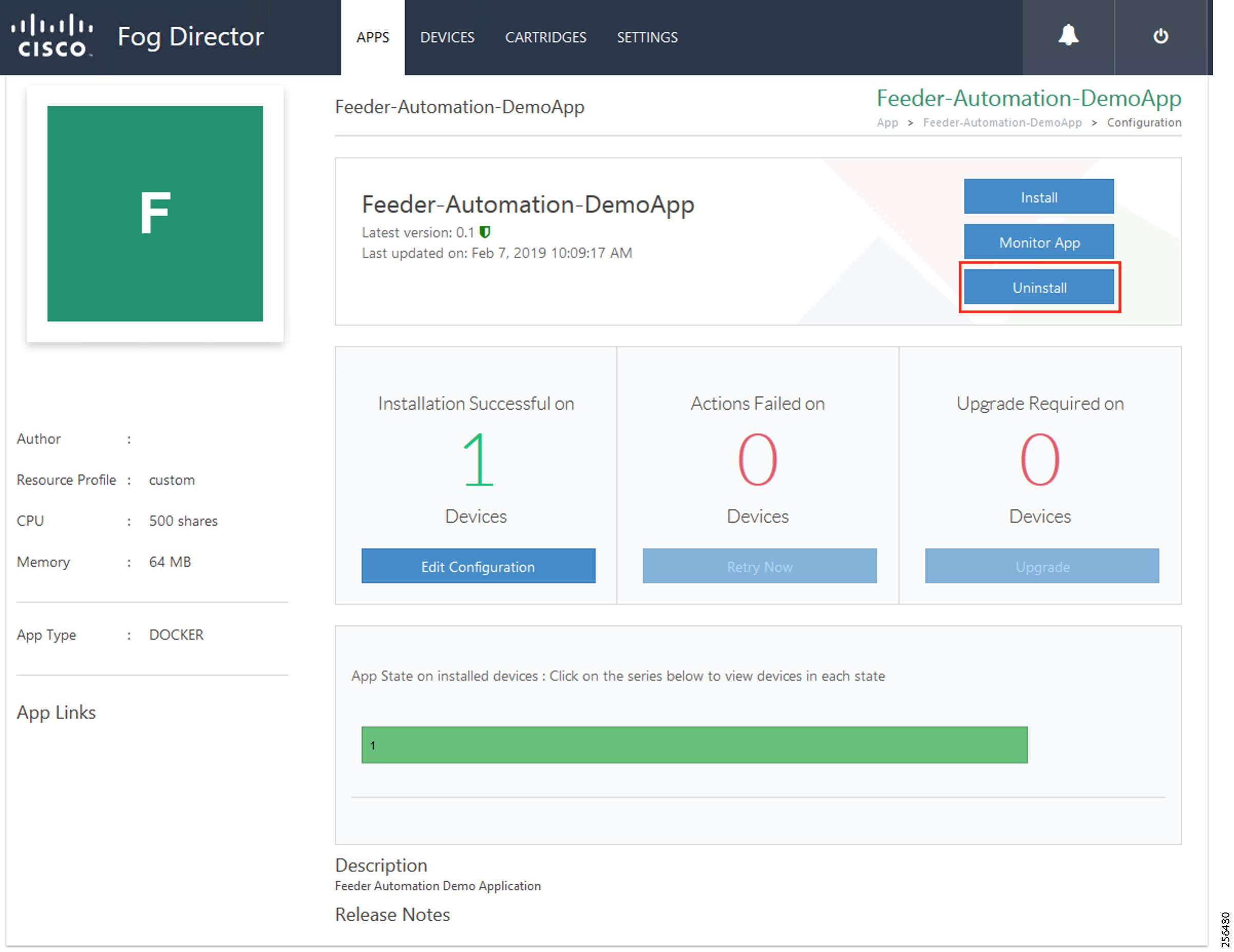

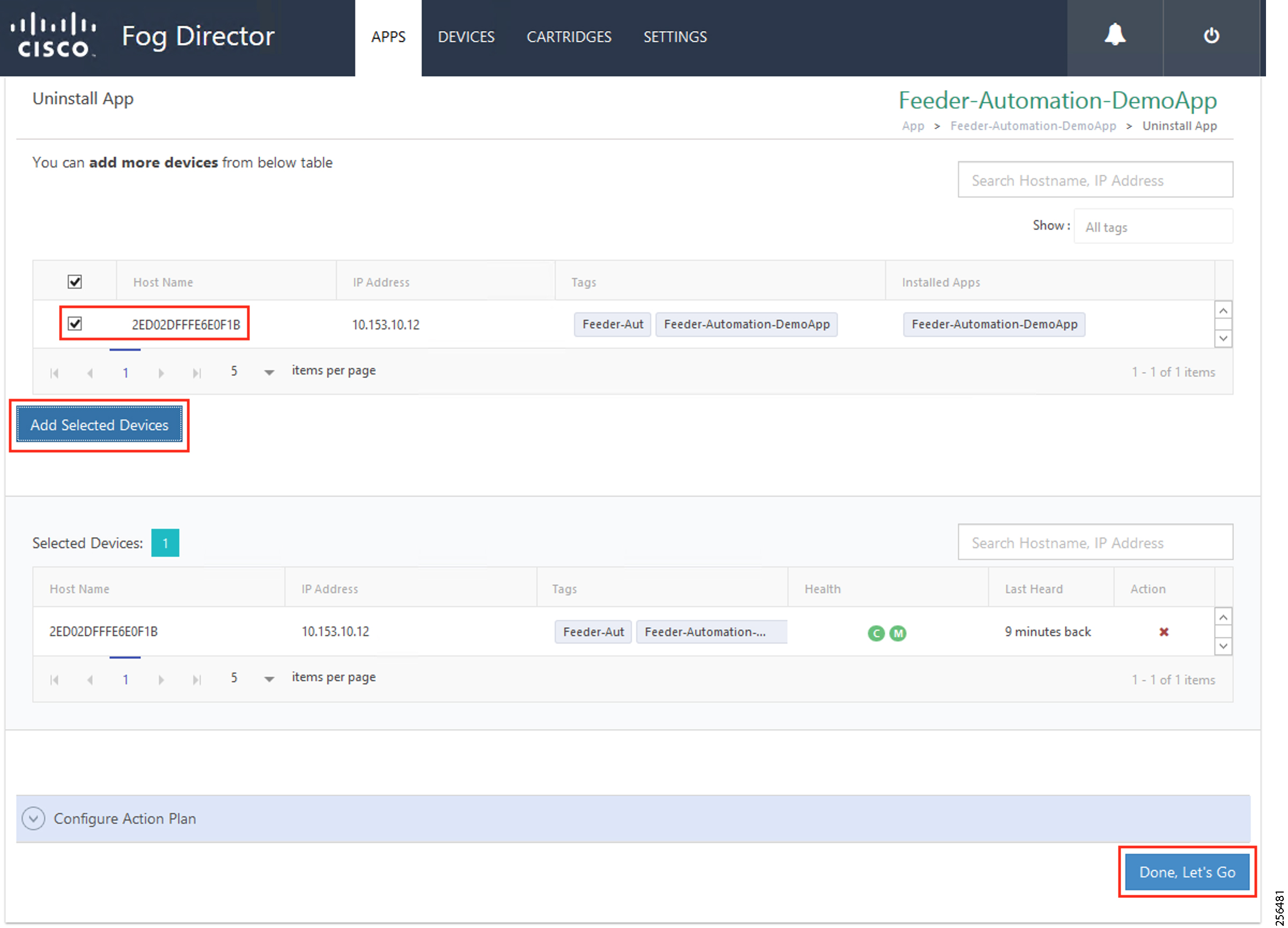

