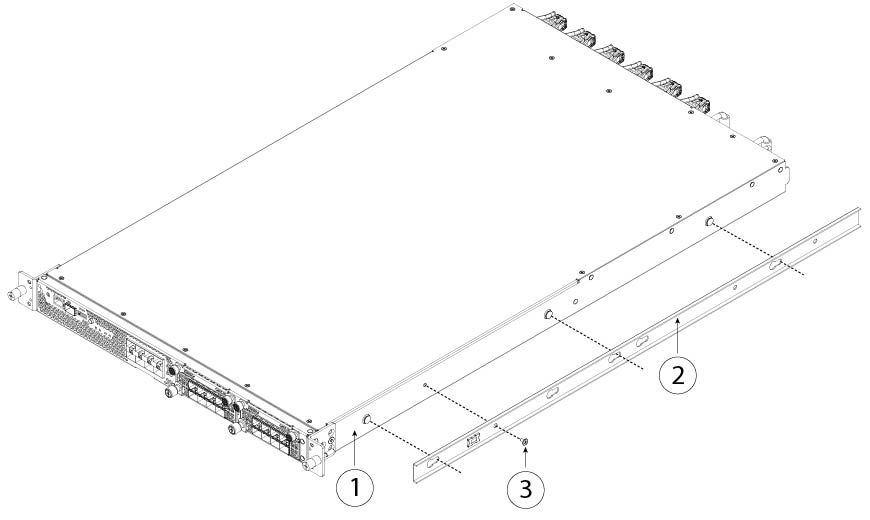

This procedure describes how to install the Firepower 4100 in a rack using the rack kit that

shipped with the chassis.

The rack is a standard Electronic Industries Association (EIA) rack. It is a

4-post-EIA-310-D, which is the current revision as specified by EIA. The vertical

hole spacing alternates at .50 inches (12.70 mm) to .625 inches (15.90 mm) to .625

inches (15.90 mm) and repeats. The start and stop space is in the middle of the

.50-inch holes. The horizontal spacing is 18.312 inches (465.1 mm), and the rack

opening is specified as a minimum of 17.75 inches (450 mm).

You need the following to install the chassis in a rack (4-post EIA-310-D rack):

Slide rail assemblies work with 4-post racks and cabinets with square slots, round 7.1-mm

holes and 10-32-inch threaded holes on the rack post front. The slide rail works

with front to back spacing of rack posts from 24 to 36 inches. The rack-mounting

posts need to be 2 to 3.5 mm thick to work with the slide rail rack mounting.

Note

|

Internal obstructions between rails can make slide rail installation more

complicated. Use racks that do not have internal obstructions between rails for

unhindered slide rail installation.

|

- Safety Warnings

- Take note of the following rack-mount safety warnings:

-

Warning

|

Statement

1006—Chassis Warning for Rack-Mounting and Servicing

To prevent bodily injury when mounting or servicing this unit in a rack, you must

take special precautions to ensure that the system remains stable. The following

guidelines are provided to ensure your safety:

-

This unit should be mounted at the bottom of the rack if it is the only unit

in the rack.

-

When mounting this unit in a partially filled rack, load the rack from the

bottom to the top with the heaviest component at the bottom of the rack.

-

If the rack is provided with stabilizing devices, install the stabilizers

before mounting or servicing the unit in the rack.

|

Warning

|

Statement

1032—Lifting the Chassis

To prevent personal injury or damage to the chassis, never attempt to lift or tilt

the chassis using the handles on modules, such as power supplies, fans, or cards.

These types of handles are not designed to support the weight of the unit.

|

Warning

|

Statement 1047—Overheating Prevention

To reduce the risk of fire or bodily injury, do not operate the unit

in an area that exceeds the maximum recommended ambient temperature

of 104°F (40°C).

|

Warning

|

Statement 1098 —Lifting Requirement

Two people are required to lift the heavy parts of the product. To

prevent injury, keep your back straight and lift with your legs, not

your back.

|

Ground the chassis. See Ground the Chassis for the procedure.

Install the FIPS opacity shield if

necessary. See Install the FIPS Opacity Shield for the procedure.

Install the cables according to your software configuration as described in the Cisco Firepower 4100 Getting Started

Guide.

Feedback

Feedback