Package Contents

Each AP package contains the following items:

-

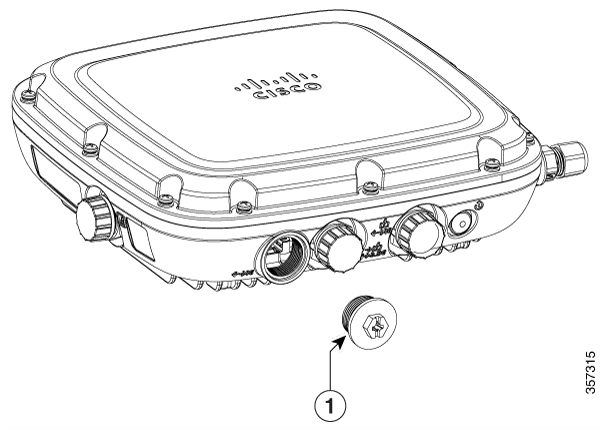

One C9124AXI or C9124AXD or C9124AXE Outdoor AP

-

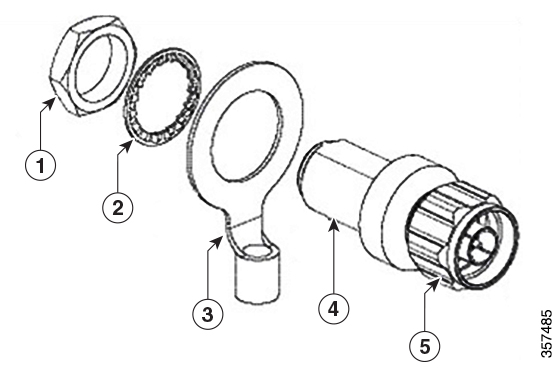

Ground lug and screws with lock washers

-

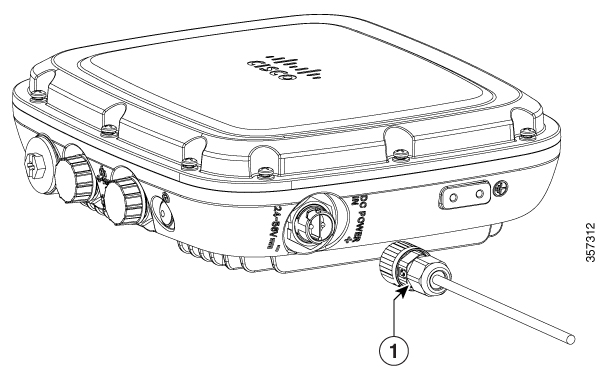

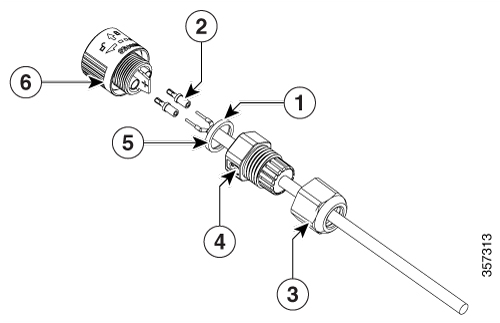

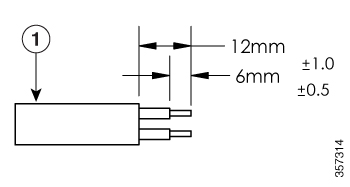

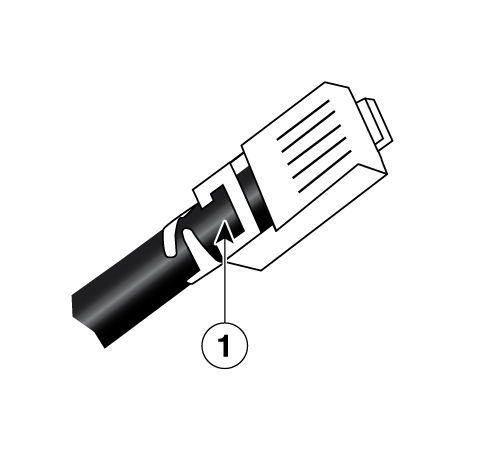

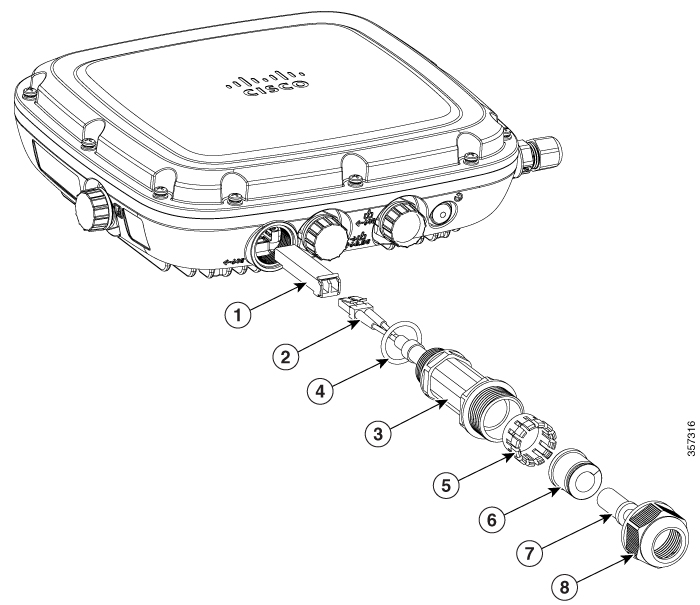

CAT 5e RJ45 Ethernet port termination plug

Note

The provided CAT 5e gland must be used with CAT 5e cable only. When using CAT 6/6A cable you need to use AIR-ACC-CAT6= kit which is an orderable accessory from Cisco.

-

Anticorrosion sealant

-

Weatherization tape (with C9124AXE only)

-

Cisco product documentation and pointer card

Feedback

Feedback