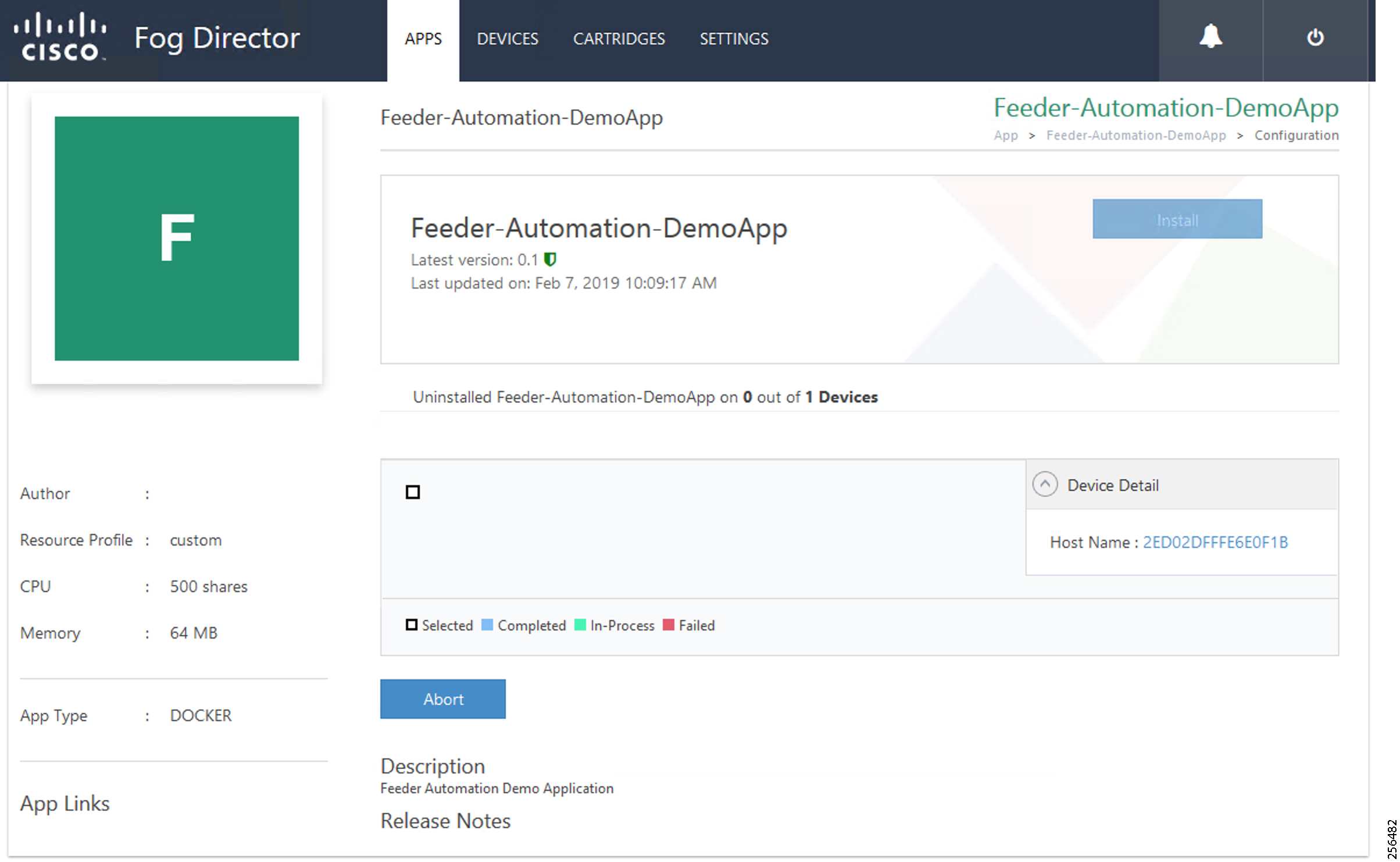

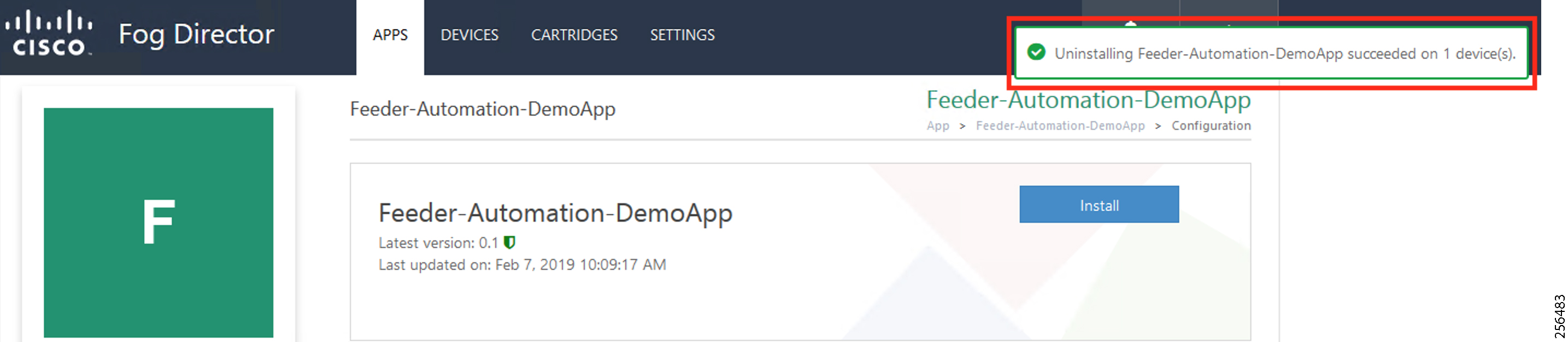

