Power the Unit via DC Power Cable

- Safety Warnings

-

Take note of the following warnings:

Warning |

|

Warning |

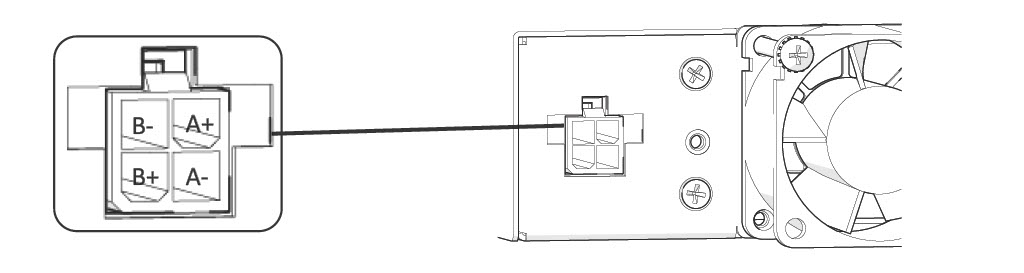

DC power connections:

|

To power the unit via the power cable:

Before you begin

-

Make sure that the chassis ground is connected on the chassis before you begin installing the DC power supply. See Ground the Chassis for the procedure.

Note |

Powering options are ordered separately. |

Procedure

|

Step 1 |

Establish the proper connections, between the cable end and the power sources. |

|

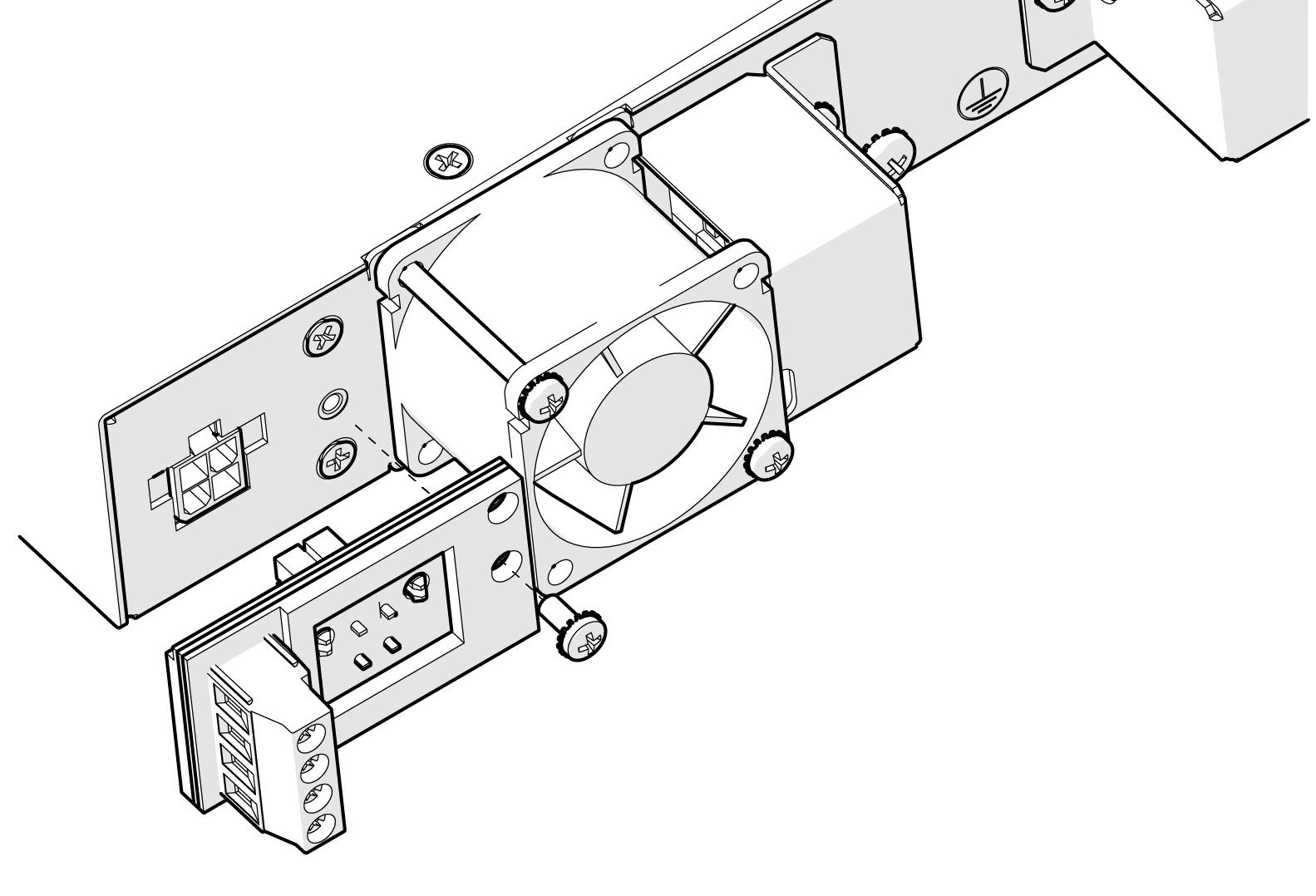

Step 2 |

Connect the DC connector to the back of the Module.

|

Feedback

Feedback