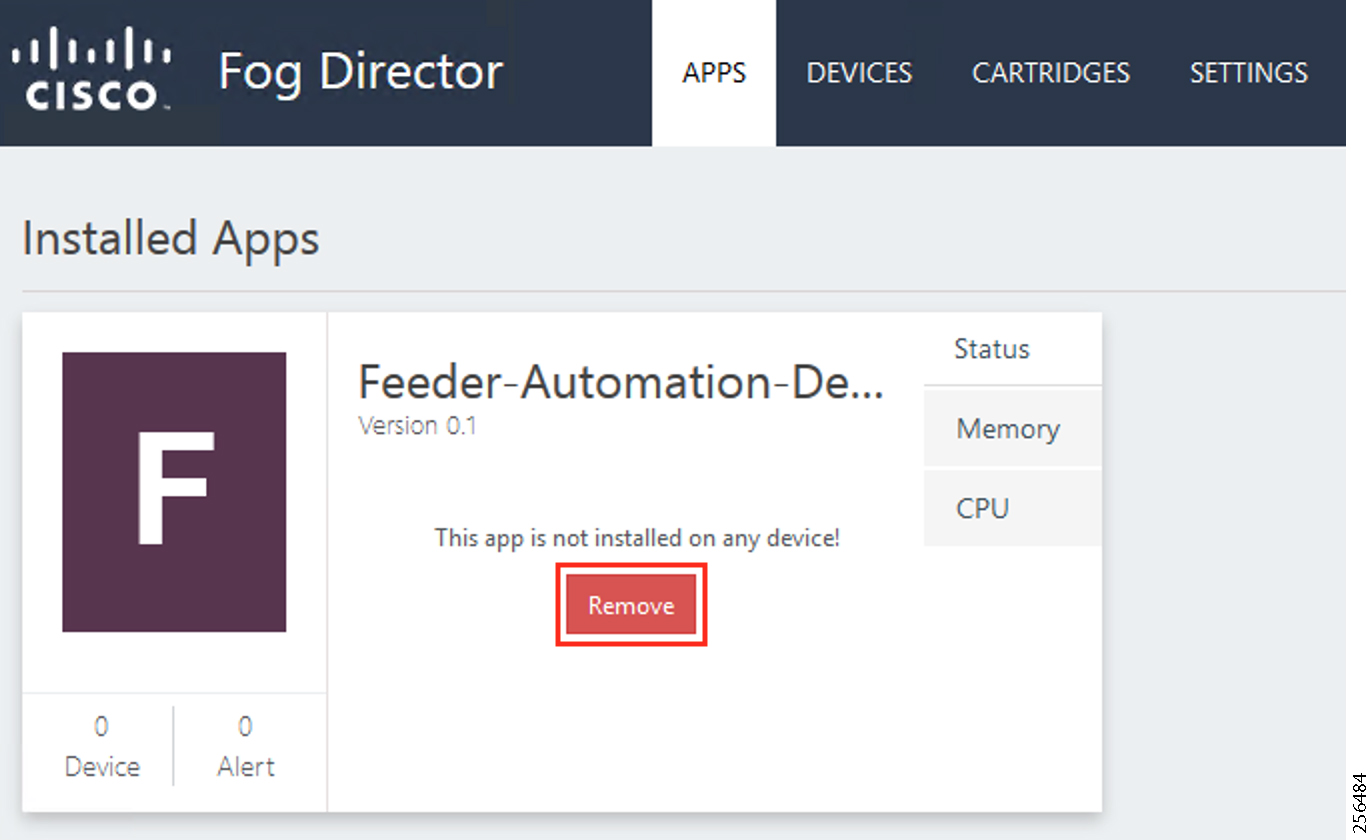

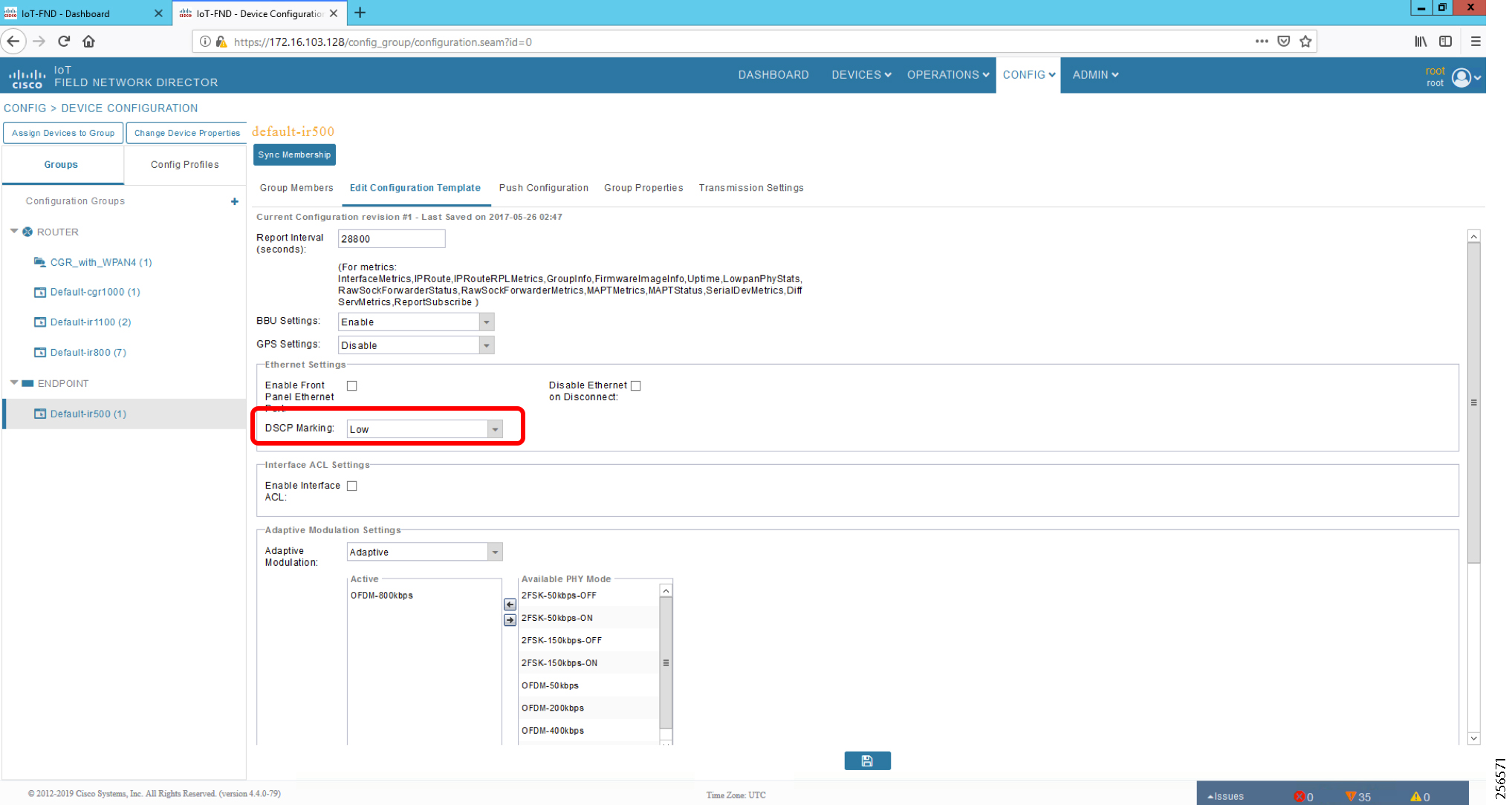

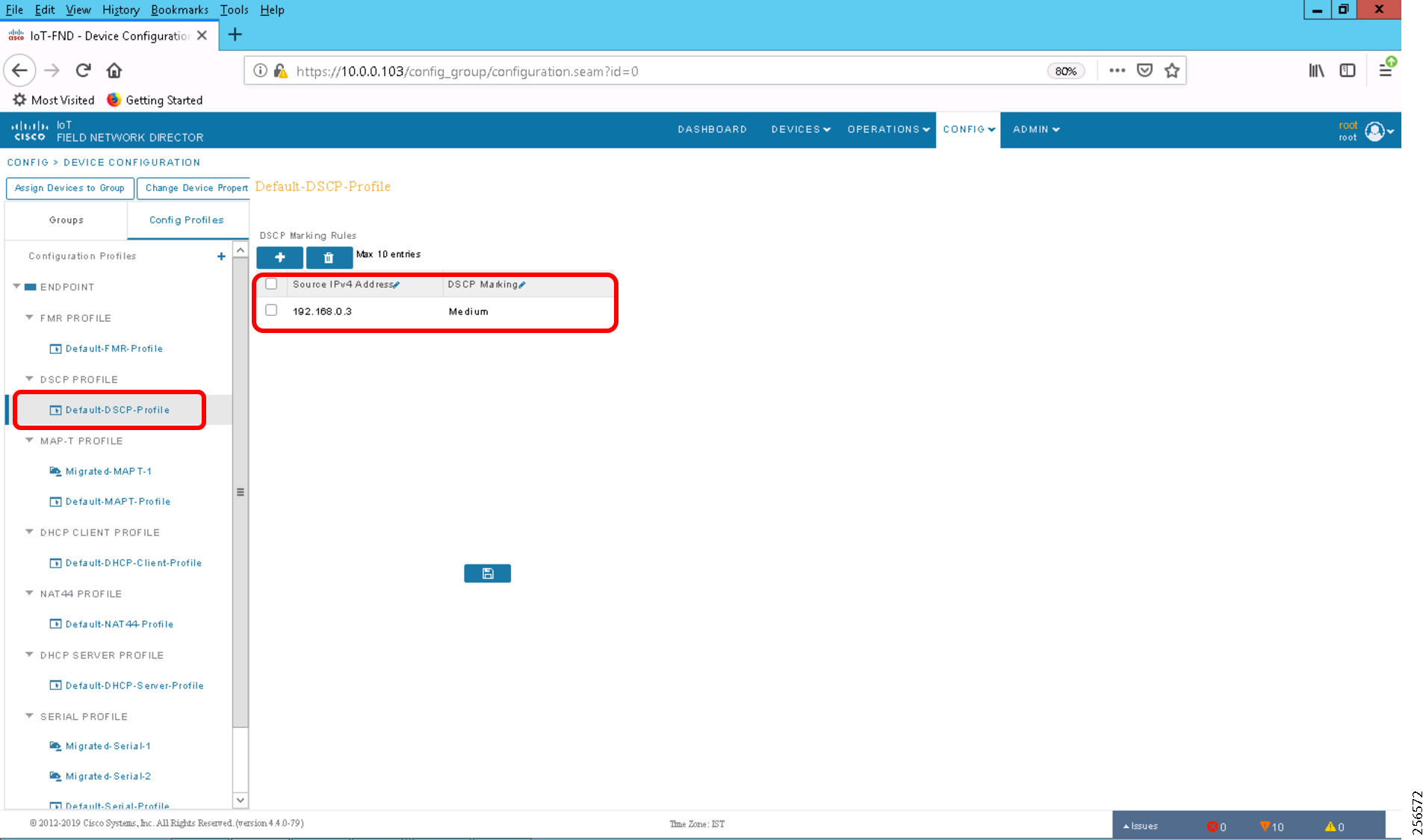

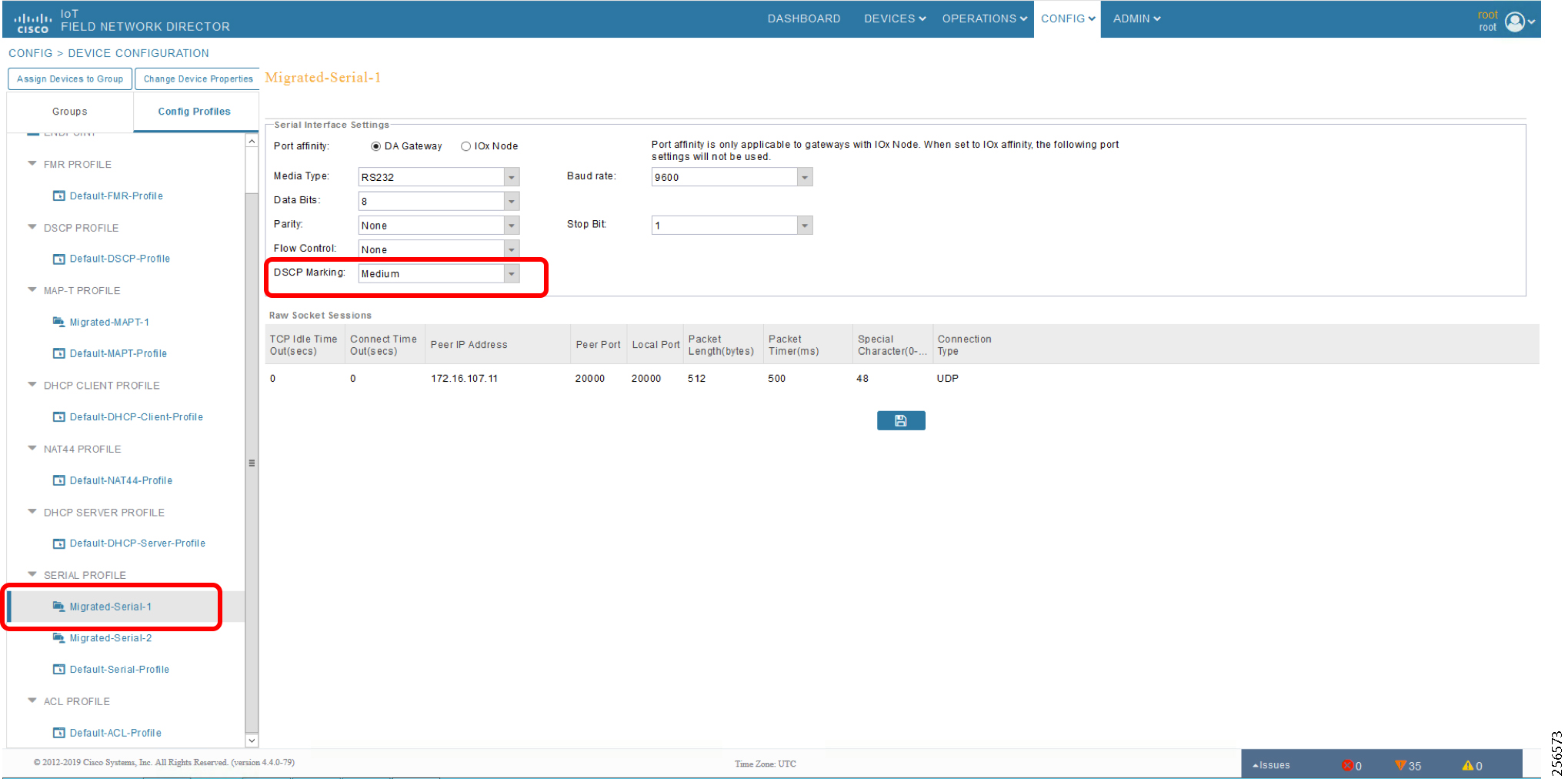

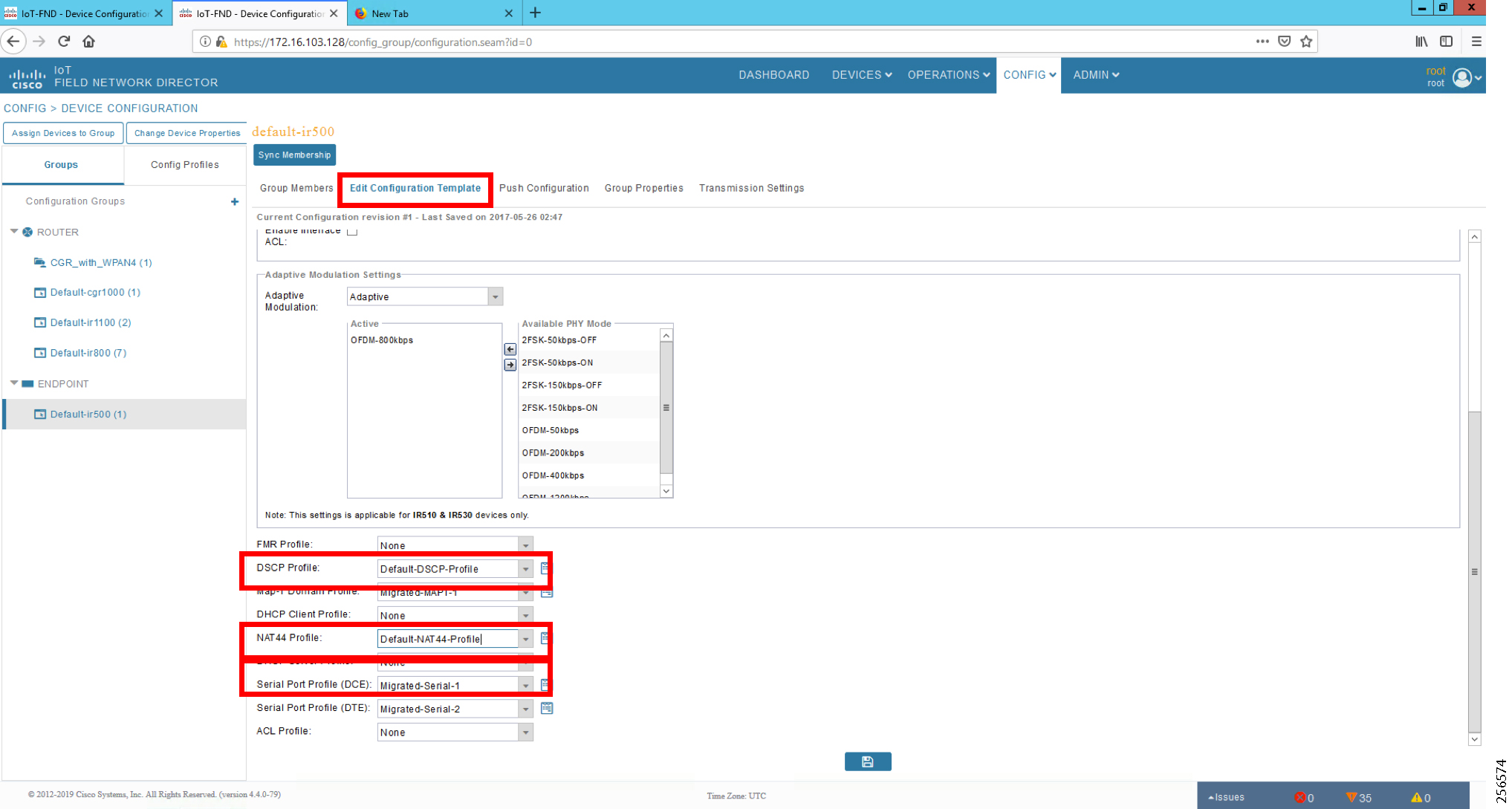

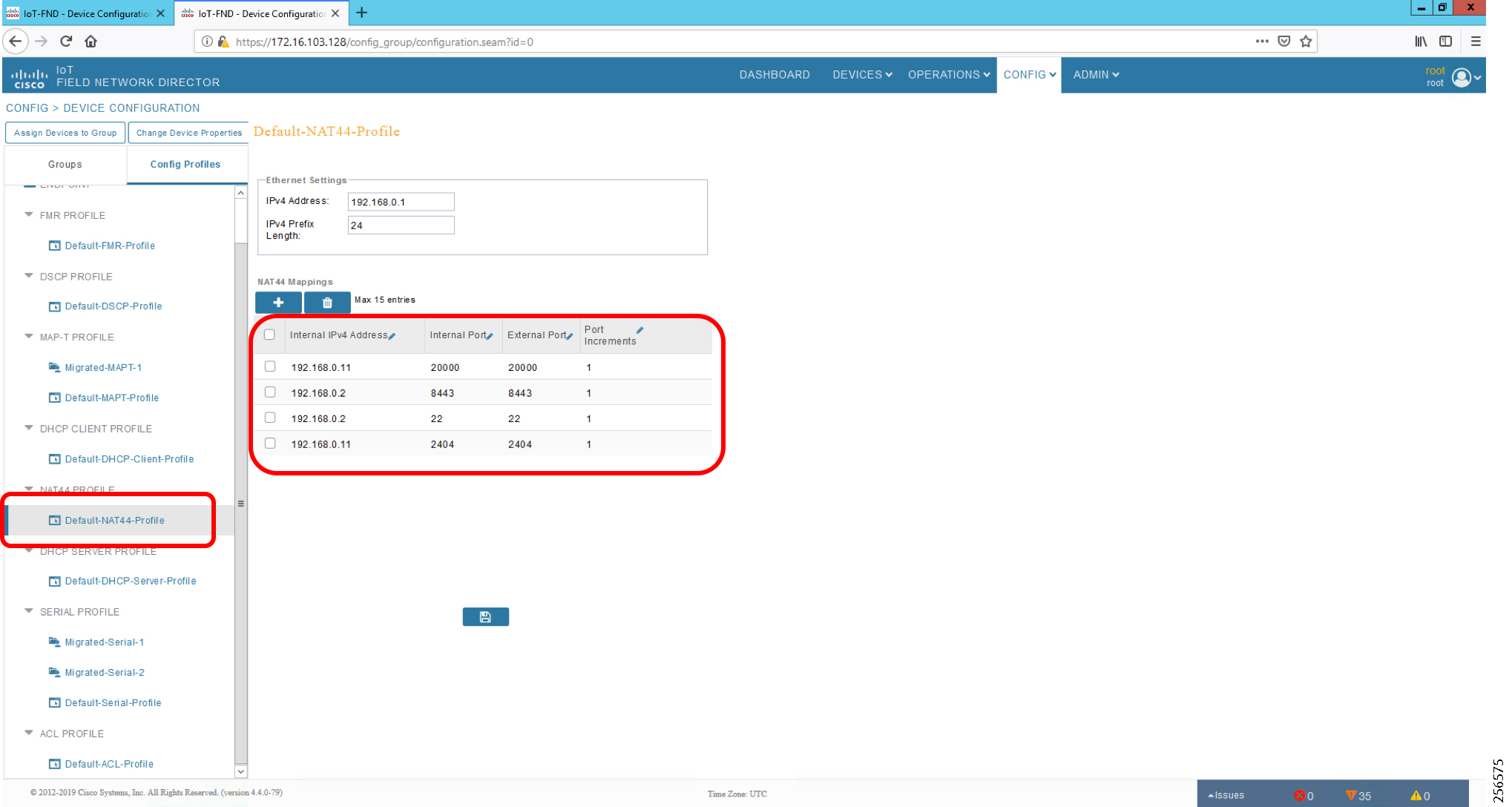

IoT Gateway sends out a registration request to FND IPv4 address 172.16.103.100 (or) IPv6 address 2001:db8:16:103::100 on port 9121. Once registered successfully, IOT Gateway is remotely manageable from the FND.